Академический Документы

Профессиональный Документы

Культура Документы

Aluminum Seal

Загружено:

pradip_kumarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Aluminum Seal

Загружено:

pradip_kumarАвторское право:

Доступные форматы

2

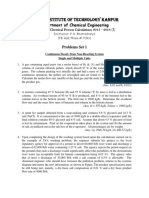

Aluminium Seal For LPG Cylinder

PRODUCT CODE

: 335902006

QUALITY AND STANDARDS

: Buyers Specifications

PRODUCTION CAPACITY

: Qty.

Value

: 180 lakhs (per annum)

: Rs. 40.20 Lakhs

MONTH AND YEAR

OF PREPARATION

: February, 2003

PREPARED BY

: Small Industries Service Institute

111-112, B. T. Road,

Kolkata - 700035

INTRODUCTION

The Aluminium Seal is used in the LPG

Cylinder as a security measure i.e. before

delivery to the customers. So no body

can tamper with it and use the gas partly,

so as to avoid customer being cheated.

Working Hours No. of Shifts

Working days

Labour Charges -

8 Hrs./day

1/ day.

300/year

As per the

Minimum

Wages Act.

MARKET POTENTIAL

IMPLEMENTATION SCHEDULE

This type of product is required by all

the manufacturers of LPG Bottles, i.e.

I.O.L., HPCL. BPCL etc. The product has

got increasing and steady demand as

the production of LPG cylinders is

increasing day by day.

This project will take its time of 7 to

8 months from the date of approval.

Break up of activities with expected

time and schedule is given below:

B ASIS AND PRESUMPTIONS

The basis of calculation of production

capacity is based on present local market

rates on single shift per day and efficiency

at 70% of installed capacity. The cost of

machinery and equipments as indicated

in this profile refer to a particular make

and prices are approximate.

Sl.No. Activity

Period

1. Market Survey and Scheme

Preparation

2 Months

2. SSI approval and registration

1 Month

3. Sanction of Loan and

Disbursement

2 to 5 Months

4. Placement of Order and

Procurement of machines

5 to 6 Months

5. Installation of machines and

power connection

6 to 7 Months

6. Trial run and

Commencement of

production

7 to 8 Months

14

A LUMINIUM SE A L

FOR

LPG CYLINDER

TECHNICAL ASPECTS

Sl. Description

No.

Process of Manufacture

Al-Sheets (0.2/0.3 mm or 36 SWG) of

size 20" 30" cutted from the continuous

coil, will be used as the raw material.

The above raw material will be fed into

high speed power press for blanking and

drawing. After the operation of power

press, the material will be processed in

the knotching press for keeping gap.

Finally, the trimming operation is done,

for removal of extra material and

polishing, the seals are polished in the

polishing barrel. The finished Al-sheets

are inspected, properly packed and

despatched.

Quality Control and Standards

There is no Indian Standard

Specification for this item. All the

parameters are covered by I.O.L./H.P.

Specification vide Ref. No. RD 15G 214.

FINANCIAL ASPECTS

A. Fixed Capital

Qty.

Rate

(Rs.)

Amount

(In Rs.)

20,000

5,000

Tools and Dies,

Work Bench etc.

7. Installation and

Electrification

Charge

8. Office Furniture

L.S.

Total

2,29,000

B. Working Capital ( per month)

(i) Staff and Labour (per month)

Sl. Designation

No.

No.

Amount

(In Rs.)

1. Manager/Supervisor

3,500

2. Machine Operator

10,000

3. Skilled Worker

8,000

4. Helper/Peon

3,000

Total

24,500

(ii) Raw Material (per month)

Item

Qty.

Al-Sheet 0.2

3 Ton

mm thick in the

form of roll.

Rate

(Rs.)

Amount

(In Rs.)

84/ Kg.

2,52,000

Total

2,52,000

(iii) Other Contingent Expenses (per month) (In Rs.)

(i) Land and Building (Rented) Amount (In Rs.)

1. Rent

2,500

Covered Area 400 Sq.Ft.

2. Power and Water

3,000

3. Consumable Stores

2,000

2,500/ month

(ii) Machinery and Equipments

Sl. Description

No.

1. High Speed

Power Press-10

Ton Cap.

Motorised

Qty.

4

Rate

(Rs.)

Amount

(In Rs.)

25000

1,00,000

5. Office Expenses

1,500

Total

19,000

(iv) Total Working Capital (per month) (In Rs.)

2. Trimming Machine 2

Motorised

12,000

24,000

3. Knotching

Machine-Hand

operated

5,000

10,000

4. Treadle

Shearing

Machine

20,000

20,000

5. Polishing Barrel

10,000

20,000

30,000

6. Composite

4. Packaging, Grease, Kerosene Oil etc. 10,000

L.S.

1. Raw Material

2,52,000

2. Staff and Labour

24,500

3. Other Contingent Expenses

19,000

Total

2,95,500.00

C. Total Capital Investment

1. Machinery and Equipment

Rs. 2,29,000

2. Working Capital (for 3

months) 2,95,500 3

Rs. 8,86,500

Total

Rs. 11,15,500

A LUMINIUM SE A L

FINANCIAL ANALYSIS

1. Recurring Expenditure

35,46,000

2. Depreciation on Machinery and

Office Equipment @ 15%

34,350

3. Interest on total capital

investment @ 16%

1,78,500

Total

37,58,850

Say

37,59,000

By sale of scrap @ Rs 40 per

Kg. for 6000 Kgs.

Total

37,80,000

2,40,000

40,20,000

(3) Net Profit

Rs. 40,20,000 37,59,000 =

Rs. 2,61,000

( 4 ) Net Profit Ratio

Profit 100

Sales

261000 100

4020000

6.5%

Fixed Cost

Amt. (In Rs.)

Rent

30,000

Interest

1,78,500

Depreciation

34,350

40% of Salary

1,17,600

40% of Other Contingent

Expenses

(5) Rate of Return

=

Net Profit 100

Total Capital Investment

2,61,000 100

11,15,500

23.4%

91,200

Total

Amt. (In Rs.)

By sale of 180 Lakhs pieces of

Aluminium Seal @ Re. 0.21each

LPG CYLINDER

(6) Break-even Point

(1) Cost of Production (per annum) Amt. (In Rs.)

(2) Turn-over (per year)

FOR

B.E.P.

Fixed Cost 100

Fixed Cost + Profit

4,51,650 100

4,51,650 + 2,61,000

63.3%

4,51,650

Addresses of Machinery Suppliers

1. M/s. Batliboi and Co.

190A, Forbes Street,

Fort, Mumbai-1.

2. M/s. H.P. Singh

75, Ganesh Ch. Avenue,

Kolkata13.

3. M/s. Oriental Machinery Works

23, R.N. Mukherjee Road,

Kolkata-13.

15

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hemi EnginesДокумент18 страницHemi EnginesSano SanojОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Manual GomacoДокумент153 страницыManual GomacoJuan Tena100% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Practitioner Guide 0512 Inspection, Maintenance & Testing of Equipment Installed at PetroleumДокумент88 страницPractitioner Guide 0512 Inspection, Maintenance & Testing of Equipment Installed at PetroleumsusanwebОценок пока нет

- Piping Design Course SyllabusДокумент7 страницPiping Design Course SyllabusKagira Drawing Soltuion0% (1)

- Gentsshirtsandtrousers PDFДокумент12 страницGentsshirtsandtrousers PDFwwwaqarОценок пока нет

- Beauty ParlourДокумент7 страницBeauty ParloursundeepparkarОценок пока нет

- Pre-Feasibility Study for Seed Processing UnitДокумент22 страницыPre-Feasibility Study for Seed Processing UnitYasir MukhtarОценок пока нет

- TDC-510S Machine Instruction ManualДокумент53 страницыTDC-510S Machine Instruction ManualsunhuynhОценок пока нет

- Top Companies in Pakistan's Oil, Gas and Fertilizer IndustriesДокумент64 страницыTop Companies in Pakistan's Oil, Gas and Fertilizer IndustriesAshiq Ramzan MaanОценок пока нет

- Steel Making ShoukeryДокумент95 страницSteel Making ShoukeryAlaa Hosney100% (1)

- Doosan Retrofit ServiceДокумент99 страницDoosan Retrofit Servicestopless_dalian685Оценок пока нет

- Air PreheaterДокумент31 страницаAir PreheaterAkashKishoreОценок пока нет

- Cold StorageДокумент33 страницыCold Storagepradip_kumarОценок пока нет

- IB Recruitment 2017 - Official NotificationДокумент11 страницIB Recruitment 2017 - Official NotificationKshitija100% (15)

- Projection of BalboaДокумент7 страницProjection of Balboapradip_kumarОценок пока нет

- SMEDA Aloe Vera ProcessingДокумент34 страницыSMEDA Aloe Vera ProcessingMuhammad Zargham Haider100% (2)

- Bricks Industries ODISHAДокумент1 страницаBricks Industries ODISHApradip_kumarОценок пока нет

- Beauty ParlourДокумент9 страницBeauty ParloursundeepparkarОценок пока нет

- Beauty ParlourДокумент9 страницBeauty ParloursundeepparkarОценок пока нет

- Application For Population CertificateДокумент1 страницаApplication For Population Certificatepradip_kumar40% (5)

- SMEDA Off-Season Vegetables Farming (Walk-In Tunnel)Документ27 страницSMEDA Off-Season Vegetables Farming (Walk-In Tunnel)pradip_kumarОценок пока нет

- Otet 2016 Answer KeyДокумент2 страницыOtet 2016 Answer Keypradip_kumarОценок пока нет

- SMEDA Rose Water PDFДокумент20 страницSMEDA Rose Water PDFpradip_kumarОценок пока нет

- Claim Applnfor Nomnhasbeen Regdwith POДокумент1 страницаClaim Applnfor Nomnhasbeen Regdwith POSumeet JainОценок пока нет

- Claim Applnfor SCwhere Nomn Regdwith POДокумент1 страницаClaim Applnfor SCwhere Nomn Regdwith POVardhan ReddyОценок пока нет

- UpholteryДокумент8 страницUpholterypradip_kumarОценок пока нет

- Claim App LN With LeClaimApplnwithLegalEvidencegal EvidenceДокумент2 страницыClaim App LN With LeClaimApplnwithLegalEvidencegal EvidencealluseОценок пока нет

- Trumock Shoe with TPR Sole ProductionДокумент5 страницTrumock Shoe with TPR Sole Productionpradip_kumarОценок пока нет

- Trumock Shoe with TPR Sole ProductionДокумент5 страницTrumock Shoe with TPR Sole Productionpradip_kumarОценок пока нет

- Split LeatherДокумент6 страницSplit Leatherpradip_kumarОценок пока нет

- Sports FootwearДокумент9 страницSports Footwearpradip_kumarОценок пока нет

- Leather BeltДокумент4 страницыLeather Beltpradip_kumarОценок пока нет

- Shuttle Cock Manufacturing Project ProfileДокумент5 страницShuttle Cock Manufacturing Project Profilepradip_kumarОценок пока нет

- Portfolio BagДокумент5 страницPortfolio Bagpradip_kumarОценок пока нет

- Leather GarmentsДокумент7 страницLeather Garmentspradip_kumarОценок пока нет

- Shower Proof GarmentДокумент7 страницShower Proof Garmentpradip_kumarОценок пока нет

- Batting GlovesДокумент4 страницыBatting Glovespradip_kumarОценок пока нет

- Leather BagДокумент7 страницLeather Bagpradip_kumarОценок пока нет

- Leather SandalДокумент6 страницLeather Sandalpradip_kumarОценок пока нет

- Types of Solutions - C11-4-01Документ8 страницTypes of Solutions - C11-4-01Shashi PareekОценок пока нет

- New NipeX Product Code Booklet Vs DPR Permts Revised and Re Issued July 2017 PDFДокумент133 страницыNew NipeX Product Code Booklet Vs DPR Permts Revised and Re Issued July 2017 PDFendyОценок пока нет

- ChE 251A: Chemical Process Calculations Problems Set 1Документ5 страницChE 251A: Chemical Process Calculations Problems Set 1Deepak TholiaОценок пока нет

- Maintenance Manual 1T-4T (LPG) - EN 英语Документ128 страницMaintenance Manual 1T-4T (LPG) - EN 英语Jose Luis LavinОценок пока нет

- Six stroke engine types and designsДокумент13 страницSix stroke engine types and designskarthiksubramanian94Оценок пока нет

- Overall Network (GVN) Function - 205Документ8 страницOverall Network (GVN) Function - 205Ritesh100% (1)

- SOP Reach Stacker01Документ7 страницSOP Reach Stacker01vozefjadav100% (1)

- Load Test on 4-Stroke Diesel EngineДокумент4 страницыLoad Test on 4-Stroke Diesel EngineRanjit DasОценок пока нет

- 2014 Program ScheduleДокумент329 страниц2014 Program ScheduleKeerti S SОценок пока нет

- Aeroquip Military and Marine CatalogДокумент206 страницAeroquip Military and Marine CatalogJenner Volnney Quispe ChataОценок пока нет

- Diagnosis of Excessive Water Production in Horizontal Wells Using WOR PlotsДокумент9 страницDiagnosis of Excessive Water Production in Horizontal Wells Using WOR Plotsjefpri simanjuntakОценок пока нет

- Steam Boiler fuel atomization and combustion researchДокумент4 страницыSteam Boiler fuel atomization and combustion researchjonas lintagОценок пока нет

- Copic Color Wheel 358Документ1 страницаCopic Color Wheel 358kotoirОценок пока нет

- Hydraulic Circuits Design and AnalysisДокумент19 страницHydraulic Circuits Design and AnalysisklashincoviskyОценок пока нет

- Pulsar Rs 200 0Документ87 страницPulsar Rs 200 0Michael PuentesОценок пока нет

- Thermal Power Plant Working - Indian Power SectorДокумент21 страницаThermal Power Plant Working - Indian Power Sectorrohanknh150% (1)

- Gail Investor PresentationДокумент31 страницаGail Investor Presentationsurya167Оценок пока нет

- AC250 Data SheetДокумент5 страницAC250 Data SheetAshutosh SinghОценок пока нет

- Multiphase Method For Converting WHP To BHPДокумент7 страницMultiphase Method For Converting WHP To BHPHichem FakhfekhОценок пока нет

- 15Документ72 страницы15Rohit KumarОценок пока нет

- Colombia Oil & Gas Report Q3 2015Документ157 страницColombia Oil & Gas Report Q3 2015edgarmerchan100% (1)