Академический Документы

Профессиональный Документы

Культура Документы

Metric Seamless Tube Stock Sizes & Specifications

Загружено:

mcrajpuraОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Metric Seamless Tube Stock Sizes & Specifications

Загружено:

mcrajpuraАвторское право:

Доступные форматы

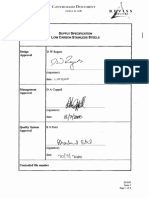

WALLCHART PDF

3/1/01

METRIC SEAMLESS TUBe

5:02 AM

Page 1

Metric Seamless Tube Stock Sizes & Specifications

Tube

Tube

Outside

Wall

Diameter Thickness

(mm)

(mm)

Tube

Inside

St. 37.4

Diameter Phosphated

(mm)

& Oiled

St. 37.4

Zinc Plated

& Yellow

Chromate

Static

Pressure

Rating

(Bar)

Dynamic

Pressure

Burst

Rating Pressure

(Bar)

(Bar)

R04X0.5

R04X0.5VZ

313

274

1160

0.047

R04X0.75VZ

409

393

1820

0.063

600

3850

0.075

1.4571

Weight Stainless

(kg/m) Steel

Static

Pressure

Burst

Rating Pressure

(Bar)

(Bar)

Weight

(kg/m)

0.5

0.75

2.5

R04X1

R04X1VZ

522

502

2850

0.074

R04X171

R05X1VZ

432

416

2120

0.099

0.75

4.5

R06X0.75VZ

333

289

1230

0.103

R06X1

R06X1VZ

389

374

1680

0.123

R06X171

426

2340

0.125

1.5

R06X1.5

R06X1.5VZ

549

528

3050

0.166

R06X1.571

600

3250

0.169

R06X2VZ

692

665

0.197

2.25

1.5

R06X2.25VZ

757

728

0.208

R08X1

R08X1VZ

333

289

1190

0.222

R08X171

368

1660

0.175

1.5

R08X1.5

R08X1.5VZ

431

414

1860

0.240

R08X1.571

472

2800

0.244

R08X2

R08X2VZ

549

528

3020

0.296

Tensile Strength: 340 N/mm 2 (49,000 lb/in 2) minimum

2.5

R08X2.5VZ

658

632

0.339

Yield Strength: 235 N/mm 2 (34,000 lb/in 2) minimum

10

R10X1

R10X1VZ

282

249

870

0.222

R010X171

294

1290

0.225

% Elongation: 25% minimum

10

1.5

R10X1.5

R10X1.5VZ

373

358

1380

0.314

R10X1.571

389

1930

0.319

Condition: Seamless, cold drawn, annealed (NBK) per DIN 2391C Part 2

10

R10X2

R10X2VZ

478

460

2100

0.395

R10X271

498

3100

0.401

Surface Finish: Tubes with inside diameter of 1.5 to 5 mm

outside and inside oiled

10

2.5

R10X2.5VZ

576

553

3180

0.462

10

R10X3VZ

666

641

0.518

12

10

R12X1

R12X1VZ

235

210

760

0.271

R12X171

245

1220

0.275

12

1.5

R12X1.5

R12X1.5VZ

353

305

1150

0.388

R12X1.571

368

1580

0.394

12

R12X2

R12X2VZ

409

393

1580

0.493

R12X271

426

2380

0.501

12

2.5

R12X2.5VZ

495

476

2600

0.586

12

R12X3VZ

576

553

3200

0.666

12

3.5

R12X3.5VZ

651

627

0.734

14

1.5

11

R14X1.5VZ

302

265

940

0.462

R14X1.571

315

1550

0.469

14

10

R14X2

R14X2VZ

403

343

1340

0.592

R14X271

420

2180

0.601

14

2.5

R14X2.5VZ

434

417

1760

0.709

R14X2.571

452

2800

0.720

14

R14X3VZ

507

487

2400

0.814

15

13

R15X1

R15X1VZ

188

171

590

0.345

R15X171

196

860

0.351

15

1.5

12

R15X1.5

R15X1.5VZ

282

249

980

0.499

R15X1.571

294

1140

0.507

15

11

R15X2

R15X2VZ

376

323

1250

0.641

R15X271

392

1750

0.651

16

1.5

13

R16X1.5

R16X1.5VZ

264

234

820

0.536

R16X1.571

276

750

0.545

16

12

R16X2

R16X2VZ

353

305

1170

0.691

R16X271

368

1800

0.701

16

2.5

11

R16X2.5

R16X2.5VZ

386

372

1470

0.832

R16X2.571

403

2120

0.845

16

10

R16X3

R16X3VZ

452

435

1920

0.962

R16X371

472

2800

0.977

18

16

R18X1VZ

157

143

510

0.419

18

1.5

15

R18X1.5

R18X1.5VZ

235

210

780

0.610

R18X1.571

245

1050

0.620

18

14

R18X2

R18X2VZ

313

274

1040

0.789

R18X271

327

1520

0.801

18

2.5

13

R18X2.5

R18X2.5VZ

392

335

1320

0.956

18

12

R18X3VZ

409

393

1830

1.111

20

1.5

17

R20X1.5VZ

212

191

570

0.684

% Elongation: 25% minimum

20

16

R20X2

R20X2VZ

282

249

920

0.888

R20X271

294

1250

0.901

Condition: Seamless, cold drawn, annealed (NBK) per DIN 2391C Part 2

20

2.5

15

R20X2.5

R20X2.5VZ

353

305

1220

1.079

R20X2.571

368

1550

1.095

Surface Finish: Outside surface zinc plated (8-12 m) and yellow

chromate inside surface oiled

20

14

R20X3

R20X3VZ

373

358

1450

1.258

R20X371

389

1960

1.277

Example of Part Number: R25X2VZ where R indicates tube, 25 =

outside diameter (mm), 2 = wall thickness (mm), and VZ indicates zinc

with yellow chromate

20

3.5

13

R20X3.5

R20X3.5VZ

426

410

1720

1.424

20

12

R20X4VZ

478

460

2080

1.578

22

1.5

19

R22X1.5

R22X1.5VZ

192

174

590

0.758

R22X1.571

200

720

0.770

22

18

R22X2

R22X2VZ

256

228

850

0.986

R22X271

267

1020

1.002

22

2.5

17

R22X2.5

R22X2.5VZ

320

280

1040

1.202

22

16

R22X3VZ

385

329

1.406

25

21

R25X2

R25X2VZ

226

202

670

1.134

25

2.5

20

R25X2.5

R25X2.5VZ

282

249

920

1.387

R25X2.571

294

1190

1.408

25

19

R25X3

R25X3VZ

338

294

1050

1.628

R25X371

353

1520

1.653

25

17

R25X4

R25X4VZ

394

379

1520

2.072

25

4.5

16

R25X4.5

R25X4.5VZ

437

420

1780

2.275

28

1.5

25

R28X1.5

R28X1.5VZ

151

139

450

0.980

R28X1.571

158

620

0.995

28

24

R28X2

R28X2VZ

201

182

620

1.282

R28X271

210

880

1.302

28

2.5

23

R28X2.5

R28X2.5VZ

252

224

770

1.572

28

22

R28X3

R28X3VZ

302

265

920

1.850

30

26

R30X2VZ

188

171

620

1.381

30

2.5

25

R30X2.5

R30X2.5VZ

235

210

770

1.695

R30X2.571

245

890

1.722

30

24

R30X3

R30X3VZ

282

249

920

1.998

R30X371

294

1140

2.028

30

22

R30X4

R30X4VZ

376

323

1250

2.565

R30X471

392

1650

2.605

30

20

R30X5

R30X5VZ

409

393

1580

3.083

35

31

R35X2

R35X2VZ

161

147

470

1.628

R35X271

168

670

1.653

35

2.5

30

R35X2.5

R35X2.5VZ

201

182

620

2.004

Yield Strength: 245 N/mm 2 (35,500 lb/in 2) minimum

35

29

R35X3

R35X3VZ

242

216

720

2.367

% Elongation: 35% minimum

35

27

R35X4VZ

322

281

960

3.058

Condition: Seamless, cold drawn, free of scale, heat-treated in

accordance with DIN 17458 Table 6

38

2.5

33

R38X2.5VZ

186

168

550

2.189

Example of Part Number: R25X271 where R indicates tube, 25 =

outside diameter (mm), 2 = wall thickness (mm), and 71 indicates

1.4571 stainless steel

38

32

R38X3

R38X3VZ

223

200

660

2.589

38

30

R38X4

R38X4VZ

297

261

970

3.354

R38X471

309

1240

3.405

38

28

R38X5

R38X5VZ

371

319

1350

4.069

38

26

R38X6VZ

390

375

4.735

38

24

R38X7VZ

446

429

5.352

42

38

R42X2

R42X2VZ

134

124

390

1.973

R42X271

140

520

2.003

42

36

R42X3

R42X3VZ

201

182

580

2.885

R42X371

210

860

2.930

42

34

R42X4

R42X4VZ

269

238

850

3.749

Parker Hannifin Corporation

50

38

R50X6

338

290

6.511

Tube Fittings Division

3885 Gateway Blvd. Columbus, Ohio 43228

Telephone: (614) 279-7070 Fax: (614) 279-7685

www.parker.com/tfd

65

49

R65X8

347

300

11.246

Seamless Carbon Steel Tube

Material: St. 37.4 fine-grain quality per DIN 1630

Tubes with 6 mm and greater inside diameter outside

and inside phosphate and oiled

Example of Part Number: R25X2 where R indicates tube, 25 = outside

diameter (mm), and 2 = wall thickness (mm)

Seamless Carbon Steel Tube with Zinc Plating

Material: St. 37.4 fine-grain quality per DIN 1630

Tensile Strength: 340 N/mm 2 (49,000 lb/in 2) minimum

Yield Strength: 235 N/mm 2 (34,000 lb/in 2) minimum

Seamless Stainless Steel Tube

Material: 1.4571 (X6CrNiMoTi17122)

Tensile Strength: 500 N/mm 2 (72,500 lb/in 2) minimum

The Fitting Authority

Bulletin WC-4300-MST

Parker Hannifin Corporation

Static pressures are calculated in accordance with DIN 2413 Part 1.

Dynamic pressure ratings are calculated in accordance with

DIN 2413 Part 3.

Specific design factors may be determined by using the burst

pressures shown in the above table.

Part numbers shown are standard from stock. Other sizes are

available upon request. See Catalog 4300 for a complete listing

of available sizes.

Conversion Factors:

Bar X 14.5 = psi

kg/m X 0.672 = lb/ft

N/mm 2 X 145 = lb/in 2

Вам также может понравиться

- Metric Seamless TubeДокумент4 страницыMetric Seamless Tuberaghu_mnОценок пока нет

- AISI SteelДокумент7 страницAISI SteelEtiОценок пока нет

- Dismantling Joint: 3" To 40" (ANSI 300)Документ1 страницаDismantling Joint: 3" To 40" (ANSI 300)fklicekОценок пока нет

- CR StandardsДокумент6 страницCR Standardsalpha_beta48Оценок пока нет

- Metric Tube - ParkerДокумент6 страницMetric Tube - ParkerJenny Cecilia Ureña ZuriОценок пока нет

- 2 - KSD3503-Rolled Steels For General StructureДокумент16 страниц2 - KSD3503-Rolled Steels For General StructureHikmat Ayer100% (1)

- Pipes and TubesДокумент16 страницPipes and TubesDaniel Sandoval FernándezОценок пока нет

- PTE LTD: Dimensional Specification (Inch) For Stud Bolts As Per Asme B18.2.1Документ4 страницыPTE LTD: Dimensional Specification (Inch) For Stud Bolts As Per Asme B18.2.1Balderas Rosas WilibaldoОценок пока нет

- Viking Johnson Dismantling Joint DN350-1600 (PN40) Datasheet EnglishДокумент1 страницаViking Johnson Dismantling Joint DN350-1600 (PN40) Datasheet EnglishfklicekОценок пока нет

- Structural SteelsДокумент1 страницаStructural SteelsrjueiОценок пока нет

- Swagelok Fitting PDFДокумент16 страницSwagelok Fitting PDFmattuiffОценок пока нет

- Tata Steel Cutting Edges GuideДокумент2 страницыTata Steel Cutting Edges GuideKen SmithОценок пока нет

- Schedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Документ2 страницыSchedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Caolboy ButchОценок пока нет

- Swagelok CatalogueДокумент16 страницSwagelok CatalogueZacharia JohnОценок пока нет

- Hoja Tecnica Aislador Polimerico PDFДокумент66 страницHoja Tecnica Aislador Polimerico PDFJose Alberto Jorge JiménezОценок пока нет

- Ubkhep Ob Design CheckДокумент72 страницыUbkhep Ob Design CheckPrayas SubediОценок пока нет

- Pipe Fittings: 1/16 To 1 In. Sizes 316 Stainless Steel, Brass, and Carbon Steel NPT, ISO/BSP, and SAE ThreadsДокумент16 страницPipe Fittings: 1/16 To 1 In. Sizes 316 Stainless Steel, Brass, and Carbon Steel NPT, ISO/BSP, and SAE ThreadsMehmet YılmazОценок пока нет

- DN350 To DN2400 (PN16) : Dismantling JointДокумент1 страницаDN350 To DN2400 (PN16) : Dismantling JointBlashko GjorgjievОценок пока нет

- 2011628233138490Документ14 страниц2011628233138490adventure11111Оценок пока нет

- Bar STDДокумент8 страницBar STDtushk20100% (1)

- Din 2393-2Документ0 страницDin 2393-2Yalavarthi ChandrasekharОценок пока нет

- Low Carbon Stainless Supply SpecДокумент4 страницыLow Carbon Stainless Supply SpecOmeОценок пока нет

- 296 - Material Database Ver E4.01Документ4 страницы296 - Material Database Ver E4.01BAHADIRОценок пока нет

- Schedule 40 PipeДокумент2 страницыSchedule 40 Piperasnowmah2012Оценок пока нет

- Portland Bolt Strength Requirements by Grade ChartДокумент3 страницыPortland Bolt Strength Requirements by Grade ChartPhilip D AguirreОценок пока нет

- Jis G3101 1995Документ3 страницыJis G3101 1995Kholer BurgmanОценок пока нет

- Lasercut WB 100 enДокумент0 страницLasercut WB 100 enfbp81Оценок пока нет

- Cat Astm A312Документ0 страницCat Astm A312Nguyễn Thanh CườngОценок пока нет

- Level Switch Side MountedДокумент2 страницыLevel Switch Side MountedArun GuptaОценок пока нет

- Bourdon Tube Pressure Gauges High Purity Series Type 130.15: ApplicationsДокумент5 страницBourdon Tube Pressure Gauges High Purity Series Type 130.15: ApplicationsbehnamatgОценок пока нет

- DIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84Документ2 страницыDIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84nunosobralОценок пока нет

- P-Numbers Guide to Base Metal CharacteristicsДокумент6 страницP-Numbers Guide to Base Metal CharacteristicsSaurabh SinghОценок пока нет

- Piping ComponentДокумент19 страницPiping Componentreach_arindomОценок пока нет

- Stud Bolt Specification 3Документ7 страницStud Bolt Specification 3santoshblonkarОценок пока нет

- API 2H Grade 50 Steel Plate SpecificationДокумент3 страницыAPI 2H Grade 50 Steel Plate SpecificationJym GensonОценок пока нет

- Norsok Material Data Sheet (M-630r2)Документ77 страницNorsok Material Data Sheet (M-630r2)karuna346Оценок пока нет

- Metric TubeДокумент6 страницMetric TubePartsGopher.comОценок пока нет

- Galvanized Iron Tubes: Galvanized Plain End, Screwed and End, Screwed and Socketed. Socketed, 15 MM To 150 MMДокумент2 страницыGalvanized Iron Tubes: Galvanized Plain End, Screwed and End, Screwed and Socketed. Socketed, 15 MM To 150 MMbalabhaviniОценок пока нет

- Speeds & Feeds DrillsДокумент9 страницSpeeds & Feeds DrillsHolleyMooreОценок пока нет

- Steel Grade ComparisonsДокумент3 страницыSteel Grade ComparisonsKevin Chen100% (3)

- Rate/ Unit Amount Supply & Installation Qnty Unit Item Description Sl. NoДокумент1 страницаRate/ Unit Amount Supply & Installation Qnty Unit Item Description Sl. NofranciscoОценок пока нет

- Wika 23x 54 Data SheetДокумент2 страницыWika 23x 54 Data Sheetvivek_enggОценок пока нет

- ASME B16.5 FLANGE SIZES AND MATERIAL OPTIONSДокумент201 страницаASME B16.5 FLANGE SIZES AND MATERIAL OPTIONSrenepunterОценок пока нет

- Fasteners GradeДокумент4 страницыFasteners GradeGilbert PereiraОценок пока нет

- Fastenal - Mechanical Properties of Inch FastenersДокумент4 страницыFastenal - Mechanical Properties of Inch FastenersbclarkeoobОценок пока нет

- Din 17100Документ4 страницыDin 17100Sheby SandyОценок пока нет

- Shurjoint Geral 2015 English v3 ImpДокумент218 страницShurjoint Geral 2015 English v3 ImpBárbara VoltarelliОценок пока нет

- 2016-2017 Shurjoint General CatalogДокумент217 страниц2016-2017 Shurjoint General CatalogsafirioОценок пока нет

- Swagelok Flange AdaptersДокумент6 страницSwagelok Flange AdapterstotcsabОценок пока нет

- EN 10025: 2004 Is The New European Standard For Structural Steel.Документ6 страницEN 10025: 2004 Is The New European Standard For Structural Steel.Alin DavidОценок пока нет

- AFNOR 42 CD 4 SteelДокумент2 страницыAFNOR 42 CD 4 SteelMagoroku D. YudhoОценок пока нет

- Astm A269Документ5 страницAstm A269Jose M-hОценок пока нет

- Swagelok High Pressure FittingsДокумент8 страницSwagelok High Pressure FittingsSyahirul AlimОценок пока нет

- All-in-One Manual of Industrial Piping Practice and MaintenanceОт EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceРейтинг: 5 из 5 звезд5/5 (1)

- Materials Data for Cyclic Loading: Low-Alloy SteelsОт EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsРейтинг: 5 из 5 звезд5/5 (2)

- Pipeline and Energy Plant Piping: Design and TechnologyОт EverandPipeline and Energy Plant Piping: Design and TechnologyРейтинг: 5 из 5 звезд5/5 (2)

- Hardox 450 PDFДокумент2 страницыHardox 450 PDFmcrajpuraОценок пока нет

- Breathers and Filler Breathers GuideДокумент6 страницBreathers and Filler Breathers GuidemcrajpuraОценок пока нет

- 100 Years at A Glance: Whirlpool CorporationДокумент16 страниц100 Years at A Glance: Whirlpool CorporationmcrajpuraОценок пока нет

- JBL Pulse4 Spec Sheet EnglishДокумент2 страницыJBL Pulse4 Spec Sheet EnglishmcrajpuraОценок пока нет

- 18865-OnePlus 7T Pro User Manual ENДокумент108 страниц18865-OnePlus 7T Pro User Manual ENYogesh RathiОценок пока нет

- Chrome Plated Steel Breather Filters for Industrial EquipmentДокумент2 страницыChrome Plated Steel Breather Filters for Industrial EquipmentmcrajpuraОценок пока нет

- Select The Right Sony TV For YouДокумент1 страницаSelect The Right Sony TV For YouJaimichu07Оценок пока нет

- Casting Defects With Respect To Indian Standards On Cast Iron in FoundryДокумент15 страницCasting Defects With Respect To Indian Standards On Cast Iron in FoundryKhushal TripathiОценок пока нет

- LF16011Документ1 страницаLF16011mcrajpuraОценок пока нет

- Stage Speakers: Home Audio Loudspeaker SystemДокумент4 страницыStage Speakers: Home Audio Loudspeaker SystemmcrajpuraОценок пока нет

- Stadium Marine Speakers: Take JBL Concert Level Sound To The High SeasДокумент3 страницыStadium Marine Speakers: Take JBL Concert Level Sound To The High SeasmcrajpuraОценок пока нет

- JBL - Stage3 - Speakers - Spec - Sheet - English - GLOBAL (NO USA)Документ3 страницыJBL - Stage3 - Speakers - Spec - Sheet - English - GLOBAL (NO USA)mcrajpuraОценок пока нет

- JBL Stadium Speakers Spec Sheet EnglishДокумент4 страницыJBL Stadium Speakers Spec Sheet EnglishmcrajpuraОценок пока нет

- Professional 3-Way Main Screen Speaker: HighlightsДокумент2 страницыProfessional 3-Way Main Screen Speaker: HighlightsmcrajpuraОценок пока нет

- HELLA 922000841 M26 Horn (Low Tone) 24V Part Number - 922.000-841 MRP: Inr 377 DetailsДокумент1 страницаHELLA 922000841 M26 Horn (Low Tone) 24V Part Number - 922.000-841 MRP: Inr 377 DetailsmcrajpuraОценок пока нет

- HELLA 922000851 M26 Horn (High Tone) 24V Part Number - 922.000-851 MRP: Inr 377 DetailsДокумент1 страницаHELLA 922000851 M26 Horn (High Tone) 24V Part Number - 922.000-851 MRP: Inr 377 DetailsmcrajpuraОценок пока нет

- PPДокумент12 страницPPmcrajpuraОценок пока нет

- Philips 4Документ12 страницPhilips 4mcrajpuraОценок пока нет

- 8brief Overview of Vehicle Seat Test Standards PDFДокумент3 страницы8brief Overview of Vehicle Seat Test Standards PDFmcrajpuraОценок пока нет

- EatonДокумент8 страницEatonmcrajpuraОценок пока нет

- PhilipsДокумент12 страницPhilipsmcrajpuraОценок пока нет

- LED Lighting Solutions GuideДокумент11 страницLED Lighting Solutions Guidemcrajpura100% (1)

- PhilipsДокумент2 страницыPhilipsmcrajpuraОценок пока нет

- Standard Test Procedures For The Lateral Stability of Heavy Vehicle Combinations - AurellДокумент20 страницStandard Test Procedures For The Lateral Stability of Heavy Vehicle Combinations - AurellmcrajpuraОценок пока нет

- SIGN128 GE LED Lighting Signage Batten DataSheetДокумент2 страницыSIGN128 GE LED Lighting Signage Batten DataSheetmcrajpuraОценок пока нет

- PhilipsДокумент2 страницыPhilipsmcrajpuraОценок пока нет

- Philips LightingДокумент2 страницыPhilips LightingmcrajpuraОценок пока нет

- Philips 2Документ2 страницыPhilips 2mcrajpuraОценок пока нет

- PhilipsДокумент2 страницыPhilipsmcrajpuraОценок пока нет

- LedДокумент4 страницыLedmcrajpuraОценок пока нет

- ECS448 - Topic 1Документ28 страницECS448 - Topic 1dixn__Оценок пока нет

- Set - 1 Kuppam Engineering College, Kuppam - 517425 Iii/I B.Tech (R09) Eee (B) - Jntua Descriptive Mid Test No: I Control SysremsДокумент4 страницыSet - 1 Kuppam Engineering College, Kuppam - 517425 Iii/I B.Tech (R09) Eee (B) - Jntua Descriptive Mid Test No: I Control SysremsManohar_3020Оценок пока нет

- UNIFLAIR ACCESS FLOOR QUOTEДокумент2 страницыUNIFLAIR ACCESS FLOOR QUOTEBaba HansОценок пока нет

- Operator Driven Reliability BrochureДокумент8 страницOperator Driven Reliability Brochuremcdiazr1961Оценок пока нет

- List of Courses Offered by Yaba College of Technology - MySchoolGistДокумент1 страницаList of Courses Offered by Yaba College of Technology - MySchoolGistalinahelen17Оценок пока нет

- Hager Abdelftah: ContactДокумент2 страницыHager Abdelftah: ContactSamsmithОценок пока нет

- The Strategic Context of ProjectsДокумент40 страницThe Strategic Context of ProjectsDaisy100% (1)

- HIT-RE 500 Epoxy Injection Mortar SystemДокумент3 страницыHIT-RE 500 Epoxy Injection Mortar Systemdeanz_75Оценок пока нет

- Control 3-Phase Motors with Digistart Soft StartersДокумент15 страницControl 3-Phase Motors with Digistart Soft StartersriqkeОценок пока нет

- VSL News 1997 1Документ16 страницVSL News 1997 1DrPadipat ChaemmangkangОценок пока нет

- Midas Design+ PDFДокумент1 страницаMidas Design+ PDFRaeghoОценок пока нет

- Seeking Bioinspiration Online: A Descriptive Account: Swaroop VATTAM, Ashok GOELДокумент10 страницSeeking Bioinspiration Online: A Descriptive Account: Swaroop VATTAM, Ashok GOELemiliodesignОценок пока нет

- Types of Slope ProtectionДокумент40 страницTypes of Slope ProtectionLouies Ungria100% (3)

- Heap Leach Facility Liner Design - LupoДокумент25 страницHeap Leach Facility Liner Design - LupoAbraham FIgueroa ARevaloОценок пока нет

- Delhi Technological University: Result NotificationДокумент4 страницыDelhi Technological University: Result NotificationHarsh SrivastavaОценок пока нет

- Integrals Ex SchedulesДокумент7 страницIntegrals Ex SchedulesChukzdeОценок пока нет

- AN18.01 Achieving Best Price Performance Parallel Power SuppliesДокумент5 страницAN18.01 Achieving Best Price Performance Parallel Power SuppliesFarhan ShahОценок пока нет

- Dalal Patel ResumeДокумент2 страницыDalal Patel ResumeVijay KrishnaОценок пока нет

- Is SP 7 4 2005Документ281 страницаIs SP 7 4 2005HabeebMohammedFarooqОценок пока нет

- 7th Sem Time Table PDFДокумент40 страниц7th Sem Time Table PDFUmesh KsОценок пока нет

- TQM Principles and ElementsДокумент81 страницаTQM Principles and ElementsRahul MishraОценок пока нет

- Distribution System Grounding FundamentalsДокумент17 страницDistribution System Grounding FundamentalsJose Alberto RodriguezОценок пока нет

- Addis Ababa Science and Technology UniversityДокумент6 страницAddis Ababa Science and Technology Universityabdulkerim seidОценок пока нет

- Che461-Week1 - Fall 2017 (16 Slides)Документ16 страницChe461-Week1 - Fall 2017 (16 Slides)Nouman AliОценок пока нет

- Classification of Engineering ServicesДокумент24 страницыClassification of Engineering ServicesPaul Vincent De GuzmanОценок пока нет

- Professional Engineering Exam: Common PartДокумент32 страницыProfessional Engineering Exam: Common Partkako2006Оценок пока нет

- Example 5.1Документ6 страницExample 5.1Aisyah JamalОценок пока нет

- Seminar On: Earthquake Resistant TechniquesДокумент26 страницSeminar On: Earthquake Resistant TechniquesrohitОценок пока нет

- Eurocodes 7 Geotechnical Design Course Outline 2016 Sihle PDFДокумент8 страницEurocodes 7 Geotechnical Design Course Outline 2016 Sihle PDFernestnsabimana74Оценок пока нет