Академический Документы

Профессиональный Документы

Культура Документы

VisualManager e

Загружено:

ThaiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

VisualManager e

Загружено:

ThaiАвторское право:

Доступные форматы

TEXTILE MACHINERY DIVISION

Green-Bldg, 2-6-26, Kitahama, Chuo-ku, Osaka, 541-0041, JAPAN

TEL: +81-(0)6-6202-1385 FAX: +81-(0)6-6202-3096

http://www.muratec.co.jp

INQUIRIES REGARDING OPERATIONS

MURATA MACHINERY, LTD.

TEXTILE MACHINERY DIVISION

TECHNICAL SERVICE DEPARTMENT

136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto, 612-8686, JAPAN

TEL: +81-(0)75-672-8230 FAX: +81-(0)75-672-8304

INQUIRIES REGARDING PARTS

MURATA PARTS SALES, LTD.

136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto, 612-8686, JAPAN

TEL: +81-(0)75-672-8371 FAX: +81-(0)75-671-0789

http://www.muratec.co.jp/parts.html

GLOBAL SALES & SERVICE NETWORK

MURATA MACHINERY USA INC.

TEXTILE MACHINERY DIVISION

2120 Queen City Drive, P.O.Box 667609,

Charlotte, N.C. 28208, U.S.A.

TEL: +1-704-394-8331 FAX: +1-704-392-6541

http://www.muratec-usa.com

MURATA MACHINERY (SHANGHAI) CO., LTD.

[Registry Add]

135 Fu Te Xi Yi Rd., Wai Gao Qiao Free Trade Zoon,

Pudong, Shanghai, CHINA

[Contact Add]

150 Xin Gao Rd., Qingpu Industrial Zone,

Shanghai, 201700, CHINA

TEL: +86-(0)21-6921-2300 FAX: +86-(0)21-6921-2311

MURATA MACHINERY (SHANGHAI) CO., LTD.

XINJIANG OFFICE

Rm.318, No.75, District 23,North 3 Rd.,Shihezi,

Xinjiang, 832000, CHINA

TEL:+86-(0)993-2085-318 FAX:+86-(0)993-2085-333

MURATA DO BRASIL COMERCIO

E REPRESENTACAO DE MAQUINAS LTDA.

Estrada de Santa Izabel, 3383-KM 38,5,

Itaquaquecetuba-SP-CEP 08599-000 BRASIL

TEL: +55-(0)11-4648-6222 FAX: +55-(0)11-4648-6737

MURATA MACHINERY (SHANGHAI) CO., LTD.

BEIJING BRANCH

Rm.309 Yulin Bldg.,No.5 Er Xiang Jia, Xiangjun Nan Li,

Chaoyang-qu, Beijing, 100020, CHINA

TEL: +86-(0)10-6597-8829 FAX: +86-(0)10-6597-8830

MURATA MACHINERY (H.K.), LTD.

Unit 9-11 5F, Telford House, Wang Hoi Road,

Kowloon Bay, Kowloon, Hong Kong, CHINA

TEL: +852-2332-0009 FAX: +852-2780-6340

MURATA MACHINERY EUROPE GMBH

Hanns-Martin-Schleyer-Strasse 3, D-47877,

Willich, GERMANY

TEL: +49-(0)2154-914-0 FAX: +49-(0)2154-914-188

MURATA MACHINERY (SHANGHAI) CO., LTD.

GUANGZHOU BRANCH

Room 635, United Star Hotel, 172 Chang Gang Rd., C.,

Guangzhou, 510250, CHINA

TEL:+86-(0)20-8434-2882 FAX:+86-(0)20-8434-3463

MURATA MACHINERY TAIWAN, LTD.

18F., No.17, Sec.1, Chengde Rd.,

Taipei 10351, Taiwan, CHINA

TEL: +886-(0)2-2558-3908 FAX: +886-(0)2-2558-3907

MURATA MACHINERY EUROPE GMBH

ITALY LIAISON OFFICE

Via Pajetta 33, 13836 Cossato,

(BI) ITALY

TEL: +39-015-9842527 FAX: +39-015-927614

MURATA MACHINERY (SHANGHAI) CO., LTD.

SHANDONG BRANCH

Rm.DS188 Daixi Villa, Zouping,

Shandong, 256200, CHINA

TEL: +86-(0)543-4359-488 FAX: +86-(0)543-4359-189

MURATA (THAILAND) CO., LTD.

896/14 S.V. City Building 1, 9th Floor, Rama III Road

Bangpongpang, Yannawa, Bangkok 10120, THAILAND

TEL:+66-(0)2294-7734-40 FAX:+66-(0)2294-7732

MURATA MACHINERY, LTD.

CAIRO LIAISON OFFICE

APT 604, 6th Floor, 8, El Mansour Mohamed Street,

Zamalek, Cairo, A.R.EGYPT

TEL: +20-(0)2-7355168 FAX: +20-(0)2-7355168

MURATA MACHINERY, LTD.

TURKEY LIAISON OFFICE

Barbaros Bulvari, Eser Apt. 78/11, Balmumcu 34349,

Istanbul, TURKEY

TEL: +90-(0)212-288-9123 FAX: +90-(0)212-288-9147

KIWOO SUNGUP CO., LTD.

SEOUL OFFICE

1519 Gwanghwamun Offica, 163 Shinmunno-1ga,

Jongno-gu, Seoul, 110-999 KOREA

TEL: +82-(0)2-732-9408 FAX: +82-(0)2-732-9409

MMI SERVICES PRIVATE, LTD.

MUMBAI OFFICE

94, C, Wing (9th Floor), Mittal Tower, 210, Nariman Point,

Mumbai, 400021, INDIA

TEL: +91-(0)22-2-284-4079 FAX: +91-(0)22-2-284-6820

TEXCONE ENGINEERING

290/1 Sonargaon Road, Dhaka, 1205, BANGLADESH

TEL: +880-(0)2-966-6809 FAX: +880-(0)2-966-6810

KIWOO SUNGUP CO., LTD.

DAEGU OFFICE

18F., Yeongnamtower, 111 Sincheon-dong, Dong-gu,

Daegu, 701-020, KOREA

TEL: +82-(0)53-745-0217 FAX: +82-(0)53-745-0219

MMI SERVICES PRIVATE, LTD.

DELHI OFFICE

1010, Hemkunt Tower, 98, Nehru Place,

New Delhi, 110019, INDIA

TEL: +91-(0)11-2-628-0056 FAX: +91-(0)11-2-628-0058

SPINTEX (PRIVATE) LTD.

C-92, KDA Scheme No.1, Karachi, PAKISTAN

TEL: +92-(0)21-4523739, 4523729 FAX: +92-(0)21-4523727

P.T. INDOTEXMAT PRIMA

Ruko Gyan Plaza, D-3, Jln. Terusan Pasirkoja Blok 8,

Bandung, 40222, INDONESIA

TEL:+62-(0)22-604-6633 FAX:+62-(0)22-604-6612

MMI SERVICES PRIVATE, LTD.

COIMBATORE OFFICE

1023, Eureka Chambers 1st Floor, Avanashi Road,

Coimbatore, 641018, INDIA

TEL: +91-(0)422-435-0350 FAX: +91-(0)422-2216872

(AUTHORIZED SERVICE AGENCIES)

We reserve our right to modify them at any time, to be confirmed by authorized specification.

CAT. NO. 21P0M2 07-08-1(NS)

Visual Manager

For Muratec Automatic Winders

(LIAISON OPERATIONS)

MURATA MACHINERY, LTD.

HO CHI MINH LIAISON OFFICE

8A/9C1 Thai Van Lung Street, Ben Nghe Ward,

Dist.1, Ho Chi Minh City, VIETNAM

TEL:+84-(0)8-822-8996 FAX+84-(0)8-827-3068

Integrated Management System

Visual Manager

Integrated Management System for

Muratec Automatic Winders

Integrated Management System

for Muratec Automatic Winders

Visual Manager

The Advantages of Visual Manager

1 Early discovery of problems

From "solving problems" to "preventing problems" - we at Muratec are striving

to help our customers derive maximum performance from their machines, and to

contribute to amplification of yarn quality and productivity. Therefore, we

consider "preventative maintenance" a key element of our customer support.

Visual Manager analyzes data for deviation from the standard

data, and can even pinpoint problems in data from winders

where there is a lot of dispersion.

It enables discovery and correction of small problems before

they become major difficulties.

Visual Manager collects data for analysis via MMM / MMC / VOS built into the

Mach Coner / Link Coner / Process Coner. It then displays data relating to

maintenance, production and quality, as required by the machine supervisor, in

an easy-to-understand manner.

If Visual Manager discovers abnormal data, it advises the origin of the data, and

displays instruction on how to handle the problem. In this way, Visual Manager

software assists in maintaining the machine in the best operating condition at all

times.

Visual Manager can process detailed data for each spindle at each shift, and find

problems in their early stages to enable prompt countermeasures to be taken.

2 Appropriate countermeasures reduce maintenance time

Visual Manager works out the appropriate maintenance

required from the abnormal data, and uses diagrams and

photographs to provide an easy-to-understand explanation.

3 Quality control from the yarn breakage data

Visual Manager analyses yarn breakage data according to

the causes of yarn clearer cuts (S, L, T, etc.).

It can then provide appropriate feedback to the previous

process when abnormal yarn breakages occur.

4 Original data analysis is simple

All data is easily changed to text file format. Utilising these

data for your own analysis is therefore a simple matter.

ail

E-m

5 Networkable

Maintenance

Visual Manager software runs under WindowsXP, so

networking with other systems in the plant is simple.

Productivity

Oroductivity

rk

wo

Yarn

Quality

Quality

Ne

g

ltin

u

s

on tec

C

ote Mura

m

Re by

6 Data transmission by e-mail

Visual Manager enables data transmission by e-mail.

You can check production data via the Internet from

anywhere.

7 Muratec remote diagnosis service (option)

Muratec staff can implement periodic diagnosis of machine

operating conditions over the telephone line, providing advice

as required, thereby helping to raise quality and productivity

(for a separate chargeable contract).

The Ideal Tool

for Winder Management

Visual Manager

Integrated Management System

for Muratec Automatic Winders

Functions of Visual Manager

[ Maintenance ]

Locates places that require maintenance

from abnormal data

1. Visual Manager analyses data from each shift of the last two weeks, providing

notification of abnormal data and the relevant location. At the same time, it

determines the points to check from the type of abnormal data, and displays the

procedure on the screen.

2. The explanation for the check points uses photographs and diagrams to help

understanding, and allows even inexperienced maintenance operators to carry

out the correct countermeasures.

[ Productivity ]

Production control

1. Displays graphs for the production of the past year.

2. Displays a graph of production per lot, machine, and daily.

Production display

Abnormal location display

[ Quality ]

Check point display

Quality control based on yarn breakage rate

1. Visual Manager checks the yarn breakage rate for each shift on a machine and a

spindle basis.

A target value is set on a machine basis, and this value is used to determine if the

collected data is abnormal or not.

2. The yarn breakage data from the past two weeks is shown on a shift basis using

displays such as those below. This allows you to quickly grasp the situation.

3. The causes of yarn clearer cut are also displayed, so feedback to the previous

process is possible.

Matrix display

Graph of yarn breakage causes

The Ideal Tool

for Winder Management

Visual Manager

Integrated Management System

for Muratec Automatic Winders

Functions of Visual Manager

[ Running Data ]

Displays detailed data of the past

month in machine, spindle, lot, and

group units.

You can quickly locate spindles

that have abnormal data from the

graph display.

[ Spinning ]

The spinning efficiency can be displayed when Visual Manager is used for the Link

Coner. This allows you to visually check the production balance between the

spinning machine and the winder. If productivity is low, this enables you to

determine whether the cause is the spinning machine or the winder.

[ Manual ]

The Visual Manager manual is on-line in PDF file format. It can be consulted as

needed by pressing the HELP button.

[ Trend Graph ]

Displays the past working

condition data for each machine.

Data from a maximum of two years

can be displayed.

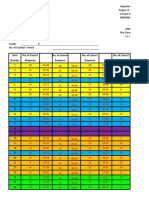

S pec ific ations of Vis ual Manager

Specifications

1. Visual Manager is intended for use with winders equipped with either the MMM

(MK-7, MK-8), MMC (MMC, MMC/2, MMC3), or VOS, VOS-II

(*excluding the MMM MK-II and MK-5)

2. The customer is required to provide the personal computer and other software

specified below

3. Hardware failures can result in destruction of data . Be certain to back up your

data periodically.

4. We recommend that you use a UPS to prevent data loss due to power failures.

Computer Specifications

[ Past Lot Data ]

1.

2.

3.

4.

5.

6.

7.

OS: Microsoft WindowsXP Professional SP2

CPU: Pentium4, or better

Memory: 512MB or larger

Hard disk: 10GB or larger (Visual Manager requires approx. 2.5GB)

Display: 17 inch or larger (1024 x 765, 16bit color or more)

Color printer

Ethernet network card: indispensable for connecting to VOS

Displays up to two years of quality

(yarn breakage cause) and

production data for each lot.

WindowsXP are registered trade names of the Microsoft Corporation.

Pentium4 is a registered trade name of the Intel Corporation.

Вам также может понравиться

- UltimoДокумент4 страницыUltimoziniya rahman100% (1)

- AqmДокумент13 страницAqmDeepanshu Ohlan Kewlness RedefinedОценок пока нет

- Ri̇eter Tesi̇s PDFДокумент2 страницыRi̇eter Tesi̇s PDFdipak kambleОценок пока нет

- Slub Effect of Reieter Yarn PDFДокумент12 страницSlub Effect of Reieter Yarn PDFashik1111007Оценок пока нет

- Management Information System Project: Sri Karpagam Spinning Mills LTDДокумент5 страницManagement Information System Project: Sri Karpagam Spinning Mills LTDPradeep DurairajОценок пока нет

- Instruction Manual For Novibra SpindlesДокумент12 страницInstruction Manual For Novibra SpindlesAdam SetyawanОценок пока нет

- Basic Course Workshop Dhaka 2007Документ11 страницBasic Course Workshop Dhaka 2007Shoreless ShaikatОценок пока нет

- Carl A. Lawrence. Fundamental of Spun Yarn Technology. CRC Press, 2003Документ4 страницыCarl A. Lawrence. Fundamental of Spun Yarn Technology. CRC Press, 2003HawОценок пока нет

- Maintenance Management Assignment 1: Total Productive Maintenance in RMG IndustryДокумент15 страницMaintenance Management Assignment 1: Total Productive Maintenance in RMG IndustryPrakritiОценок пока нет

- Electronic Shedding Modern Development in WeavingДокумент3 страницыElectronic Shedding Modern Development in WeavingNatraj kanaharajОценок пока нет

- Compact SpinnigДокумент17 страницCompact Spinnigshahadat hossainОценок пока нет

- Sussen CompactДокумент8 страницSussen CompactArumugham RMОценок пока нет

- Shedding Mechanism of Sulzer Projectile Loom HP7300: Advance Yarn Fabric ManufacturingДокумент7 страницShedding Mechanism of Sulzer Projectile Loom HP7300: Advance Yarn Fabric ManufacturingFarah SaadОценок пока нет

- Fuka HamaДокумент54 страницыFuka HamaG.M. Farhad100% (1)

- A Comprehensive Study On PPC For Denim ManufacturingДокумент26 страницA Comprehensive Study On PPC For Denim ManufacturingPradi Krish100% (1)

- 44 45 Spinning HRS CardingДокумент2 страницы44 45 Spinning HRS CardingMansoor KhanaliОценок пока нет

- Novibra SpindlesДокумент12 страницNovibra SpindlesAbirami SpinnersОценок пока нет

- Buser 11 1 WebДокумент12 страницBuser 11 1 WebpavanuОценок пока нет

- Garment Analyzer™: Flexible Predetermined Motion Time SystemДокумент30 страницGarment Analyzer™: Flexible Predetermined Motion Time SystemardinrajaОценок пока нет

- Use of Software in Textile: Jawaharlal Drda Institute of Engineering and Technology, YavatmalДокумент8 страницUse of Software in Textile: Jawaharlal Drda Institute of Engineering and Technology, YavatmalRajesh Dwivedi100% (1)

- Control Systemte of BlowroomДокумент18 страницControl Systemte of BlowroomNiveditaKumariОценок пока нет

- Cardingmachine 140324082245 Phpapp01Документ33 страницыCardingmachine 140324082245 Phpapp01SantoshОценок пока нет

- Optimax-I Brochure 2019 enДокумент22 страницыOptimax-I Brochure 2019 enACE CONSULTANTS100% (1)

- Yarn Manufacture - Set of 2 VolsДокумент2 страницыYarn Manufacture - Set of 2 VolsAnonymous Pt7NHkat9Оценок пока нет

- Rieter c70 Card Brochure 2810 v3 89526 enДокумент32 страницыRieter c70 Card Brochure 2810 v3 89526 enzubairОценок пока нет

- Conveyor BeltsДокумент12 страницConveyor BeltsJohn Renzel Rivera IIIОценок пока нет

- Qualifications Pack Production SupervisorДокумент33 страницыQualifications Pack Production SupervisorANKITОценок пока нет

- User Guide PDFДокумент113 страницUser Guide PDFHanaОценок пока нет

- Non Woven Fabric: Dr. Jimmy Lam Institute of Textiles & ClothingДокумент24 страницыNon Woven Fabric: Dr. Jimmy Lam Institute of Textiles & ClothingPhoenixjor JorОценок пока нет

- Visual PresentationДокумент41 страницаVisual PresentationHanna SianturiОценок пока нет

- Uster: Measuring PrinciplesДокумент48 страницUster: Measuring Principlesnminhtuan88Оценок пока нет

- Cutting Room TerminologiesДокумент2 страницыCutting Room TerminologiesMuhammad Sharif HasanОценок пока нет

- Qpro 9 en Auto Doffer.Документ24 страницыQpro 9 en Auto Doffer.Md Hanif SonketОценок пока нет

- Uster Technologies Regularly Publishes Standards Such As USTERДокумент12 страницUster Technologies Regularly Publishes Standards Such As USTERHeba AlaaОценок пока нет

- Alicat Scientific MFCs-Technology & BenefitsДокумент6 страницAlicat Scientific MFCs-Technology & BenefitsyuvionfireОценок пока нет

- GOT Program Restore Using GT Designer3Документ8 страницGOT Program Restore Using GT Designer3Jacob B ChackoОценок пока нет

- Machine Vision For Quality ImprovementДокумент20 страницMachine Vision For Quality ImprovementBhaswati PandaОценок пока нет

- mSMIT TEXTILE JS900 Air-Jet Weaving MachineДокумент2 страницыmSMIT TEXTILE JS900 Air-Jet Weaving Machine9464776238Оценок пока нет

- Novibra Spindles Hps enДокумент8 страницNovibra Spindles Hps ensitra spinningОценок пока нет

- BSL PrintДокумент62 страницыBSL Printrishi100% (1)

- Tuchler Vs ReiterДокумент17 страницTuchler Vs ReiterUmer IrshadОценок пока нет

- UQ3 Techdata en 201905 PDFДокумент13 страницUQ3 Techdata en 201905 PDFVishnuMaliОценок пока нет

- A 12 UNIfloc Leaflet 2936-V11 86370 Original English 86370Документ2 страницыA 12 UNIfloc Leaflet 2936-V11 86370 Original English 86370Yogeshkumar j joshi100% (1)

- Application of Kaizen Methodology For Process Improvementin Textile MillДокумент6 страницApplication of Kaizen Methodology For Process Improvementin Textile MillMuhammad Rofiq muhammadrofiq.2020Оценок пока нет

- New Rieter Center P+® Ring Centering Device: Info No. G 14 Ring Spinning Machines: All ModelsДокумент2 страницыNew Rieter Center P+® Ring Centering Device: Info No. G 14 Ring Spinning Machines: All ModelsVenkatesh BabuОценок пока нет

- M01 Understand GarmentnproductinДокумент51 страницаM01 Understand GarmentnproductinJocy ShiferaОценок пока нет

- 177uster Quantum 3Документ7 страниц177uster Quantum 3Ae LiОценок пока нет

- Rieter Rotor Semi r36 Brochure 3101 v1 87068 enДокумент28 страницRieter Rotor Semi r36 Brochure 3101 v1 87068 enHai PhamОценок пока нет

- Omniplus-I Brochure 2020 enДокумент24 страницыOmniplus-I Brochure 2020 ensubramanianОценок пока нет

- J 20 Air-Jet Spinning Machine Brochure 2386-V1 en 34515Документ16 страницJ 20 Air-Jet Spinning Machine Brochure 2386-V1 en 34515Ishwar DudagiОценок пока нет

- Speed Frame Operator 2.0Документ73 страницыSpeed Frame Operator 2.0Danish NawazОценок пока нет

- Recent Development of Modern Spinning and WeavingДокумент20 страницRecent Development of Modern Spinning and WeavingsuganОценок пока нет

- Zaxet enДокумент12 страницZaxet enkathirvelus9408Оценок пока нет

- Gujarat Technological University: W.E.F. AY 2018-19Документ2 страницыGujarat Technological University: W.E.F. AY 2018-19Rushi TannaОценок пока нет

- Automation in WeavingДокумент7 страницAutomation in Weavingsalsabila fuОценок пока нет

- IEMS Module 6Документ6 страницIEMS Module 6VenkatramananОценок пока нет

- Uster ZweigleДокумент9 страницUster ZweigleShoaib ArifОценок пока нет

- ZJ BrochureДокумент12 страницZJ Brochureibayraktar775208Оценок пока нет

- Product Guide: Teraspin Spindle Bearing Units and Complete SpindlesДокумент6 страницProduct Guide: Teraspin Spindle Bearing Units and Complete SpindlesNeelakandan DОценок пока нет

- SEW MC SCOPE Software ManualДокумент35 страницSEW MC SCOPE Software ManualRoman JambrekОценок пока нет

- Commercial Private Equity Announces A Three-Level Loan Program and Customized Financing Options, Helping Clients Close Commercial Real Estate Purchases in A Few DaysДокумент4 страницыCommercial Private Equity Announces A Three-Level Loan Program and Customized Financing Options, Helping Clients Close Commercial Real Estate Purchases in A Few DaysPR.comОценок пока нет

- Proposal For Real Estate Asset Management and Brokerage ServicesДокумент2 страницыProposal For Real Estate Asset Management and Brokerage ServicesTed McKinnonОценок пока нет

- MELC5 - First ObservationДокумент4 страницыMELC5 - First ObservationMayca Solomon GatdulaОценок пока нет

- UXBenchmarking 101Документ42 страницыUXBenchmarking 101Rodrigo BucketbranchОценок пока нет

- Catalogue 2021Документ12 страницCatalogue 2021vatsala36743Оценок пока нет

- Review Questions & Answers For Midterm1: BA 203 - Financial Accounting Fall 2019-2020Документ11 страницReview Questions & Answers For Midterm1: BA 203 - Financial Accounting Fall 2019-2020Ulaş GüllenoğluОценок пока нет

- GooseberriesДокумент10 страницGooseberriesmoobin.jolfaОценок пока нет

- Lifeline® Specialty: Fire Resistant QFCI Cable: Fire Resistant, Flame Retardant Halogen-Free Loose Tube - QFCI/O/RM-JMДокумент2 страницыLifeline® Specialty: Fire Resistant QFCI Cable: Fire Resistant, Flame Retardant Halogen-Free Loose Tube - QFCI/O/RM-JMkevinwz1989Оценок пока нет

- Item AnalysisДокумент7 страницItem AnalysisJeff LestinoОценок пока нет

- TrematodesДокумент95 страницTrematodesFarlogy100% (3)

- Rudolf Steiner - Twelve Senses in Man GA 206Документ67 страницRudolf Steiner - Twelve Senses in Man GA 206Raul PopescuОценок пока нет

- CS 124/LINGUIST 180 From Languages To Information: Conversational AgentsДокумент58 страницCS 124/LINGUIST 180 From Languages To Information: Conversational AgentsamanОценок пока нет

- Precertification Worksheet: LEED v4.1 BD+C - PrecertificationДокумент62 страницыPrecertification Worksheet: LEED v4.1 BD+C - PrecertificationLipi AgarwalОценок пока нет

- Karak Rules - EN - Print PDFДокумент8 страницKarak Rules - EN - Print PDFWesley TeixeiraОценок пока нет

- ANI Network - Quick Bill Pay PDFДокумент2 страницыANI Network - Quick Bill Pay PDFSandeep DwivediОценок пока нет

- Food Combining PDFДокумент16 страницFood Combining PDFJudas FK TadeoОценок пока нет

- Specification - Pump StationДокумент59 страницSpecification - Pump StationchialunОценок пока нет

- 059 Night of The Werewolf PDFДокумент172 страницы059 Night of The Werewolf PDFomar omar100% (1)

- Seangio Vs ReyesДокумент2 страницыSeangio Vs Reyespja_14Оценок пока нет

- Do You Agree or Disagree With The Following StatementДокумент2 страницыDo You Agree or Disagree With The Following StatementVũ Ngọc Minh ThuОценок пока нет

- Anxxx PDFДокумент13 страницAnxxx PDFDamion HaleОценок пока нет

- Type of MorphologyДокумент22 страницыType of MorphologyIntan DwiОценок пока нет

- лк CUDA - 1 PDCnДокумент31 страницалк CUDA - 1 PDCnОлеся БарковськаОценок пока нет

- Dumont's Theory of Caste.Документ4 страницыDumont's Theory of Caste.Vikram Viner50% (2)

- Marriot CaseДокумент15 страницMarriot CaseArsh00100% (7)

- FAMILYДокумент3 страницыFAMILYJenecel ZanoriaОценок пока нет

- 1-Gaikindo Category Data Jandec2020Документ2 страницы1-Gaikindo Category Data Jandec2020Tanjung YanugrohoОценок пока нет

- Concordia: The Lutheran Confessions - ExcerptsДокумент39 страницConcordia: The Lutheran Confessions - ExcerptsConcordia Publishing House28% (25)

- Literatures of The World: Readings For Week 4 in LIT 121Документ11 страницLiteratures of The World: Readings For Week 4 in LIT 121April AcompaniadoОценок пока нет

- Unit 3 RequirementsДокумент4 страницыUnit 3 Requirementsravioli kimОценок пока нет