Академический Документы

Профессиональный Документы

Культура Документы

AZZ HVBS Case Study - 0

Загружено:

osvald970 оценок0% нашли этот документ полезным (0 голосов)

62 просмотров2 страницыAZZ designed, built, shipped, installed, and commissioned replacement SF6 gas insulated line (GIL) in just 39 days. Due to the severity of the transformer fault and collateral damage, this repair required a total of 36 sections to bring the generator back online. 22 tons of AZZ high voltage transmission equipment were air freighted to Saudi Arabia via 747, a 48-hour transit from origin to destination that normally requires 8 weeks.

Исходное описание:

Оригинальное название

AZZ HVBS Case Study_0

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документAZZ designed, built, shipped, installed, and commissioned replacement SF6 gas insulated line (GIL) in just 39 days. Due to the severity of the transformer fault and collateral damage, this repair required a total of 36 sections to bring the generator back online. 22 tons of AZZ high voltage transmission equipment were air freighted to Saudi Arabia via 747, a 48-hour transit from origin to destination that normally requires 8 weeks.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

62 просмотров2 страницыAZZ HVBS Case Study - 0

Загружено:

osvald97AZZ designed, built, shipped, installed, and commissioned replacement SF6 gas insulated line (GIL) in just 39 days. Due to the severity of the transformer fault and collateral damage, this repair required a total of 36 sections to bring the generator back online. 22 tons of AZZ high voltage transmission equipment were air freighted to Saudi Arabia via 747, a 48-hour transit from origin to destination that normally requires 8 weeks.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

High Voltage Bus Systems Case Study

Rapid Response to Transformer

Explosion at Power Plant

AZZ designed, built, shipped, installed, and commissioned replacement SF6 gas insulated line

(GIL) in just 39 days

AZZ received an urgent call that an explosion had

occurred on a critical 864 MVA generator step-up

transformer (GSU) at a major power plant in Saudi

Arabia. The explosion caused significant damage to

the transformer and the gas insulated line (GIL) which

connects the transformer to a 380 kV Gas Insulated

Substation (GIS).

AZZ immediately dispatched the local Country Manager

from Riyadh to the site to assess the damage and

determine how AZZ could help. Damage photos and

copies of Instruction Book drawings were sent to AZZs

High Voltage Bus Systems division (HVBS) in Medway,

MA, U.S. From these photos and drawings, HVBS was

able to prepare a layout drawing outlining the best

solution. In order to complete the detailed design, HVBS

dispatched the Field Services Manager to the site to

take detailed measurements of the equipment the GIL

would need to connect with. With the detailed interface

measurements from site, the Engineering team was able

to complete the designs and release for manufacturing at

AZZs HVBS plant.

Due to the severity of the transformer fault and

collateral damage, this repair required a total of 36

sections to bring the generator back online, which

required expedited manufacturing of additional standard

components, including flanges, silver plated contact

assemblies, adjustment bellows and epoxy insulators.

AZZ maintains an emergency supply of standard

GIL components as well as an in-house capability to

produce additional components and thus was able to

rapidly produce the needed components within days of

understanding the full required scope of supply.

AZZ | One Museum Place, 3100 West 7th St., Fort Worth, TX 76107 | 817.810.0095 | azz.com

High Voltage Bus Systems Case Study

In total, 22 tons of AZZ high voltage transmission

equipment were air freighted to Saudi Arabia via 747, a

48-hour transit from origin to destination that normally

requires 8 weeks.

After seven days of around-the-clock installation

coordinated by AZZ, the equipment was ready for high

voltage testing and commissioning, which were completed

in less than one week. The plant was brought back on line

three full days before the start of Ramadan as strongly

desired by the utility due to mid-summer being the time

of peak demand.

AZZ High Voltage Bus Systems was able to accomplish in

39 days what would typically have required 5-6 months

and would have left utilitys customers without power

during the Ramadan holiday and the hottest time of year.

Loading of equipment onto chartered plane at JFK

Replacement transformer with new AZZ GIL ready for energization

AZZ | One Museum Place, 3100 West 7th St., Fort Worth, TX 76107 | 817.810.0095 | azz.com

Вам также может понравиться

- SVC PTSДокумент966 страницSVC PTSTori Small50% (2)

- #1 - Casky, KY - Project Survey: Project Summary Location DescriptionДокумент6 страниц#1 - Casky, KY - Project Survey: Project Summary Location Descriptionpo099Оценок пока нет

- Ras Az Zawr FileДокумент20 страницRas Az Zawr FileMohammad Sazid AlamОценок пока нет

- Profile: Employment HistoryДокумент5 страницProfile: Employment HistoryMoin- ud-dinОценок пока нет

- Aramco Wellhead Christmas Tree RehabilitationДокумент9 страницAramco Wellhead Christmas Tree RehabilitationHaleem Ur Rashid BangashОценок пока нет

- 04 - SEC Earthwork Spec SCS-Q-002-rev 1 PDFДокумент40 страниц04 - SEC Earthwork Spec SCS-Q-002-rev 1 PDFfaisal jasim100% (1)

- Electrical Panels (Installation & Termination) NHC-CGI-PMO-ASIR-DCS-EL-0089 Rep ArsonsДокумент13 страницElectrical Panels (Installation & Termination) NHC-CGI-PMO-ASIR-DCS-EL-0089 Rep ArsonsabedОценок пока нет

- Resume: M. Ehsan Rafaqat Electrical Engineer Mobile: +966-500-609-430 EmailДокумент9 страницResume: M. Ehsan Rafaqat Electrical Engineer Mobile: +966-500-609-430 Emailengrrahman3135Оценок пока нет

- Project: Sarnafil and King of Texas Exhibit High-Flying Performance at DFW AirportДокумент2 страницыProject: Sarnafil and King of Texas Exhibit High-Flying Performance at DFW Airportrobox514Оценок пока нет

- Naveed E&I EngrДокумент5 страницNaveed E&I EngrShahed HussainОценок пока нет

- Ahmed ArafiaДокумент6 страницAhmed ArafiaAbhilash PaulОценок пока нет

- Industriual Training Rashid AshrafДокумент36 страницIndustriual Training Rashid AshrafUMAR MAJEED MIR 209-MEET-18Оценок пока нет

- Otc 25777 MS PDFДокумент9 страницOtc 25777 MS PDFObi MogboОценок пока нет

- Metal Enclosed Switchgear For AirportДокумент2 страницыMetal Enclosed Switchgear For AirportjuevesОценок пока нет

- Aramco Wellhead Christmas Tree RehabilitationДокумент9 страницAramco Wellhead Christmas Tree RehabilitationKannan KarunakaranОценок пока нет

- R O W of High Voltage Transmission LinesДокумент8 страницR O W of High Voltage Transmission LinesMohamad Al-SayedОценок пока нет

- Aerospace & Defense Technology - April 2020Документ52 страницыAerospace & Defense Technology - April 2020Titel BОценок пока нет

- Blackveatch ProposalДокумент139 страницBlackveatch ProposalAriel HughesОценок пока нет

- DecisionERCCaseNo2015 055MCДокумент16 страницDecisionERCCaseNo2015 055MCrajgonzОценок пока нет

- NASA: 188509main 09-06-07Документ1 страницаNASA: 188509main 09-06-07NASAdocumentsОценок пока нет

- PP 55Документ3 страницыPP 55Mauricio GuanellaОценок пока нет

- General Dynamics Knifefish UUV Team Eyes Production After Finishing Critical Design ReviewДокумент2 страницыGeneral Dynamics Knifefish UUV Team Eyes Production After Finishing Critical Design ReviewBeatriceWasongaОценок пока нет

- Salim 2010Документ20 страницSalim 2010Mohamed ElkumatiОценок пока нет

- REFCard - Additional Air Compressor and Air Dryer Package - EN-2012Документ1 страницаREFCard - Additional Air Compressor and Air Dryer Package - EN-2012amini_mohiОценок пока нет

- 58 77NVEClarkДокумент20 страниц58 77NVEClarkaustintanОценок пока нет

- 004-MS For Earthing System PDFДокумент10 страниц004-MS For Earthing System PDFKöksal Patan100% (1)

- Esmat CVДокумент8 страницEsmat CVعصمت ضيف اللهОценок пока нет

- E-Magazine For Latest Projects in Saudi ArabiaДокумент4 страницыE-Magazine For Latest Projects in Saudi ArabiaASIFОценок пока нет

- Dimensions: OSPAS Manager Suleman A. Al-Bargan Oversees The State-Of-The-Art SystemДокумент10 страницDimensions: OSPAS Manager Suleman A. Al-Bargan Oversees The State-Of-The-Art SystemKian Keong YeeОценок пока нет

- Dsouza 2017Документ10 страницDsouza 2017Dany JoshuaОценок пока нет

- 0002 702Документ9 страниц0002 702Buddharaju Kiran0% (2)

- MOINindustriual Training Rashid AshrafДокумент54 страницыMOINindustriual Training Rashid AshrafUMAR MAJEED MIR 209-MEET-18Оценок пока нет

- Amir Mohamed: Aramco For Khurais PipelineДокумент7 страницAmir Mohamed: Aramco For Khurais PipelineHatem HusseinОценок пока нет

- Piping Engineer Anwar's CVДокумент6 страницPiping Engineer Anwar's CVAnwar hussain89% (9)

- WEF Chp07 - Final Scoping ReportДокумент17 страницWEF Chp07 - Final Scoping ReportRaji VydaniОценок пока нет

- Basit Abdm TiДокумент5 страницBasit Abdm TiZubair IshaqueОценок пока нет

- Labour Comparison - Implosive Vs Compression DeadendsДокумент7 страницLabour Comparison - Implosive Vs Compression DeadendsprincemanhasОценок пока нет

- Final Pts 12cc348Документ233 страницыFinal Pts 12cc348shantivan50% (2)

- Unprecedented Savings and ASME Code Case Compliance in Fossil PowerДокумент1 страницаUnprecedented Savings and ASME Code Case Compliance in Fossil PowerOvais AhmedОценок пока нет

- Project Description:: Equipment ListДокумент2 страницыProject Description:: Equipment ListsunjeyОценок пока нет

- Zinc Ribbon Anode Installation Procedure - TPL WITH COMMENTSДокумент18 страницZinc Ribbon Anode Installation Procedure - TPL WITH COMMENTSNeil JavierОценок пока нет

- Bulletin 81Документ36 страницBulletin 81Fraidi AsisiОценок пока нет

- October 5, 2017 - SWET Amended PrecertificationДокумент2 страницыOctober 5, 2017 - SWET Amended PrecertificationSWETОценок пока нет

- A07 Za e 7002586 - Baa - DДокумент17 страницA07 Za e 7002586 - Baa - DRAMIL100% (1)

- Delta Submits The Lowest Bid of $14 Million For Al Qiran 132/13.8kV Substation in Riyadh AreaДокумент2 страницыDelta Submits The Lowest Bid of $14 Million For Al Qiran 132/13.8kV Substation in Riyadh AreasunjeyОценок пока нет

- Center of MassДокумент27 страницCenter of Massm 418Оценок пока нет

- ER 132kV DC TR - Line SOWДокумент3 страницыER 132kV DC TR - Line SOWProject ManagerОценок пока нет

- Shams Solar PowerДокумент6 страницShams Solar PowerRINJUОценок пока нет

- Descon News Spring-Summer 2009Документ36 страницDescon News Spring-Summer 2009Hassan Safdar MalikОценок пока нет

- MP 1Документ161 страницаMP 1SAEL SOLARОценок пока нет

- DC Cable LayingДокумент8 страницDC Cable LayingAhamed UmarОценок пока нет

- NEZYox 5 OДокумент9 страницNEZYox 5 OBouchra MrabetiОценок пока нет

- Saudi Electricity Company: Eastern Region BranchДокумент8 страницSaudi Electricity Company: Eastern Region BranchmygoldieОценок пока нет

- 3 SectiongtrДокумент176 страниц3 SectiongtrBalkishan AgrawalОценок пока нет

- MOS For Metallic Conduit InstallationДокумент23 страницыMOS For Metallic Conduit InstallationAhmed MhnaОценок пока нет

- MS AND JSA SG6427-SY-CN0P-MTD-736-005 - Method Statement of Conduit Installation - RevbДокумент25 страницMS AND JSA SG6427-SY-CN0P-MTD-736-005 - Method Statement of Conduit Installation - Revbbrian sanchezОценок пока нет

- CS2 CRD Drive Modification WorkДокумент3 страницыCS2 CRD Drive Modification WorksudhakarraomОценок пока нет

- Sg6427-Sy-ck0p-Mtd-736-009 - Method Statement of Cable Transit & Multi Cable Transit Installation - Rev.cДокумент9 страницSg6427-Sy-ck0p-Mtd-736-009 - Method Statement of Cable Transit & Multi Cable Transit Installation - Rev.cbrian sanchezОценок пока нет

- Industrial Piping and Equipment Estimating ManualОт EverandIndustrial Piping and Equipment Estimating ManualРейтинг: 5 из 5 звезд5/5 (7)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- HV Engineered Motors Catalog 06 2018 LR PDFДокумент136 страницHV Engineered Motors Catalog 06 2018 LR PDFosvald97100% (1)

- Electrical, Instrumentation & Control Installations Installations Generic Construction ActivitiesДокумент50 страницElectrical, Instrumentation & Control Installations Installations Generic Construction Activitiesosvald97Оценок пока нет

- IEC 60364-6-2016 Low Voltage Electrical... Allations - Part 6 VerificationДокумент114 страницIEC 60364-6-2016 Low Voltage Electrical... Allations - Part 6 Verificationosvald9780% (5)

- A Review of Polarization Index and IEEE Standard 43-2000Документ5 страницA Review of Polarization Index and IEEE Standard 43-2000vasanth11kvОценок пока нет

- S F D E E: Alvaging Lood Amaged Lectrical QuipmentДокумент5 страницS F D E E: Alvaging Lood Amaged Lectrical QuipmentBharat NandulaОценок пока нет

- Instrument Hook Up DrawingДокумент221 страницаInstrument Hook Up DrawingMr.thawatchai100% (1)

- Insulation Resistance Test Values For Electrical Distribution EquipmentДокумент7 страницInsulation Resistance Test Values For Electrical Distribution Equipmentosvald97Оценок пока нет

- Insulation Resistance Test - Open ElectricalДокумент4 страницыInsulation Resistance Test - Open Electricalosvald97Оценок пока нет

- ProposedTIA1121 Nfpa780Документ1 страницаProposedTIA1121 Nfpa780ajalbornozОценок пока нет

- Hilti HIT-RE 500 V3: Instructions For Use en Instrucciones de Uso Es Mode D Emploi FR Instruções de Utilização PTДокумент64 страницыHilti HIT-RE 500 V3: Instructions For Use en Instrucciones de Uso Es Mode D Emploi FR Instruções de Utilização PTosvald97Оценок пока нет

- CadmiumДокумент1 страницаCadmiumosvald97Оценок пока нет

- Pre Fab Hook UpsДокумент2 страницыPre Fab Hook Upsosvald97Оценок пока нет

- Arc Flash StudyДокумент150 страницArc Flash Studyosvald97Оценок пока нет

- IMIA WGP 6910 Transmission and Distribution Lines20 - 05 - 2010 3 PDFДокумент42 страницыIMIA WGP 6910 Transmission and Distribution Lines20 - 05 - 2010 3 PDFosvald97Оценок пока нет

- 500 Overhead Line Stringing Equipment and MachinesДокумент33 страницы500 Overhead Line Stringing Equipment and Machinesosvald97Оценок пока нет

- UPoles - Training - Marketing - Student ManualДокумент20 страницUPoles - Training - Marketing - Student ManualGeEs AnggaОценок пока нет

- Romelt Process For Ironmaking - IspatguruДокумент10 страницRomelt Process For Ironmaking - Ispatguruosvald97Оценок пока нет

- TowersДокумент72 страницыTowersboltgingerkoppyОценок пока нет

- Electrical & Instrumentation LeadДокумент2 страницыElectrical & Instrumentation Leadosvald97Оценок пока нет

- ACCC Installation Guidelines 2016Документ95 страницACCC Installation Guidelines 2016osvald97Оценок пока нет

- Diccionario Del Liniero Eléctrico (En Inglés)Документ15 страницDiccionario Del Liniero Eléctrico (En Inglés)Champarret SosaОценок пока нет

- 0100 07Документ5 страниц0100 07osvald97Оценок пока нет

- 2015 SWEPCO Electric Service Handbook4!7!2015Документ88 страниц2015 SWEPCO Electric Service Handbook4!7!2015osvald97Оценок пока нет

- Romelt Process For Ironmaking - IspatguruДокумент10 страницRomelt Process For Ironmaking - Ispatguruosvald97Оценок пока нет

- Burndy Grounding CountermatДокумент1 страницаBurndy Grounding CountermatwilmanzitoОценок пока нет

- Guide Low Voltage Overhead Electric Lines Near StructuresДокумент5 страницGuide Low Voltage Overhead Electric Lines Near Structuresosvald97Оценок пока нет

- Content Online Commissioning Training - Members - Rev. 0012Документ10 страницContent Online Commissioning Training - Members - Rev. 0012osvald97Оценок пока нет

- Kalibrierung GBДокумент4 страницыKalibrierung GBosvald97Оценок пока нет

- Mangere Plant Only - General Field InstrumentationДокумент4 страницыMangere Plant Only - General Field Instrumentationosvald97Оценок пока нет

- MRA4Документ4 страницыMRA4Marjorie dela CruzОценок пока нет

- Flexenclosure Esite Brochure PDFДокумент5 страницFlexenclosure Esite Brochure PDFajdCruiseОценок пока нет

- Top 70 SOlar Assets in The USAДокумент3 страницыTop 70 SOlar Assets in The USAMJ CemsОценок пока нет

- CatalogueNEX24NEW SchneiderДокумент26 страницCatalogueNEX24NEW Schneidermaniking1Оценок пока нет

- IBEF Power SectorДокумент36 страницIBEF Power Sectorshee JОценок пока нет

- Earthing Transformer or Grounding TransformerДокумент6 страницEarthing Transformer or Grounding TransformerarunОценок пока нет

- Computer Power System AnalysisДокумент155 страницComputer Power System AnalysisSamir ElabasiryОценок пока нет

- DIESEL GENSET 300kVA (Prime Power) : Engine SpecsДокумент2 страницыDIESEL GENSET 300kVA (Prime Power) : Engine SpecsRafatОценок пока нет

- Full Wave RectifierДокумент8 страницFull Wave RectifierSanjana SinghОценок пока нет

- 5 Serious Environmental Impacts of HVAC Over HVDC Overhead Transmission LinesДокумент8 страниц5 Serious Environmental Impacts of HVAC Over HVDC Overhead Transmission Lineskrit_kasemОценок пока нет

- A Look at The Power Rating of ResistorsДокумент2 страницыA Look at The Power Rating of ResistorsTigrilloОценок пока нет

- BoilersДокумент39 страницBoilerstheОценок пока нет

- High Voltage Circuit BreakersДокумент42 страницыHigh Voltage Circuit BreakersItalo MartinangeliОценок пока нет

- Summative Test in Science 10 Mod 5Документ4 страницыSummative Test in Science 10 Mod 5Ruth Anne BarriosОценок пока нет

- Yoko CW500 ManualДокумент135 страницYoko CW500 ManualIrfan YuliОценок пока нет

- Joslyn Hi-Voltage Overhead Reclosers and Switches PDFДокумент46 страницJoslyn Hi-Voltage Overhead Reclosers and Switches PDFFlogisto79Оценок пока нет

- Voltage Current Resistance and Ohms LawДокумент62 страницыVoltage Current Resistance and Ohms LawAllysa Nicole AldaОценок пока нет

- Commissioning Variable Speed DrivesДокумент5 страницCommissioning Variable Speed DrivesAleksandar Lazić100% (2)

- Dda 1Документ49 страницDda 1Chris MaytumОценок пока нет

- DcX140W Diagrama HidráulicoДокумент47 страницDcX140W Diagrama HidráulicoRonaldi motter100% (2)

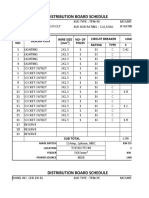

- Distribution Board ScheduleДокумент14 страницDistribution Board ScheduleGada RobaleОценок пока нет

- Integral AC Motor Selection and Application Guide For Fans FE 800Документ8 страницIntegral AC Motor Selection and Application Guide For Fans FE 800Chaudhry MehrozОценок пока нет

- Veritek Current TransformersДокумент1 страницаVeritek Current TransformersVibuddha VidarshanaОценок пока нет

- ABB MCCB CatalogueДокумент14 страницABB MCCB CatalogueMohsin SaifiОценок пока нет

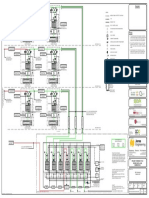

- QSS1-JEG-MV-XX-SH-E-5301-S4.C03 MV Schematic 2 of 2Документ1 страницаQSS1-JEG-MV-XX-SH-E-5301-S4.C03 MV Schematic 2 of 2mahesh reddy mОценок пока нет

- VFXL69-250-54CE (Rev.3 - 25.08.16) PDFДокумент26 страницVFXL69-250-54CE (Rev.3 - 25.08.16) PDFlquinter75Оценок пока нет

- Combined Catalogue - AuXC-2000, ATS, ACCLДокумент68 страницCombined Catalogue - AuXC-2000, ATS, ACCLmangalelectric CorporationОценок пока нет

- Proposed PV System Electricity Generation and Electricity RateДокумент3 страницыProposed PV System Electricity Generation and Electricity RateSangeet BhandariОценок пока нет

- EEGUДокумент2 страницыEEGUJohn DhinaОценок пока нет

- V6840 561 00 GBДокумент2 страницыV6840 561 00 GBMiki BalanoiuОценок пока нет

- 1 Met & SsepДокумент705 страниц1 Met & Ssepsamineni harishОценок пока нет