Академический Документы

Профессиональный Документы

Культура Документы

Grundfos Lifting Stations

Загружено:

marijeanneИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Grundfos Lifting Stations

Загружено:

marijeanneАвторское право:

Доступные форматы

GRUNDFOS WASTEWATER

Lifting Stations

Grundfos Lifting Stations

Reduced costs

and optimised efficiency

Grundfos offers a range of highly efficient, lowmaintenance wastewater lifting stations for a

Unique customer benefits

The Grundfos lifting stations form part of a

complete range of wastewater removal and

sewage handling products. Like all Grundfos

products the lifting stations offer unique

customer benefits, making them the natural

choice for any application.

multiple of applications. The lifting stations incorporate state-of-the-art technology and straightforward thinking to provide simple solutions to

complex problems.

All models have been designed to reduce operating

and installation costs and optimise operating efficiency. The Grundfos range of lifting stations comprises a variety of models from small, one-source

units to dual pump systems with volume capacities

of up to 1200 litres.

> Compact

The Grundfos lifting stations are of a very

compact design, easy to fit even where

space is limited.

> Durable

Made of durable, non-corroding materials

the Grundfos lifting stations are robust and

virtually maintenance-free. All outside

surfaces are smooth and easy to clean.

> Versatile

The Grundfos range comprises a model

for every purpose. They are easy to install

with easily accessible pipe connections.

> Handling of large volumes

The Grundfos lifting stations cover a wide

capacity range from the one-source

Sololift to the powerful Multilift series,

designed for handling large volumes of

wastewater and sewage.

The Range

>

The Range

Sololift 3-0

Sololift 4-2

Liftaway B 40-1

Liftaway C 40-1

Multilift M

Multilift MD

Multilift APLD

3

(Photographs not to scale.)

The Range

>

Grundfos Sololift

The Grundfos Sololift 3-0 and 4-2 are sewage

removal units designed for efficient removal

of sewage and wastewater in one-family

houses or other places with a limited discharge requirement. The Sololift is available

in two sizes: the Sololift 3-0 for single-toilet

installation, and the Sololift 4-2 capable of

servicing an entire bathroom with toilet,

washbasin, shower, bidet, etc.

Sololift 4-2

Sololift 3-0

Sololifts

>

Customer benefits

> Robust and efficient

> Elegant, compact design

> Maintenance-free and easy to clean

> Direct toilet connection

> Gas and odour-proof

> Guaranteed reliability

Sololift 3-0

The Sololift 3-0 is designed for efficient removal of

sewage from single toilets situated above or below

sewer level. The unit is connected direct to the toilet.

Installed below sewer level, for example in a basement, the Sololift lifts the toilet discharge up to the

sewer line.

Easy to install

The Grundfos Sololift are cost-saving solutions, easy

to install the ideal alternative to extensive and

costly plumbing work. Both models are supplied

ready for installation complete with all the necessary

fittings for toilet, washbasin drains and outlets for

shower and bidet.

Sololift 4-2

The Sololift 4-2 is designed for collecting and pumping of the entire volume of wastewater and sewage

from a toilet, washbasin, shower and bidet. The

Sololift is useful where the existing pipe installations do not permit the discharges to flow to the

sewer line by itself.

1

2

3

4

5

6

Safe to use

The Sololift are constructed in accordance with

DIN/EN 12050 part 3, they are maintenance-free

and easy to clean. The units incorporate a built-in

pump with an efficient cutter system. A non-return

valve ensures that no liquid returns from the sewer

line, and a special ventilation outlet with an active

carbon filter prevents odours from escaping into

the bathroom. The motor has a built-in thermal

protection.

Toilet strainer

Efficient stainless cutter system

Integrated, pneumatically operated level switch

Integrated non-return valve

Carbon filter to prevent odours

Easy-to-clean surface

Sololifts

>

Grundfos Sololifts

Performance

Technical data

Use the performance curve below when sizing the

discharge for Sololift 3-0 and Sololift 4-2.

Voltage:

Frequency:

Enclosure class:

Insulation class:

Sound pressure level:

Thermal protection:

H

[m]

Sololift 3-0 / Sololift 4-2

1 x 230 V

50 Hz

IP 44

F

<55dB (A)

Motor with built-in

thermal protection

(restarts after cooling).

Sizing

In order to obtain optimum operation, the positioning

of the discharge pipe must start in a vertical direction before it continues horizontally to the pumping destination.

The diagram shows performance limits for a DN

25 mm pressure pipe.

H [m]

5

0

10 m

Q [m3/h]

20 m

4

0.0

0.2

0.4

0.6

0.8

1.0

1.2 Q [l/s]

30 m

3

40 m

2

Pumped liquids

50 m

The Grundfos Sololifts are used for the pumping of:

Sewage containing toilet paper and faeces

(not sanitary articles).

Wastewater

from shower and washbasin

0

L [m]

(Sololift 4-2 only).

Connections:

Max. liquid temperature: 35C

Resistant to weak acids with pH values of 4 to 10.

Wastewater containing fat must not be discharged

into the Sololift.

Inlet:

Discharge:

Connections to

other units:

DN 100 with sealing sleeve.

DN 25/DN 32 flexible.

2 x DN 40 (Sololift 4-2 only).

Electrical data, type designation and product numbers

Inlet level

[mm]

Power

input

P1 [kW]

Number

of poles

Schuko

plug

Voltage

[V]

Weight

[kg]

Product

number

Sololift 3-0

180

0.45

1 x 230

6.6

96003830

Sololift 4-2

180

0.45

1 x 230

6.8

96003831

Sololift

Sololifts Technical Data

>

Dimensions

Sololift 3-0

Sololift 4-2

Approvals

Z 53.2 306

VA 2.71 / 9609

Sololifts Dimensions

>

Grundfos Liftaway

For kitchens, bathrooms or utility rooms

located below sewer level the flexible

Grundfos Liftaway (collection tank in combination with a Grundfos AP or KP pump)

provide efficient removal of domestic wastewater without the need for major structural

modifications. The Grundfos range comprises

two models, Liftaway B 40-1 and Liftaway C

40-1. The Grundfos Liftaways are constructed

in accordance with EN 12050 part 2.

Liftaway B 40-1

Liftaway C 40-1

Liftaways

>

Customer benefits

Liftaway C 40-1

> Flexible, discreet installation

> Odour-proof

> Rubber-coated, stainless steel

non-return valve

Liftaway B 40-1

Designed for installation below floor level, the Liftaway B 40-1 provides a simple solution for existing

buildings where wastewater has to be pumped to

the sewer system.

The Liftaway C 40-1 model is designed for mounting on the floor or on a wall. Fitted with different

types of pumps, it provides a flexible solution for

pumping of wastewater from e.g. washing machines,

dishwashers, washbasins or tubs.

In spite of the compact design, the Liftaway C 40-1

has a large and efficient lifting volume. Ideally combined with a Grundfos KP pump, the ready-to-install

unit is supplied complete with an installation package comprising pipes and fittings and a rubber-coated

non-return valve of stainless steel. (The pump must

be bought separately.) Liftaway C 40-1 is equipped

with an overflow protection device and an active

carbon filter to eliminate odours.

The Liftaway B 40-1 is ideal for pumping wastewater

from washbasins, washing machines, sanitary rooms,

showers, floor drains, etc. It can also be used as a

drainage pit for pumping drainage and surface water.

The Liftaway B 40-1 can be used in combination with

a stainless steel Grundfos KP or AP 12 pump with float

switch for automatic start/stop. (The pump must

be bought separately.)

The unit is supplied with all necessary pipes and fittings, including a rubber-coated stainless steel nonreturn valve. Liftaway B 40-1 features a telescopic

part for easy height adjustment. The unit is easy to

install. It is turnable for individual positioning and

connection via three DN 100 inlets, placed at intervals of 90 degrees, and one DN 70 connection for

air release.

Carbon filter

to eliminate

odours

Inlet or

discharge

Overflow

preventter

Inlet

Grundfos KP

Pump with

float switch

Inlet or

discharge

Inlet

The discharge pipe can be connected either to the

right or left-hand side of the tank.

Liftaway C 40-1 can be set to two different start levels:

Normal operation, approx. 260 mm.

Low-level operation, approx. 135 mm

(discharge from showers).

Turnable top cover

with strainer

Water seal

to eliminate odours

Telescopic part

for height adjustment

(additional telescopic

part is available)

Grundfos KP or AP

pump with

level switch

Liftaway B 40-1 features a telescopic part for easy height adjustment.

Liftaways

>

Grundfos Liftaways

Technical data

Pumped liquids (both models)

Discharge connection:

Liftaway B

R 1 1/4

Liftaway C

DN 40

Inlet connections:

Liftaway B

3 x DN 100

Liftaway C

3 x DN 40, 1 x DN 40/50

Connection for venting and/or cable entry:

Liftaway B

1 x DN 70

Liftaway C

Cable entry as a rubber sealing

No need for a venting pipe

Sound pressure level: <65 dB (A)

Wastewater, not containing solid particles or fibres.

Liquid temperature for KP pumps: Max. 50C.

Liquid temperature for AP pumps: Max. 55C.

For short periods of max. 2 minutes up to 70C at

minimum 30 minutes intervals.

The tank is resistant to weak acids with pH values

of 4 to 10.

Wastewater containing fat must not be discharged

into the tank.

Technical data for pumps: See KP / AP brochure.

Electrical data, pump designation and product numbers

Liftaway

10

Inlet level

[mm]

Power imput

P1 [kW]

Number

of poles

Schuko

plug

Voltage

[V]

Weight

[kg]

Product

number

Liftaway B 40-1

for KP pumps

310

14.7

96003974

Liftaway B 40-1

for AP12 pumps

310

14.7

96003975

with KP 150-A1

310

0.15

1 x 230

20.3

96003974 +

011H1600

with KP 250-A1

310

0.25

1 x 230

21.0

96003974 +

012H1600

with KP 350-A1

310

0.35

1 x 230

21.7

96003974 +

013N1600

with AP12.40.04.A1

310

0.40

1 x 230

25.7

96003975 +

96011017

with AP12.40.06.A1

310

0.60

1 x 230

25.7

96003975 +

96001735

with AP12.40.08.A1

310

0.80

1 x 230

27.3

96003975 +

96001798

Liftaway C 40-1

for KP pumps

100

200

with KP 150-A1

100

200

0.15

1 x 230

8.0

96003985 +

011H1600

with KP 250-A1

100

200

0.25

1 x 230

8.8

96003985 +

012H1600

with KP 350-A1

100

200

0.35

1 x 230

9.5

96003985 +

013N1600

2.5

96003985

Liftaways Technical Data

>

Performance

Dimensions

Pump types and performance curves for

Liftaway B 40-1 and C 40-1.

H

[m]

Liftaway B 40-1 + KP/AP

ISO 9906 Annex A

AP 12.40.08

14

AP 12.40.06

12

10

AP 12.40.04

KP 350

KP 250

KP 150

(Additional

telescopic part)

Liftaway B 40-1

10

12

14

16

Q [m3/h]

Q [l/s]

H

[m]

Liftaway C 40-1 + KP

ISO 9906 Annex A

KP 350

9

8

KP 250

7

6

KP 150

5

4

3

2

1

Liftaway C 40-1

0

0

0.0

11

0.5

1.0

1.5

2.0

10

2.5

12

3.0

3.5

Q [m3/h]

Q [l/s]

Liftaways Dimensions and Performance

>

Grundfos Multilifts M and MD

Grundfos Multilift M and MD are designed

for the removal of larger volumes of wastewater and sewage for instance in blocks

of flats, small hotels, restaurants or other

building complexes. The Multilift stations

are designed specially for the collection and

pumping of wastewater and raw sewage

from wastewater pipes and water closets

situated below the sewer level. The Multilift

stations lift the wastewater and sewage

and carry it forward to the sewer line.

Multilift M

Multilift MD

12

Multilift Stations

>

Ready to install

Customer benefits

> Complete units ready for installation

> Gas and odour-proof

> Corrosion resistant

> Low-noise operation

> Shock and break-proof polyethylene tank

Multilift M

Equipped with one pump and with a tank capacity

of 100 litres, Multilift M is ideally dimensioned for

one-family homes or smaller commercial buildings.

The Multilift M is available in seven different models

with output power ranging from 1.2 to 3.2 kW.

Multilift MD

With two pumps and a tank capacity of 120 litres,

the Multilift MD is ideal for multi-family homes or

commercial building projects where the additional

capacity and the operational security offered by a

two-pump system is advantageous. Multilift MD is

available in five different models with output power

ranging from 1.5 to 3.2 kW.

The Grundfos Multilift M and MD stations are supplied as complete units ready for installation. The

units consist of one or two vortex impeller pumps

fully integrated with the collecting tank. Solutions

for single or three-phase power supply are available.

The Multilift M and MD stations are supplied complete with all necessary flexible connections for inlet,

discharge and ventilation pipes. The Multilift M and

MD have polypropylene level sensor unit with built-in

pressure switches.

An LC 109 controller for Multilift M and an LCD 109

controller for Multilift MD are supplied with the units.

Multilift M and MD are fitted with a DN 80 mm

vertical discharge port with a non-return flap valve.

The Multilift MD model is fitted with two non-return

flap valves and a breeches pipe. The collecting tank

is made of non-breakable, non-corrosive, airtight

polyethylene. It is completely watertight as well as

gas and odour-proof.

Pumped liquids

The Multilift M and MD stations are suitable for

handling wastewater and other liquids containing

solids, such as fibres, textiles, and faeces, with a

pH value of 4 to 10.

The Multilift M and MD are capable of handling

liquid temperatures between 0 and +40C, for short

periods of time up to +60C.

Tank volume

M

180

250

180

250

Tank capacity [l]

100

100

120

120

54

74

72

92

Effective volume [l]

13

MD

Inlet level [mm]

1

2

3

4

Motor/pump

Non-return valve

Level sensor

Collecting tank

Multilift Stations

>

Grundfos Multilift Stations M and MD

Electrical data, type designation and product numbers

Multilift

Power

Inlet level output

P2

[mm]

[kW]

M.12.1.4

1.2

M.12.3.4

1.2

M.15.1.4

1.5

M.15.3.4

1.5

2.2

M.22.3.4

M.24.3.2

180

and

250

M.32.3.2

2.4

3.2

MD.15.3.4

1.5

Inspection cover with integrated level

sensor unit

2.2

2.4

3.2

CEE

plug

2

4

MD.32.3.2

Schuko

plug

1.5

MD.24.3.2

Plug type

MD.15.1.4

MD.22.3.4

14

Number

of

poles

Motor/pump and non-return valve with

hose connection

Voltage

[V]

Weight

[kg]

Product

number

1 x 230

39.0

96075436

3 x 230

37.5

96075442

3 x 400

36.6

96075441

1 x 230

41.5

96075443

3 x 230

39.5

96075445

3 x 400

38.5

96075444

3 x 230

41.5

96075447

3 x 400

41.5

96075438

3 x 230

41.5

96075449

3 x 400

41.5

96075457

3 x 230

41.5

96477864

3 x 400

41.5

96477865

1 x 230

80.5

96075450

3 x 230

76.0

96075452

3 x 400

76.0

96075437

3 x 230

80.0

96075454

3 x 400

80.0

96075439

3 x 230

79.5

96075456

3 x 400

79.5

96075455

3 x 230

79.5

96477867

3 x 400

79.5

96477866

Optional vertical or horizontal inlet

connections

Multilift Stations Technical Data

>

Technical data

Type key

Discharge connection:

DN 80 flange

with 110 mm socket

for flexible connection

Inlet connections:

3 x D N 100

1 x D N 150

1 x D N 50

Connection for venting:

The type key is used to interpret the letters and

figures in the product type designation:

Example

.22

.3 .4

Type range (Multilift)

Blank = one pump

D = two pumps

Power output , P2/100 (W)

1 = single-phase

3 = three-phase

2 = 2-pole motor

4 = 4-pole motor

1 x D N 75

Connection for manually

operated diaphragm pump: 1 x D N 25

Sound pressure level:

<64 dB (A)

Performance

The performance curves show pump performance with only one pump in operation and the minimum

recommended flow to avoid sedimentation in the pipe system.

H

[m]

M/MD

20

50 Hz

ISO 9906 Annex A

M.32.2

Min. flow with pressure pipe DN80.

18

16

Min. flow with pressure pipe DN100.

M.24.2

14

12

M.22.4

10

M.15.4

8

M.12.4

6

4

2

0

0

0

15

4

10

6

20

8

30

10

12

40

14

50

16

18

60

Q [l/s]

Q [m3/h]

Multilift Stations Performance

>

Grundfos Multilifts M and MD

Installation

The numbers on the drawing refer to

the accessories overview, page 25/26.

The Grundfos Multilift M and MD are ideally suited

for installation below existing sewer level. The

Multilift M and MD are supplied complete with all

necessary flexible connections, clamps, bolts and

nuts, anchor bolts for fixing to the floor, and a controller with a 3 m cable for automatic operation.

Before installing the Multilift M and MD, ensure

that all local regulations covering access to the

stations, venting, etc. are observed.

Optional inlet connections

The Grundfos Multilift M and MD offer the following

optional inlet connection facilities:

For the

connection of

DN

180 mm above

floor level

Euro-standardised

water closets

100

250 mm above

floor level

Wall mounted

water closets

100

At the top

of the tank

Various types of

drain pipes

100/

150

Position of inlet port

Horizontally

Vertically

Drain pipe from washbasin, shower, etc.

16

50

Multilift Stations Installation and Dimensions

>

Dimensions

Multilift M

Controllers

The LC 109 and LCD 109 controllers are designed

for the control of Multilift M and MD stations. The

controllers incorporate all necessary components

such as contactors, control board with lights for

indication of operating condition and alarms.

Control features

The LC 109 and LCD 109 controllers are designed

for direct on-line starting (DOL). In addition, the

controllers provide a number of control features,

such as:

Control of one or two pumps based on signals

from the level sensor in the tank.

Automatic pump changeover (alternation).

Deselection of automatic test run during

long periods of inactivity (every 24 hours).

Battery back-up in case of mains supply failure.

Starting delay within a range from 0 to 255 sec.

Multilift MD

17

(random) after returning from battery operation to mains operation.

Selection of automatic alarm resetting.

Selection of automatic restarting.

Setting of stop delays matching the actual

operating conditions.

Indication of liquid level.

Alarm indication of high liquid level, high

motor temperature, wrong phase sequence,

mains supply failure, and faulty pressure

switch assembly.

Multilift Station Controllers

>

Grundfos Multilift APLD 400 l tanks

The Grundfos Multilift APLD is a low-noise

unit capable of handling large volumes of

wastewater and sewage. It is, therefore,

ideally suited for multi-user applications

such as blocks of flats, hotels and restaurants,

hospitals, schools, and other public buildings

as well as industry. The Grundfos Multilift

APLD is designed for installation below main

sewer level. The Multilift station collects the

sewage, lifts it and carries it forward to the

sewer system.

Multilift APLD

18

Multilift Station APLD

>

Customer benefits

> Complete units ready for installation

> Gas and odour-proof

> Corrosion-resistant collecting tanks

> Straightforward installation

> Large tank capacity

> Possibility of parallel coupling of

Pumped liquids

The Multilift APLD is suitable for handling wastewater and other liquids containing solids up to

70 mm in diameter (AP70) or 100 mm (AP100),

for instance fibres, textiles, and faeces, with a

pH value of 4 to 10.

The Multilift APLD handles liquid temperatures

between 0 and +40C, for short periods of time

up to +60C.

Tank volume

Number of tanks

up to 3 tanks

Ready to install

Total volume (l)

400

800

1200

Effective volume (l)

220

440

660

Max. inflow (l/sec.)

7.2

14.5

22.0

The Multilift APLD is fitted with two powerful

sewage pumps. The unit is supplied with either

one or two 400-litre collecting tanks and a level

controller.

The pumps available for the systems are Grundfos

AP70 or AP100. The AP70 pumps are delivered with

a base plate for horizontal installation including

a 100 flanged pipe stub. AP100 pumps have cast

feet on the pump housing and a support for the

motor.

3

4

2

Multilift APLD with AP70 pumps are delivered

with one 400-litre tank, and Multilift stations

with AP100 pumps are delivered with either one

or two 400-litre tanks. All necessary flexible connections, clamps and anchor bolts are included.

An LCD 103 level controller is supplied with the

units.

Isolating valves, non-return valves, discharge

pipes, a manually operated diaphragm pump,

bolts and gaskets as well as a third 400-litre

tank are available as accessories.

19

6

1

1

2

3

4

5

6

One or two powerful sewage pumps

Non-return valve

Level sensor

400-litre collecting tank

Control panel

Connections for additional 400 l tank

Multilift Station APLD

>

Grundfos Multilift Station APLD 400 l tanks

Collecting tank

The 400-litre collecting tank is made of gas and

odour-proof polyethylene. The tank has a DN 150

horizontal inlet, DN 100 vertical inlet, DN 70

connection for vent pipe, DN 100 connections

for one or two pumps, and a DN 50 connection

for a manually operated diaphragm pump.

All necessary flexible connections, clamps and

anchor bolts are included.

Performance

H

[m]

16

Min. flow with pressure pipe DN 100

14

12

10

AP

L(D

)80

.19

Parallel coupling of tanks

Flexible connections are included with the systems to facilitate connection of two or three tanks

in parallel. This is effexted through the DN 150

connections at the top and bottom on both sides

of the tank, and provides a total tank volume of

800 or 1200 litres respectively.

/4

00

AP

L(D

)80

.13

/4

AP

00

L(D

AP )80

.

L(D 24

)80 /40

.09 0

/4

00

4

2

Parallel coupling of three tanks

If three tanks are coupled in parallel, the DN 150

inlet pipe must always be connected to the third

tank. In order to avoid sedimentation, this tank

must be without a pump to act both as a collecting tank and as a through-flow tank.

Multilift Stations

APL(D)80, 50 Hz

Min. flow with pressure pipe DN 80

0

0

25

H

[m]

50

10

100 Q [m3/h]

75

15

20

25

Q [l/s]

Multilift Stations

APL(D)100, 50 Hz

Min. flow with pressure pipe DN 100

22

Min. flow with pressure pipe DN 150

20

18

16

AP

L(D

)10

14

0.6

1/4

L(D

00

)10

AP

0.5

L(D

4/

4

)10

0.4 00

5/4

00

AP

L(D

)10

0.3

2/4

AP

00

L(D

)10

0.2

4/

40

0

AP

12

10

8

6

4

Parallel coupling of three tanks.

The third tank must be ordered separately as an

accessory. It is supplied with all the necessary

flexible connections, clamps and anchor bolts.

20

2

0

0

0

50

5

10

15

100

20

25

30

Q [m3/h]

150

35

40

45

Q [l/s]

Multilift Station APLD Performance

>

Electrical data, type designation and product numbers

P1/ P2

[kW]

IN

[A]

Cos

IStart/

IN

3 x 230

1.20/0.90

4,5

0.70

4.8

3 x 400 1.20/0.90

2.6

0.70

3 x 230

1.70/1.30

5.8

3 x 400

1.70/1.30

3 x 230

Product

number

400

135

96002648

4.6

400

135

96002644

0.78

3.7

400

135

96002649

3.3

0.78

3.6

400

135

96002645

2.70/1.90

9.6

0.80

4.4

400

187

96002650

3 x 400

2.70/1.90

5.5

0.80

4.2

400

187

96002646

3 x 230

3.50/2.40

11.0

0.80

4.4

400

187

96002651

3 x 400 3.50/2.40

6.3

0.80

4.3

400

187

96002647

APLD.100.24/400

3 x 400 3.00/2.40

5.9

0.79

6.2

400

295

96002307

APLD.100.32/400

3 x 400 4.00/3.20

7.5

0.84

6.0

400

307

96002308

APLD.100.45/400

3 x 400

5.50/4.50

10.6

0.84

6.0

400

321

96002309

APLD.100.54/400

3 x 400 6.50/5.40

12.0

0.84

6.4

400

343

96002310

APLD.100.61/400

3 x 400

7.50/6.10

13.6

0.83

5.7

400

343

96002311

APLD.100.24/400-2

3 x 400 3.00/2.40

5.9

0.79

6.2

800

350

96002312

APLD.100.32/400-2

3 x 400 4.00/3.20

7.5

0.84

6.0

800

362

96002313

APLD.100.45/400-2

3 x 400

5.50/4.50

10.6

0.84

6.0

800

376

96002314

APLD.100.54/400-2

3 x 400 6.50/5.40

12.0

0.84

6.4

800

398

96002315

APLD.100.61/400-2

3 x 400

13.6

0.83

5.7

800

398

96002316

APLD.80.09/400

APLD.80.13/400

APLD.80.19/400

APLD.80.24/400

APLD, single 400-litre tank.

21

Voltage

Weight

[kg]

Multilift APLD

7.50/6.10

Tank volume

[l]

APLD, two 400-litre tanks connected in parallel.

Multilift Station APLD Technical Data

>

Grundfos Multilift Station APLD 400 l tanks

Installation

The numbers on the drawing refer to

the accessories overview, page 25/26.

System with 2 pumps and 3 tanks

All pipe connections to the Multilift station must be carried out with noise-absorbing flexible connections,

and all pipes in connection with the lifting station must be supported in such a way that they do not stress

the station.

22

Multilift Station APLD Installation

>

Dimensions

Multilift Stations APLD

Dimensions in mm

Pump type

AP70

1814

536

380

DN 80

260

180

820

90

AP100

2062

784

465

DN 100

300

190

955

123

Type key

Example

APL

D .100

Type range

With two pumps

Nominal diameter (mm) of

discharge port (AP70)

Power output P2/100 [W]

Two 400-litre tanks

23

.24

/400-2

Multilift Station APLD Dimensions

>

Grundfos Controller LCD 103

The LCD 103 level controller features a pneumatic-

The level sensor is factory set to stop the system

before air enters the pumps.

ally operated level sensor, motor protection and

monitoring of pump operation. The controller is

designed for wall mounting.

Levels

APLD

Start level 1

Start level 2

Alarm level

200 l

220 l

260 l

In addition to the indicator lights, the following

functions are available on the controller front:

The operating conditions (pump failure, highlevel alarm, phase sequence, and operation)

are indicated by indicator lights on the front

cover. An acoustic alarm can be given in case

of system failure. Furthermore, an external

alarm device can be connected to a potentialfree NO-contact.

24

Function selector with positions:

Man, 0 and Aut

On/off switch for built-in acoustic alarm

Reset button for motor starter

The LCD 103 controller automatically ensures

an even distribution of operating hours on both

pumps by changing the starting sequence after

each pump stop (alternation).

A back-up accumulator maintaining the alarm

signal in case of supply failure is available as an

accessory. The accumulator ensures that an alarm

can be given within 15 hours after the electricity

supply has been switched off.

Multilift Station APLD Controller

>

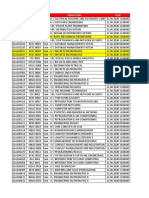

Accessories

A range of accessories is available for the Grundfos Lifting Stations.

The accessories must be ordered separately.

Pump type

Accessories

Pos

1

Picture

Description

Flanged socket for PVC pipe

Dimensions

DN 100

96 00 20 12

DN 150

96 00 34 27

DN80

96 00 20 09

DN100

96 00 20 85

96 47 78 93

1"

96 00 01 88

11/2

96 00 37 21

DN80/80

96 00 37 04

Bolts, nuts and gasket, 8 of each 16 x 65mm

DN 100

Bolts, nuts and gasket, 8 of each 20 x 75mm

DN 150

Isolating valve

DN 80/100

Flange/hose unit

DN 100/100

DN 150/150

53

75

6

Flexible connecting piece

110

160

53

75

Clamp

110

160

Manually operated diaphragm pump

DN80/100

9

Breeches pipe

DN100/100

DN100/150

25

Product

number

DN 80

DN 80

DN 80/80

APLD

DN 150

Bolts, nuts and gasket, 8 of each 16 x 65mm

Non return valve

cast iron ball-type PN10

M/MD

96 00 37 01

96 00 19 99

96 00 38 23

96 00 36 05

96 00 20 11

96 07 53 63

96 47 78 94

96 47 78 95

96 47 29 43

96 07 54 23

96 07 54 22

96 47 30 60

96 07 54 27

96 07 54 26

96 07 54 25

96 47 30 61

96 00 37 05

96 00 37 06

96 00 37 07

Accessories

>

Accessories

Pump type

Accessories

Pos

11

Picture

Description

Dimensions

APLD

Cover plate

Product

number

96 47 78 96

12

Extra tank number 3 incl. two

flexible connections, clamps and anchor bolts

13

Accumulator for controller, 9.6 V

14

Signal lamp

62 50 00 20

Indoors

62 50 00 22

Outdoors

62 50 00 21

230 V

96 00 25 14

400 V

96 00 25 15

230 V

96 00 25 16

400 V

96 00 25 17

230 V

96 00 25 18

400 V

96 00 25 19

25 A

15

16

17

18

400 l

96 00 37 18

96 00 25 20

Signal horn

Hour counter

Start counter

Combined hour and start counter

40 A

19

96 00 25 12

96 00 25 13

96 00 25 11

External main switch for supply cable

80 A

26

M/MD

Accessories

>

The Grundfos Wastewater Range

The sewage grinder

pumps range

Heavy-duty submersible

sewage pumps

Brochure covers the new

Grundfos range of sewage grinder

(SEG) pumps for pumping of

wastewater with toilet discharge.

Brochure covers the Grundfos range

of submersible channel impeller

pumps from 1.65 kW up to 21 kW

and SuperVortex pumps up to

29 kW. All designed for handling

unscreened raw sewage.

Heavy-duty submersible

sewage pumps

Brochure covers the Grundfos

range of sewage pumps from 16 kW

up to 155 kW for handling of raw

sewage in heavy-duty applications.

Super heavy-duty

submersible sewage and

raw water pumps

Brochure covers the Grundfos range

of super heavy-duty channel pumps,

axial flow pumps, and propeller

pumps from 2.8 kW up to 520 kW.

The stainless steel range for

pumping of corrosive liquids

Brochure covers the Grundfos

range of heavy-duty stainless

steel pumps (SEN) for aggressive

and corrosive environments.

The portable dewatering

pumps range

Brochure covers the Grundfos range

of portable dewatering pumps (DW)

from 0.8 kW to 20 kW for pumping

raw water with abrasives.

27

The KP/AP stainless

steel range

Brochure covers a wide range of

high quality stainless steel pumps

for a variety of domestic and

commercial applications.

The range of controls

Brochure covers the Grundfos

range of controls for the wastewater pumping systems.

The Range

>

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

Business with an attitude

Knowledge The sharing of knowledge, experience

and expertise across our global network will always

lead our business forward.

Innovation Combining the best technology with

fresh ways of thinking, we will continue to develop

even better pumps, systems, services and standards.

Solution With a complete product range, capable

of providing every conceivable water solution, we are

96 48 62 50 05 02

VENTURE MARKETING AS

the most complete player on the market.

www.grundfos.com

Вам также может понравиться

- DA-42 Performance Calculator v2.3.1Документ23 страницыDA-42 Performance Calculator v2.3.1DodgeHemi1Оценок пока нет

- Design and Control Considerations For An Example of The Waste Water Pumping StationДокумент10 страницDesign and Control Considerations For An Example of The Waste Water Pumping StationKim Daniel EstoyОценок пока нет

- WET WellДокумент19 страницWET WellNayan GanjiОценок пока нет

- The 4 TH LectureДокумент42 страницыThe 4 TH LectureMahmoud Ahmed Ali AbdelrazikОценок пока нет

- Torque ConvertersДокумент61 страницаTorque ConvertersJay FarabeeОценок пока нет

- Pre-Combustion Technology For Coal-Fired Power Plants: Thomas F. EdgarДокумент23 страницыPre-Combustion Technology For Coal-Fired Power Plants: Thomas F. Edgaranon_938213605Оценок пока нет

- Length Conversion 1 in 25.4 MMДокумент20 страницLength Conversion 1 in 25.4 MMRubyJanePartosaОценок пока нет

- Weight of Piping MaterialДокумент9 страницWeight of Piping Materialviny22Оценок пока нет

- Losses in PipesДокумент43 страницыLosses in PipesSomnath Swamy100% (1)

- Excel Pivot Tables PDFДокумент38 страницExcel Pivot Tables PDFTheGimhan123Оценок пока нет

- Ubaid RaanДокумент31 страницаUbaid RaanUbaid RaanОценок пока нет

- Excel Formula SheetzДокумент8 страницExcel Formula Sheetzmuhammad sohail janjuaОценок пока нет

- Refrigeration: Refrigerant CompressorДокумент88 страницRefrigeration: Refrigerant CompressorKhalidОценок пока нет

- GRP CatalogueДокумент41 страницаGRP CatalogueBINODH DОценок пока нет

- Co2 Capture and Storage in IGCC PlantsДокумент23 страницыCo2 Capture and Storage in IGCC PlantsAbhiram KukunuriОценок пока нет

- Scientific Writing 201: Zuojun Yu, PH.DДокумент24 страницыScientific Writing 201: Zuojun Yu, PH.DArjunBuchibabu100% (1)

- Pumps For Lifting SewageДокумент15 страницPumps For Lifting SewageAkshayShrivastava100% (1)

- NTPC PresentationДокумент19 страницNTPC PresentationYogesh Gurjar100% (1)

- Pump Cost v10Документ98 страницPump Cost v10Taris BellОценок пока нет

- Fuel FiringДокумент39 страницFuel Firingnetygen1Оценок пока нет

- CO Capture in The Cement Industry: Technical Study Report Number: 2008/3 Date: July 2008Документ221 страницаCO Capture in The Cement Industry: Technical Study Report Number: 2008/3 Date: July 2008DANIEL ESTEBAN CORTEZ LEIVAОценок пока нет

- Natural Gas Production, Transportation - StorageДокумент36 страницNatural Gas Production, Transportation - StorageNeeraj YadavОценок пока нет

- Module 2 - Oil and Gas Separation - LectДокумент62 страницыModule 2 - Oil and Gas Separation - LectmahmoudОценок пока нет

- Pump by BoseДокумент26 страницPump by BoseSonu SinghОценок пока нет

- Clean Coal Technologies For SustainabilityДокумент37 страницClean Coal Technologies For SustainabilityAnoop PatelОценок пока нет

- Pipe System DesignДокумент64 страницыPipe System DesignRonald GeorgeОценок пока нет

- Cooling Tower 434Документ15 страницCooling Tower 434arslan MaqboolОценок пока нет

- Lecture 6Документ41 страницаLecture 6Pragati GhumadeОценок пока нет

- Industrial BoilersДокумент22 страницыIndustrial BoilersAbdul Razzaq MughalОценок пока нет

- Dry Well PSДокумент7 страницDry Well PSprajmenОценок пока нет

- Strength of CementДокумент7 страницStrength of CementNad NoorОценок пока нет

- Piping GuideДокумент11 страницPiping GuidetmmehtaОценок пока нет

- NGCC Plant Case - FClass With CCS - 051607Документ4 страницыNGCC Plant Case - FClass With CCS - 051607DWWillsonОценок пока нет

- Designs For CO2 RemovalДокумент2 страницыDesigns For CO2 RemovaljuhriloverОценок пока нет

- Spo 1Документ89 страницSpo 1Fidal SibiaОценок пока нет

- D. Design Load D.1. Loading DataДокумент14 страницD. Design Load D.1. Loading DataEdОценок пока нет

- CO2 Capture System With Chilled Ammonia: Pilot To Demonstration To Commercial ScaleДокумент40 страницCO2 Capture System With Chilled Ammonia: Pilot To Demonstration To Commercial Scalerecsco2Оценок пока нет

- Chapter 3 Fluid Mechanics For EngineeringДокумент51 страницаChapter 3 Fluid Mechanics For EngineeringAnn RazonОценок пока нет

- Chapter 2-Distillation Process (ELEARN)Документ73 страницыChapter 2-Distillation Process (ELEARN)amirulhaqimОценок пока нет

- Title: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectДокумент24 страницыTitle: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectRamalingam PrabhakaranОценок пока нет

- Distillation: Unit Operations (Che 347/ 251)Документ27 страницDistillation: Unit Operations (Che 347/ 251)Amira KormainОценок пока нет

- Air Heater & Air Heater Performance IndicesДокумент36 страницAir Heater & Air Heater Performance IndicesShubham PatelОценок пока нет

- De Super HeaterДокумент2 страницыDe Super HeatergateauxboyОценок пока нет

- Drain Flow CalculatorДокумент4 страницыDrain Flow CalculatorarcelitasОценок пока нет

- VAD Variable Area Desuperheaters: Desuperheater OverviewДокумент6 страницVAD Variable Area Desuperheaters: Desuperheater OverviewLucasZanaОценок пока нет

- Water SprayДокумент1 страницаWater SpraySubharajkОценок пока нет

- Cogeneration Class PDFДокумент66 страницCogeneration Class PDFeselcosacОценок пока нет

- HKP Gas Turbine Power PlantsДокумент46 страницHKP Gas Turbine Power PlantsHarshad PatelОценок пока нет

- Fire Fighting SystemsДокумент4 страницыFire Fighting SystemsUsmanОценок пока нет

- A-Hydraulics 2 7-12-05 (Rev 2-06) .PpsДокумент138 страницA-Hydraulics 2 7-12-05 (Rev 2-06) .Ppscarolina Portocarrero100% (1)

- 12-Design Fundamentals of BoilerДокумент12 страниц12-Design Fundamentals of BoilerVishalVaishОценок пока нет

- MKPP2513: Petroleum Production EngineeringДокумент15 страницMKPP2513: Petroleum Production EngineeringhenryОценок пока нет

- 2dm Plant OprДокумент25 страниц2dm Plant OprAbhishek Prakash SrivastavaОценок пока нет

- Comprehensive Pump, Motor & Piping CalculatorДокумент6 страницComprehensive Pump, Motor & Piping CalculatorMadan TiwariОценок пока нет

- Chapter 6 - 24 Oct 17Документ74 страницыChapter 6 - 24 Oct 17Jiana NasirОценок пока нет

- CECO Environmental Presentaton - Gabelli Q122 Waste Environ. Serv. Symposium - 033122Документ28 страницCECO Environmental Presentaton - Gabelli Q122 Waste Environ. Serv. Symposium - 033122teddyfang21Оценок пока нет

- Sololift Plus BrochureДокумент8 страницSololift Plus BrochureSeyhun AgimОценок пока нет

- ACO Grease and Ligth Oil Separators in PE-HDДокумент24 страницыACO Grease and Ligth Oil Separators in PE-HDmsilva1985Оценок пока нет

- Grundfosliterature 3599974 PDFДокумент9 страницGrundfosliterature 3599974 PDFGoranОценок пока нет

- Literatura Tehnica - 22Документ16 страницLiteratura Tehnica - 22roco_3213Оценок пока нет

- Zenit Box Range Brochure en-US PDFДокумент11 страницZenit Box Range Brochure en-US PDFKadiri OlanrewajuОценок пока нет

- Seminar1final ReviewДокумент19 страницSeminar1final ReviewMounika ChОценок пока нет

- Staff Code Subject Code Subject Data FromДокумент36 страницStaff Code Subject Code Subject Data FromPooja PathakОценок пока нет

- Jetline: Theoretical Working Point Performance ChartДокумент1 страницаJetline: Theoretical Working Point Performance ChartMohamed GamalОценок пока нет

- Notes Ch. 4 - Folk and Popular CultureДокумент7 страницNotes Ch. 4 - Folk and Popular CultureVienna WangОценок пока нет

- FlazasulfuronДокумент2 страницыFlazasulfuronFenologiaVinhaОценок пока нет

- Dragons and Winged SerpentsДокумент5 страницDragons and Winged SerpentsYuna Raven100% (1)

- SmartSlope C 110 Installation Manual PDFДокумент5 страницSmartSlope C 110 Installation Manual PDFAivan Dredd PunzalanОценок пока нет

- Definition of Logistics ManagementДокумент4 страницыDefinition of Logistics ManagementzamaneОценок пока нет

- Procrustes AlgorithmДокумент11 страницProcrustes AlgorithmShoukkathAliОценок пока нет

- Core12 Mod 1Документ1 страницаCore12 Mod 1Michael SaberonОценок пока нет

- Brief List of Temples in Haridwar Is Given BelowДокумент8 страницBrief List of Temples in Haridwar Is Given BelowPritesh BamaniaОценок пока нет

- Mohd Mopti Bin Yassin V Lembaga Kemajuan Perusahaan Pertanian Negeri Pahang (LKPP) Corp SDN BHD & AnorДокумент12 страницMohd Mopti Bin Yassin V Lembaga Kemajuan Perusahaan Pertanian Negeri Pahang (LKPP) Corp SDN BHD & AnorA random humanОценок пока нет

- Despiesse de Las Guallas D6H SERIE 3ZF06342Документ4 страницыDespiesse de Las Guallas D6H SERIE 3ZF06342David manjarresОценок пока нет

- Quran On GeologyДокумент10 страницQuran On GeologyMM NabeelОценок пока нет

- Relatório Final Do Período Experimental - Paulo Manuel Correia Da SilvaДокумент56 страницRelatório Final Do Período Experimental - Paulo Manuel Correia Da SilvaMagda RuanoОценок пока нет

- TamasДокумент180 страницTamaslike 2Оценок пока нет

- DysphagiaДокумент4 страницыDysphagiaMicaОценок пока нет

- An Overview of The IEEE Color BooksДокумент6 страницAn Overview of The IEEE Color BooksOhm666Оценок пока нет

- O221771s - Mil Pipe Pro 450 RFC PDFДокумент84 страницыO221771s - Mil Pipe Pro 450 RFC PDFJavier Isaac Berrocal Torres100% (1)

- Methanol Technologies of Tkis: A Brief OverviewДокумент12 страницMethanol Technologies of Tkis: A Brief OverviewMuhammad NaeemОценок пока нет

- A Review of Linear AlgebraДокумент19 страницA Review of Linear AlgebraOsman Abdul-MuminОценок пока нет

- CJR Fisika Umum IДокумент17 страницCJR Fisika Umum IveronikaОценок пока нет

- Oertel - Extracts From The Jāiminīya-Brāhma A and Upanishad-Brāhma A, Parallel To Passages of TheДокумент20 страницOertel - Extracts From The Jāiminīya-Brāhma A and Upanishad-Brāhma A, Parallel To Passages of Thespongebob2812Оценок пока нет

- 2014 Catbalogan Landslide: September, 17, 2014Документ6 страниц2014 Catbalogan Landslide: September, 17, 2014Jennifer Gapuz GalletaОценок пока нет

- Stock+List 6ct8.3g2 Esn#30549237 Cpl#2218 GeneradorДокумент34 страницыStock+List 6ct8.3g2 Esn#30549237 Cpl#2218 GeneradorAlexis SanchezОценок пока нет

- TRL Explanations - 1Документ4 страницыTRL Explanations - 1Ana DulceОценок пока нет

- Money, Interest, and Inflation: Answers To CheckpointsДокумент16 страницMoney, Interest, and Inflation: Answers To Checkpointsb96309Оценок пока нет

- Alternatives To Shifting Cultivation-248Документ9 страницAlternatives To Shifting Cultivation-248Chandrashekhar KhobragadeОценок пока нет

- Sdo Tle Grade 8 Dressmaking 2nd Q Week 1 8 1Документ64 страницыSdo Tle Grade 8 Dressmaking 2nd Q Week 1 8 1Maggie De jesusОценок пока нет