Академический Документы

Профессиональный Документы

Культура Документы

As-NZS1594 HU300 Xlercoil

Загружено:

Edward TanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

As-NZS1594 HU300 Xlercoil

Загружено:

Edward TanАвторское право:

Доступные форматы

AS/NZS 1594 - HU300

XLERCOIL

DATE:

September 2002

PRODUCT DESCRIPTION

Hot-rolled structural product with a minimum yield strength of 300 MPa, good ductility and good

weldability.

SUPPLY CONDITIONS

Surface finish: Hot-rolled / Skin passed*

Edge Condition: Mill Edge / Trimmed*

Tolerances: AS1365

Flatness: Class A

Certificate: BlueScope Steel - Analysis and Mechanical tests

*Optional supply condition. May be subject to size range restrictions

TYPICAL USES

Structural members

Roll forming applications

Light Poles

Brake press forming applications

General fabrication

Trailer & automotive components

FEATURES & BENEFITS

Guaranteed minimum strength levels

Excellent weldability

Good formability

WARNINGS

This material should be used in conjunction with the appropriate structural design and welding

standards.

A mill edge may contain minor surface discontinuities as a result of the rolling process. It is

recommended that customers satisfy themselves that the edge is suitable for the application.

Where material is required for galvanising it is recommended that the steel has a maximum of

0.03% silicon.

NEAREST OVERSEAS SPECIFICATIONS

ASTM A 1011 SS Grade 40

JIS G 3101 SS400

EN10 025 S275JR

For more information contact BlueScope Steel Direct:

Phone 1800 024 402

Email us at steeldirect@bluescopesteel.com

or visit the website at www.xlercoil.com

Date Published: September 2002

The information contained in this datasheet is provided by way of general information only, and should not be relied upon by any

person. You must seek specific advice as to the suitability of this product for the purpose for which, and the manner in which,

you propose to use it. This may involve further independent analysis and testing. BlueScope Steel Limited and its related

bodies corporate take no responsibility for any adverse consequences of any nature which arise as a result of reliance on this

datasheet.

BlueScope Steel Limited ABN 16 000 011 058.

AS/NZS 1594 - HU300

XLERCOIL

CHEMICAL COMPOSITION

Element

Guaranteed

Maximum %

Typical %

Carbon

0.20

0.15

Silicon

0.35

0.01

Manganese

1.60

0.75

Phosphorus

0.040

0.015

Sulfur

0.030

0.010

Aluminium

0.10

0.030

CEQ(IIW)**

0.39

0.28

** CEQ (IIW) = C + Mn + ( Cr+Mo+V ) + ( Cu+Ni )

6

5

15

MECHANICAL PROPERTIES

Tensile Properties (Longitudinal)

Guaranteed Min.

Typical

Yield Strength (MPa)

300

320 - 390

Tensile Strength (MPa)

400

420 - 500

3mm (on 80mm GL)

15

24 - 32

>3mm (on 200 mm GL)

16

22 - 30

3mm

1t

1t

>3mm

2t

1t

Elong. (%)

180 Bend (Transverse)

DIMENSIONS

Preferred Widths (mm):

910 - 1800 (increments of 10mm)

Preferred Thicknesses (mm):

3.3 - 6.5 (increments of 0.1 mm)

Thicknesses less than 3.3 mm are available from BlueScope Steel

FABRICATING PERFORMANCE

Bending

Good

Roll-forming

Good

Welding

WTIA Group 3***

*** Refer to WTIA Technical Note 1 or AS/NZS 1554.1

Date Published: September 2002

The information contained in this datasheet is provided by way of general information only, and should not be relied upon by any

person. You must seek specific advice as to the suitability of this product for the purpose for which, and the manner in which,

you propose to use it. This may involve further independent analysis and testing. BlueScope Steel Limited and its related

bodies corporate take no responsibility for any adverse consequences of any nature which arise as a result of reliance on this

datasheet.

BlueScope Steel Limited ABN 16 000 011 058.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- MICROMACHININGДокумент34 страницыMICROMACHININGChandu Sunag100% (1)

- Study The Effect of Stress Relief Annealing On The Tensil Properties Hardness and Microstructure of The Medium Carbon SteelДокумент13 страницStudy The Effect of Stress Relief Annealing On The Tensil Properties Hardness and Microstructure of The Medium Carbon SteelZaid TariqОценок пока нет

- Inspections For Disassembled PartsДокумент2 страницыInspections For Disassembled PartsLanceal TanОценок пока нет

- معلومات عامه تفيد مهندسي النفط اДокумент56 страницمعلومات عامه تفيد مهندسي النفط اMustafa HusseinОценок пока нет

- BLOWENGINEERING PLASTIC MACHINES Blow Molding Machine Manufacturer PDFДокумент6 страницBLOWENGINEERING PLASTIC MACHINES Blow Molding Machine Manufacturer PDFJoenetDarmawanОценок пока нет

- HF 431 / HF 434 / HF 437 Series: Suction FiltersДокумент4 страницыHF 431 / HF 434 / HF 437 Series: Suction FilterssitnikovsОценок пока нет

- Parts of A Centre LatheДокумент21 страницаParts of A Centre LatheMuralikrishnan GMОценок пока нет

- Jotamastic 70Документ9 страницJotamastic 70Muhammad HanafiОценок пока нет

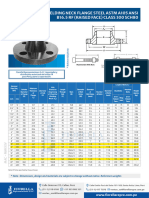

- Bridas WN Clase 300Документ1 страницаBridas WN Clase 300juan ormacheaОценок пока нет

- Ni 2680Документ17 страницNi 2680marceloОценок пока нет

- Corrosion and Its PreventionsДокумент21 страницаCorrosion and Its PreventionsWaldy Nur PatriaОценок пока нет

- Vacuum DistillationДокумент8 страницVacuum DistillationPrashanth Chidambaram100% (1)

- Wheel Tool Manual For Amada Thick Turret 2007Документ17 страницWheel Tool Manual For Amada Thick Turret 2007bob zimmОценок пока нет

- Welding Cast Iron PDFДокумент15 страницWelding Cast Iron PDFAmr Mohamed SolimanОценок пока нет

- Countersink, Counterbore & SpotfaceДокумент8 страницCountersink, Counterbore & SpotfaceŤhe Đûke100% (1)

- Welding Journal 1960 12Документ151 страницаWelding Journal 1960 12AlexeyОценок пока нет

- Notes CNC ProgramДокумент58 страницNotes CNC Programzairul100% (1)

- Bekisting KolomДокумент6 страницBekisting KolomJoe GrosirОценок пока нет

- Welding ProceduresДокумент29 страницWelding ProceduresLaith Salman100% (1)

- Welding of Duplex Stainless SteelДокумент7 страницWelding of Duplex Stainless SteelAnthony YUОценок пока нет

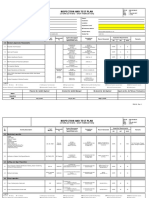

- Water Tank ItpДокумент5 страницWater Tank Itptuan mai vanОценок пока нет

- Mekelle University Ethiopian Institute of Technology-Mekelle Department of Chemical Engineering Process EngineeringДокумент77 страницMekelle University Ethiopian Institute of Technology-Mekelle Department of Chemical Engineering Process EngineeringetayhailuОценок пока нет

- SABA Ecoseal Bio HM PDS ENДокумент2 страницыSABA Ecoseal Bio HM PDS ENArda YILDIZEL I Reliant E&CОценок пока нет

- Gedee Technical Training InstituteДокумент53 страницыGedee Technical Training Institutekishore pmОценок пока нет

- Crsi Technical Rebar GuideДокумент4 страницыCrsi Technical Rebar Guideحسن كاظم ريسان B-4Оценок пока нет

- Device and Method For Adaptive Control of Blanks MachiningДокумент4 страницыDevice and Method For Adaptive Control of Blanks MachiningspriditisОценок пока нет

- Extraction of Tin From Hardhead by Oxidation and Fusion With Sodium HydroxideДокумент6 страницExtraction of Tin From Hardhead by Oxidation and Fusion With Sodium HydroxideNURIZZANIE FEBRINA ARISMANОценок пока нет

- Beverage PackagingДокумент3 страницыBeverage PackagingsnrahmanОценок пока нет

- Y-Strainer - Data SheetДокумент7 страницY-Strainer - Data SheetŁukasz OlszewskiОценок пока нет

- Options For Plant Design/ Upgrading of Comminution Circuits: LD Michaud July 14, 2016Документ14 страницOptions For Plant Design/ Upgrading of Comminution Circuits: LD Michaud July 14, 2016Rodrigo GarcíaОценок пока нет