Академический Документы

Профессиональный Документы

Культура Документы

PSA

Загружено:

ihllhmАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PSA

Загружено:

ihllhmАвторское право:

Доступные форматы

http://www.betamachinery.

com/services/pipe-stress-analysis

Pipe Stress Analysis

(Thermal Analysis, Piping Flexibility Analysis)

A Pipe Stress Analysis (thermal flexibility analysis) will predict stresses in piping and loads

on equipment resulting from thermal gradients, thermal transients, weights, pressure, and boltup strain. This study is typically required for piping that experiences high temperature

fluctuations, or for long pipe runs such as hot piping to coolers or headers. Cases where

equipment is sensitive to external loads may also require a Pipe Stress Analysis.

The study methodology becomes more complicated for piping systems in vibratory service.

As discussed below, the design must address conflicting requirements between the Pipe Stress

Analysis (where flexibility is desired) versus the Mechanical Vibration Analysis (which

requires stiff supports). Methods are available to manage this conflict and create an optimal

piping design.

This link provides a general overview of static and dynamic piping design requirements:

Piping Vibration Design Considerations (Static and Dynamic)

Contents [ hide ]

1 Scope

2 Options

3 How to Avoid Conflict Between Pipe Stress and Vibration Analysis

4 BETA Advantages

5 Customer Benefits

6 Related Information

7 Related Services

8 Key Words

1 Scope

This analysis calculates piping stresses resulting from thermal cycles, pipe and fitting weights,

and static pressure for the main process piping. Generally, CAESAR II is used for modeling

the system, although other specialty computer programs such as NozzlePRO and FETee are

sometimes required.

Evaluates stress due to thermal cycles, weight, and static pressures in the piping as per

all industry piping codes, such as B31.3, B31.8, CSA Z662, BS826, BS7159, FDBR,

DNV, Stoomwezen and others.

Calculates loads on equipment (e.g., vessels, coolers, pumps, and compressors) and

designs them to meet industry standards.

Recommends pipe layout, pipe support, and clamp designs.

2 Options

Assessment of piping system subject to environmental loads (wind/seismic)

Design piping system to withstand PSV discharge loads

Detailed analysis of vessel nozzle loads to meet ASME Section VIII, Div. 2 pressure

vessel stress requirements

Design cooler nozzle loads to meet strict API 661 requirements

Analysis of underground or buried pipe

Fatigue analysis of high pressure piping per ASME B31.3, Section IX

3 How to Avoid Conflict Between Pipe Stress and Vibration Analysis

When machinery is involved in the piping system, the same consultants performing the

dynamic mechanical Finite Element Analysis (FEA) should also complete the Pipe Stress

Analysis. This will avoid conflicts between stiffness assumptions and requirements for

supports, and also expedite a solution. Typically dynamic mechanical analysis will specify

high stiffness supports, while piping flexibility analysis will require flexible supports. It is

important to simultaneously consider both static and dynamic requirements.

Controlling vibration, and vibratory stress typically involves restraining the pipe. It

also requires closer spacing of pipe supports (between clamps) to raise the mechanical

natural frequency of the pipe to avoid resonance. Vibration control standards also

require that pipe supports have enough stiffness to stop vibration at the support and

caution against the use of hangers and guides.

Pipe Stress Analysis mitigates static deflections and stresses and typically involves

selectively providing flexibility with a mixture of rest supports, guides, line stops,

hangers, spring supports, and hold downs.

Recommendations for the pipe stress analysis can be directly opposite to the

vibration design requirements. This conflict can, and does, result in significant

confusion and problems during construction and operations.

To avoid this conflict, the standard industry approach is to have the same consultant perform

both the vibration analysis and the piping stress analysis. This ensures the vibration control

and piping design are adequately addressed, including realistic pipe support stiffness

assumptions, and use of vibratory clamps/restraints that have enough flexibility for thermal

growth (see articles below for more info).

4 BETA Advantages

Our practical recommendations are based on nearly 50 years of field and design

experience. Having machinery and field experience provides many practical

advantages when evaluating the piping design.

Our analysts are experts in the latest analytical software for pipe stress analysis

including ANSYS, CAESAR II, NozzlePRO, FETee/FESIF, and other applicable

software packages. BETAs software tools provide more accurate stress intensification

factors resulting in better results (less conservative recommendations).

FEA and field testing ensures accurate boundary conditions for the

computer simulations;

especially valuable are accurate stiffness assumptions for piping supports.

Our proprietary piping restraint designs accommodate vibratory loads as well as

thermal expansion.

Our proven approach to address dynamic and static designs avoids conflicting

recommendations and approaches between thermal and dynamic/vibratory

requirements.

We have a comprehensive piping analysis offering that covers FIV, AIV, Energy

Institute, surge, water hammer, etc.

With offices and support in many regions, we offer responsive global support.

Our depth of engineering resources support any size project.

Our pricing is competitive.

5 Customer Benefits

System designs ensure safe operation.

Extend equipment longevity and minimize maintenance costs through appropriately

balanced thermal and dynamic support requirements.

Minimize number of pipe layout and support revisions when BETA conducts the

piping flexibility study and API 618 DA2 and DA3 mechanical studies.

6 Related Information

Recommended Approach to Piping Flexibility Studies to Avoid Compressor

System Integrity Risk, GMRC 2011 (pdf)

Improved Thermal Piping Analysis for Reciprocating Compressor Piping Systems

(GMC paper 2012, pdf)

Pipe Support Stiffness, GMRC research overview, 2014

BETA training class Piping Systems: Techniques to Mitigate Vibration (pdf)

7 Related Services

Piping Vibration and integrity Assessment

Troubleshooting (Machinery Pulsation and Vibration Problems)

Piping Systems (general information static and dynamic piping analysis)

8 Key Words

Thermal Flexibility

Piping Flexibility

B31.3

API M11 Study

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Cleaning-In-Place in The Dairy IndustryДокумент11 страницCleaning-In-Place in The Dairy IndustryihllhmОценок пока нет

- Guide To The Selection of Rotodynamic Pumps FinalДокумент35 страницGuide To The Selection of Rotodynamic Pumps FinalAmeer BashaОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Applying NPSH To Metering PumpsДокумент3 страницыApplying NPSH To Metering PumpsJoce88888100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Sulphide Scavengers in Oil and Gas Industry - A ReviewДокумент8 страницSulphide Scavengers in Oil and Gas Industry - A ReviewMartín Diego MastandreaОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Aalborg OmДокумент4 страницыAalborg OmihllhmОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- 10 Reasons To Move From AutoCAD To AutoCAD P&IDДокумент2 страницы10 Reasons To Move From AutoCAD To AutoCAD P&IDihllhmОценок пока нет

- Ammonia Handling Manual PDFДокумент14 страницAmmonia Handling Manual PDFEdenson Flores TrujilloОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Tank InstrumentsДокумент10 страницTank InstrumentsihllhmОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Chemical EquationsДокумент6 страницChemical EquationsihllhmОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Vapour Pressure HCL Water PDFДокумент1 страницаVapour Pressure HCL Water PDFihllhmОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Ballast Water Management MethodsДокумент2 страницыBallast Water Management MethodsRajesh Kumar ChaubeyОценок пока нет

- AmmoniaДокумент4 страницыAmmoniaYutt WattОценок пока нет

- Implementing Off Page ConnectorsДокумент9 страницImplementing Off Page ConnectorsihllhmОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- QPM Oil Gas Petro Example PDFДокумент4 страницыQPM Oil Gas Petro Example PDFihllhmОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Boiling Liquid Expanding Vapor Explosion - Simulation and RiskДокумент1 страницаBoiling Liquid Expanding Vapor Explosion - Simulation and RiskihllhmОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- AutoCAD PID 2011 Features and BenefitsДокумент2 страницыAutoCAD PID 2011 Features and BenefitsPaula ErazoОценок пока нет

- PFD&PID With AUtoCAD P&ID PDFДокумент7 страницPFD&PID With AUtoCAD P&ID PDFihllhmОценок пока нет

- Implementing Off Page ConnectorsДокумент9 страницImplementing Off Page ConnectorsihllhmОценок пока нет

- Composite Boiler Aalborg PDFДокумент2 страницыComposite Boiler Aalborg PDFihllhmОценок пока нет

- Work Breakdown Structures: White PaperДокумент6 страницWork Breakdown Structures: White PaperjmpbarrosОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- DOE Guidance WBS PDFДокумент18 страницDOE Guidance WBS PDFEl KhanОценок пока нет

- Boiler Efficiency Guide PDFДокумент24 страницыBoiler Efficiency Guide PDFAsnfiasnfd FenfeОценок пока нет

- 10 Reasons To Move From AutoCAD To AutoCAD P&IDДокумент2 страницы10 Reasons To Move From AutoCAD To AutoCAD P&IDihllhmОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Project Control SetupДокумент2 страницыProject Control SetupihllhmОценок пока нет

- Stemming The TideДокумент48 страницStemming The TideDevika Hemalatha DeviОценок пока нет

- Ge Oil &gas Turbocompressor Trains On First Floating LNG PlantДокумент12 страницGe Oil &gas Turbocompressor Trains On First Floating LNG PlantihllhmОценок пока нет

- Navgathi-New Shipbuilding Project Management PDFДокумент16 страницNavgathi-New Shipbuilding Project Management PDFihllhm100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Ge Oil &gas Turbocompressor Trains On First Floating LNG Plant PDFДокумент12 страницGe Oil &gas Turbocompressor Trains On First Floating LNG Plant PDFihllhmОценок пока нет

- The Narrative Constitution of Identity: A Relational and Network ApproachДокумент46 страницThe Narrative Constitution of Identity: A Relational and Network ApproachMartha MárquezОценок пока нет

- Cell Cycle Division Lecture NotesДокумент16 страницCell Cycle Division Lecture NotesZachary HamidОценок пока нет

- Tulving 2002 Memoria EpisodicaДокумент29 страницTulving 2002 Memoria EpisodicaMaximo SacerdoteОценок пока нет

- Self - Study Ebook (IM08)Документ95 страницSelf - Study Ebook (IM08)Bảo HàОценок пока нет

- Cbse 12th 2021 - MCQ Series Application of DerivativesДокумент112 страницCbse 12th 2021 - MCQ Series Application of DerivativesHunterr Is BackОценок пока нет

- UDM Psych Catch Up The Clinical Interview and Process RecordingДокумент70 страницUDM Psych Catch Up The Clinical Interview and Process RecordingRhea Jane Quidric BongcatoОценок пока нет

- BPAE-102 Assignments 2018-19 (English)Документ4 страницыBPAE-102 Assignments 2018-19 (English)Abhijeet kumar yadavОценок пока нет

- Student Handbook PDFДокумент51 страницаStudent Handbook PDFAssad SaghirОценок пока нет

- Michelle Phan Anorexia Nervosa FinalДокумент12 страницMichelle Phan Anorexia Nervosa Finalapi-298517408Оценок пока нет

- Thematic Apperception TestДокумент82 страницыThematic Apperception TestMs. Rachel Samson75% (4)

- Architecture - Hybris Lifecycle FrameworkДокумент214 страницArchitecture - Hybris Lifecycle Frameworkrindang cahyaningОценок пока нет

- Varun Sodhi Resume PDFДокумент1 страницаVarun Sodhi Resume PDFVarun SodhiОценок пока нет

- 12 Esl Topics Quiz HealthДокумент2 страницы12 Esl Topics Quiz HealthSiddhartha Shankar NayakОценок пока нет

- Blockchain VCДокумент39 страницBlockchain VCkaala_yuvrajОценок пока нет

- Key Performance Indicators of DTH (Direct To Home) Industry in IndiaДокумент10 страницKey Performance Indicators of DTH (Direct To Home) Industry in IndiaShiv Ashish SinghОценок пока нет

- Total Assessment Guide: Psychology Ch. 1Документ34 страницыTotal Assessment Guide: Psychology Ch. 1TruettCoffieldОценок пока нет

- Institute of Professional Psychology Bahria University Karachi CampusДокумент16 страницInstitute of Professional Psychology Bahria University Karachi Campusayan khwajaОценок пока нет

- Geoarchaeology2012 Abstracts A-LДокумент173 страницыGeoarchaeology2012 Abstracts A-LPieroZizzaniaОценок пока нет

- Lets Get Started Deweys StatementДокумент8 страницLets Get Started Deweys StatementGlenn F. Jove100% (1)

- OGL 481 Pro-Seminar I: PCA-Ethical Communities WorksheetДокумент6 страницOGL 481 Pro-Seminar I: PCA-Ethical Communities Worksheetapi-624910201Оценок пока нет

- Clinical Map of Family Therapy ModelsДокумент3 страницыClinical Map of Family Therapy ModelsTe-Erika87% (15)

- Mentoring Research Poster PortfolioДокумент1 страницаMentoring Research Poster Portfolioapi-463444835Оценок пока нет

- Projects and Programmes Committee ReportДокумент5 страницProjects and Programmes Committee ReportElbekriОценок пока нет

- Discussion QuestionsДокумент4 страницыDiscussion QuestionsDavid MoonОценок пока нет

- Techniques To Memorize SwiftlyДокумент33 страницыTechniques To Memorize SwiftlyAsad ChishtiОценок пока нет

- Unit 11 Science Nature Lesson PlanДокумент2 страницыUnit 11 Science Nature Lesson Planapi-590570447Оценок пока нет

- What Are The Advantages and Disadvantages of Computers?Документ4 страницыWhat Are The Advantages and Disadvantages of Computers?Muhammad SajidОценок пока нет

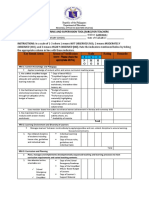

- Monitoring and Supervision Tool (M&S) For TeachersДокумент3 страницыMonitoring and Supervision Tool (M&S) For TeachersJhanice Deniega EnconadoОценок пока нет

- F240 Early Childhood Education Inners FINAL Web PDFДокумент319 страницF240 Early Childhood Education Inners FINAL Web PDFSandra ClОценок пока нет

- Answer Sheet For Foundation in Software TestingДокумент22 страницыAnswer Sheet For Foundation in Software Testingh_verma0% (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridОт EverandShorting the Grid: The Hidden Fragility of Our Electric GridРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Waste: One Woman’s Fight Against America’s Dirty SecretОт EverandWaste: One Woman’s Fight Against America’s Dirty SecretРейтинг: 5 из 5 звезд5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionОт EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionРейтинг: 3 из 5 звезд3/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressОт EverandNuclear Energy in the 21st Century: World Nuclear University PressРейтинг: 4.5 из 5 звезд4.5/5 (3)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!От EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Оценок пока нет

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesОт EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesРейтинг: 4.5 из 5 звезд4.5/5 (21)