Академический Документы

Профессиональный Документы

Культура Документы

4th Lecture On Separation Processes

Загружено:

Fabrice BassamaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

4th Lecture On Separation Processes

Загружено:

Fabrice BassamaАвторское право:

Доступные форматы

Unit Operations and Separation Processes

Lecture 4

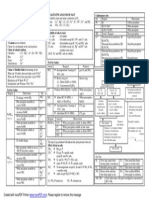

Calculation of Height of Gas Absorption Column and Material Balance for Plate Towers

Characteristics of an Absorption Tower

Let us consider gas liquid absorption tower

operated in a counter current design mode

We can define the following quantities;

moles of solute gas per mole of inert gas in the gas

phase

moles of solute gas per mole of solute free liquid in

liquid phase

Area of interface between the two phases is unknown

Interfacial area per unit volume of column

Characteristics of an Absorption Tower

Equation (11)

NA = k G (PAG PAi) = k L (CAi CAL)(11)

Can be rewritten as follows;

NAdZa = kGa(PAG PAi)A dZ(31)

= kLa(CAi CAL)A dZ

where:

NA= kmol of solute absorbed per unit time and unit interfacial

area,

a = surface area of interface per unit volume of column,

A = cross-sectional area of column, and

Z = height of packed section.

Absorption Tower (Counter current flow)

CFO 4 ET012

Calculation of Column Height based on conditions in the gas

film

Assumptions

Gm = moles of inert gas/(unit time) (unit cross-section of tower),

Lm = moles of solute-free liquor/(unit time) (unit cross-section of tower)

Y = moles of solute gas A/mole of inert gas B in gas phase, and

X = moles of solute A/mole of inert solvent in liquid phase.

where

Molar ratios of the diffusing material in the gas and liquid

phases are Y and X respectively,

5

Calculation of Column Height(Gas film conditions)

Over a small height dZ, the moles of gas leaving the gas

phase will equal the moles taken up by the liquid.

This behaviour is described by

AGm dY = ALm dX.(32)

But

AGmdY = NA = kGa(PAi PAG)A dZ...............(33)

(a) Substituting for PAG in terms of gas partial pressure and moles of solute gas

(b) Rearranging Gm dY in terms of partial pressure and moles of solute gas

(c) And integrating the height of column Z required to achieve a change from Y1

(bottom of column)to Y2 (top of column)

Calculation of Column Height(Gas film conditions)

Z (Height of column required to achieve a change in

Y from Y1 at the bottom to Y2 at the top of the

column is;

Z=

.(34)

kG is assumed to be constant throughout the

column

Calculation of Column Height(Liquid film conditions)

Over a small height dZ, the moles of gas leaving the gas

phase will equal the moles taken up by the liquid.

This behaviour is described by

ALm dX = kLa(CAi CAL)A dZ...(35)

where

Concentration C (moles of solute per unit volume of liquid).

If CT = (moles of solute + solvent) (volume of liquid), then:

CA

CT CA

moles of solute

moles of solvent

=X

8

Calculation of Column Height(Liquid film conditions)

Z (Height of column required to achieve a change in

Y from Y1 at the bottom to Y2 at the top of the

column is;

Z=

X2 dX

Lm

..

X

kLaCT 1 XXi

(36)

kL and CT is assumed to be constant throughout the

column

CFO 4 ET012

10

Plate Towers for Gas Absorption

Sieve trays and bubble cap columns are similar to

those used for distillation

Preferred to packed towers when;

the load is excessive; diameter of column > 2m

there is likelihood of deposition of solids which could

choke packed tower

liquid flow rate is very high and could cause flooding in

packed towers

Ratio of liquid rate to gas rate is higher with plate

towers than in distillation however, plate

efficiencies are lower than with distillation

equipment

11

CFO 4 ET012

12

Definition of Tower Characteristics

Lm is the molar rate of flow per unit area of solute free liquid

Gm is the molar rate of flow per unit area of inert gas

n refers to the plate numbered from the bottom upwards (and

suffix n refers to material leaving plate n)

x defines the mole fraction of the absorbed component in the

liquid

y defines the mole fraction of the absorbed component in the gas

s is the total number of plates in the column.

13

Material Balance for Absorbed Component for Plate Towers

Material balance for the absorbed component from

the bottom to a plane above plate n gives:

Gmyn + Lmx1 = Gmy0 + Lmxn+1.(37)

Material leaving plate

+1 + y0 - x1 ..(38)

yn

=

14

CFO 4 ET012

15

Number of Transfer Units/Height of Transfer Units

Height (HOG ) of an overall transfer unit for a Packed Column

Gm

= HOG =

.(39)

KGaP

where Gm is the molar gas flow rate

KGa is the overall transfer coefficient

P is the partial pressure of Gas

Number of transfer units (NOG) in a Packed Column is

expressed as an integral value of the change in composition

of the gas in the column per unit driving force

y2 d

..

y1 ye

where y is mole fraction of A in gas phase

ye is mole fraction of A at equilibrium

(40)

Height of Column (Z)

No of Transfer units

Height of Column

(NOG) =

Height of Transfer Unit

Therefore column height (Z) = NOG x HOG

Z

HOG

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Energy Balance of SolutionsДокумент16 страницEnergy Balance of Solutionsnhalieza1067Оценок пока нет

- Part+1+of+20+ +Applications+for+a+Plasmoids+Form+and+Functions+ +Draft+518,400+b+Kmv+ +August+Monday+29th+2022Документ72 страницыPart+1+of+20+ +Applications+for+a+Plasmoids+Form+and+Functions+ +Draft+518,400+b+Kmv+ +August+Monday+29th+2022totoОценок пока нет

- Calculations Based On Fuel AnalysisДокумент3 страницыCalculations Based On Fuel AnalysisBrille Adrian FernandoОценок пока нет

- Casein PDFДокумент3 страницыCasein PDFEasy ways2017Оценок пока нет

- Sample Problem - ThermodynamicsДокумент30 страницSample Problem - ThermodynamicscyhdzОценок пока нет

- Chapter 4: Biocatalysis: SUBTOPIC: 4.1 Properties of Enzymes and Mechanism of Actions Learning OutcomesДокумент8 страницChapter 4: Biocatalysis: SUBTOPIC: 4.1 Properties of Enzymes and Mechanism of Actions Learning OutcomesNURUL HIDAYAH BINTI SAIFUL ANUAR MoeОценок пока нет

- Gate MaterialsДокумент6 страницGate MaterialsManoharChinta100% (1)

- Recent Progress of Metal-Air Batteries-A Mini Review-Aplicatii MAB PDFДокумент22 страницыRecent Progress of Metal-Air Batteries-A Mini Review-Aplicatii MAB PDFAna-Maria HodorogeaОценок пока нет

- Teacher: Mervi Vera Buitron de Gratal Trabajo Grupal: 1) Giron Ugarte, Luis AurelioДокумент3 страницыTeacher: Mervi Vera Buitron de Gratal Trabajo Grupal: 1) Giron Ugarte, Luis AurelioNaomi HerreraОценок пока нет

- Multiphase Flow in PipeДокумент27 страницMultiphase Flow in PipeMohammed YousifОценок пока нет

- Openstax - Chemistry - Answer Key (Odds)Документ75 страницOpenstax - Chemistry - Answer Key (Odds)Windel AventuradoОценок пока нет

- GHG PDFДокумент10 страницGHG PDFAnonymous sPmTooHtgmОценок пока нет

- Segi University: (Chemical Engineering Laboratory #2)Документ9 страницSegi University: (Chemical Engineering Laboratory #2)PunithanОценок пока нет

- User Instruction HIC402A - 404A - 406A - 408A - 410A - 412A - 416AДокумент2 страницыUser Instruction HIC402A - 404A - 406A - 408A - 410A - 412A - 416AHamd1971Оценок пока нет

- Polymer Rheology and ProcessingДокумент57 страницPolymer Rheology and ProcessingAbhishek KumarОценок пока нет

- Analisis Kualitatif GaramДокумент1 страницаAnalisis Kualitatif GaramAbu AimanОценок пока нет

- Oxidation Behavior of Zirconium Alloys in Transient ConditionsДокумент141 страницаOxidation Behavior of Zirconium Alloys in Transient ConditionsElenaОценок пока нет

- Statico en LowДокумент12 страницStatico en LowRobert PeharОценок пока нет

- Boiler Maintenance and Safety Study Guide - Combustion - ChimneyДокумент7 страницBoiler Maintenance and Safety Study Guide - Combustion - ChimneyObayomi KennyОценок пока нет

- Thermal Properties of Black Pepper and Its Volatile Oil: Murlidhar Meghwal and T K GoswamiДокумент11 страницThermal Properties of Black Pepper and Its Volatile Oil: Murlidhar Meghwal and T K Goswamirosita devi anggrainiОценок пока нет

- EGE 401 - Experiment 7Документ24 страницыEGE 401 - Experiment 7kevin leeОценок пока нет

- General Chemistry 2Документ3 страницыGeneral Chemistry 2SHERWIN BERMEJOОценок пока нет

- Semiconductors: Quantum Photonics: Optoelectronics and PhotonicsДокумент34 страницыSemiconductors: Quantum Photonics: Optoelectronics and PhotonicsGafeer FableОценок пока нет

- Previous Year Questions (Neet, Aiims, Aipmt, Jipmer)Документ3 страницыPrevious Year Questions (Neet, Aiims, Aipmt, Jipmer)abhishekОценок пока нет

- Formative Test 2.1: GRADE 8: AtomsДокумент4 страницыFormative Test 2.1: GRADE 8: AtomsKeisha Gabrielle RabanoОценок пока нет

- IntroductionДокумент29 страницIntroductionanamendoza1868Оценок пока нет

- 64j0105-C-Piping ClassДокумент85 страниц64j0105-C-Piping ClassDubois100% (1)

- A Critical Review of LiAir BatteriesДокумент31 страницаA Critical Review of LiAir BatteriesAnkit GulumkarОценок пока нет

- Flame Photometry Topic McqsДокумент9 страницFlame Photometry Topic McqsAli Hamza Sajid Ali Hamza Sajid100% (5)

- Combustion and FlameДокумент24 страницыCombustion and FlameVikranth PonnalaОценок пока нет