Академический Документы

Профессиональный Документы

Культура Документы

ELSA - Exploded View - Clutch Release Mechanism

Загружено:

bmИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ELSA - Exploded View - Clutch Release Mechanism

Загружено:

bmАвторское право:

Доступные форматы

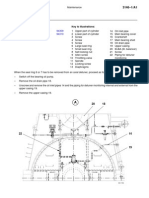

Exploded view - clutch release mechanism

Page 1 of 6

Exploded view - clutch release mechanism

Special tools and workshop equipment required

t Thrust plate -VW 402t Press tool -VW 412t Press tool -VW 454-

t Torque wrench -V.A.G 1331-

t -1-Internal puller -Kukko 21/5t -4-Counter-support -Kukko 22/1t Sealing grease -G 052 128 A1t Copper grease -Z 381 351 TEt Adhesive -AMV 195 KD1 01-

vw-wi://rl/A.en-GB.A03.5901.45.wi::35500035.xml?xsl=3

2/3/2013

Exploded view - clutch release mechanism

Page 2 of 6

1 - Clutch slave cylinder

q Removing and installing on vehicles with 8-cylinder engine Chapter

q Removing and installing on vehicles with 6-cylinder TDI engine Chapter

q Do not operate clutch pedal after slave cylinder has been removed.

q Follow correct procedure when bleeding Chapter

q Tighten bleeder valve to 4.5 Nm.

q When installing, push in until the securing bolt can be fitted.

2 - Hexagon socket head bolt, 23 Nm

q Clutch slave cylinder to gearbox

q Self-locking

q Renew

3 - Bracket

vw-wi://rl/A.en-GB.A03.5901.45.wi::35500035.xml?xsl=3

2/3/2013

Exploded view - clutch release mechanism

Page 3 of 6

q For pipe/hose assembly

q Bolt to gearbox with clutch slave cylinder

q Not fitted on all versions

4 - Plunger

q Lubricate end of plunger with copper grease -Z 381 351 TE5 - O-ring

q Always renew Fig.

q Lubricate with gear oil before installing

6 - Oil seal

q For input shaft

q Removing Fig.

q Original dimension Fig.

q Installing Fig.

q Pack space between sealing lip and dust lip half full with sealing grease -G 052 128 A1-.

7 - Guide sleeve

q Removing and installing Fig.

8 - Clutch release lever

q Removing and installing Fig.

q Before installing, lubricate area which makes contact with plunger of slave cylinder with copper

grease -Z 381 351 TE-.

9 - Release bearing

q Do not wash out; wipe clean only

q Renew bearing if noisy

q Checking release bearing Chapter

q Retainer lugs on release bearing must engage in release lever

10 - Bolt, 25 Nm

q Self-locking

q Always renew

11 - Leaf spring

12 - Bolt, 25 Nm

q 2x

q Self-locking

q Always renew

13 - Retaining piece

q For guide sleeve

q Removing and installing Fig.

14 - Intermediate piece

q Renew if damaged

vw-wi://rl/A.en-GB.A03.5901.45.wi::35500035.xml?xsl=3

2/3/2013

Exploded view - clutch release mechanism

Page 4 of 6

15 - Gearbox

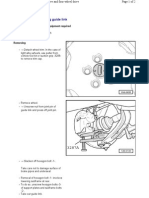

Removing and installing clutch release lever

Removing

Slacken off bolt -1- and remove leaf spring

-2-.

Remove clutch release lever -3- together

with release bearing.

Disengage retaining tabs of release bearing

at release lever.

Installing

Prior to installing clutch release lever,

apply a thin coat of copper paste Z 381 351 TE- to contact surface for

plunger of clutch slave cylinder.

Fit clutch release lever -3- together with

release bearing onto guide sleeve.

Insert leaf spring -2- and tighten new bolt 1- to 25 Nm.

Removing and installing guide sleeve

Removing

Unscrew bolts -arrows- and remove

retaining piece -1-.

Fit a thin insulating hose or shrink hose

tightly over splines of input shaft.

Pull guide sleeve -2- over insulating hose

and out of gearbox housing.

Installing

Renew O-ring in gearbox housing Fig..

Pack space between sealing lip and dust lip

with sealing grease -G 052 128 A1-.

Lightly oil outer circumference of guide

sleeve.

Push guide sleeve -2- over input shaft and

into gearbox housing.

Remove insulating hose/shrink hose.

Fit retaining piece -1-.

Clean threads of bolts -arrows- with a wire

brush. Then insert bolts with locking fluid

-AMV 185 101 A1- and tighten to 24 Nm.

vw-wi://rl/A.en-GB.A03.5901.45.wi::35500035.xml?xsl=3

2/3/2013

Exploded view - clutch release mechanism

Page 5 of 6

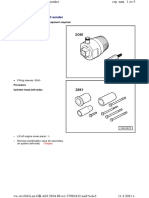

Renew O-ring

Pry out O-ring -arrow- using a small

screwdriver.

Lubricate new O-ring with gear oil before

installing.

Pulling out input shaft oil seal

A - Counter-support -Kukko 22/1B - Internal puller -Kukko 21/5-

Original dimension - input shaft oil seal

Dimension x = 7.75 mm 0.5 mm

A30-0149

Pressing in input shaft oil seal

Lightly lubricate outer circumference of

seal with gear oil.

Press in input shaft oil seal Fig.

Original dimension - input shaft oil

seal (make sure oil seal remains straight).

The open side of seal faces towards press

tool -VW 454-.

Pack space between sealing lip and dust lip

half-full with sealing grease -G 052 128

vw-wi://rl/A.en-GB.A03.5901.45.wi::35500035.xml?xsl=3

2/3/2013

Exploded view - clutch release mechanism

Page 6 of 6

A1-.

vw-wi://rl/A.en-GB.A03.5901.45.wi::35500035.xml?xsl=3

2/3/2013

Вам также может понравиться

- DP0 / AL4 Technical NoteДокумент58 страницDP0 / AL4 Technical NoteSimone C89% (9)

- Assembling Fabia Engine AZQДокумент9 страницAssembling Fabia Engine AZQbuerebista100% (2)

- R8 Spyder V10 - Engine RemovalДокумент41 страницаR8 Spyder V10 - Engine RemovalohshafiОценок пока нет

- MTX 75Документ54 страницыMTX 75bripservОценок пока нет

- VW 1.4TSI CZDA - Timing Belt - ReplaceДокумент19 страницVW 1.4TSI CZDA - Timing Belt - ReplaceZamirul Syafiq0% (1)

- Document PDFДокумент304 страницыDocument PDFNurul AriffahОценок пока нет

- KAF950GDF - Kawasaki Trans Diesel 4x4 Service ManualДокумент557 страницKAF950GDF - Kawasaki Trans Diesel 4x4 Service ManualSimon Mclennan100% (5)

- Supply Chain ManagementДокумент20 страницSupply Chain ManagementMuhammad Haris100% (2)

- Body MK5 Jetta GolfДокумент549 страницBody MK5 Jetta Golfvixentd100% (3)

- PD InjectorДокумент5 страницPD InjectorTomas NoneeОценок пока нет

- Audi R8 Front Spoiler ReplacementДокумент5 страницAudi R8 Front Spoiler ReplacementohshafiОценок пока нет

- Skoda Workshop Manuals - Fabia Mk2 - Power Unit - 1,4 - 63 KW MPI Engine - EngineДокумент4 страницыSkoda Workshop Manuals - Fabia Mk2 - Power Unit - 1,4 - 63 KW MPI Engine - EngineJose Antonio Jimenez AlvarezОценок пока нет

- Transmission JB1 MANUALДокумент23 страницыTransmission JB1 MANUALmustardbassman100% (1)

- mK5 Jetta BrakesДокумент45 страницmK5 Jetta Brakesvixentd100% (2)

- 0B5 Mechatronic - Service - PCBДокумент3 страницы0B5 Mechatronic - Service - PCBpecirepiОценок пока нет

- B1 20 3Документ30 страницB1 20 3Marcel BurlacuОценок пока нет

- Toyota Innova BrochureДокумент11 страницToyota Innova BrochureBima GalangОценок пока нет

- CC2800 62151 Part1 - enДокумент448 страницCC2800 62151 Part1 - encristhian100% (1)

- Removing and Installing Camshaft Drive Gear: ChapterДокумент6 страницRemoving and Installing Camshaft Drive Gear: ChapterDomonique BermanОценок пока нет

- Touareg R5 Setting TDCДокумент3 страницыTouareg R5 Setting TDCtidorОценок пока нет

- D3 A8 Front Sealing FlangeДокумент14 страницD3 A8 Front Sealing Flangecu52Оценок пока нет

- 55-1 Hood PDFДокумент11 страниц55-1 Hood PDFmefisto06cОценок пока нет

- Tailgate, (Wagon) : Assembly OverviewДокумент14 страницTailgate, (Wagon) : Assembly OverviewDenis RaudseppОценок пока нет

- Removing and Installing Cylinder Head (Cylinder Head Assembly) - ALLDATA Repair Vento 1.6ltsДокумент5 страницRemoving and Installing Cylinder Head (Cylinder Head Assembly) - ALLDATA Repair Vento 1.6ltsFran SanchezОценок пока нет

- Diagram Cylinder HeadДокумент4 страницыDiagram Cylinder Headwizardzx2Оценок пока нет

- Desmontaje Palier Skoda FabiaДокумент3 страницыDesmontaje Palier Skoda FabiaFrancisco José MarotoОценок пока нет

- Cylinder Head Removing and InstallingДокумент9 страницCylinder Head Removing and Installingblackj3ckОценок пока нет

- Removing and Installing Toothed BeltДокумент12 страницRemoving and Installing Toothed BeltJulien VasilevОценок пока нет

- Touareg R5 Alternator RemovalДокумент5 страницTouareg R5 Alternator RemovalJeff GordonОценок пока нет

- Aph 15 Cylinder Head Valvetrain BNДокумент65 страницAph 15 Cylinder Head Valvetrain BNRicarGliОценок пока нет

- UntitledДокумент4 страницыUntitledDomonique BermanОценок пока нет

- TCG 2016 Cylinder Head DismountingДокумент10 страницTCG 2016 Cylinder Head DismountingObrenovОценок пока нет

- 30-1 Clutch Mechanism ServiceДокумент22 страницы30-1 Clutch Mechanism Servicemefisto06cОценок пока нет

- Aph 13 Crankshaft Cylinder Block BNДокумент64 страницыAph 13 Crankshaft Cylinder Block BNGica HagiОценок пока нет

- A2 TorquesДокумент25 страницA2 TorquesGabriel CazacuОценок пока нет

- Renewing Valve Stem Oil Seals With Cylinder Head Installed: Special Tools and Workshop Equipment RequiredДокумент5 страницRenewing Valve Stem Oil Seals With Cylinder Head Installed: Special Tools and Workshop Equipment RequiredArkidОценок пока нет

- Demontare Caseta de DirectieДокумент8 страницDemontare Caseta de DirectieSerban SimiОценок пока нет

- Audi 100Документ93 страницыAudi 100Dalibor Angelovski100% (1)

- Cylinder HeadДокумент3 страницыCylinder HeadjorntangenОценок пока нет

- Audi A6 c5 TDI Timing BeltДокумент3 страницыAudi A6 c5 TDI Timing Beltamit kuziОценок пока нет

- Valve Gear - Exploded ViewДокумент5 страницValve Gear - Exploded ViewJulien VasilevОценок пока нет

- Audi Workshop Manuals - A3 Mk1 Installing GearboxДокумент8 страницAudi Workshop Manuals - A3 Mk1 Installing GearboxAlbertОценок пока нет

- Traducion SX125Документ13 страницTraducion SX125Ivan Gonzalez LopezОценок пока нет

- Engine Install PDFДокумент9 страницEngine Install PDFiveyОценок пока нет

- Mitsubishi Transfer Case Recall BulletinДокумент20 страницMitsubishi Transfer Case Recall BulletinSteven LewisОценок пока нет

- Desmontaje Filtro Particulas Skoda Fabia 1.6 TDIДокумент7 страницDesmontaje Filtro Particulas Skoda Fabia 1.6 TDIFrancisco José MarotoОценок пока нет

- Axial Detuner MaintenanceДокумент5 страницAxial Detuner MaintenanceKarthik ReddiarОценок пока нет

- Desarmado BrazoДокумент6 страницDesarmado Brazojuliocop02Оценок пока нет

- Check Valve TimingДокумент2 страницыCheck Valve Timingzozo0424Оценок пока нет

- TransmissionДокумент22 страницыTransmissionrefei100% (1)

- Removing and Installing 2Документ5 страницRemoving and Installing 2Russel CrowОценок пока нет

- 34-18 Transmission Remove & InstallДокумент21 страница34-18 Transmission Remove & Installmefisto06cОценок пока нет

- Aeg Cylinder Head Bentley GuideДокумент45 страницAeg Cylinder Head Bentley Guideryan sundeОценок пока нет

- Captiva 2008Документ197 страницCaptiva 2008yorjan alvarez dorado100% (1)

- Clutch Release Mechanism, Servicing: 1 - Transmission 2 - Ball Pivot PinДокумент12 страницClutch Release Mechanism, Servicing: 1 - Transmission 2 - Ball Pivot Pinmefisto06cОценок пока нет

- Rame 1Документ2 страницыRame 1vmiklenic1799Оценок пока нет

- Camshaft and Camshaft Adjusters Removing and InstallingДокумент9 страницCamshaft and Camshaft Adjusters Removing and InstallingpizandolaОценок пока нет

- 1991 Nissan-Datsun 240SX Cylinder Head RemovalДокумент11 страниц1991 Nissan-Datsun 240SX Cylinder Head Removalgigabyte3235840Оценок пока нет

- Renewing Oil Seal at Hall SenderДокумент5 страницRenewing Oil Seal at Hall SenderJulien VasilevОценок пока нет

- Desmontaje Suspensión Skoda FabiaДокумент6 страницDesmontaje Suspensión Skoda FabiaFrancisco José MarotoОценок пока нет

- Glow Plug SystemДокумент3 страницыGlow Plug SystemING. RUBENSОценок пока нет

- Removing EngineДокумент11 страницRemoving EngineValuableManualsОценок пока нет

- Brake Fluid ChangeДокумент8 страницBrake Fluid ChangeMichel FonsecaОценок пока нет

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesОт EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesРейтинг: 5 из 5 звезд5/5 (1)

- HondaДокумент55 страницHondaNisha GehlotОценок пока нет

- Financial Ratio Analysis of Indus MotorsДокумент31 страницаFinancial Ratio Analysis of Indus MotorsAli Husanen100% (1)

- MeetingДокумент3 страницыMeetingJanking Madriaga IОценок пока нет

- Technological Systems Compete at Otis: Hydraulic Versus Electric ElevatorsДокумент27 страницTechnological Systems Compete at Otis: Hydraulic Versus Electric ElevatorsAnne MillbrookeОценок пока нет

- Isa Presentation 2018Документ16 страницIsa Presentation 2018Fernando Ramalho MartinsОценок пока нет

- Designing Systems Visualisations For Decision SupportДокумент259 страницDesigning Systems Visualisations For Decision SupporterdaltekinОценок пока нет

- Aksa Master Pricelist 2014Документ1 страницаAksa Master Pricelist 2014Wissam JarmakОценок пока нет

- CM20181112 50357 30701Документ12 страницCM20181112 50357 30701vitaliyОценок пока нет

- Manual de AceitesДокумент329 страницManual de AceitesRomulo CalatayudОценок пока нет

- Top Gear - Alfa Romeo 145-2-0 Cloverleaf Alfa Romeo vs. Audi vs. BMW vs. Citroen vs. Fiat vs. Honda vs. Nissan vs. VW vs. Peugeot vs. Rover Vs - Seat vs. Vauxhall TESTДокумент17 страницTop Gear - Alfa Romeo 145-2-0 Cloverleaf Alfa Romeo vs. Audi vs. BMW vs. Citroen vs. Fiat vs. Honda vs. Nissan vs. VW vs. Peugeot vs. Rover Vs - Seat vs. Vauxhall TESTAriel IsaiasОценок пока нет

- Development of Additive ManufacturingДокумент10 страницDevelopment of Additive ManufacturingrhusheinОценок пока нет

- Mpps v16 Vehicle ListДокумент48 страницMpps v16 Vehicle Listvladimir_dungovskiОценок пока нет

- Sabar Group: Three Phase Cooling Tower MotorsДокумент2 страницыSabar Group: Three Phase Cooling Tower MotorsHrithik Sai TummalaОценок пока нет

- Summer ProjectДокумент63 страницыSummer ProjectAvinash Arjun SОценок пока нет

- This Study Resource Was: ContentДокумент9 страницThis Study Resource Was: ContentLakshani AkalankaОценок пока нет

- NCS Auto Mechanic RevisedДокумент56 страницNCS Auto Mechanic RevisedmarranОценок пока нет

- 33611B SUV & Light Truck Manufacturing in The US Industry ReportДокумент38 страниц33611B SUV & Light Truck Manufacturing in The US Industry ReportSubhash BabuОценок пока нет

- Automotive-Report-2020 TecAlliance v2.1.8 PDFДокумент64 страницыAutomotive-Report-2020 TecAlliance v2.1.8 PDFAndresОценок пока нет

- A Project Report On ExideДокумент90 страницA Project Report On ExidePiyush Bhardwaj100% (3)

- Rothaermel - 2021 - Chapter 1Документ40 страницRothaermel - 2021 - Chapter 1neyla tohacaОценок пока нет

- All The Information in The Brochure Is For Reference Only. Great Wall Motors Reserves The Right of Final InterpretationДокумент19 страницAll The Information in The Brochure Is For Reference Only. Great Wall Motors Reserves The Right of Final InterpretationUserfabian215Оценок пока нет

- Nissan Clay ModellingДокумент6 страницNissan Clay ModellingSohel KhanОценок пока нет

- Final Part 3Документ53 страницыFinal Part 3Alisha ChawlaОценок пока нет