Академический Документы

Профессиональный Документы

Культура Документы

11-Backfiling at Station No

Загружено:

Akhilesh KumarИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

11-Backfiling at Station No

Загружено:

Akhilesh KumarАвторское право:

Доступные форматы

JAIHIND PROJECTS LIMITED PROCEDURE

BACK FILING AT STATION

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

PROCEDURE FOR BACKFILLING AT STATION

JPL/GSPL/PNJPL/FTS -55

Date: 28th MAY 2007

DOCUMENT RELEASE AUTHORIZATION

JPL

BIBPL

DCIL

PREPARED BY

REVIEWED BY

CHECKED &

APPROVED BY

GSPL

APPROVED

Name:

Designation:

Signature:

Date:

BACKFILING ATSTATION

DOCUMENT No.

JPL/GSPL/PNJPL/FAS-55

REV

00

Page 1 of 1

BY

JAIHIND PROJECTS LIMITED PROCEDURE

BACK FILING AT STATION

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

Owner

: GUJARAT STATE PETRONET LTD.

Format: JPL/GSPL/PNJPL/FAS-46 17

Consultant

: DORSCH CONSULT (INDIA) PVT.LTD.

Revision : 1

TPIA

: BAXCOUNSCEL INSPECTION SUREAU PVT .LTD.

Contractor

: JAIHIND PROJECT LIMITED.

Project

Sr.

No

Date:

: PAGUTHAN NTPC JHANORE PIPELINE PROJECT.

Activity Description

Controlling

Specification

Acceptance Criteria

Verifying

Document

Frequency of

Insp./ Testing

Inspection Category

Issued as: CONTROLLED COPY

This document is the property of HCC and is copyright protected.

Unauthorized photocopy either partly or fully is prohibited. Authorized

controlled copy of this document can be had from Doc. Controller

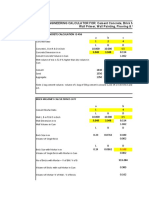

CONTENTS

SR. NO

DESCRIPTION

PAGE NO

1.

Purpose

2.

Reference

3.

Scope

3.

4.

Equipment

Material

Method

3&4

Tolerance

8

9

BACKFILING ATSTATION

Health, safety and Environment

Documentation

DOCUMENT No.

JPL/GSPL/PNJPL/FAS-55

4

4

REV

00

Page 1 of 1

Remarks

JAIHIND PROJECTS LIMITED PROCEDURE

BACK FILING AT STATION

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

PURPOSE

The purpose of this is to prepare guidelines / Methodology of Backfilling in

order to archive result as per tender specification.

2.

REFRENCE

GSPL specification Doc No:

3.

SCOPE

This procedure covers backfilling of pits and trenches for the foundation of

structures and the compaction of the backfill material.

4.

EQUIPMENTS

Compactor, Rammer, 10 ton vibration type roller, Moisture Meter, Oven,

Electric weight & Testing equipments (Proctor apparatus)

5.

MATERIAL

Accepted Material excavated from within the site area of from approved

borrow areas 20 mm to 40 mm crushed lock shall be graded with sufficient

fine material to ensure proper Binding of compaction.

6.

METHOD

6.1.1 Before starting the backfilling work, entire topsoil will be removed and

stockpiled in areas shown on the owners representatives drawings and

all others trees, bushes and other vegetations will also be removed.

6.1.2 Area will be stopped for a depth of 200mm and will be compacted to 95%

of the maximum density at OMC.

6.1.3 Accepted fill material will be carted through dumper, tractor trailer and

will be spread in uniform layers of 250mm with the help of suitable dozers.

6.1.4 Next backfill layers will be placed within 24 hours of moisture treatment

and compacted. Lab result of OMC & MDD shall be provided before

compaction. According to OMC, calculated quantity of water shall be

added & then required compaction shall be done.

6.1.5 For large areas of filling, approximately 18 Mtrs. Long and 4,.5 Mtrs. Wide

strips will be prepared for test purpose. Then this strip will be tested for

compaction either in lab or at site. After this test large areas will be

backfilled.

BACKFILING ATSTATION

DOCUMENT No.

JPL/GSPL/PNJPL/FAS-55

REV

00

Page 1 of 1

JAIHIND PROJECTS LIMITED PROCEDURE

BACK FILING AT STATION

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

6.1.6 Loose layer thickness will be 250 mm thick before compaction.

6.1.7 Backfilling of foundation pits and trenches will be carried out after

adequate strength has reached for foundations and structural work.

6.1.8 After spreading of backfill material, it will be watered and compacted in

layer not exceeding 150mm in depth, when compacted to achieve 95% of

the maximum dry density & moisture content within 2 % of OMC.

6.1.9 For compaction plate compactors and any other suitable compactors will

be used for achieving desired compaction.

6.1.10 Timber sheeting and other excavation supports will be removed as the

process of backfilling proceeds.

6.1.11 To prevent ponding of water, a system of temporary drainage will be

provided.

7.

TOLERANCE

As per Specification

8.

HEALTH, SAFETY AND ENVIRONMENT

1. PPE is a must in this activity

2. The Pits and trenches should be properly barricaded.

9.

DOCUMENTATION

Inspection Test Plan:

Inspection Report

Dry Density

JPL/GSPL/PNJPL/FAS :

JPL/GSPL/PNJPL/FAS:

JPL/GSPL/PNJPL/FAS -

Note: In case of any conflict between the requirements of this procedure and that

of the above referred specification the requirements of the latter shall govern,

until and unless specific intention is meant.

BACKFILING ATSTATION

DOCUMENT No.

JPL/GSPL/PNJPL/FAS-55

REV

00

Page 1 of 1

JAIHIND PROJECTS LIMITED PROCEDURE

BACK FILING AT STATION

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

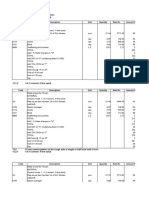

Owner

: GUJARAT STATE PETRONET LTD.

Format: JPL/GSPL/PNJPL/FAS-46 17

Consultant

: DORSCH CONSULT (INDIA) PVT.LTD.

Revision : 1

TPIA

: BAXCOUNSCEL INSPECTION SUREAU PVT .LTD.

Contractor

: JAIHIND PROJECT LIMITED.

Project

: PAGUTHAN NTPC JHANORE PIPELINE PROJECT.

Sr.

No

Submission & Obtaining

approval of procedure

Recording of levels prior to

backfilling

Controlling

Specification

Acceptance Criteria

Contract

Specification

1013-113-202

Approved

Procedure HCC

NOVA P 46 17 11

Approved

Procedure HCC

NOVA P 46 17 11

Approved

Procedure HCC

NOVA P 46 17 11

Approved

Procedure HCC

NOVA P 46 17 11

Approved

Procedure HCC

NOVA P 46 17 11

Approved

Procedure HCC

NOVA P 46 17 11

Approved

Procedure HCC

NOVA P 46 17 11

Contract

Specification

1013-113-202

Approved

Procedure HCC

NOVA P 46 17 11

Approved

Procedure HCC

NOVA P 46 17 11

Approved

Procedure HCC

NOVA P 46 17 11

Approved

Procedure HCC

NOVA P 46 17 11

Approved

Procedure HCC

NOVA P 46 17 11

Approved

Procedure HCC

NOVA P 46 17 11

Approved

Procedure HCC

NOVA P 46 17 11

Activity Description

Date:

Selection and approval of

materials and determination

of OMC, MDD & Others

Pre watering and leveling of

first layer, watering and

compaction

Density tests / Degree of

Compaction

Leveling of Subsequent

layers till required level is

achieved

Removal of timbers supports

if any

Safety

Legend

W : Witness

H : Hold

RM : Random Inspection

R : Review Documents

Verifying

Document

Inspection Category

Frequency of

Insp./ Testing

TPIA

DCIL/

GSPL

Approved

Procedure

At the

Beginning

AP

AP

HCC NOVA F

46 17 11-01

Prior to

Backfilling

RM

RM

Source

Approval

At the

Beginning

RM

W/R

HCC NOVA F

46 17 11-01

Every Layer

RM

RM

HCC NOVA F

46 17 11-02

Every Layer

RM

RM

HCC NOVA F

46 17 11-01

For Final

Layer

RM

RM

HCC NOVA F

46 17 11-01

At the

Beginning

RM

RM

HCC NOVA F

46 17 11-01

RM

RM

I

: Implementation

AP : Acceptance/Approval

For JPL

For BIBPL

For DCIL / GSPL

Name:

Name:

Name:

Sign:

Sign:

Sign:

Date:

Date:

Date:

BACKFILING ATSTATION

JPL

DOCUMENT No.

JPL/GSPL/PNJPL/FAS-55

REV

00

Page 1 of 1

Remarks

JAIHIND PROJECTS LIMITED PROCEDURE

BACK FILING AT STATION

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

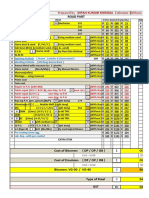

Owner

: GUJARAT STATE PETRONET LTD.

Format: JPL/GSPL/PNJPL/FAS-

Consultant

: DORSCH CONSULT (INDIA) PVT.LTD.

Revision : 1

TPIA

: BAXCOUNSCEL INSPECTION SUREAU PVT .LTD.

Contractor

: JAIHIND PROJECT LIMITED.

Project

Date:

: PAGUTHAN NTPC JHANORE PIPELINE PROJECT.

Observation

SL

No

Description

Recording of levels prior to

backfilling

Pre watering and leveling

of first layer, watering and

compaction

Density tests / Degree of

Compaction

Leveling of Subsequent

layers till required level is

achieved

Removal of timbers supports

if any

Safety

Yes/Ok

For JPL

Name:

Sign:

Date:

Owner

For BIBPL

Name:

Sign:

Date:

: GUJARAT STATE PETRONET LTD.

BACKFILING ATSTATION

DOCUMENT No.

JPL/GSPL/PNJPL/FAS-55

No

Remarks

N/A

For DCIL / GSPL

Name:

Sign:

Date:

Format: JPL/GSPL/PNJPL/FAS-

REV

00

Page 1 of 1

JAIHIND PROJECTS LIMITED PROCEDURE

BACK FILING AT STATION

PROJECT: NTPC JHANORE GAS PIPELINE PROJECT

Consultant

TPIA

Contractor

Project

: DORSCH CONSULT (INDIA) PVT.LTD.

Revision : 1

: BAXCOUNSCEL INSPECTION SUREAU PVT .LTD. Date:

: JAIHIND PROJECT LIMITED.

: PAGUTHAN NTPC JHANORE PIPELINE PROJECT.

Inspection date:

Location:

Spread:

From ________To_________

S No

Activity / description

Sample 1

1

Weight of core cutter + wet soil (Ws) gm

2

Weight of core cutter (We). gm

Weight of wet soil (Ws - We) gm

Volume of core cutter (Ve) cm3

Bulk density (BD = (Ws - We)/ve) gm/cm3

Water content container no

Weight of container with lid (W1) gm

Weight of container with lid and wet soil (W2) gm

Weight of container with lid and Dry soil (W3), gm

Water content (W), percent

W = {(W2-W3) x [ 100 / (W3 W1)}

Field Dry Density

FDD= 100 x BD / (100 + W) in gram / cc

Lab Dry Density gram / CC

Lab.OMC %

Percentage of field DD in respect of lab

DD = FDD x 100

MDD

Laboratory dry density in grms / cc

10

11

12

13

14

Layer:

Sample 2

Sample 3

Sample 4

Remarks:

For JPL

For BIBPL

For DCIL / GSPL

Name:

Name:

Name:

Sign:

Sign:

Sign:

Date:

Date:

Date:

BACKFILING ATSTATION

DOCUMENT No.

JPL/GSPL/PNJPL/FAS-55

REV

00

Page 1 of 1

Вам также может понравиться

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDДокумент16 страницProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarОценок пока нет

- Load Sheet 1Документ14 страницLoad Sheet 1kapilОценок пока нет

- DomasДокумент3 страницыDomasPOC TELKOMSELОценок пока нет

- No. of Rebars: 1/3 of Clear Span 1/3 of Clear SpanДокумент2 страницыNo. of Rebars: 1/3 of Clear Span 1/3 of Clear SpanNelОценок пока нет

- 1 E 2401 Expansion Joint Stability Analaysis Report - Rev0 inДокумент141 страница1 E 2401 Expansion Joint Stability Analaysis Report - Rev0 inFelipeОценок пока нет

- Civil Engg Work Qty Calculator 1 Sept 21Документ8 страницCivil Engg Work Qty Calculator 1 Sept 21Tahseen KhanОценок пока нет

- RE500 Fastening With Rebar (SEP 2011)Документ60 страницRE500 Fastening With Rebar (SEP 2011)Homer DongОценок пока нет

- DAR 2021 Vol 2 CompressedДокумент1 710 страницDAR 2021 Vol 2 Compresseder.ankitnegi1988Оценок пока нет

- NH Sor 6TH Revision 2018 Combine PDFДокумент170 страницNH Sor 6TH Revision 2018 Combine PDFM/s Gogoi AssociatesОценок пока нет

- Lot 1 - Expansion Civil WorksДокумент6 страницLot 1 - Expansion Civil WorksJethro AbanadorОценок пока нет

- Drip Irrigation SheetДокумент2 страницыDrip Irrigation Sheetnarasimma8313Оценок пока нет

- Data BookДокумент66 страницData Bookvishnukesavieam10% (1)

- Measurement Sheet - Site Construction - Ra01xlsДокумент1 страницаMeasurement Sheet - Site Construction - Ra01xlsUmamaheshwarrao VarmaОценок пока нет

- Guidelines For Excavation Works in The Vicinity of MV and LV CablesДокумент9 страницGuidelines For Excavation Works in The Vicinity of MV and LV CablesNehal Aladdin Ibrahim100% (1)

- 2013-2014 ADMITTED BATCH: 1 & 2 Year Course StructureДокумент58 страниц2013-2014 ADMITTED BATCH: 1 & 2 Year Course StructureGanesh PeketiОценок пока нет

- Product Manual For Pressed Ceramic Tiles ACCORDING TO IS 15622: 2017Документ13 страницProduct Manual For Pressed Ceramic Tiles ACCORDING TO IS 15622: 2017Abhijit KarpeОценок пока нет

- QCT For GSB (Formets)Документ123 страницыQCT For GSB (Formets)Bilal Ahmed BarbhuiyaОценок пока нет

- Block 74-A Champawat-A - RateAnalysis - MORTHДокумент477 страницBlock 74-A Champawat-A - RateAnalysis - MORTHBhawan Bisht100% (1)

- Item Rate Boq: Discount Percentage (%) Discount Amount Total Amount of Schedule A & BДокумент16 страницItem Rate Boq: Discount Percentage (%) Discount Amount Total Amount of Schedule A & BPratik GuptaОценок пока нет

- Division 1 - General RequirementsДокумент2 страницыDivision 1 - General RequirementsHOFFERОценок пока нет

- Salitex Expansion Joint Filler BoardДокумент2 страницыSalitex Expansion Joint Filler BoardSandipОценок пока нет

- Carrying Out Geo Technical Investigation FOR: An Iso 9001-2008.iso 17025 Certified CompaniesДокумент30 страницCarrying Out Geo Technical Investigation FOR: An Iso 9001-2008.iso 17025 Certified CompaniesAaron WilsonОценок пока нет

- Ramp CalculationДокумент15 страницRamp CalculationHerlina KartikaОценок пока нет

- Waterproofing Treatment and Installation Work Procedure FOR SRA - 03 Raj InfiniaДокумент6 страницWaterproofing Treatment and Installation Work Procedure FOR SRA - 03 Raj InfiniaThink itОценок пока нет

- Current Rate of Building MaterialsДокумент6 страницCurrent Rate of Building MaterialsHari PrasadОценок пока нет

- Idssp Accelerated ProgrammeДокумент3 страницыIdssp Accelerated Programmeedla3710Оценок пока нет

- Dear All, I Edited and Collected Links For IS Codes, IRC Etc From Following Links On Date 20-March-2009Документ16 страницDear All, I Edited and Collected Links For IS Codes, IRC Etc From Following Links On Date 20-March-2009aymmon8950Оценок пока нет

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDДокумент14 страницProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarОценок пока нет

- Checking Est. 2018 (115) 9th Pur Pakur (14.10.20) SDH GSTДокумент454 страницыChecking Est. 2018 (115) 9th Pur Pakur (14.10.20) SDH GSTAchintya DasОценок пока нет

- Design BasicДокумент10 страницDesign BasicAlpesh ShahОценок пока нет

- Road EstimateДокумент2 страницыRoad EstimateCarlos Valverde PortillaОценок пока нет

- CSR 16-17 Amt (1) - 1Документ283 страницыCSR 16-17 Amt (1) - 1Jawed PathanОценок пока нет

- PaintingДокумент6 страницPaintingAkhilesh KumarОценок пока нет

- Courier: Structcon Designs Pvt. Ltd. Structcon Designs Pvt. Ltd. Structcon Designs Pvt. Ltd. Structcon Designs Pvt. LTDДокумент1 страницаCourier: Structcon Designs Pvt. Ltd. Structcon Designs Pvt. Ltd. Structcon Designs Pvt. Ltd. Structcon Designs Pvt. LTDpravinОценок пока нет

- 2073-074 Rate AnalysisДокумент40 страниц2073-074 Rate AnalysisŔàju YadavОценок пока нет

- Site Photos For Treatment To Expansion Joint PDFДокумент4 страницыSite Photos For Treatment To Expansion Joint PDFRohil JulaniyaОценок пока нет

- Quality Control - Works Inspection: Modular False CeilingДокумент2 страницыQuality Control - Works Inspection: Modular False CeilingParasОценок пока нет

- S.No DIA Unit WT of Bar WT (Act) WT (The) Differ Weight (KG) Incrg (DIA) % of WT IncrgДокумент2 страницыS.No DIA Unit WT of Bar WT (Act) WT (The) Differ Weight (KG) Incrg (DIA) % of WT IncrgAtulJainОценок пока нет

- 04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTAДокумент5 страниц04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTAjay2kay5793Оценок пока нет

- CPWD Dar Vol II 14092023 CivilДокумент1 149 страницCPWD Dar Vol II 14092023 CivilNizar AhamedОценок пока нет

- Cost Analysis For Brick WorkДокумент14 страницCost Analysis For Brick WorkVittal Kumar50% (2)

- Steel Calculator & Angle CalculatorДокумент4 страницыSteel Calculator & Angle CalculatorKamran AnjumОценок пока нет

- 2BHK Contract Estimate Template Version 1.1Документ12 страниц2BHK Contract Estimate Template Version 1.1himmatchavanОценок пока нет

- Chemrite - 520 M NEWДокумент2 страницыChemrite - 520 M NEWghazanfarОценок пока нет

- Fire Proof PlasterДокумент1 страницаFire Proof PlasterMuhammad Sarmad SonyalОценок пока нет

- BSRДокумент92 страницыBSRAfrath_nОценок пока нет

- C1 - Checklist For EarthworksДокумент46 страницC1 - Checklist For EarthworksPetals ParadiseОценок пока нет

- Method Statement: Underground Waterproofing Using Hdpe Waterproofing System From FosrocДокумент10 страницMethod Statement: Underground Waterproofing Using Hdpe Waterproofing System From Fosrocdindo lauronОценок пока нет

- Proedure For PlasteringДокумент4 страницыProedure For PlasteringAkhilesh KumarОценок пока нет

- BC BM WMM DBM GSBДокумент8 страницBC BM WMM DBM GSBRavishankar HobannaОценок пока нет

- 29 - Mix Design With Fly Ash For G40 ConcreteДокумент2 страницы29 - Mix Design With Fly Ash For G40 ConcreteAmila KulasooriyaОценок пока нет

- Procedure For ScafoldingДокумент4 страницыProcedure For ScafoldingAkhilesh KumarОценок пока нет

- Sor CivilДокумент33 страницыSor CivilYugal Pandey Sonu100% (1)

- Building Regs Part LДокумент59 страницBuilding Regs Part Ldropkick94Оценок пока нет

- Brick Frog Mark: Date of Sampling Date of Testing Tested As PerДокумент1 страницаBrick Frog Mark: Date of Sampling Date of Testing Tested As PersubhaschandraОценок пока нет

- Civil Work - CONCRETE GRADE - M5 1 - 4 - 8 M10 1 - 3 - 6 M15 1 - 2 - 4 M20 PDFДокумент6 страницCivil Work - CONCRETE GRADE - M5 1 - 4 - 8 M10 1 - 3 - 6 M15 1 - 2 - 4 M20 PDFArjun S SanakanОценок пока нет

- SF - RE500 + G500 Rebar (Sep2015)Документ88 страницSF - RE500 + G500 Rebar (Sep2015)Wesleykit WongОценок пока нет

- Chemical Anchor Re500Документ3 страницыChemical Anchor Re500Pratheesh PrasannanОценок пока нет

- 12 Form WorkДокумент7 страниц12 Form WorkAkhilesh KumarОценок пока нет

- 06-Earthwork in ExcavationДокумент7 страниц06-Earthwork in ExcavationAkhilesh KumarОценок пока нет

- PlasteringДокумент56 страницPlasteringAkhilesh KumarОценок пока нет

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDДокумент14 страницProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarОценок пока нет

- FlooringДокумент10 страницFlooringAkhilesh KumarОценок пока нет

- PaintingДокумент6 страницPaintingAkhilesh KumarОценок пока нет

- Api 571Документ8 страницApi 571Akhilesh KumarОценок пока нет

- False CeilingДокумент48 страницFalse CeilingAkhilesh KumarОценок пока нет

- ConcretingДокумент28 страницConcretingAkhilesh KumarОценок пока нет

- Back FillingДокумент70 страницBack FillingAkhilesh KumarОценок пока нет

- WaterproofingДокумент5 страницWaterproofingAkhilesh KumarОценок пока нет

- Chainlink FencingДокумент56 страницChainlink FencingAkhilesh KumarОценок пока нет

- Anti TermiteДокумент30 страницAnti TermiteAkhilesh KumarОценок пока нет

- Brick MasonaryДокумент80 страницBrick MasonaryAkhilesh KumarОценок пока нет

- 12 Form WorkДокумент7 страниц12 Form WorkAkhilesh KumarОценок пока нет

- Procedure For Plumbing Sanitary WorkДокумент5 страницProcedure For Plumbing Sanitary WorkAkhilesh Kumar100% (1)

- 15 ConcretingДокумент22 страницы15 ConcretingAkhilesh KumarОценок пока нет

- Procedure For Roof Water ProofingДокумент4 страницыProcedure For Roof Water ProofingAkhilesh KumarОценок пока нет

- Procedure For Road WorkДокумент5 страницProcedure For Road WorkAkhilesh KumarОценок пока нет

- Procedure For Fencing WorksДокумент3 страницыProcedure For Fencing WorksAkhilesh KumarОценок пока нет

- 06-Earthwork in ExcavationДокумент7 страниц06-Earthwork in ExcavationAkhilesh KumarОценок пока нет

- Procedure For RCCДокумент3 страницыProcedure For RCCAkhilesh KumarОценок пока нет

- Procedure For Horticulture WorksДокумент4 страницыProcedure For Horticulture WorksAkhilesh KumarОценок пока нет

- Procedure For PVC DoorsДокумент3 страницыProcedure For PVC DoorsAkhilesh KumarОценок пока нет

- Procedure For Flooring WorksДокумент4 страницыProcedure For Flooring WorksAkhilesh Kumar0% (1)

- Procedure For Aluminum Door Window and VentilatorsДокумент3 страницыProcedure For Aluminum Door Window and VentilatorsAkhilesh KumarОценок пока нет

- Materials Concrete Mix TestingДокумент5 страницMaterials Concrete Mix TestingAkhilesh KumarОценок пока нет

- Procedure For Antitermite TreatmentДокумент4 страницыProcedure For Antitermite TreatmentAkhilesh KumarОценок пока нет

- Procedure For Area Grading and Development WorksДокумент3 страницыProcedure For Area Grading and Development WorksAkhilesh KumarОценок пока нет

- False Ceiling Proc.Документ4 страницыFalse Ceiling Proc.Akhilesh KumarОценок пока нет

- Muscular System Coloring Book: Now You Can Learn and Master The Muscular System With Ease While Having Fun - Pamphlet BooksДокумент8 страницMuscular System Coloring Book: Now You Can Learn and Master The Muscular System With Ease While Having Fun - Pamphlet BooksducareliОценок пока нет

- Tours and Travel MNGTДокумент16 страницTours and Travel MNGTArpita Jaiswal100% (5)

- Granulometry of ClinkerДокумент18 страницGranulometry of ClinkerNael100% (12)

- Veris Case StudyДокумент2 страницыVeris Case StudyPankaj GargОценок пока нет

- RAMSCRAM-A Flexible RAMJET/SCRAMJET Engine Simulation ProgramДокумент4 страницыRAMSCRAM-A Flexible RAMJET/SCRAMJET Engine Simulation ProgramSamrat JanjanamОценок пока нет

- Merchant Accounts Are Bank Accounts That Allow Your Business To Accept Card Payments From CustomersДокумент43 страницыMerchant Accounts Are Bank Accounts That Allow Your Business To Accept Card Payments From CustomersRohit Kumar Baghel100% (1)

- Miso Soup Miso Soup Miso Soup: Ingredients Ingredients IngredientsДокумент8 страницMiso Soup Miso Soup Miso Soup: Ingredients Ingredients IngredientsEllie M.Оценок пока нет

- Financial/ Accounting Ratios: Sebi Grade A & Rbi Grade BДокумент10 страницFinancial/ Accounting Ratios: Sebi Grade A & Rbi Grade Bneevedita tiwariОценок пока нет

- VISCOLAM202 D20 Acrylic 20 Thickeners 202017Документ33 страницыVISCOLAM202 D20 Acrylic 20 Thickeners 202017Oswaldo Manuel Ramirez MarinОценок пока нет

- 4th Conference ParticipantsДокумент14 страниц4th Conference ParticipantsmaxОценок пока нет

- PCI Secure Software Standard v1 - 0Документ67 страницPCI Secure Software Standard v1 - 0Antonio ClimaОценок пока нет

- SAP IAG Admin GuideДокумент182 страницыSAP IAG Admin GuidegadesigerОценок пока нет

- Digital-To-Analog Converter - Wikipedia, The Free EncyclopediaДокумент8 страницDigital-To-Analog Converter - Wikipedia, The Free EncyclopediaAnilkumar KubasadОценок пока нет

- Flyweis Services Pvt. LTDДокумент11 страницFlyweis Services Pvt. LTDFlyweis TechnologyОценок пока нет

- User Manual - Wellwash ACДокумент99 страницUser Manual - Wellwash ACAlexandrОценок пока нет

- Local, Local Toll and Long Distance CallingДокумент2 страницыLocal, Local Toll and Long Distance CallingRobert K Medina-LoughmanОценок пока нет

- Provable Security - 8th International Conference, ProvSec 2014Документ364 страницыProvable Security - 8th International Conference, ProvSec 2014alahbarОценок пока нет

- Kharrat Et Al., 2007 (Energy - Fuels)Документ4 страницыKharrat Et Al., 2007 (Energy - Fuels)Leticia SakaiОценок пока нет

- Belimo ARB24-SR Datasheet En-UsДокумент2 страницыBelimo ARB24-SR Datasheet En-Usian_gushepiОценок пока нет

- My Report in Assessment 1Документ67 страницMy Report in Assessment 1Eddie Wilson BroquezaОценок пока нет

- Bajaj Allianz General Insurance CompanyДокумент4 страницыBajaj Allianz General Insurance Companysarath potnuriОценок пока нет

- Topic 3 Module 2 Simple Annuity (Savings Annuity and Payout Annuity)Документ8 страницTopic 3 Module 2 Simple Annuity (Savings Annuity and Payout Annuity)millerОценок пока нет

- Spermatogenesis: An Overview: Rakesh Sharma and Ashok AgarwalДокумент25 страницSpermatogenesis: An Overview: Rakesh Sharma and Ashok Agarwalumar umarОценок пока нет

- 12 Layer PCB Manufacturing and Stack Up OptionsДокумент12 страниц12 Layer PCB Manufacturing and Stack Up OptionsjackОценок пока нет

- Amazon Tax Information InterviewДокумент2 страницыAmazon Tax Information Interviewasad nОценок пока нет

- Consumer PresentationДокумент30 страницConsumer PresentationShafiqur Rahman KhanОценок пока нет

- Ref Drawing 2. Ref Code: 3. Design DatasДокумент3 страницыRef Drawing 2. Ref Code: 3. Design DatasJoe Nadakkalan100% (3)

- GRADE 1 MUSIC Week 1 Learning PacketsДокумент16 страницGRADE 1 MUSIC Week 1 Learning PacketsQuennie Rose EderОценок пока нет

- Teacher Resource Disc: Betty Schrampfer Azar Stacy A. HagenДокумент10 страницTeacher Resource Disc: Betty Schrampfer Azar Stacy A. HagenRaveli pieceОценок пока нет

- What Is An InfographicДокумент4 страницыWhat Is An InfographicAryaaaОценок пока нет