Академический Документы

Профессиональный Документы

Культура Документы

Heavy Lift AIM

Загружено:

anandakoeАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Heavy Lift AIM

Загружено:

anandakoeАвторское право:

Доступные форматы

HEAVYLIFTANALYSIS

HEAVY

LIFT ANALYSIS

USINGMULTITIERRIGGINGSYSTEM

PresentedinSciCOP

March30th ,2012

Presentedby:

ABRAHAMIMAMMUTTAQIN

PRESENTATIONOUTLINE

CriticalLiftPlanning

Critical Lift Check List

CriticalLiftCheckList

HeavyLiftandItsAssociatedDesignTasks

LiftingArrangement

Ri i A

RiggingArrangement

t

3DComputerModel

MethodologyofDefiningLiftPointsLocation

SlingLoadsCalculationResult

UnityCheckandMaxDeflectionSummary

Miscellaneous Calculation

MiscellaneousCalculation

Summary

CRITICALLIFTPLANNING

WHATISTHECHECKLISTFORCRITICALLIFT?

HEAVYLIFTANDITSASSOCIATEDDESIGNTASKS

HEAVYLIFTUSINGMULTITIERRIGGINGSYSTEM

LIFTINGARRANGEMENT(PLANVIEW)

Check this !

LIFTINGARRANGEMENT(ELEVATIONVIEW)

Check this !

CRANEBARGE MOORINGARRANGEMENT

RIGGINGARRANGEMENT

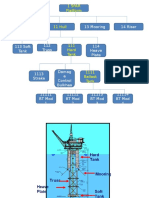

3DCOMPUTERMODEL

10

COMPUTERMODEL(CONTD)

38.5 M

54 M

See the breakdown !

11

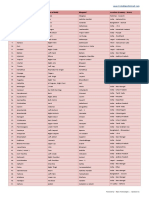

LIFTWEIGHTBREAKDOWNDETAILS

ITEM

1

FINAL WEIGHT

(MT)

FINAL WEIGHT (MT),

(incl. 10% cont. factor, for lifting

analysis and AH II lifting wt)

1003.14

1103.45

1003.14

1103.45

4.067

4.47

74.60

82.06

2.050

2.26

36.200

39.82

116.92

128.61

Instrument Items

Field run & support

1.92

2.00

Electrical Items

Lighting & Receptacle Supports

Field run supports

Cable Ladder Supports

Cable ladder

Sub-total

1.78

1.43

19.98

2.70

25.89

1.96

1.57

21.98

2.97

28.48

Scaffolding

Scaffolding below JM

13.80

15.18

1161.67

1277.72

DESCRIPTION

Structural, includes;

Primary framing & node

Secondary framing & equip. support

D k iinfill

Deck

fill lleg (12 nos.))

Crane pedestal

Deck plating

Drain box and support trimmers

Handrailing & stair landing

Sub-total

Piping spool & supports

Piping Spools

Pipe supports (below JM) for Area-E1,

Area-E2, portion of Area-E3 & portion of

Area-E4

Pipe

p supports

pp

on top

p of JM

Added pipe supports to replace scaffold

weight allocation

Sub-total

TOTAL WT. JM SECTION

12

METHODOLOGYOFDEFININGLIFTPOINTSLOCATION

To have equal loads on

the slings,

slings Roller Sheave

shall be installed at this

points !

KEY NOTE : TO HAVE AN EQUAL LOAD ON THE SLINGS, ANGLE7 = ANGLE8

(WHICH ENABLED SLING TENSION EQUALISATION FOR THE DOUBLED SLINGS)

13

ROLLERSHEAVEDETAILS

14

SLINGLOADSCALCULATIONRESULT

PAIR SLINGS MUST

HAVE EQUAL LOADS !

15

UNITYCHECK RESULT

The maximum deflection is found 180mm at joint 350

while the deflection at lift point (j

(joint 237)) is 116mm.

Hence, the actual deflection at structure during

stacking is 64mm.

MEMBER

NO.

SECTION

UNITY

CHECK

(MAX.)

431

PG1600 x 628

0.75

2091

PG1600 x 628

0.75

2090

PG1600 x 628

0.56

2094

PG1600 x 628

0.61

2093

PG1600 x 628

0.78

2097

PG1600 x 628

0.52

2063

PG1600 x 490

0.59

2060

PG1600 x 490

0 62

0.62

2072

PG1600 x 490

0.63

2074

PG1600 x490

0.63

16

MISCELLANEOUSCALCULATION

17

THELIFTINGPROCESS

18

SUMMARY

Properselectionofriggingschemeforgivenmodulestructureand

designofliftpointsisESSENTIALforsuccessfulliftinstallation

Flexible module requires more lift points (in this case is SIX lift

Flexiblemodulerequiresmoreliftpoints(inthiscaseisSIXlift

points)tobeprovidedsuchthatariggingsystemwithmultipletiers

ofdoubledslingsminimizedtheDISTORTIONduringlifting

Examples :

Examples:

MalampayaWeatherDeckrequirestwelves(12)liftpoints

(Decksize45mWx90mL,LiftWeight=1100MT)

JMPTTPArthitDeckrequiressix(6)liftpoints

(Decksize38.5mWx54mL,LiftWeight=1279MT)

ThesheavesystemmustbeSMOOTHwhichminimizethefrictional

effectonthedoubledslings

Rollersheavesystemgivesbenefitofoptimizedtheriggingsystem

insteadofusingspreaderbeam/frameanddemonstratesbetter

structuralbehaviour

19

Вам также может понравиться

- Rigging Study Lifting Study - 2017 HaGun Training+Документ48 страницRigging Study Lifting Study - 2017 HaGun Training+Gunawan100% (3)

- Crosby Rigging EquipmentДокумент20 страницCrosby Rigging EquipmentJason MillerОценок пока нет

- Basic Rigging Engineer HaGunДокумент19 страницBasic Rigging Engineer HaGunGunawan HaGun100% (4)

- Lifting Plan GuidelinesДокумент45 страницLifting Plan GuidelinesFerry H. Sitohang100% (5)

- My Industrial Rigging and CranesДокумент203 страницыMy Industrial Rigging and CranesJShearer67% (6)

- Lifting Plan OverviewДокумент10 страницLifting Plan Overviewrery1985100% (2)

- LiftingДокумент52 страницыLiftingRenish Regi100% (1)

- Specialized RiggingДокумент90 страницSpecialized Riggingjr_mcmillin88% (8)

- Crane Rigging Exercise by Kiewit - LiteratureДокумент50 страницCrane Rigging Exercise by Kiewit - LiteratureJogi Oscar Sinaga100% (1)

- Rigging CaculationДокумент3 страницыRigging Caculationegyinspectoryahoo100% (4)

- Mammoet & LEEA Rigging and Planning ManualДокумент67 страницMammoet & LEEA Rigging and Planning ManualRab Frame88% (26)

- Rigging CalculationДокумент11 страницRigging CalculationSyafiq Halim100% (5)

- Rigging GuideДокумент4 страницыRigging Guidemanufighter100% (3)

- Basic Rigging EngineerДокумент1 страницаBasic Rigging EngineerGunawan HaGun86% (7)

- A Guide To Rigging 1-174Документ173 страницыA Guide To Rigging 1-174S Anantha Prasanna Venkatesh96% (27)

- Rigging PracticesДокумент58 страницRigging Practicesravi00098Оценок пока нет

- Rigging Study Lifting Study - TW FKMTSI Tarakan 2013Документ52 страницыRigging Study Lifting Study - TW FKMTSI Tarakan 2013Gunawan HaGun93% (15)

- Training Rigging EngineersДокумент25 страницTraining Rigging Engineersa_roghib100% (3)

- 8 Vessel Upending Techniques For Lift Planners & Rigging EngineersДокумент15 страниц8 Vessel Upending Techniques For Lift Planners & Rigging EngineersLiftec Eirl GruerosОценок пока нет

- Tec Test Appointed Person A61Документ10 страницTec Test Appointed Person A61ambaroscuro50% (2)

- Safe Rigging PracticesДокумент86 страницSafe Rigging Practicesmagantiramudu94% (33)

- HaGun Rigging Study and Lifting StudyДокумент110 страницHaGun Rigging Study and Lifting StudyGunawan HaGun100% (9)

- Rigging and Lifting Handbook SampleДокумент26 страницRigging and Lifting Handbook Samplemohan100% (1)

- HEAVY LIFT TH89 - The Mechanics of A Super LiftДокумент62 страницыHEAVY LIFT TH89 - The Mechanics of A Super LiftAris100% (1)

- Handbook in Rigging and LiftingДокумент50 страницHandbook in Rigging and LiftingGunawan Hagun100% (2)

- Crane & Rigging SafetyДокумент38 страницCrane & Rigging Safetybeneesetas100% (6)

- Rigging HandbookДокумент123 страницыRigging Handbookhelp100% (2)

- RiggingДокумент30 страницRiggingFarhanОценок пока нет

- Rigging Safety Training FINALДокумент70 страницRigging Safety Training FINALpammu1886% (14)

- Lifting Plan - 3800 Series DraftДокумент3 страницыLifting Plan - 3800 Series Draftjesusgameboy100% (1)

- Sample Lifting Plan and Rigging StudyДокумент13 страницSample Lifting Plan and Rigging StudyKhawaja Arslan Ahmed85% (13)

- Crane Rigger HandbookДокумент140 страницCrane Rigger Handbookmfxl2997% (32)

- Heavy Lift PresentationДокумент46 страницHeavy Lift PresentationFasil Paruvanath100% (1)

- Lift PlanДокумент44 страницыLift PlanKasolo Hassan100% (3)

- BP HBK 76100 00001 PDFДокумент424 страницыBP HBK 76100 00001 PDFCodrut Coicea100% (2)

- Rigging TechniquesДокумент184 страницыRigging TechniquesAAlmeidas86% (7)

- Boiler Unloading Lifting Plan 29.11.2022Документ7 страницBoiler Unloading Lifting Plan 29.11.2022tfpl hseОценок пока нет

- Construction Cranes PPT v.05.18.15Документ32 страницыConstruction Cranes PPT v.05.18.15yazardОценок пока нет

- Lifting & Rigging PR67POGC001Документ82 страницыLifting & Rigging PR67POGC001behnam197100% (1)

- Wire Rope Sling Handbook - WireRopeSlingGuide1-09cДокумент28 страницWire Rope Sling Handbook - WireRopeSlingGuide1-09cRoberto Alleyne100% (3)

- Hoisting and RiggingДокумент170 страницHoisting and Riggingjr_mcmillin100% (5)

- Critical Lift PlanДокумент3 страницыCritical Lift PlanRafaqat AliОценок пока нет

- CraneДокумент71 страницаCraneNithin Kannan100% (1)

- Three-Dimensional Crane Modelling and ControlДокумент9 страницThree-Dimensional Crane Modelling and ControlAna MusraОценок пока нет

- ManualДокумент2 страницыManualGkkОценок пока нет

- SC-251 - Design of Guidance Systems For Lifting and PlacementДокумент68 страницSC-251 - Design of Guidance Systems For Lifting and PlacementSantanuОценок пока нет

- Design of Mechatronics SystemsДокумент29 страницDesign of Mechatronics SystemsReza Maliki AkbarОценок пока нет

- ProjectДокумент17 страницProjectRavi ChotaliyaОценок пока нет

- Computer Aided DesignДокумент45 страницComputer Aided Designsirajudeen IОценок пока нет

- Quick-Return Mechanism Design and Analysis ProjectsДокумент16 страницQuick-Return Mechanism Design and Analysis ProjectsMahesh Daxini ThakkerОценок пока нет

- Design and Analysis of Hydraulic Scissor LiftДокумент47 страницDesign and Analysis of Hydraulic Scissor LiftAnkit MandalОценок пока нет

- Advanced Simulation of Tower Crane Operation Utilizing System Dynamics Modeling and Lean PrinciplesДокумент10 страницAdvanced Simulation of Tower Crane Operation Utilizing System Dynamics Modeling and Lean Principlessuresh_501Оценок пока нет

- Bridge Seismic Design Csi Sap 2000Документ97 страницBridge Seismic Design Csi Sap 2000jrobert123321100% (5)

- Quick-Return Mechanism Design and Analysis Project PDFДокумент16 страницQuick-Return Mechanism Design and Analysis Project PDFرضا حسنОценок пока нет

- Computer Application in Mining Ii Part 1Документ56 страницComputer Application in Mining Ii Part 1Isha IssahОценок пока нет

- Design and Analysis of Screw ConveyorДокумент21 страницаDesign and Analysis of Screw Conveyoravinash1987Оценок пока нет

- Lecture 1: Introduction To Aircraft DesignДокумент61 страницаLecture 1: Introduction To Aircraft DesignAgostino De GiuseppeОценок пока нет

- 2 Ce 4Документ29 страниц2 Ce 4Sankalp AgrawalОценок пока нет

- Jcninp Load - WHT-BH2Документ1 страницаJcninp Load - WHT-BH2anandakoeОценок пока нет

- UC RangeДокумент2 страницыUC RangeanandakoeОценок пока нет

- 1Документ1 страница1anandakoeОценок пока нет

- Sacinp - WHT BH2 JKT InplaceR2Документ1 527 страницSacinp - WHT BH2 JKT InplaceR2anandakoeОценок пока нет

- SaclstДокумент281 страницаSaclstanandakoeОценок пока нет

- ContohДокумент13 страницContohanandakoeОценок пока нет

- Use of Simplified Structural Models To Predict Dynamic Response To Wave-In-Deck LoadsДокумент7 страницUse of Simplified Structural Models To Predict Dynamic Response To Wave-In-Deck LoadsanandakoeОценок пока нет

- ANSYS Example BeamBendДокумент6 страницANSYS Example BeamBendhaitham08Оценок пока нет

- LECTURE 7: Finite Element Methods in Fracture MechanicsДокумент7 страницLECTURE 7: Finite Element Methods in Fracture MechanicsanandakoeОценок пока нет

- CIVIL BREADTH and STRUCTURAL DEPTH Exam Specifications: Principles and Practice of EngineeringДокумент6 страницCIVIL BREADTH and STRUCTURAL DEPTH Exam Specifications: Principles and Practice of EngineeringanandakoeОценок пока нет

- ANSYS Short Course: Tim Langlais Langlais@me - Umn.edu August 31, 1998Документ14 страницANSYS Short Course: Tim Langlais Langlais@me - Umn.edu August 31, 1998Radu NeaguОценок пока нет

- Essential Ansys PDFДокумент9 страницEssential Ansys PDFanandakoeОценок пока нет

- Nonlinear Ansys Tension Test Tutorial: 1. Preparing Element and Material ModelДокумент9 страницNonlinear Ansys Tension Test Tutorial: 1. Preparing Element and Material ModelAniruddha KulkarniОценок пока нет

- Limit LoadДокумент16 страницLimit Load001tabОценок пока нет

- Mathcad Tutorial: by Colorado State University StudentДокумент51 страницаMathcad Tutorial: by Colorado State University StudentDiana ScodreanuОценок пока нет

- ANSYS Computer RequirementsДокумент6 страницANSYS Computer RequirementsSandeep ReddyОценок пока нет

- Ansys Asas BrochureДокумент4 страницыAnsys Asas BrochureTomás CampoverdeОценок пока нет

- Finite Element Analysis Ii Coursework: Areas of StudyДокумент1 страницаFinite Element Analysis Ii Coursework: Areas of StudyanandakoeОценок пока нет

- Welds in Pro/E and ANSYS WorkbenchДокумент6 страницWelds in Pro/E and ANSYS WorkbenchSandeep KadamОценок пока нет

- 2 08-NonlinДокумент11 страниц2 08-NonlinanandakoeОценок пока нет

- Chap 16Документ50 страницChap 16sarumaniОценок пока нет

- Stress Analysis Using ANSYSДокумент20 страницStress Analysis Using ANSYSanandakoeОценок пока нет

- 31Документ14 страниц31anandakoeОценок пока нет

- 12 Topsides 13 Mooring 14 Riser: 1 Spar PlatformДокумент2 страницы12 Topsides 13 Mooring 14 Riser: 1 Spar PlatformanandakoeОценок пока нет

- Er Be IДокумент8 страницEr Be IanandakoeОценок пока нет

- Plasticity: Jake Blanchard Spring 2008Документ9 страницPlasticity: Jake Blanchard Spring 2008miki156799Оценок пока нет

- Pipe Fea Using AnsysДокумент14 страницPipe Fea Using AnsysanandakoeОценок пока нет

- MECH 387 Lab Exercise 9 Fatigue AnalysisДокумент19 страницMECH 387 Lab Exercise 9 Fatigue AnalysisanandakoeОценок пока нет

- Findind Workbench Tutorial On GeometryДокумент3 страницыFindind Workbench Tutorial On Geometryhimanshuve1991Оценок пока нет

- Sea Eye Tiger ROV System: Allied Marine & Equipment Sdn. BHDДокумент1 страницаSea Eye Tiger ROV System: Allied Marine & Equipment Sdn. BHDanandakoeОценок пока нет

- Carcass Strength Relationships Conveyor BeltsДокумент9 страницCarcass Strength Relationships Conveyor Beltseduardo_chaban100% (1)

- Second Term English Exam: Level TCST June 2021Документ6 страницSecond Term English Exam: Level TCST June 2021benfaresОценок пока нет

- Comparative Superlative With Key PDFДокумент1 страницаComparative Superlative With Key PDFAnonymous 8AHCMsPuОценок пока нет

- p14.6 - D.C. Motor - Igcse AidДокумент2 страницыp14.6 - D.C. Motor - Igcse Aidrandom channelОценок пока нет

- Pre Post Tests For HPPДокумент3 страницыPre Post Tests For HPPapi-434982019Оценок пока нет

- 05 Astm Grain Size MeasurementsДокумент27 страниц05 Astm Grain Size MeasurementsnareshОценок пока нет

- Wheatley Hp600 Quintuplex Plunger PumpДокумент2 страницыWheatley Hp600 Quintuplex Plunger Pumpmetasoniko2014Оценок пока нет

- Tugas Topic 4 Devi PermatasariДокумент8 страницTugas Topic 4 Devi PermatasariMartinaОценок пока нет

- Annals of The New York Academy of Sciences - 2023 - Hess - Accelerating Action To Reduce Anemia Review of Causes and RiskДокумент13 страницAnnals of The New York Academy of Sciences - 2023 - Hess - Accelerating Action To Reduce Anemia Review of Causes and RiskIdmОценок пока нет

- Dobdsm 304Документ39 страницDobdsm 304LuisangelDueñasОценок пока нет

- BDSM List FixedДокумент4 страницыBDSM List Fixedchamarion100% (3)

- CEPF640/CEBF640 CEFF640: N-Channel Enhancement Mode Field Effect Transistor FeaturesДокумент4 страницыCEPF640/CEBF640 CEFF640: N-Channel Enhancement Mode Field Effect Transistor FeaturesAngel FaneitezОценок пока нет

- Kelvin Hughes LTD: Technical Advice SheetДокумент7 страницKelvin Hughes LTD: Technical Advice SheetVladymirОценок пока нет

- VisakhapatnamДокумент27 страницVisakhapatnamCherukupalli Gopala KrishnaОценок пока нет

- Iso TR 16922 2013 (E)Документ18 страницIso TR 16922 2013 (E)Freddy Santiago Cabarcas LandinezОценок пока нет

- Intercont Tersus DatasheetДокумент5 страницIntercont Tersus DatasheetJocemir FerstОценок пока нет

- Remote Control Based Home Appliances Final ReportДокумент22 страницыRemote Control Based Home Appliances Final ReportVishal Vn50% (2)

- Testo-Flue Gas in Industry 3-27-2008Документ149 страницTesto-Flue Gas in Industry 3-27-2008leruaitesОценок пока нет

- Aljac Sampler: Environmentally Acceptable, Operationally Efficient and Safe, Eliminating Any Product LossДокумент3 страницыAljac Sampler: Environmentally Acceptable, Operationally Efficient and Safe, Eliminating Any Product LossT. LimОценок пока нет

- Liquid SizingДокумент38 страницLiquid SizingChetan ChuriОценок пока нет

- Uptime KitsДокумент3 страницыUptime KitsMtto Materia PrimaОценок пока нет

- Jcpenney Roto Tiller Front in e ManualДокумент34 страницыJcpenney Roto Tiller Front in e Manualcb4pdfs100% (2)

- Fate NumeneraДокумент24 страницыFate Numeneraimaginaari100% (1)

- A Study On Risk Assessment in The Construction of High-Rise BuildingsДокумент5 страницA Study On Risk Assessment in The Construction of High-Rise BuildingsMohamedSaidОценок пока нет

- Unit 21Документ22 страницыUnit 21Yuni IndahОценок пока нет

- Transient Stability of A Multi Machine Power System: Devender Kumar, Balwinder Singh SurjanДокумент4 страницыTransient Stability of A Multi Machine Power System: Devender Kumar, Balwinder Singh SurjanVerruumm AmineОценок пока нет

- American National Standard Safety Signs: ANSI Z535.1-2016Документ42 страницыAmerican National Standard Safety Signs: ANSI Z535.1-2016Luis Enrique GonzalesОценок пока нет

- Peethas ListДокумент1 страницаPeethas ListChetan PrajapatiОценок пока нет

- Method Statement of T-Beams PDFДокумент14 страницMethod Statement of T-Beams PDFKAmi KaMranОценок пока нет

- Content (SG)Документ88 страницContent (SG)Kusuma Cakra WardayaОценок пока нет