Академический Документы

Профессиональный Документы

Культура Документы

Bk10lq ST d10 A 001 Rev.0 Structural Design Brief

Загружено:

Tran Van DaiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bk10lq ST d10 A 001 Rev.0 Structural Design Brief

Загружено:

Tran Van DaiАвторское право:

Доступные форматы

COMPANY

CONTRACTOR

BK-10

LIVING QUARTER

STRUCTURAL DESIGN BRIEF

Cheon

Jai

KANG

Cheon

Jai

KANG

Cheon

Cheon

Jai

Jai

KANG

KANG

Ethiraj

AZIZI

Issued for Approval

Cheon

Jai

KANG

AZIZI

16/01/09

Preliminary

Cheon

Jai

KANG

DATE

Description of Revision

Prepare

Review

24/11/09

06/10/09

16/07/09

Approved For Construction

Revised issued for

Approval

Reissued for Approval

Reissued for Approval

23/11/09

D

B

22/05/09

Rev.

(DD/MM/YY)

SGNC

Company

G.L

Approved

Facilities:

Scale:

Living Quarter

None

Type of Document :

Design brief

Document identification

Project No.

BK-10 LQ

Discipline

STRUCTURE

Document No.

Rev.

BK10LQ-ST-D10-A-001

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

Revision

CONTENTS

1.0

INTRODUCTION ............................................................................................................................. 4

1.1

General ............................................................................................................................................................................... 4

1.2

Purpose .............................................................................................................................................................................. 4

1.3

Abbreviations .................................................................................................................................................................... 4

1.4

Definition ........................................................................................................................................................................... 5

1.5

Regulatory Codes and Standards.................................................................................................................................... 5

2.0

SOFTWARE, MODELS & GENERAL DESIGN REQUIREMENTS ........................................ 5

2.1

Software ............................................................................................................................................................................ 5

2.2

Model ................................................................................................................................................................................. 5

2.3

Allowable deflections ........................................................................................................................................................ 6

2.4

Minimum material thickness ........................................................................................................................................... 6

3.0

LOAD SIMULATION....................................................................................................................... 7

3.1

Functional loads................................................................................................................................................................ 7

3.2

Environmental loads ........................................................................................................................................................ 8

4.0

COMBINED LOAD CASE ............................................................................................................... 9

5.0

EVALUATIONS .............................................................................................................................. 10

5.1

Member unity check ....................................................................................................................................................... 10

5.2

Allowable stress .............................................................................................................................................................. 10

6.0

LIFTING ANALYSIS ..................................................................................................................... 10

6.1

Lug and spread bar local analysis ................................................................................................................................. 11

7.0

INSTALLATION ANALYSIS ....................................................................................................... 11

7.1

General ............................................................................................................................................................................. 11

7.2

Load factors ..................................................................................................................................................................... 11

File name: Structural design brief

Page 2 of 14

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

Revision

8.0

TRANSPORTATION ANALYSIS ................................................................................................ 12

8.1

Basic Loads ..................................................................................................................................................................... 12

8.2

Combined Load Case ..................................................................................................................................................... 12

9.0

FATIGUE ANALYSIS .................................................................................................................... 12

10.0

MISCELLANEOUS DESIGN.....................................................................................................13

10.1

Joint design ................................................................................................................................................................. 13

10.2

Padeye design .............................................................................................................................................................. 13

10.3

Sling and shackle selection ......................................................................................................................................... 13

10.4

Equipment supports ................................................................................................................................................... 13

10.5

Monorail trolley beams .............................................................................................................................................. 14

10.6

Deck plate design ........................................................................................................................................................ 14

File name: Structural design brief

Page 3 of 14

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

1.0

Revision

INTRODUCTION

1.1 General

This document describes the procedures that will be used for the structural design of the BK10-LQ structures

serving for Living Quarter (LQ) for satellite platform BK-10 for Vietsovpetro (VSP). BK-10 located at White

Tiger Oilfield, Vungtau offshore,Vietnam. The current project for BK10 Complex projects provides total

reconstruction for BK-10 and BK-1. The operation mode will become to manned operation. The facilities in the

BK10 complex include:

-

1.2

Existing BK-1, BK-10 (Reconstruction of Bk-1 and BK-10 by separate contract)

New Living Quarter (LQ)

New Link Bridge between BK-1 and BK-10 and LQ

Purpose

This Design brief is intended to cover an acceptable level of scope for designing, sizing structural steel for

Living Quarter (LQ) for satellite platform BK-10 in conformance with relevant regulations and specifications.

This design basis describes the basic requirements for the HVAC system and should be read in conjunction with

other project documents such as safety philosophy and electrical design basis.

1.3 Abbreviations

BK-10 Complex

LQ

MSF

BK-10

ICS

HD

APS

AS

CCR

CPP2

EDG

ESD

FGS

HV

ICSS

I/O

LCS

MCC

MMI

PA/GA

PCS

PLC

PSD

SSD

UPS

NFPA

MARPOL

SOLAS

File name: Structural design brief

Living Quarter, Block Conductor and Bridge

Living Quarter

Module Support Frame

Wellhead Equipment and Topside Equipment of BK-10 Platform

International Classification Society

Helideck

Abandon Platform Signal

Area Supervisory Station

Central Control Room

Central Processing Platform

Emergency Diesel Generator

Emergency Shut Down

Fire & Gas System

High Voltage

Integrated Control & Safety System

Input/Output

Local Control System

Motor Control Centre

Man Machine Interface

Public Address and General Alarm System

Process Control System

Programmable Logic Controller

Process Shutdown

Safety Shutdown System

Un-interruptible Power Supply

National Fire Protection Agency

The International Convention for Prevention of Pollution from Ships

The International Convention for the Safety of Life at Sea

Page 4 of 14

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

Revision

1.4 Definition

VENDOR

CONTRACTOR/

BUYER

PURCHASER/

OWNER

CLIENT

AUTHORITY

CLASS

Supplier of the Equipment designated by PURCHASER to provide equipment

and services indicated in the Requisition and its attachments.

Company responsible for engineering of the living quarter

SESCO/GINC/NVO

Company ordering the equipment to the Purchaser.

Vietsovpetro J.V

The party, which buys the equipment and its auxiliaries for its own use.

Vietsovpetro J.V

National or international regulations to which the vessel will be built.

Classification Society responsible for approval of the vessel/equipment according

to a set of established rules.

Germanischer Lloyd Aktiengesellschaft (GL)

1.5 Regulatory Codes and Standards

The following documents will used for evaluation of structural safety of LQ structure.

Table 1.5.1 Regulatory Codes and Standards

Title

GL Industrial Service Rules, Ch 4, Pt 6

American Institute of Steel Construction (AISC)

American Petroleum Institute (API RP 2A)

2.0

Remark

Edition, 2007

SOFTWARE, MODELS & GENERAL DESIGN REQUIREMENTS

2.1 Software

The SACS suite of programs will be used for structural modelling and analysis with the exception of

transportation stress and non-linear analyses. SACS comprises a number of program modules to perform

various tasks; appropriate program modules will be used depending upon the analysis to be performed.

2.2 Model

3-dimensional computer models will be constructed for BK-10 LQ structure this model will be used for the

following structural analyses:

In-place storm, operating and earthquake conditions.

Lifting analysis.

Installation analysis.

Transportation analysis

Fatigue analysis (where appropriate).

The computer models will include all primary structural trusses, column members, primary and secondary deck

members, stringers and deck plating contributing lateral stiffness. The helideck and MSF will not be modelled

integral with the topsides.

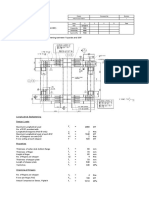

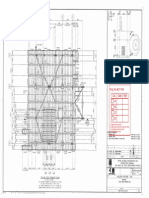

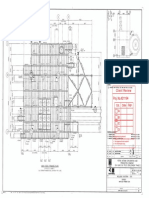

The model extend is shown as following figure 2.2.1.

File name: Structural design brief

Page 5 of 14

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

Revision

Figure 2.2.1 Analysis Model Extent

2.3 Allowable deflections

Maximum allowable deflections for beams and columns will be given below:

Beams:

Maximum deflection under imposed live load (including weight of equipment and

piping) span / 325.

Columns:

Maximum deflection height / 300.

2.4 Minimum material thickness

The minimum thickness of steel sections will comply with the following:

Application

Minimum Thickness (mm)

Floor deck plates a) laydown areas

b) other areas

8

8

External wall plates other than non-structural

cladding

Primary structural members a) flanges

b) webs

12

19

Secondary structural members

b) webs

9

6

a) flanges

Tubulars

16

Galvanised sealed hollow sections

3.25

Miscellaneous steel in exposed locations

There will be no corrosion allowance added to structural as necessary protection shall be provided by painting.

File name: Structural design brief

Page 6 of 14

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

3.0

Revision

LOAD SIMULATION

3.1 Functional loads

3.1.1 Dead Loads

Dead weight of structure will be automatically generated. Other dead loads will be modeled as forces applied to

the members and joints. Applied dead loads will include the following depending upon the function of the

structure:

Unmodelled primary and secondary steel

Miscellaneous steel including deck and wall plates, grating

Equipment dry weight

Piping dry weight

Electrical dry weight

Instrument dry weight

HVAC dry weight

Fire and safety dry weight

Architectural dead loads including partitions, ceilings, screed, floor finishes, cabinet, galley, etc.

Fire walls dead loads

Helideck loads

Cabinet, galley & etc. weight

The loads will be derived with reference to the weight control report and distributed in accordance with the

latest equipment and piping layouts, architectural and structural drawings.

3.1.2 Design deck / live Load

The design deck / live loads for the LQ area will be applied as described on below.

AREA

Local analysis

deck

plate/stringers

Global analysis

Primary

members/truss

framing

Roof

10 kN/m2

5 kN/m2

Accommodation area

5 kN/m2

5 kN/m2

External Accessways

5 kN/m2

5 kN/m2

Laydown area

25 kN/m2

15 kN/m2

File name: Structural design brief

Page 7 of 14

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

Revision

3.2 Environmental loads

3.2.1 Wind Loads for In-Place Condition

Wind forces are calculated based on the GL Industrial Service Rules, Ch 4, Pt 6 Sec.1 &2.

The reference wind speeds at 10 m above sea level are used for the different conditions for the analyses of all

the LQ are as follows:

Operating storm conditions :

30 m/sec

Extreme storm conditions :

57.4 m/sec

The wind force is calculated as follows:

Where,:

q:

:

u:

Cs:

Wind Pressure (kPa)

Density of air = 0.001224 (kNs2/m4)

Design wind speed (m/sec)

Shape coefficient.

For large flat surface (hull, deckhouse, smooth underdeck areas), Cs= 1.0.

CH:

Z:

Height coefficient depending on the height above sea level of the structural

member exposed to wind,

Coordinate for height above sea level (m)

The wind loads for each direction of LQ are summarized in Table 2.4.1 below and show on Figure 2.4.5~2.4.8.

Table 3.2.1 Wind Forces

Condition

Operating

Extreme

0

78.48

287.32

Wind Forces (kN)

Direction

90

180

66.24

96.27

242.51

352.44

270

63.32

231.82

3.2.2 Seismic Loads

The Richter scale of seismic condition of BK10 LQ is 6. This value is corresponded with Modified Mercalli scale

. And MM scale is equivalent to acceleration of gravity 0.25g(g is gravity).

Therefore, the seismic loads are calculated as below.

Self weight of LQ structure (applied weight growth factor) 0.25

File name: Structural design brief

Page 8 of 14

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

4.0

Revision

COMBINED LOAD CASE

The Combined Load Case is divided Operating condition, Extreme condition and Seismic condition.

4.1 Operating condition

Combined load conditions

Load types

OP1

OP2

OP3

OP4

OP5

OP6

OP7

OP8

Dead load (z-dir)

-1.2

-1.2

-1.2

-1.2

-1.2

-1.2

-1.2

-1.2

Helideck load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

Air Handling Uint load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

Air cooled type condensing Unit

load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

MCC & EMCC Unit load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

Live load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

Wind load(operating)

0

1.0

90

0.707

1.0

180

0.707

1.0

270

0.707

0.707

0.707

1.0

0.707

0.707

0.707

*Note : Dead load is included structure weight and fitting weight(equipments, piping bulks, electrical & instrument

bulks)

4.2 Extreme condition

Combined load conditions

Load types

EX1

EX2

EX3

EX4

EX5

EX6

EX7

EX8

Dead load (z-dir)

-1.2

-1.2

-1.2

-1.2

-1.2

-1.2

-1.2

-1.2

Helideck load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

Air Handling Uint load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

Air cooled type condensing Unit

load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

CC & EMCC Unit load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

Live load

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.5

Wind load(Extreme)

0

90

180

270

1.0

0.707

1.0

0.707

1.0

0.707

0.707

0.707

1.0

0.707

0.707

0.707

*Note : Dead load is included structure weight and fitting weight(equipments, piping bulks, electrical & instrument

bulks)

File name: Structural design brief

Page 9 of 14

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

Revision

4.3 Seismic condition

SEISMIC

Load types

SE1

SE2

SE3

SE4

SE5

SE6

SE7

SE8

Dead load (z-dir)

-1.2

-1.2

-1.2

-1.2

-1.2

-1.2

-1.2

-1.2

Helideck load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

Air Handling Uint load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

Air cooled type condensing Unit

load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

MCC & EMCC Unit load

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

Live load

0.33

0.33

0.33

0.33

0.33

0.33

0.33

0.33

Seismic load(x-dir)

1.0

0.0

-1.0

0.0

0.707

-0.707

-0.707

0.707

Seismic load(y-dir)

0.0

1.0

0.0

-1.0

0.707

0.707

-0.707

-0.707

*Note : Dead load is included structure weight and fitting weight(equipments, piping bulks, electrical & instrument

bulks).

5.0

EVALUATIONS

5.1 Member unity check

Member unity checks will be performed based on member forces and section properties using provision for

combined axial & bending stresses as specified in AlSC & API RP2A (members unity check)

5.2 Allowable stress

Basic allowable AISC/API stresses will be increased by one-third for storm and by 70% for seismic conditions.

6.0

LIFTING ANALYSIS

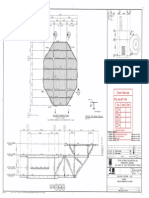

BK10 LQ module will be lifted offshore using two pairs of slings to a single hook four point lift.

Two lifting cases will be considered in the analysis. The first case is the base case which is a four slings lift

without application of the skew factors (a simple lift case). The second case is with the distribution of load on

opposite diagonal slings utilising a skew load distribution of 75:25 to allow for in determinate load distribution

in the sling pairs. In both cases, load factors are applied to the lifting loads to account for Centre of gravity

(CoG) shift, dynamic amplification and the importance of structural element.

In addition to the contingency factors, the following three factors will be applied to the factored lift weight. The

first factor is the CoG shift factor of 1.05. Next is the dynamic application factor of 1.20 for lift weight. The last

load factor is the consequence factor which depends upon the importance of the structural element and is

tabulated below:

File name: Structural design brief

Page 10 of 14

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

Element Type

Type 1

Type 2

Type 3

Revision

Factor

: Lift points and spreader beams

: Members framing into lift point

: Other members

1.35

1.15

1.00

6.1 Lug and spread bar local analysis

The lug and spread bar will be analysis by 3D FEM program, MSC Patran / MSC Nastran. The analysis model

will be constructed by plate element. And the Average size of element will be 100 ~ 150 mm and near the lug

area is 40 ~ 50 mm.

The input load will be obtained from global lifting analysis.

7.0

INSTALLATION ANALYSIS

7.1 General

The installation analysis will be considered the mating condition. When the LQ module is mated to MSF, the

four supports are not contact to stool at the same time. One or two points are contact first. And other points are

contacted next time. Therefore, the load cases will be created twelve cases. LC1~4 cases are considered with

one support contact condition and LC5~8 are two support contact condition and LC9~12 are three support

contact condition for each directions. The joint fixities will be applied as following table.

Load case

Joint No.

LC1

LC2

LC3

LC4

LC5

LC6

LC7

LC8

LC9

LC10

LC11

LC12

11111

1

11111

1

11011

1

11011

1

11011

1

11111

1

11111

1

11011

1

11111

1

11011

1

11011

1

11011

1

11111

1

11111

1

11111

1

11111

1

11111

1

11011

1

11011

1

11011

1

11011

1

11111

1

11011

1

11011

1

11111

1

11011

1

11011

1

11111

1

11011

1

11111

1

11111

1

Hook1

110111

111111

111111

111111

110111

111111

Hook2

111111

110111

111111

111111

110111

110111

Hook3

111111

111111

110111

111111

111111

110111

Hook4

111111

111111

111111

110111

111111

111111

Support1

111111

111111

Support2

111111

111111

111111

Support3

111111

111111

Support4

111111

11111

1

11111

1

11111

1

11111

1

11111

1

11111

1

11111

1

11111

1

11111

1

*Note : Hook point 1~4 are located same position.

7.2 Load factors

The load factors will be applied to same with lifting analysis. The first factor is the CoG shift factor of 1.05.

Next is the dynamic application factor of 1.20 for lift weight. The last load factor is the consequence factor 1.0.

File name: Structural design brief

Page 11 of 14

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

8.0

Revision

TRANSPORTATION ANALYSIS

The Transportation analysis is performed by SACS tow program and applied loads are as follows.

8.1 Basic Loads

8.1.1 Structural Dead Load

The structural dead weight will be able to generate automatically and considering piping dry weight, electrical

dry weight, and paint & weld and so on, the structural dead load will be increased by increase factor.

8.1.2 Acceleration Load

The acceleration load will be applied as follows.

Barge motion

Direction

Acceleration

Pitching

X-dir.

0.25g

Rolling

Y-dir.

0.40g

Heaving

Z-dir.

0.20g

8.2 Combined Load Case

The following load case will be applied to this analysis.

Load combination

Load Case 1

Load Case 2

Load Case 3

Load Case 4

Load Case 5

Load Case 6

Load Case 7

Load Case 8

Motion Load

+R + H

+R - H

-R + H

-R - H

+P + H

+P - H

-P + H

-P - H

*Note : R Rolling

P Pitching

H Heaving

9.0

FATIGUE ANALYSIS

The fatigue analysis will be performed by SACS5.2 and design life is 20 years. The approach of this fatigue

analysis will be used deterministic fatigue analysis option. The input data of this approach is stress range and

number of occurrences of cyclic loads. The cyclic load is wind load and the wind speed will selected from

environmental design criteria. And this wind speed will be used to calculate wind load for LQ structure by GL

Industrial Service Rules, Pt 6, Ch 4, Sec.1 &2. And the number of occurrences of cyclic load is referred to GL

Rules, , Pt 6, Ch 4, Sec 3.

File name: Structural design brief

Page 12 of 14

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

10.0

Revision

MISCELLANEOUS DESIGN

Miscellaneous design shall include all steel items not mentioned in the previous sections but required for the

functional purpose of the platform. Some of the major items are included in this section.

10.1 Joint design

Wide Flange/Wide Flange and Tubular/Wide Flange Joints

Joints will be designed in accordance with the AISC specification. The actual brace loads from all relevant

global analyses will be used in the joint design.

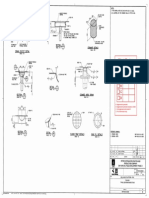

10.2 Padeye design

The lifting padeyes shall be designed to API RP2A.

The design load for padeye, sling and shackle design shall be based on the appropriate calculated sling loads for

global lifting analysis. The following shall be considered in the design:

The vertical component of the sling force shall be taken as the vertical component of the padeye force, based on

the centre of gravity from the Weight Report.

The maximum sling force shall govern the safe working load of all four slings.

The shackle force shall be equal to the sling force.

In padeye design, an additional side load will be applied transverse to the padeye at the pinhole.

The following checks will be performed for padeye design.

- Pin contact stress.

- Pin bearing stress.

- Pin shear/pull out failure.

- Tension failure

- Main plate bending.

- Combined stresses.

- Connection weld design.

10.3 Sling and shackle selection

Sling and shackles shall be selected in accordance with the requirements of API-RP2A-WSD, 20th Edition,

section 2.4.2f for loads derived as per Sect.8.2.

10.4 Equipment supports

Design of Equipment Supports

Equipment supports will be design to withstand the maximum forces arising from the equipment during the

various pre-service and in-service conditions, e.g. normal operation, hydrotest, earthquake and transportation. In

general equipment supports will be designed by hand calculation.

Large Rotating Machinery

File name: Structural design brief

Page 13 of 14

Project

: BK-10 LIVING QUARTER

Title

: Structural Design Brief

Doc.No : BK10LQ-ST-D10-A-001

Revision

Dynamic loads generated by rotating machinery during start-up, normal running and stopping(including

emergency stop) phases shall be determined from equipment vendors.

Machine-Induced Dynamic Loads

The dynamic loads induced during operation of the machine will be accounted for. It is assumed that these loads

can be produced in any perpendicular direction to the machine axis.

For final design, vendor data will be incorporated. Until that time reasonable assumptions will be made.

Machine-Induced Vibration

All rotating equipment causing forced vibration problems will be investigated

The magnitude of unbalanced forces for the equipment will be obtained from the equipment vendors.

Initial investigations will use hand calculation methods to investigate potential problems. Failing this, rigorous

analysis will be performed. Limits on vibration will follow UK DEn Guidance Notes.

The natural frequencies of skids supporting rotating equipment will be designed to lie outside the range of 0.7 to

1.3 times the excitation frequency of the machine. The use of flexible mountings shall also be considered.

Saddle Supported Vessels

Design of supporting steelwork for equipment supported on multiple saddles will take into account possible

horizontal loads due to thermal expansion of the equipment.

10.5 Monorail trolley beams

The monorail trolley beams will be designed in accordance with BS 2853. The monorail and the supporting

stringers will be designed based on a monorail capacity of 5.0 MT.The following factors will be applied to the

static hoist for beam design:

Operation

Vertical DAF

Lateral to

beam

Longitudinal

to beam

Manual

1.1

0.2 x static load x vertical

DAF

0.2 x static load x vertical

DAF

Powered

1.2

0.2 x static load x vertical

DAF

0.2 x static load x vertical

DAF

10.6 Deck plate design

The deck plate design will be performed by rule scantling.

The scantling calculations are will be based on the Germanischer Lloyd Aktiengesellschaft (GL) rules as

follows;

-

GL Part 1, Chapter 1

GL Part 6, Chapter 4

File name: Structural design brief

Page 14 of 14

Вам также может понравиться

- BOC 02PDT ENG RP 003 01 - STD Topside Removal Lift Point DesignДокумент91 страницаBOC 02PDT ENG RP 003 01 - STD Topside Removal Lift Point DesignSarva BharОценок пока нет

- Total Strength Assessment: Buckling and Ultimate StrengthДокумент30 страницTotal Strength Assessment: Buckling and Ultimate Strengthding liuОценок пока нет

- Appendix D 2Документ7 страницAppendix D 2Wistie AnnelyaОценок пока нет

- Concrete Offshore Gravity StructuresДокумент38 страницConcrete Offshore Gravity StructuresVlad Kudryavtsev100% (1)

- Topside Seafastening.002Документ6 страницTopside Seafastening.002Sai SushankОценок пока нет

- Appendices Front PageДокумент39 страницAppendices Front PageMd Emdadul HoqueОценок пока нет

- PDF of EilДокумент156 страницPDF of EilPrasanth Raju100% (4)

- Soroosh and Nowrooz Integrated Development Project: SO EST AN Spp1 55000 D0Документ54 страницыSoroosh and Nowrooz Integrated Development Project: SO EST AN Spp1 55000 D0AnjuОценок пока нет

- Appendix e (Sacs Output)Документ6 страницAppendix e (Sacs Output)Tran Van DaiОценок пока нет

- PT - Mcci Document Register List Rev.B 110811Документ3 страницыPT - Mcci Document Register List Rev.B 110811adityadhОценок пока нет

- CMM86503 - V1 Turret Chain Stopper Calculation PDFДокумент24 страницыCMM86503 - V1 Turret Chain Stopper Calculation PDFTran LinhОценок пока нет

- 2019.09.03 - EST & SCHED - r.2 - Combined OverviewДокумент1 страница2019.09.03 - EST & SCHED - r.2 - Combined OverviewSriОценок пока нет

- Boatlanding and Riser Protecter Design-3Документ16 страницBoatlanding and Riser Protecter Design-3samiransmitaОценок пока нет

- BB.G VSP Pve Ed 00 PM Pro 008 Numbering Procedure Rev 0Документ14 страницBB.G VSP Pve Ed 00 PM Pro 008 Numbering Procedure Rev 0Brewer HouseОценок пока нет

- Calculation Report For Monorail and Hatch Cover REV.0Документ15 страницCalculation Report For Monorail and Hatch Cover REV.0Tran Van DaiОценок пока нет

- Detailed and Const Support Eng Pre QuaДокумент45 страницDetailed and Const Support Eng Pre QuaRavikumar mahadevОценок пока нет

- Section 4: Specifications Specifications For Quick Release HookДокумент17 страницSection 4: Specifications Specifications For Quick Release HookAnonymous iM2totBrОценок пока нет

- 12414-00-1761 - Rev.0 - RT ProcedureДокумент39 страниц12414-00-1761 - Rev.0 - RT ProcedureNguyen Anh TuanОценок пока нет

- Tep 900 Spe CV BP4 0004 - B04Документ30 страницTep 900 Spe CV BP4 0004 - B04Teguh WiradinataОценок пока нет

- MS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabДокумент19 страницMS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabPuspita LerianaОценок пока нет

- Offshore Load Out Day 3Документ109 страницOffshore Load Out Day 3bubbly_blu2Оценок пока нет

- 4.CSP-04 Rev.4Документ133 страницы4.CSP-04 Rev.4Othman RejabОценок пока нет

- Pipeline Stalk Fabrication Plan For Wp2: Etame Expansion Project Offshore Installation 12022Документ25 страницPipeline Stalk Fabrication Plan For Wp2: Etame Expansion Project Offshore Installation 12022William O OkolotuОценок пока нет

- Bonga Pipe in Pipe LayДокумент66 страницBonga Pipe in Pipe LayWilliam O OkolotuОценок пока нет

- Cowgd725 75 Gen 301 (Design Basis) Rev.0Документ39 страницCowgd725 75 Gen 301 (Design Basis) Rev.0ajay100% (1)

- Swamp DredgingДокумент19 страницSwamp Dredgingmaniacs14Оценок пока нет

- H8 SSP 00 066 N01 68585 - 0 - 006 PDFДокумент37 страницH8 SSP 00 066 N01 68585 - 0 - 006 PDFemmanuelОценок пока нет

- NCS2-TPGM-CW-1-00-02-PR-136 - POS-TOS - AlphaNDT Procedure For RT, MT, MUT (LFS-LFP, Tie-In, PLEM, Structural) - AC - Approved PDFДокумент115 страницNCS2-TPGM-CW-1-00-02-PR-136 - POS-TOS - AlphaNDT Procedure For RT, MT, MUT (LFS-LFP, Tie-In, PLEM, Structural) - AC - Approved PDFnkvonОценок пока нет

- 6.9. Handling Storage & Preservation ProcedureДокумент10 страниц6.9. Handling Storage & Preservation Procedurerendra syamОценок пока нет

- Manned SubmersiblesДокумент156 страницManned SubmersiblesBuceo Mantto OCEAN INTREPIDОценок пока нет

- 50037-ME-DOC-001 - Marine Spread Specifications and Certifications DossierДокумент9 страниц50037-ME-DOC-001 - Marine Spread Specifications and Certifications DossierseehariОценок пока нет

- Rational Unified ProcessДокумент40 страницRational Unified ProcessNitesh IОценок пока нет

- Failure Modes, Inspection, Testing and Monitoring: Flexible PipesДокумент34 страницыFailure Modes, Inspection, Testing and Monitoring: Flexible PipesHamad HameedОценок пока нет

- P1465a-Ca03-Rev0-Intact Stability ComputationsДокумент141 страницаP1465a-Ca03-Rev0-Intact Stability ComputationshalimОценок пока нет

- KOM Loadout InterfaceДокумент49 страницKOM Loadout InterfaceNguyen Dinh Ngoc Duy100% (1)

- Job Name: Phase: Job Number: Detailed Engineering: A1 Ifidc 16.JAN.23 L.T.Luan L.M.Hung T.D.Hai B.T.HanДокумент164 страницыJob Name: Phase: Job Number: Detailed Engineering: A1 Ifidc 16.JAN.23 L.T.Luan L.M.Hung T.D.Hai B.T.HanTrong VuОценок пока нет

- HL-OSS-SMPTSC-PMT-PRC-39520 (1.0) HL OSS Welding Procedure Specification HL-WPS-01Документ27 страницHL-OSS-SMPTSC-PMT-PRC-39520 (1.0) HL OSS Welding Procedure Specification HL-WPS-01Le Phi HungОценок пока нет

- Project Name: Repair of Afam Vi Boiler (HRSG) Evaporator TubesДокумент12 страницProject Name: Repair of Afam Vi Boiler (HRSG) Evaporator TubesLeann WeaverОценок пока нет

- How02 Z01uab12&cdc112 Ga 117Документ1 страницаHow02 Z01uab12&cdc112 Ga 117Ajizul Rohim AkbarОценок пока нет

- Ps For HelideckДокумент18 страницPs For HelideckPalani KarthiОценок пока нет

- TBDP-A-S-RPT-1020 - Substructure Inplace AnalysisДокумент45 страницTBDP-A-S-RPT-1020 - Substructure Inplace AnalysisViktor DươngОценок пока нет

- #How02 Z01apa01 Elh501 c01 Rcs Earthing Layout-001 CellarДокумент1 страница#How02 Z01apa01 Elh501 c01 Rcs Earthing Layout-001 CellarKonge ThethtunaungОценок пока нет

- PMS12 - Baltim - Inspection and Test Plan (ITP) For Offshore Pipelay ActivitiesДокумент15 страницPMS12 - Baltim - Inspection and Test Plan (ITP) For Offshore Pipelay ActivitiesyehiaОценок пока нет

- Api-Mip-5lДокумент76 страницApi-Mip-5lVan LinhОценок пока нет

- Bfi Urea Export Jetty Pile Drive Report Sheet: 1.Date/Hour 2.Date/HourДокумент1 страницаBfi Urea Export Jetty Pile Drive Report Sheet: 1.Date/Hour 2.Date/Hour唐亮Оценок пока нет

- Mumbai Trans Harbour Link Package 1 Sewri Interchange Pavement DesignДокумент9 страницMumbai Trans Harbour Link Package 1 Sewri Interchange Pavement Designasif_22ukОценок пока нет

- 7234 PP Qa 009 Ver C0300Документ9 страниц7234 PP Qa 009 Ver C0300baskaran ayyapparajОценок пока нет

- HL-OSS-SMPTSC-STR-SPC-37002 (2.0) HL OSS Foundation Specification For St...Документ17 страницHL-OSS-SMPTSC-STR-SPC-37002 (2.0) HL OSS Foundation Specification For St...Tuan Nguyen AnhОценок пока нет

- Sample: Job Safety AnalysisДокумент7 страницSample: Job Safety AnalysisHesanRajaraniОценок пока нет

- Draft CalcДокумент13 страницDraft CalcДмитрий ЯрычОценок пока нет

- Indra: For ConstructionДокумент13 страницIndra: For ConstructionIksan Adityo MulyoОценок пока нет

- BGEP TETL B104 GENX PI 10 012 0023 D - Rev - 0 - Specification For Piping Fabrication, Erection and InstallationДокумент26 страницBGEP TETL B104 GENX PI 10 012 0023 D - Rev - 0 - Specification For Piping Fabrication, Erection and InstallationMitchel Fernandes100% (1)

- Tonnage CalculationДокумент5 страницTonnage CalculationeОценок пока нет

- GLE LNG Ship Approval ProcedureДокумент9 страницGLE LNG Ship Approval Procedureanujgupta1982Оценок пока нет

- SP Ci SS 002Документ10 страницSP Ci SS 002rieza_fОценок пока нет

- RAPID-FE1-TPX-CMM-SPN-0001-0903, Rev 1Документ6 страницRAPID-FE1-TPX-CMM-SPN-0001-0903, Rev 1Đình NamОценок пока нет

- 3.CSP-03 Rev.3Документ66 страниц3.CSP-03 Rev.3Othman RejabОценок пока нет

- TBD-TJ-W8-SD-DR-4028 - B - Code B - Stairway Plan and SectionsДокумент5 страницTBD-TJ-W8-SD-DR-4028 - B - Code B - Stairway Plan and SectionsGeta Oisis Arya PutraОценок пока нет

- Subsea Pipelines and Risers: Yong BaiДокумент18 страницSubsea Pipelines and Risers: Yong Bainina_kawai88745Оценок пока нет

- Case Study 2101 Jack Up Unit Helideck Strength Verification1Документ1 страницаCase Study 2101 Jack Up Unit Helideck Strength Verification1Moe LattОценок пока нет

- Fitup (2019!06!01) Report-91 OfficialДокумент2 страницыFitup (2019!06!01) Report-91 OfficialCarlosОценок пока нет

- Material SubmittalДокумент157 страницMaterial SubmittalahmedОценок пока нет

- CD ListДокумент1 страницаCD ListTran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- 2013-3289!62!0100 - Rev.0 - Jacket Elevations at Row AДокумент2 страницы2013-3289!62!0100 - Rev.0 - Jacket Elevations at Row ATran Van DaiОценок пока нет

- List of Deliverabls-Aker ProposalДокумент4 страницыList of Deliverabls-Aker ProposalTran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Analyser PDFДокумент172 страницыAnalyser PDFRandy LangleyОценок пока нет

- Exercise1 AssignmentДокумент5 страницExercise1 Assignmentfrank_grimesОценок пока нет

- Resume of Jmclarke55Документ1 страницаResume of Jmclarke55api-24783078Оценок пока нет

- Aloha TS 6.1 PMS InterfaceДокумент74 страницыAloha TS 6.1 PMS InterfaceTim WatsonОценок пока нет

- Zachman Framework: A Tutorial On The Zachman Enterprise Architecture FrameworkДокумент16 страницZachman Framework: A Tutorial On The Zachman Enterprise Architecture FrameworkDiniiAdiyarnitaОценок пока нет

- Hospital MGMT System PDFДокумент54 страницыHospital MGMT System PDFboomaОценок пока нет

- Check Point Full Disk EncryptionДокумент16 страницCheck Point Full Disk EncryptionDun HillОценок пока нет

- Motion Media and InformationДокумент29 страницMotion Media and InformationLerwin GaringaОценок пока нет

- Talk Pad AAC Device PDFДокумент9 страницTalk Pad AAC Device PDFKidz to Adultz ExhibitionsОценок пока нет

- PKT Radius PDFДокумент3 страницыPKT Radius PDFIvan SorondoОценок пока нет

- PCS-9611 - X - Instruction Manual - EN - Overseas General - X - R1.00 - (EN - DYBH5301.0086.0001) PDFДокумент282 страницыPCS-9611 - X - Instruction Manual - EN - Overseas General - X - R1.00 - (EN - DYBH5301.0086.0001) PDFngocanhvy100% (1)

- Mongoengine Cheat Sheet: by ViaДокумент1 страницаMongoengine Cheat Sheet: by ViamrnovoaОценок пока нет

- Modeling Business Processes Using BPMN and ARIS: Applies ToДокумент11 страницModeling Business Processes Using BPMN and ARIS: Applies Totapera_mangeziОценок пока нет

- SCADAConnectSimulator FireДокумент29 страницSCADAConnectSimulator FireMidwardFranciscoQuispeLivisiОценок пока нет

- Scheduling: Theory, Algorithms and Systems Development: January 1992Документ9 страницScheduling: Theory, Algorithms and Systems Development: January 1992Francesco BОценок пока нет

- Solving Active Directory Replication FailureДокумент3 страницыSolving Active Directory Replication Failurekamakom78Оценок пока нет

- Dirty Little SecretДокумент5 страницDirty Little SecretbpgroupОценок пока нет

- Netscaler 12 0Документ3 804 страницыNetscaler 12 0barriobajeroОценок пока нет

- Compiler ConstructionДокумент5 страницCompiler ConstructionEman noorОценок пока нет

- FusionServer 2288H V6 Server Technical White Paper PDFДокумент302 страницыFusionServer 2288H V6 Server Technical White Paper PDFCarlos BastosОценок пока нет

- Alphageek (TM) Quiz Answers ForДокумент10 страницAlphageek (TM) Quiz Answers ForNavyaMSОценок пока нет

- Instruments eДокумент96 страницInstruments evgdlpcОценок пока нет

- DxDiag File Report Via 64bitДокумент17 страницDxDiag File Report Via 64bitAlecHughesОценок пока нет

- 141 CC 403 02008 - Q - CommentДокумент25 страниц141 CC 403 02008 - Q - CommentChandra KanthОценок пока нет

- MAT 1302A - Mathematical Methods II: Alistair SavageДокумент28 страницMAT 1302A - Mathematical Methods II: Alistair SavageCatherine LiОценок пока нет

- Python - BookДокумент257 страницPython - BookvisupaceОценок пока нет

- Name: Soumik Paul Class: XI Roll No.: 30 Stream: Science Subject: Computer ScienceДокумент24 страницыName: Soumik Paul Class: XI Roll No.: 30 Stream: Science Subject: Computer ScienceSanchita KunduОценок пока нет

- Create Sample SolutionДокумент11 страницCreate Sample SolutionMay Zin MgОценок пока нет

- Python Classes ObjectsДокумент8 страницPython Classes ObjectsJohn DoeОценок пока нет