Академический Документы

Профессиональный Документы

Культура Документы

Document QA and QC

Загружено:

EmilJaredVirayPabustan0 оценок0% нашли этот документ полезным (0 голосов)

83 просмотров4 страницыThe document outlines the roles and responsibilities of a QA/QC engineer which includes reviewing technical documents and specifications, preparing method statements, conducting inspections and surveillance, issuing non-conformance reports, and preparing QA/QC reports. It also lists the necessary qualifications of a QA/QC engineer such as having an engineering license and experience, as well as skills in communication, computer skills, reading drawings, and time management. Quality assurance means providing confidence that quality requirements will be met through preventative measures while quality control focuses on detection and correction of defects during production through testing and inspection.

Исходное описание:

Document QA and QC

Авторское право

© © All Rights Reserved

Доступные форматы

RTF, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe document outlines the roles and responsibilities of a QA/QC engineer which includes reviewing technical documents and specifications, preparing method statements, conducting inspections and surveillance, issuing non-conformance reports, and preparing QA/QC reports. It also lists the necessary qualifications of a QA/QC engineer such as having an engineering license and experience, as well as skills in communication, computer skills, reading drawings, and time management. Quality assurance means providing confidence that quality requirements will be met through preventative measures while quality control focuses on detection and correction of defects during production through testing and inspection.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате RTF, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

83 просмотров4 страницыDocument QA and QC

Загружено:

EmilJaredVirayPabustanThe document outlines the roles and responsibilities of a QA/QC engineer which includes reviewing technical documents and specifications, preparing method statements, conducting inspections and surveillance, issuing non-conformance reports, and preparing QA/QC reports. It also lists the necessary qualifications of a QA/QC engineer such as having an engineering license and experience, as well as skills in communication, computer skills, reading drawings, and time management. Quality assurance means providing confidence that quality requirements will be met through preventative measures while quality control focuses on detection and correction of defects during production through testing and inspection.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате RTF, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

QA/QC (KALBO)

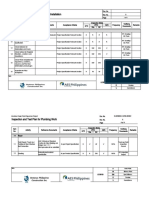

How to prepare a good inspection for test

1. Read specification

2. Drawing method statement and material submittal

3. Define activity description

4. Test or inspection performed

5. Stage or frequency

6. Code or specification

7. acceptance criteria

8. Inspection or Verification

(7) ROLES AND RESPONSIBILITIES OF A QA/QC ENGINEER

9. Review the material technical data sheet

10. Preparation of method statement

11. Review method statement approval or comments of the engineer and

take action

12. Submit inspection request for engineers inspection

13. Issue internal NCR or site observation

14. Conduct regular sire surveillance

15. Prepare QA/QC reports

QUALIFICATION OF QA/QC ENGINEER

education

has a liscence as engineer

work experience

acknowledge of standars or codes

interpersonal and communication skill

SKILL THAT A QUALITY ENGINEER MUST HAVE

communication skill

computer skill

can read drawings

time management skills

(MOKS)

Quality - is a measure of excellence or a state of being free from defects,

deficiencies, and significant variations, brought about by the strict and consistent

adherence to measurable and verifiable standards to achieve uniformity of output

that satisfies specific customer or userrequirements.

Quality Assurance - Means of providing confidence that

quality requirements will be met.

Quality Control - Mechanism used, such as checks or tests that are performed

to ensure that requirements are met.

QUALITY ASSURANCE

you plan to avoid the defects in the first place

is all about prevention

is a process based approach

quality audit is an example of QA

the goal of the QA process is to develop a process so that defects do

not arise when you are producing a product

QUALITY CONTROL

on the other hand in QC, you try to find the defects and correct them

while making the product

is all about the detection

is a product based approach

inspection and testing are example of QC

identifies the defects after the product is produced but is not yet

released or still in the production phase

TESTING AND COMMISSIONING

functionality testing

commissioning

energization

activation

hand over

(OLIVER)

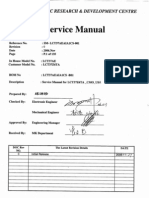

* the material inspection a quality engineer task

16. obtain delivery note

17. fill the material inspection form

18. attachment for the materials inspection

19. joint inspection with the consultant

* How to control materials and delivery to the construction site

20. Procurement

21. materials submission for approval

22. checking of quality engineer

23. store keeper responsibility

24. materials delivery on sight

25. thanks

* Project documents that QA/QC engineer must read before start work

specification

project quality plan

drawings

* 10 Project Forms that a QA/QC Engineer must have

26. document transmittal sheet

27. material submittal sheet

28. request for information

29. subcontractor approval

30. confirmation of verbal instruction

31. inspection request

32. daily report

33. weekly report

34. concrete puoring request

35. non conformance report

Вам также может понравиться

- QC MANUAL (Project Quality Plan) WisnuДокумент10 страницQC MANUAL (Project Quality Plan) WisnuNovie DwiyantiОценок пока нет

- 2 QUALITY CONTROL Manual FINALДокумент8 страниц2 QUALITY CONTROL Manual FINALBilisumman Hawwe BeekaОценок пока нет

- QA Programme Rev.3, TERFДокумент46 страницQA Programme Rev.3, TERFUmesh Mishra100% (1)

- PQP EpldtДокумент8 страницPQP Epldtmartin leeОценок пока нет

- Block Masonary Work: Method StatementДокумент5 страницBlock Masonary Work: Method StatementAneel KumarОценок пока нет

- Request For Inspection:: EmployerДокумент2 страницыRequest For Inspection:: Employerhovael laboratoryОценок пока нет

- External QC Inspection Request-Report FormДокумент1 страницаExternal QC Inspection Request-Report FormEdison WalitОценок пока нет

- QC Example Resume.01Документ4 страницыQC Example Resume.01Guru SankarОценок пока нет

- Contact No: - Contact Address: - C/OДокумент5 страницContact No: - Contact Address: - C/Ovishal bailur100% (1)

- Site Quality Observation Report #3 Tabuk-J&PДокумент15 страницSite Quality Observation Report #3 Tabuk-J&PmasahinОценок пока нет

- QC How To Close A Non-Conformance ReportДокумент3 страницыQC How To Close A Non-Conformance ReportRsjBugtong100% (1)

- 560-S27 QUALITY CONTROL PROGRAM Rev.4Документ27 страниц560-S27 QUALITY CONTROL PROGRAM Rev.4AbdelmuneimОценок пока нет

- QMS ProceduresДокумент1 страницаQMS Proceduressurenu89Оценок пока нет

- Itp Bored Pile Rev 1Документ10 страницItp Bored Pile Rev 1Pandar HasibuhanОценок пока нет

- A Qac Pro 000 38951Документ30 страницA Qac Pro 000 38951Amin GОценок пока нет

- DWST-MTHL-QP009 Non-Conforming Item Control ProcedureДокумент15 страницDWST-MTHL-QP009 Non-Conforming Item Control ProcedureDeepak UpadhayayОценок пока нет

- ITP Check List For Metal Deck InstallationДокумент2 страницыITP Check List For Metal Deck InstallationJoyce Gordonio0% (1)

- Quality Management System ProcedureДокумент3 страницыQuality Management System Procedureb3 qual100% (1)

- Site Audit FormДокумент16 страницSite Audit FormNasir IbrahimОценок пока нет

- Material Over Short and Damage ReportДокумент1 страницаMaterial Over Short and Damage ReportamirrulasyrafОценок пока нет

- Procedure For Control of Non Confirming ProductДокумент7 страницProcedure For Control of Non Confirming ProductAvijit DebnathОценок пока нет

- ER288-Rebar Test PlanДокумент4 страницыER288-Rebar Test PlanalfieОценок пока нет

- Inspection Test Plan ITP v3Документ22 страницыInspection Test Plan ITP v3Luis Gabriel Bautista100% (1)

- ITP - Civil WorkДокумент5 страницITP - Civil WorkShabeer Shaarim Abdul JabbarОценок пока нет

- E-M00006-00-Q-QCP-100 Rev.0 - IFU Project Quality PlanДокумент26 страницE-M00006-00-Q-QCP-100 Rev.0 - IFU Project Quality Planmahesh100% (1)

- DE-QC-IT-S01 (Inspection & Test Plan)Документ8 страницDE-QC-IT-S01 (Inspection & Test Plan)Zainarul Aswad RazaliОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент3 страницыSaudi Aramco Inspection ChecklistZia ur RehmanОценок пока нет

- ISO 9001:2015 Quality Management System: Risk & Opportunities Assessment RecordДокумент1 страницаISO 9001:2015 Quality Management System: Risk & Opportunities Assessment RecordkarthikumarnpОценок пока нет

- ITP - EarthworkДокумент2 страницыITP - EarthworkManish PatilОценок пока нет

- Client:: Inspection & Test Plan For Excavation WorksДокумент3 страницыClient:: Inspection & Test Plan For Excavation WorksAnonymous PxHPgLОценок пока нет

- 13427-01weekly QAQC ReportДокумент1 страница13427-01weekly QAQC ReportShyam SinghОценок пока нет

- 5.itp For Construction MaterialsДокумент8 страниц5.itp For Construction Materialsbinunalukandam100% (1)

- Qaqc Iso ProcedureДокумент135 страницQaqc Iso ProcedureGomathyselviОценок пока нет

- PPAP Fourth Edition 2006Документ5 страницPPAP Fourth Edition 2006Đại Hữu Tuấn MaiОценок пока нет

- Itp Lime StabilizationДокумент2 страницыItp Lime StabilizationMikiRoniWijayaОценок пока нет

- ASMI-OSHMS-PR-14 - Control of Documents and Record Retention ProcedureДокумент10 страницASMI-OSHMS-PR-14 - Control of Documents and Record Retention ProcedureJHUPEL ABARIALОценок пока нет

- General Inspection ChecklistДокумент5 страницGeneral Inspection ChecklistAmos MtweveОценок пока нет

- Lesson 10 Project Quality PlanningДокумент51 страницаLesson 10 Project Quality PlanningDevjit MandalОценок пока нет

- 5 Formwork ChecklistДокумент81 страница5 Formwork ChecklistAlphaОценок пока нет

- DD250 MATERIAL INSPECTION AND RECEIVING REPORT TemplateДокумент1 страницаDD250 MATERIAL INSPECTION AND RECEIVING REPORT TemplateWaqar SiddiqueОценок пока нет

- 84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsДокумент7 страниц84501-9200-9L-008 Rev-0 Technical Inspection Services Company Final Documentation RequirementsPeni M. SaptoargoОценок пока нет

- Construction QC PlanДокумент13 страницConstruction QC PlanAbdallah YounisОценок пока нет

- Quality ManualДокумент4 страницыQuality ManualAli IrvaliОценок пока нет

- Itp Civil WorkДокумент9 страницItp Civil WorkChristian Albert Sinaga RumajarОценок пока нет

- Quality Manual: M. Barbisotti & Sons LTDДокумент20 страницQuality Manual: M. Barbisotti & Sons LTDengsam777100% (1)

- 5 Exterior Doors Inspection ChecklistДокумент10 страниц5 Exterior Doors Inspection ChecklistAhmed Mostafa AL-AboudyОценок пока нет

- Quality Audit (QAP GTL 05) Rev.Документ12 страницQuality Audit (QAP GTL 05) Rev.GV Narayana ReddyОценок пока нет

- QSP-006 R0 QSP For Non-Conformance Product ControlДокумент13 страницQSP-006 R0 QSP For Non-Conformance Product ControljennyОценок пока нет

- Method Statement of Mass Concrete Block Precast WorksДокумент41 страницаMethod Statement of Mass Concrete Block Precast WorksShams JogОценок пока нет

- Civil Works Inspection - QA - QC-Construction LTDДокумент1 страницаCivil Works Inspection - QA - QC-Construction LTDNashrul KarimОценок пока нет

- QCS 2010 Section 5 Part 2 AggregatesДокумент9 страницQCS 2010 Section 5 Part 2 Aggregatesbryanpastor106Оценок пока нет

- Material Receiving Inspection ReportДокумент2 страницыMaterial Receiving Inspection Reporttuan mai vanОценок пока нет

- Section 017700 - Closeout ProceduresДокумент5 страницSection 017700 - Closeout ProceduresChase GietterОценок пока нет

- Punch List Civil Jan.13Документ10 страницPunch List Civil Jan.13Azam Islam KhanОценок пока нет

- Inspection Test Plan Rev 1Документ2 страницыInspection Test Plan Rev 1Mohd KhairiОценок пока нет

- Roles of QA QC ManagerДокумент3 страницыRoles of QA QC ManagerAbdullah AnsariОценок пока нет

- Qaqc Engineer in Oil N GasДокумент2 страницыQaqc Engineer in Oil N GasSrigala PinkОценок пока нет

- Material Testing & Quality ControlДокумент22 страницыMaterial Testing & Quality ControlJun Michael100% (1)

- GPPM 22 PDFДокумент64 страницыGPPM 22 PDFKirti Ambastha100% (1)

- Sakina Aliyeva: Early LifeДокумент2 страницыSakina Aliyeva: Early LifeEmilJaredVirayPabustanОценок пока нет

- Typing: Typewriter Computer Keyboard IBM PC Keyboard Apple Keyboard Chorded KeyboardДокумент1 страницаTyping: Typewriter Computer Keyboard IBM PC Keyboard Apple Keyboard Chorded KeyboardEmilJaredVirayPabustanОценок пока нет

- Imperial UnitsДокумент21 страницаImperial UnitsEmilJaredVirayPabustanОценок пока нет

- Capsule ProposalДокумент3 страницыCapsule ProposalEmilJaredVirayPabustanОценок пока нет

- Environmental Laws: Alyssa V. PabustanДокумент11 страницEnvironmental Laws: Alyssa V. PabustanEmilJaredVirayPabustanОценок пока нет

- Life and Death DrivesДокумент1 страницаLife and Death DrivesEmilJaredVirayPabustanОценок пока нет

- Religion: Monotheistic Pater Familias Reason Neurotic PatricideДокумент1 страницаReligion: Monotheistic Pater Familias Reason Neurotic PatricideEmilJaredVirayPabustanОценок пока нет

- Nikola Tesla Biography: Quick FactsДокумент4 страницыNikola Tesla Biography: Quick FactsEmilJaredVirayPabustanОценок пока нет

- Id, Ego and Super-EgoДокумент1 страницаId, Ego and Super-EgoEmilJaredVirayPabustanОценок пока нет

- Psychotherapy: Joel KovelДокумент3 страницыPsychotherapy: Joel KovelEmilJaredVirayPabustanОценок пока нет

- RelaysДокумент6 страницRelaysEmilJaredVirayPabustan100% (1)

- History: Rizal Is AДокумент7 страницHistory: Rizal Is AEmilJaredVirayPabustanОценок пока нет

- 12C Upgrade v2Документ33 страницы12C Upgrade v2nakguptaОценок пока нет

- Akai LCT37Z6TA CMO (11-27-06) LCDДокумент135 страницAkai LCT37Z6TA CMO (11-27-06) LCDRicardo PicassoОценок пока нет

- MarketingДокумент12 страницMarketingRoopasreeОценок пока нет

- Foxwell Bt780 ManualДокумент21 страницаFoxwell Bt780 ManualSanjay Singh RawatОценок пока нет

- SSM63817 - Smart Key Programming Advice SSM March 2013 v1Документ5 страницSSM63817 - Smart Key Programming Advice SSM March 2013 v1Kent WaiОценок пока нет

- Request For Tender: For The Provision of Passenger LiftДокумент40 страницRequest For Tender: For The Provision of Passenger LiftnaveedfndОценок пока нет

- ENTC463Key and CouplingДокумент47 страницENTC463Key and Couplingعبدالله عمرОценок пока нет

- Ginordi Series Type 5 - Machine ManualДокумент29 страницGinordi Series Type 5 - Machine ManualYogesh JainОценок пока нет

- Camion CAT 793DДокумент9 страницCamion CAT 793DdiegosmedinaОценок пока нет

- Leaked Admin Code 2017 by RobuxmaniacДокумент2 страницыLeaked Admin Code 2017 by RobuxmaniacCélioAntônioFernandesXavier100% (3)

- Amx Ni 3100Документ2 страницыAmx Ni 3100Charith PurasingheОценок пока нет

- CV Yoyok Dwi Parindra 2014Документ3 страницыCV Yoyok Dwi Parindra 2014yoyokdpОценок пока нет

- VDA 4958-3 Langzeitarchivierung 1.0Документ107 страницVDA 4958-3 Langzeitarchivierung 1.0Anonymous CoGUaJОценок пока нет

- Application Engineering BulletinДокумент15 страницApplication Engineering BulletinJose VidalОценок пока нет

- Jmeter Quick GuideДокумент51 страницаJmeter Quick GuidepoojanewОценок пока нет

- SQL Basics For RPG DevelopersДокумент76 страницSQL Basics For RPG DevelopersRamana VaralaОценок пока нет

- ABAP System Fields: Name Type Length Use DescriptionДокумент21 страницаABAP System Fields: Name Type Length Use DescriptionmagnytoОценок пока нет

- Thermoelectrics Design and Materials - 2016 - Lee - Appendix H Conversion FactorsДокумент3 страницыThermoelectrics Design and Materials - 2016 - Lee - Appendix H Conversion FactorsKen Joshua ValenciaОценок пока нет

- Hold Points, Witness Points and MilestonesДокумент6 страницHold Points, Witness Points and MilestonesKi JohnsonОценок пока нет

- Lyoprint PbaДокумент4 страницыLyoprint PbaLambo Sun100% (1)

- Specifications For Oil, Gas, Water, Sewer PipesДокумент3 страницыSpecifications For Oil, Gas, Water, Sewer PipesShams TabrezОценок пока нет

- Project Cost ControlДокумент15 страницProject Cost ControlMuhammad Sageer100% (3)

- Procedure For Maintenance of Switched Mode Power Supplies: Process ManualДокумент15 страницProcedure For Maintenance of Switched Mode Power Supplies: Process ManualGaurav AnandОценок пока нет

- 2 Ic695acc400Документ4 страницы2 Ic695acc400MUHAMMAD TAUFIQОценок пока нет

- Catalogo Chumaceras Link BeltДокумент309 страницCatalogo Chumaceras Link BeltHejage Kecuca Decuca100% (1)

- ES 49BranchConnectionsДокумент7 страницES 49BranchConnectionsrodofgodОценок пока нет

- Chemicals Zetag DATA Powder Zetag 8160 - 0410Документ2 страницыChemicals Zetag DATA Powder Zetag 8160 - 0410PromagEnviro.com100% (1)

- PD750-01 Spec SheetДокумент4 страницыPD750-01 Spec SheetService Brags & Hayes, Inc.Оценок пока нет

- Ad PatchДокумент7 страницAd Patchapi-3741317100% (1)

- Capitol Steel PDFДокумент1 страницаCapitol Steel PDFRodney LanagОценок пока нет

- Civil Engineer's Handbook of Professional PracticeОт EverandCivil Engineer's Handbook of Professional PracticeРейтинг: 4.5 из 5 звезд4.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- Real Life: Construction Management Guide from A-ZОт EverandReal Life: Construction Management Guide from A-ZРейтинг: 4.5 из 5 звезд4.5/5 (4)

- A Place of My Own: The Architecture of DaydreamsОт EverandA Place of My Own: The Architecture of DaydreamsРейтинг: 4 из 5 звезд4/5 (242)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationОт EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettРейтинг: 4 из 5 звезд4/5 (1)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyОт EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyРейтинг: 4 из 5 звезд4/5 (1)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsОт EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Estimating Construction Profitably: Developing a System for Residential EstimatingОт EverandEstimating Construction Profitably: Developing a System for Residential EstimatingОценок пока нет

- Sustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsОт EverandSustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsОценок пока нет

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionОт EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Even More Schedule for Sale: Advanced Work Packaging, for Construction ProjectsОт EverandEven More Schedule for Sale: Advanced Work Packaging, for Construction ProjectsОценок пока нет

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОт EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОценок пока нет

- Fire Protection Engineering in Building DesignОт EverandFire Protection Engineering in Building DesignРейтинг: 4.5 из 5 звезд4.5/5 (5)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesОт EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesОценок пока нет

- Piping Engineering Leadership for Process Plant ProjectsОт EverandPiping Engineering Leadership for Process Plant ProjectsРейтинг: 5 из 5 звезд5/5 (1)

- Building Construction Technology: A Useful Guide - Part 1От EverandBuilding Construction Technology: A Useful Guide - Part 1Рейтинг: 4 из 5 звезд4/5 (3)

- Starting Your Career as a Contractor: How to Build and Run a Construction BusinessОт EverandStarting Your Career as a Contractor: How to Build and Run a Construction BusinessРейтинг: 5 из 5 звезд5/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- History of Smart Textiles: A Comprehensive Guide To E-TextilesОт EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesОценок пока нет

- An Architect's Guide to Construction: Tales from the Trenches Book 1От EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Оценок пока нет

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideОт Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideРейтинг: 3.5 из 5 звезд3.5/5 (7)

- EMOTIONAL EATING: How To Stop Emotional Eating Naturally And Live A Better LifeОт EverandEMOTIONAL EATING: How To Stop Emotional Eating Naturally And Live A Better LifeРейтинг: 4 из 5 звезд4/5 (14)