Академический Документы

Профессиональный Документы

Культура Документы

Main Research Paper IJETT-V28P202

Загружено:

Srijan VyasАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Main Research Paper IJETT-V28P202

Загружено:

Srijan VyasАвторское право:

Доступные форматы

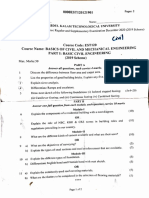

International Journal of Engineering Trends and Technology (IJETT) Volume 28 Number 1 - October 2015

Variable Compression Ratio Diesel Engine Performance

Analysis

K.Satyanarayana*1, Vinodh Kumar Padala1, T.V.Hanumantha Rao1, S.V.Umamaheswararao2

Department of Mechanical Engineering, Anil Neerukonda Institute of Technology And Sciences,

Sangivalasa, Visakhapatnam, Andhra Pradesh, India.531162

Department of Marine Engineering, Andhra University, Visakhapatnam, India--531006

ABSTRACT:-Variable Compression Ratio (V.C.R)

engine test rig can be used to determine the effect of

Compression Ratio (C.R) on the performance and

emissions of the engine. The combustion phenomena,

when provided with a pressure transducer. The

performance frequency parameters like efficiencies,

power adopted, and specific fuel consumption are

determined. Further, combustion phenomenon is also

observed through this work, we can find the optimum

compression ratio for which the best performance is

possible. In order to find out optimum compression

ratio, experiments were carried out on a single

cylinder four stroke variable compression ratio diesel

engine. Tests were carried out at compression ratios

of 16.5, 17.0, 17.5, 18.0 and 19.0 at different loads the

performance characteristics of engine like Brake

power (BP), Brake Thermal Efficiency (BTE), Brake

Specific Fuel Consumption (BSFC). Results show a

significant improved performance at a compression

ratio 19.0. The compression ratios lesser than 19.0

showed a drop in break thermal efficiency, rise in fuel

consumption.

Keywords: Diesel engine, variable compression ratio,

performance, smokes density.

1. INTRODUCTION

Worldwide pressure to reduce automotive fuel

consumption and CO2 emissions is leading to the

introduction of various new technologies for the C.I

engine as it fights for market share with the petrol. So

far, variable compression ratio (VCR) engines have

not reached the market, despite patents and

experiments dating back over decades. VCR

technology could provide the key to enable

exceptional efficiency at light loads without loss of

full load performance. This paper will review the

many embodiments of VCR, the implications for

volume manufacture and the strategy for VCR

implementation in order to produce the maximum

benefit.

2.

LITERATURE REVIEW:

.The ever increasing demand for the petroleum

based fuels and their scare availability has lead to

extensive research on Diesel fuelled engines. A better

design of the engine can significantly improve the

combustion quality and in turn will lead to better

brake thermal efficiencies and hence savings in

ISSN: 2231-5381

fuel..(M.K.G. Babu et.al, 2008 ) The potential of

Diethyl ether (DEE) as a supplementary oxygenated

fuel in a compression ignition engine has been

identified through an experimental investigation. In

this study the tests were conducted on a single

cylinder DI diesel engine fueled with neat diesel fuel

and addition of 2, 5, and 10% DEE in diesel fuel to

find out the optimal blend on the basis of performance

and emission characteristics India though rich in coal

abundantly and endowed with renewable energy in the

form of solar, wind, hydro and bio-energy has a very

small hydro carbon reserves (0.4%of the worlds

reserve) [2]. India is a net importer of energy. Nearly

25% of its energy needs are met through imports

mainly in the form of crude oil and natural gas

(Kapilan N et.al 2008).The rising oil bill has been the

focus of serious concerns due to the pressure it has

placed on scarce foreign exchange resources and is

also largely responsible for energy supply shortages.

The sub-optimal consumption of commercial energy

adversely affects the productive sectors, which in turn

hampers economic growth. [4].The present work deals

with finding the better compression ratio for the

Diesel fuelled C.I engine at variable load and constant

speed operation. The compression ratio of an internalcombustion engine or external combustion engine is a

value that represents the ratio of the volume of its

combustion chamber from its largest capacity to its

smallest capacity. It is a fundamental specification for

many common combustion engines. Experimental

results showed that there is a slight increase in brake

specific fuel consumption, brake power and brake

thermal efficiency as compared to diesel fuel. In

addition, it was found that there is a decrease in smoke,

oxides of nitrogen, unburned hydrocarbon, carbon

monoxide and ignition delay along with increase in

carbon dioxide.

(Ashok M.P et.al 2007).The

performance of the diesel engine is increased with the

addition of oxygenates to the fuel prior to the

combustion. This paper presents the effect of blending

of Diethyl ether (DEE) with diesel at various

proportions (5%,7.5% and 10%)on the performance of

diesel engine. The experimental results indicated that

with the increase in the concentration of DEE to diesel

increases the brake thermal efficiency, mechanical

efficiency and decreases the specific fuel consumption.

The performance of diesel engine at different

compression ratios (18, 16 and 14) for diesel with 5%

DEE blend was also evaluated in this work.

(Subramanian K.A. et.al 2002).The data obtained from

http://www.ijettjournal.org

Page 6

International Journal of Engineering Trends and Technology (IJETT) Volume 28 Number 1 - October 2015

experimentation is presented analyzed in this paper.To

find out the Optimum Compression Ratio of the

Computerized Variable Compression Ratio (VCR)

Single Cylinder Four Stroke Diesel Engine using

Experimentation analysis.Various parameters defining

the performance of V.C.R diesel engine are calculated

and they areused as means for obtaining optimum

compression ratio. By plotting performance graphs of

different loads and different compression ratios from

that optimum compression ratio obtained.

3.

EXPERIMENTAL SETUP

The layout of the experimental setup is shown in fig

3.1. The main components of the system are given

below.

The

engine,

Fuel

injection

pump ,Dynamometer , Device for changing starting of

fuel, Supercharging system, Dynamic injection

indicator , Data acquisition system , Smoke meter

Exhaust gas analyser,

Pressure transducer

Figure 3.1: Block Diagram of VCR Engine

Figure3.2 Experimental setup of VCR Diesel engine

ISSN: 2231-5381

http://www.ijettjournal.org

Page 7

International Journal of Engineering Trends and Technology (IJETT) Volume 28 Number 1 - October 2015

TABLE I:

V.C.R ENGINE (TEST RIG) SPECIFICATIONS

S .NO.

Features

Specifications

Make

Kirloskar diesel Engine

Type

Four stroke, Water cooled

Diesel

No of cylinders

one

Combustion Principle

Compressionignition

Max speed

1500

Crank Radius

55mm

Connecting Rod length

300mm

80mm

Clinder diameter

Stroke length

110mm

10

Compression ratio

variable from 14.0 to 20.0

11

Loading

Eddy current dynamometer

12

Load (Max.)

23.86 N-M

13

Maximum power

3.75 kW

II.THEORETICAL CALCULATIONS

PERFORMANCE

A. Calculations:

Friction Power (FP): The link between the brake

power output and indicated power output of an engine

is its friction. Friction has a dominating effect on the

performance of an engine. Almost invariably, the

frictional losses are ultimately dissipated to cooling

system (and exhaust) as they appear in the form of

frictional heat and this influences the cooling capacity

required. Moreover lower friction means availability

of more brake power, Hence brake specific fuel

consumption is lower. This fuel economy is important

because it decides the speed at which an engine can be

run economically. Thus the level of friction decides

the maximum output of the engine which can be

ISSN: 2231-5381

obtained economically. In design and testing of an

engine measurement of friction power is important for

getting an insight into the methods by which the

output of an engine can be increased. In the evaluation

of IP and mechanical efficiency measured friction

power is also used. By following methods:

Willans Line Method

Morse Test

Motoring Test

Difference between IP and BP

Indicated Power (IP): However while calculating the

Mechanical efficiency another factor called Indicated

Power (IP) is considered. It is defined as the power

developed by combustion of fuel in the combustion

http://www.ijettjournal.org

Page 8

International Journal of Engineering Trends and Technology (IJETT) Volume 28 Number 1 - October 2015

chamber (IP). It is always more than brake power. It is

the sum of Friction Power and Brake Power.

Indicated Mean Effective Pressure (IMEP): When

quoted as an indicated mean effective pressure or

IMEP (defined below), it may be thought of as the

average pressure acting on a piston during a power

stroke of its cycle.

It is obtained by using the formula.

IP =

Mechanical Efficiency (ME): Mechanical efficiency

measures the effectiveness of a machine in

transforming the

energy and power that is input to

the device into an output force and movement.

Efficiency is measured as a ratio of the measured

performance to the performance of an ideal machine:

ME= BP

(Imep) LAN

Imep

M*CV

It is given by the relation.

IP

60

So,

ITE = IP*3600

= 60IP

LAN

Brake Specific Fuel Consumption (BSFC): Brake

Specific fuel consumption (BSFC) or sometimes

simply Brake specific fuel consumption, BSFC, is an

engineering term that is used to describe the fuel

efficiency of an engine design with respect to thrust

output. Brake Specific Fuel Consumption may also be

thought of as fuel consumption (grams/second) per

unit of thrust (kilo newtons, or kN).

It is obtained by using the formulae.

BSFC = M

B. Experiment Procedure: The Variable

Compression Ratio Engine is started by using

Diesel and when the engine reaches the stable

operating conditions at a constant compression

ratio. Start applying under a certain Load. To cool

the Engine Socket, water is applied at a rate of 40

cc/Sec and the cooling water Temperature is 26.7

degrees. The tests are conducted at a constant

speed of 1500rpm.In every test all the performance

parameters like Indicated Power(IP) , Indicated

Mean

effective

pressure,

Specific

fuel

Consumption(SFC), Brake Thermal Efficiency,

Indicated Thermal Efficiency, Mechanical

Efficiency

are

determined

at

different

Compression ratios of 16.5, 17, 17.5, 18, 18.5, 19.

BP

Indicated Specific Fuel Consumption (ISFC):

Indicated Specific fuel consumption (ISFC) or

sometimes simply Indicated specific fuel consumption,

ISFC, is an engineering term that is used to describe

the fuel efficiency of an engine design with respect to

thrust output. Indicated Specific Fuel Consumption

may also be thought of as fuel consumption

(grams/second) per unit of thrust (kilo newtons, or

KN).

It is obtained by using the formulae.

ISFC = M

IP

Brake Thermal Efficiency (BTE): Brake Thermal

Efficiency is defined as brake power of a heat engine

as a function of the thermal input from the fuel. It is

used to evaluate how well an engine converts the heat

from a fuel to mechanical energy.

V.RESULTS AND DISCUSSIONS

Test was carried out at compression ratios of 16.5 at

different loads or torque like

17, 18, 19, 20, 21 N-m and The performance

characteristics of engine like Brake power (BP), Fuel

flow rate is noted and from graphs fuel consumption

(Kg/Hr) vs. B.P (KW) at a constant Speed is plotted

and the graph is extrapolated back to zero fuel

consumption as shown in figure (a) the point where

this graphs cuts the B.P (KW) axis in an indication of

the friction power of the engine at that speed.

From Friction Power, Brake Power. We calculate the

remaining performance Characteristics like Indicated

Power(IP) , Indicated Mean effective pressure,

Specific fuel Consumption (SFC), Brake Thermal

Efficiency, Indicated Thermal Efficiency, Mechanical

Efficiency are determined.

It is obtained by using the formulae

BTE = BP*3600

A. Performance Analysis

M* CV

Indicated Thermal Efficiency (ITE): The ratio

between the indicated power output of an engine and

the rate of supply of energy in the steam or fuel.

It is obtained by the relation

ISSN: 2231-5381

1) Brake Thermal Efficiency (BTE): Figure

shows that the maximum brake thermal

efficiency is obtained at a compression ratio

of 19.0; the least brake thermal efficiency is

obtained at a compression ratio 16.5. Hence,

with respect to brake thermal efficiency, 19

can be treated as optimum power output. This

http://www.ijettjournal.org

Page 9

International Journal of Engineering Trends and Technology (IJETT) Volume 28 Number 1 - October 2015

compression ratio.

C.R

C.R

C.R

C.R

C.R

19.25

18.75

16.5

17.0

17.5

18.0

19.0

18.25

17.75

17.25

16.75

16.25

x

2.45

2.55

2.6

2.65

2.7

2.75

2.8

2.85

2.9

2.95

3.05

3.1

3.15

Fuel Consumption (Kg/hr)

can be attributed to the better combustion and

better intermixing of the fuel and air at this

Brake power (KW)

2) Fuel Consumption:

y

C.R 16.5

C.R 17.0

C.R 17.5

C.R 18.0

C.R 19.0

1.6

1.55

1.5

1.45

1.4

1.35

1.3

x

2.55

2.6

2.65

2.7

2.75

2.8

2.85

2.9

2.95

3.05

3.1

3.15

1.2

Brake power (KW)

same. The high fuel consumption at higher

compression ratios can be attributed to the effect

of charge dilution. At the lower sides of the

compression ratios, the fuel consumption is high

due to incomplete combustion of the fuel.

The better fuel consumption was obtained at a

compression ratio of 19 (Figure-2). The higher

and lower compression ratios than 19 resulted in

high fuel consumptions. The fuel consumption at

a compression ratio of 17 and 17.5 was almost the

0.58 y

C.R 16.5

C.R 17.0

C.R 17.5

C.R 18.0

C.R 19

0.56

0.54

0.52

0.5

0.48

0.46

0.44

0.42

x

2.45

2.55

2.6

2.65

2.7

2.75

2.8

2.85

2.9

2.95

3.05

3.1

Mechanical efficiency (%)

3) Specific Fuel Consumption:

0.38

Brake power (KW)

ISSN: 2231-5381

http://www.ijettjournal.org

Page 10

International Journal of Engineering Trends and Technology (IJETT) Volume 28 Number 1 - October 2015

lower sides of the compression ratios, the specific

fuel consumption is high due to incomplete

combustion of the fuel.

The better specific fuel consumption was

obtained at a compression ratio of 19.0 and lower

compression ratios than 19.0 resulted in high

specific fuel consumptions. The specific fuel

consumption at a compression ratio of 18.0 and

17.5 was almost the same. At the lower sides of

the compression ratios, the specific fuel

consumption is high due to incomplete

combustion of the fuelThe better specific fuel

consumption was obtained at a compression ratio

of 19.0 and lower compression ratios than 19.0

resulted in high specific fuel consumptions. The

specific fuel consumption at a compression ratio

of 18.0 and 17.5 was almost the same. At the

4) Mechanical Efficiency: The variation in

mechanical efficiency at different loads for

different compression ratios is shown in Fig.4. It

is observed that mechanical efficiency increases

with the increase in the load due to increase in the

BP and IP. With the increase in compression ratio

the mechanical efficiency also increases. And the

mechanical efficiency at compression ratio of

16.5 and 17.0 was almost the same.

Specific Fuel Consumption (Kg/Kw-Hr)

87 y

C.R 16.5

C.R 17.0

C.R 17.5

C.R 18.0

C.R 19.0

86.5

86

85.5

85

84.5

84

83.5

83

82.5

82

x

2.55

2.6

2.65

2.7

2.75

2.8

2.85

2.9

2.95

3.05

3.1

3.15

81

Break Power

Exhaust gas temperatures were found to be increasing with the increase in load and the compression

ratio. The highest exhaust gas temperature was recorded for the compression ratio 19.0 while the least was

for 16.5.

ISSN: 2231-5381

http://www.ijettjournal.org

Page 11

International Journal of Engineering Trends and Technology (IJETT) Volume 28 Number 1 - October 2015

5) Indicative Mean Effective Pressures:

Indicative Mean Effective Pressures were found to be increasing with the increase in load and the

compression ratio. The highest Indicative Mean Effective Pressures was recorded for the compression ratio

19.0 while the least was for 16.5.

6. CONCLUSIONS

Following conclusions can be drawn from the

experimentations carried out on the C.I engine with

diesel at various compression ratios. The optimum

compression ratio is 19 as operation for the given

engine. Better fuel economy is obtained at the

compression ratio 19.Fuel consumption is higher at

compression ratio 16.5.Smoke density is less at

compression ratio 19.0.Exhaust gas temperatures are

moderate at compression ratio 16.5. For more power

at high loads the engine should operate at compression

ratio 19 due to less specific fuel consumption. For

lower power output at light loads the engine should

operate at compression ratio 16.5 due to less fuel

consumption.

REFERENCES:

[1] asoudIranmanesh, J.P.Subrahmanyam, M.K.G. Babu, Potential

of Diethyl ether as supplementary fuel to improve combustion

and emission characteristics of diesel engines,SAE paper

number 2008-28-0044 (2008)

[2] M. Senthil Kumar. Experimental investigations on diesel engine

with vegetable oils.Ph.D Thesis.IIT Madras, Chennai, India.

[3] Ganesan V. 1998. Internal Combustion Engines. Tata

McGrawhill, New Delhi.

[4] B.S. Samaga. Vegetable oil as alternative fuel for C.I

engines.8th NCICEC-83. Paper No. AF-2.

ISSN: 2231-5381

[5] J. Ray Smith and Salvador Aceves. 1995. Series Hybrid vehicles

and optimized hydrogen engine design. SAE Paper No.

951195.

[6]. Kapilan N., Mohanan P. and Reddy R.P., Performance and

Emission Studies of Diesel Engine Using Diethyl Ether as

Oxygenated Fuel Additive, SAE Paper number:2008-01- 2466

(2008).

[7]. Ashok M.P. and Saravanan C.G., Effect of Diethyl Ether with

Emulsified Fuel in a Direct Injection Diesel Engine, SAE

Paper number: 2007-01-2126 (2007)

[8]. Subramanian K.A. and Ramesh A., Use of Diethyl Ether Along

with Water-Diesel Emulsion in a Di Diesel Engine, SAE

Paper number: 2002-01-2720 (2002).

[9] K.S. Narayana, S. Phani Kumar, M.S.S. Srinivasa Rao

Thermo-Structural Finite Element Analysis of I.C. Engine

Pistons International Colloquium on Materials Manufacturing

and Metrology, ICMMM 2014, August 8-9, IIT Madras,

Chennai, India. P 882- 84.

[10] Lanka Tata Rao , Katakam Satyanarayana , M.S.S.Srinivasa

Rao, T.V. Hanumanta Rao, S.V.UmamaheswaraRao, stress

analysis of 4stroke diesel engine piston IJCESR ISSN (print):

2393-8374, (online): 2394-0697,volume-2,issue-2,2015

[11] K.Satyanarayana et al., Condition Monitoring And Detection

Of Unbalance Using Vibration Signature Analysis.

InternationalJournal of Recent Scientific Research Vol. 6,

Issue, 8, pp.5796-5800, August, 2015.

[12] D. Simhachalam, N. Indraja, M. Raja Roy"Experimental

Evaluation of Mechanical Properties of Stainless Steel by TIG

Welding at Weld Zone", International Journal of Engineering

Trends and Technology (IJETT), V26(3),120-127 August

2015. ISSN:2231-5381

http://www.ijettjournal.org

Page 12

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Diesel Power PlantДокумент2 страницыDiesel Power PlantRemae GarciОценок пока нет

- V80D I4 R0 EnglishДокумент1 страницаV80D I4 R0 English阿康Оценок пока нет

- 4 Stroke ProjectДокумент113 страниц4 Stroke ProjectSaurabh Kumar0% (4)

- V 222 TiДокумент2 страницыV 222 TiTrupp2785Оценок пока нет

- Farm Machinery and PowerДокумент111 страницFarm Machinery and PowerGary Bhullar83% (12)

- A Review of HCCI Engine Using Alternative Fuels - Formatted PaperДокумент12 страницA Review of HCCI Engine Using Alternative Fuels - Formatted PaperJogoje AjitОценок пока нет

- Fundamentals of The Automotive Relative Compression Test: General DescriptionДокумент4 страницыFundamentals of The Automotive Relative Compression Test: General DescriptionIvoo ooОценок пока нет

- Automobile Engineering Lab ExperimentДокумент7 страницAutomobile Engineering Lab ExperimentNidhi BharatiyaОценок пока нет

- Tutorial 1 - Gas Power CyclesДокумент5 страницTutorial 1 - Gas Power CyclesShahran IezzatОценок пока нет

- 01 4G64S4M & 4G69S4N Engine-1Документ36 страниц01 4G64S4M & 4G69S4N Engine-1vitor santosОценок пока нет

- 4.2 Knocking in SI EngineДокумент38 страниц4.2 Knocking in SI EngineAshwini SinghОценок пока нет

- Finding The Top Center Position For The No. 1 PistonДокумент3 страницыFinding The Top Center Position For The No. 1 PistonHugo CiprianiОценок пока нет

- Piston Rings GuideДокумент5 страницPiston Rings GuideAshok BishtОценок пока нет

- Technical File D16-Mg Krs D2E2 04: According To Marpol 73/78 Annex Vi and Nox Technical CodeДокумент12 страницTechnical File D16-Mg Krs D2E2 04: According To Marpol 73/78 Annex Vi and Nox Technical CodeinforlexОценок пока нет

- Pf6tb & Pf6tc SeriesДокумент309 страницPf6tb & Pf6tc SeriesBudi Waskito95% (44)

- (MAHINDRA) Manual de Taller Mahindra Scorpio 2006 Ingles PDFДокумент510 страниц(MAHINDRA) Manual de Taller Mahindra Scorpio 2006 Ingles PDFVictor Montesdeoca100% (1)

- Service Manual Contents Notice: For Use in Service Manual Form SB2199E SB2200E00 J U N - 1 9 9 9Документ592 страницыService Manual Contents Notice: For Use in Service Manual Form SB2199E SB2200E00 J U N - 1 9 9 9Andrey Tsymbalov100% (2)

- Taylor, Charles Fayette Internal-Combustion Engine in Theory and Practice, Volume 2 - Combustion, Fuels, Materials, Design PDFДокумент602 страницыTaylor, Charles Fayette Internal-Combustion Engine in Theory and Practice, Volume 2 - Combustion, Fuels, Materials, Design PDFbhattaramrevanth75% (4)

- Combustion Engineering - Activity 3.1 (Cognitive Domain)Документ24 страницыCombustion Engineering - Activity 3.1 (Cognitive Domain)Kamille NayraОценок пока нет

- Deutz TD2009 Workshop ManualДокумент312 страницDeutz TD2009 Workshop ManualВенцислав Венев100% (4)

- Ranger Drifter Repair Manual F161!10!99aДокумент676 страницRanger Drifter Repair Manual F161!10!99aKatu201083% (6)

- LO Analysis InterpretationДокумент36 страницLO Analysis InterpretationPatrickОценок пока нет

- Development of CNG Injection EngineДокумент8 страницDevelopment of CNG Injection EngineShasahank JoshiОценок пока нет

- Maquinaria Naval Parte A-DДокумент185 страницMaquinaria Naval Parte A-DraulbrlunaОценок пока нет

- SSC Thermal EngineeringДокумент47 страницSSC Thermal EngineeringSteph Dela MujerОценок пока нет

- Me6016 Question BankДокумент28 страницMe6016 Question BankRandy VidsОценок пока нет

- Scavenging BlowersДокумент15 страницScavenging BlowersGargee ChavanОценок пока нет

- SID97-2B: Service Information DirectiveДокумент26 страницSID97-2B: Service Information Directivefranco lopezОценок пока нет

- Aviation Mechanic Powerplant Question Book1990Документ112 страницAviation Mechanic Powerplant Question Book1990LohnJittleОценок пока нет

- Basic Civil and Basic Mechanical Engineering PYQДокумент21 страницаBasic Civil and Basic Mechanical Engineering PYQGawthamОценок пока нет