Академический Документы

Профессиональный Документы

Культура Документы

AAP S19 Check Valves & Strainers S

Загружено:

Appleuk SudarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AAP S19 Check Valves & Strainers S

Загружено:

Appleuk SudarАвторское право:

Доступные форматы

Section 19

Check Valves

and Strainers

Edition 3

271

[19] CHECK VALVES AND STRAINERS

Check Valves and Strainers

Swing Check Valves

Swing Check valves are used where the flow moves through the valve in approximately a straight line similar to that in a

gate valve, is commonly used in pipe line conveying liquids by gravity or pumping. The check mechanism of the design

incorporates a disc which swings on a hinge.

Ball Check Valves

This valve is used where full uninterrupted flow is required. The design of the valve incorporates a compartment for when the

fluid is pumped through the valves the EPDM incapsulated steel ball is pushed into this compartment and held there whilst the

up steam pressure is applied. When the pump is turned off the ball falls from its compartment and with backpressure assists

drops back into the flow path and blocks any return of fluid back to the pump.

Lift Check Valves

A lift-check valve in which the disc, sometimes called a lift, can be lifted up off its seat by higher pressure of inlet or upstream

fluid to allow flow to the outlet or downstream side. A guide keeps motion of the disc on a vertical line, so the valve can later

reseat properly. When the pressure is no longer higher, gravity or higher downstream pressure will cause the disc to lower onto

its seat, shutting the valve to stop reverse flow. Both wafer and piston checks are examples of a Lift Check Valve.

Y Type Strainers

Y type strainers are designed for inline protection of control equipment, instruments, pumps and regulators. There function is

simplistic with fluid passing through the perforated stainless steel sheet, or wire mesh basket which is housed in a Y shaped

body made of various materials, brass, steel, cast iron, stainless steel etc. The basket traps the fines and the solids which

fall into the leg of the housing. They can be flushed out while the plant is in operation with a ball valve fitted to the leg of the

housing, or the basket can be removed completely for cleaning whilst the plant is not operational.

Brass Swing Check Valve

Materials

Specifications

PART

MATERIAL

Thread

AS 1722.1

Body

Brass

Cold Working Pressure

1380kPa

Bonnet

Brass

MAX Working Temperature

200C

Hinge Pin- Nut

Brass

Applications- Oil, Water

Brass Swing Check Valve

272

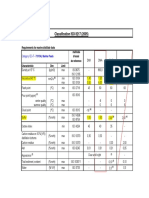

AAP CODE

IMPERIAL

SIZE

APPROX.

KG/PC

VBCS15

1/2

34

52

0.18

VBCS20

3/4

37

60

0.26

VBCS25

45

74

0.39

VBCS32

1 1/4

50

82

0.59

VBCS40

1 1/2

60

95

0.91

VBCS50

70

107

1.22

VBCS65

2 1/2

85

143

2.21

VBCS80

100

155

3.59

VBCS94

110

178

5.29

www.aapindustries.com.au

CHECK VALVES AND STRAINERS [19]

Y type Check Valve

Materials

Working Temperatures

PART

MATERIAL

Body

Brass CW 617N

Air

Stem Seat

Nylon 6

Water

0C

90C

Seat

NBR 60 SH/A

Gas

-20C

60C

Spring

Stainless Steel AISI 302

MIN

MAX

-20C

110C

Applications - Can be fitted in horizontal, vertical or oblique position. Suitable for

Hot/Cold water, Compressed Air, Oils

Y type Check Valve

AAP CODE

IMPERIAL

SIZE

APPROX.

KG/PC

kPa

VBCY10

38

46.5

34.5

0.12

1172

VBCY15

1/2

47

34.5

0.14

1172

VBCY20

3/4

53

42

0.2

1172

VBCY25

58

47.5

0.27

1172

VBCY32

1 1/4

66.5

59.5

0.36

965

VBCY40

1 1/2

68

68

0.57

965

VBCY50

77

86.5

0.77

965

VBCY65

2 1/2

93

102

1.55

758

VBCY80

97

111

2.02

758

VBCY94

110

140

2.98

758

E type Check Valve

Materials

PART

Working Temperatures

MATERIAL

MIN

MAX

Body

Brass CW 617N

Air

-20C

110C

Internal Seat

Stainless Steel plate AISI 304

fitted with NBR 60 SH/A, Cover

plate and rod in brass CW 614N

Water

0C

90C

Spring

STAINLESS STEEL AISI 302

Gas

-20C

60C

Applications - Can be fitted in horizontal, vertical or oblique position. Suitable for

Hot/Cold water, Compressed Air, Oils

E type Check Valve

AAP CODE

IMPERIAL

SIZE

APPROX.

KG/PC

kPa

VBCE10

38

55

34.5

0.17

2482

VBCE15

1/2

58.5

34.5

0.19

2482

VBCE20

3/4

63

42

0.27

2482

VBCE25

74

48

0.43

2482

VBCE32

1 1/4

83

60.5

0.54

1793

VBCE40

1 1/2

93

71

0.87

1793

VBCE50

101

87

1.32

1793

VBCE65

2 1/2

120

118

2.62

1172

VBCE80

139

139

4.21

1172

VBCE94

158.5

154

6.13

1172

www.aapindustries.com.au

273

[19] CHECK VALVES AND STRAINERS

Wafer Check Valves (Dual Disc)

Materials

Specifications

PART

MATERIAL

Flange

Body

Cast Iron

Cold Working Pressure

1600kPa

Spring

316 Stainless Steel

MAX Working Temperature

80C

Disc

316 Stainless Steel

Seat

NBR

Shaft 1

316 Stainless Steel

Shaft 2

316 Stainless Steel

Flange Gasket

NBR

AS2129 T/E

Applications - Water Oil, Gas

Wafer Check Valve (Dual Disc)

IMPERIAL

SIZE

AAP CODE

D1

APPROX.

KG/PC

VWC50

96

65

43

1.5

VWC65

2 1/2

109

80

48

VWC80

128

94

64

2.8

VWC94

160

117

64

4.1

VWC95

191

145

70

6.4

VWC96

213

170

76

8.5

VWC98

270

224

89

13.5

VWCX25

10

333

265

114

22

VWCx30

12

381

312

114

30

VWCX35

14

445

360

127

48

VWCX40

16

496

410

140

65

VWCX45

18

555

450

152

78

VWCX50

20

610

500

154

110

VWCX60

24

720

624

178

157

Wafer Check Valve Dual Disc ANSI 150 (Viton Seat)

Materials

Specifications

PART

MATERIAL

Flange

ANSI B16.5

Body

WCB

Cold Working Pressure

1965kPa

Seat

Viton

MAX Working Temperature

150C

Disc

304 Stainless Steel

Applications - Water, Oil, Gas, High Pressure Liquids

Wafer Check Valve Dual Disc ANSI 150 (Viton Seat)

274

AAP CODE

IMPERIAL

SIZE

D1

APPROX.

KG/PC

VWCCS15050

103

65

42

1.5

VWCCS15080

134

95

64

3.5

VWCCS15094

164

118

64

4.8

www.aapindustries.com.au

CHECK VALVES AND STRAINERS [19]

Wafer Check Valve (Single Disc)

Materials

Specifications

PART

MATERIAL

Flange

AS2129 T/E

Body

Cast Iron

Cold Working Pressure

1000kPa

Spring

316 Stainless Steel

MAX Working Temperature

120C

Disc

316 Stainless Steel

Seat

EPDM

Flange Gasket

NBR

Axle

2Cr13

Applications - Water Oil, Gas

Wafer Check Valve (Single Disc)

IMPERIAL

SIZE

D1

VWSC50

VWSC65

2 1/2

AAP CODE

APPROX.

KG/PC

33.3

96

44.5

1.4

42.9

109

47.6

1.9

VWSC80

52.4

128

50.8

2.7

VWSC94

76.2

160

57.2

4.5

VWSC95

95.3

191

63.5

6.5

VWSC96

120.7

213

69.9

8.5

VWSC98

163.5

270

73

11.5

VWSCX25

10

193.7

333

79.4

20

VWSCX30

12

241.3

380.8

85.7

27

VWSCX35

14

266.3

447.7

108.0

50

VWSCX40

16

317.5

498.5

108.0

60

316 Stainless Steel Wafer Check Valve Dual Disc ANSI 150 (Viton Seat)

Material List

Specifications

PART

MATERIAL

Flange

ANSI B16.5

Body

CF8M

Cold Working Pressure

2000KPa

Spring

316 Stainless Steel

MAX Working Temperature

-20 ~ 135C

Disc

CF8M

Seat

Viton

Shaft 1

316 Stainless Steel

Shaft 2

316 Stainless Steel

Gasket

PTFE

Applications - Water, Oil, Gas,

High Pressure Liquids

316 Stainless Steel Wafer Check Valve Dual Disc ANSI 150 (Viton Seat)

AAP CODE

IMPERIAL

SIZE

D1

APPROX.

KG/PC

VWCSS50A

101

65

54

1.5

VWCSS80A

133

94

57

2.8

VWCSS94A

168

117

64

4.1

VWCSS96A

219

170

76

8.5

www.aapindustries.com.au

275

[19] CHECK VALVES AND STRAINERS

Resilient Seat PN10 Flanged Ball Check Valve (Table E)

Material List

Specifications

PART

MATERIAL

Cold Working Pressure

Body

Ductile Iron

MAX Working Temperature

1000kPa

120C

Cover

Ductile Iron

Flanges

AS2129 T/E

Ball

Metal + EPDM

Face to Face

DIN3202

Gasket

EPDM

Applications - Water Treatment Plants

Resilient Seat PN10 Flanged Ball Check Valve (Table E)

AAP

CODE

IMPERIAL

SIZE

HOLE

DIAMETER

NO.

HOLES

APPROX.

KG/PC

VFBC50

200

126

18

7.7

VFBC65

2 1/2

240

145

18

11.2

VFBC80

260

168

18

15.4

VFBC94

300

186

18

21.7

VFBC98

500

350

22

90

VFBCX25

10

600

443.7

22

163

Resilient Seat PN10 Flanged Ball Check Valve (Table D)

Material List

Specifications

PART

MATERIAL

Cold Working Pressure

1000kPa

Body

Ductile Iron

MAX Working Temperature

120C

Cover

Ductile Iron

Flanges

AS2129 T/D

Ball

Metal + EPDM

Face to Face

DIN3202

Gasket

EPDM

Applications - Water Treatment Plants

Resilient Seat PN10 Flanged Ball Check Valve (Table D)

276

AAP

CODE

IMPERIAL

SIZE

HOLE

DIAMETER

NO.

HOLES

APPROX.

KG/PC

VFBC94D

300

186

18

21.7

VFBC96D

400

250

18

45.3

VFBCX25D

10

600

443.7

22

163

www.aapindustries.com.au

CHECK VALVES AND STRAINERS [19]

Resilient Seat Flanged Swing Check Valve (Table E)

Material List

Specifications

PART

MATERIAL

Flange

AS2129 T/E

Body

Cast Iron

Cold Working Pressure

1600kPa

MAX Working Temperature

120C

Cover

Cast Iron

Side Plug

Brass

Hanger Pin

Stainless Steel

Hanger

Ductile Iron

Disc

Cast Iron

Disc Trim

EPDM

Body Trim

Bronze

Gasket

Graphite

Applications - Water Treatment Plants, can be

fitted with counter lever and weight

Resilient Seat Flanged Swing Check Valve Table E

AAP

CODE

IMPERIAL

SIZE

HOLE

DIAMETER

NO.

HOLES

APPROX.

KG/PC

VRSSC50

203

121

18

14

VRSSC65

2 1/2

216

135

18

14

VRSSC80

241

141

18

22

VRSSC94

292

168

18

35

VRSSC95

330

182

18

40

VRSSC96

356

215

22

61.5

VRSSC98

495

267

22

85

VRSSCX25

10

622

305

22

12

140

VRSSCX30

12

699

343

26

12

200

Resilient Seat Flanged Swing Check Valve (Table D)

Material List

PART

MATERIAL

Body

Cover

Specifications

Flange

AS2129 T/D

Cast Iron

Cold Working Pressure

1600kPa

Cast Iron

MAX Working Temperature

120C

Side Plug

Brass

Hanger Pin

Stainless Steel

Hanger

Ductile Iron

Disc

Cast Iron

Disc Trim

EPDM

Body Trim

Bronze

Gasket

Graphite

Applications - Water Treatment Plants, can be

fitted with counter lever and weight

Resilient Seat Flanged Swing Check Valve Table D

IMPERIAL

SIZE

HOLE

DIAMETER

NO.

HOLES

VRSSC94D

292

168

18

35

VRSSCX25D

10

622

305

22

140

AAP CODE

www.aapindustries.com.au

APPROX.

KG/PC

277

[19] CHECK VALVES AND STRAINERS

Stainless Steel Check Valve

Material List

Specifications

PART

MATERIAL

Thread

AS1722.1

Body

CF8M

Cold Working Pressure

1400kPa

Bonnet

CF8M

MAX Working Temperature

200C

Hanger Pin

316 Stainless Steel

Disc

CF8M

Plug

316 Stainless Steel

Plug Gasket

PTFE

Applications - Water, Oil, Gas, Chemicals, Corrosive Environment and Liquids

Stainless Steel Check Valve 316 BSP

AAP CODE

IMPERIAL

SIZE

APPROX.

KG/PC

SSSC15

1/2

42

65

0.36

SSSC20

3/4

51

80

0.43

SSSC25

60

90

0.65

SSSC32

1 1/4

67

105

0.93

1.49

SSSC40

1 1/2

75

120

SSSC50

81

140

2.15

SSSC65

2 1/2

96

181

5.27

SSSC80

104

200

7.7

Stainless Steel 3 Piece Spring Check Valve

Material List

Specifications

PART

MATERIAL

Thread

AS1722.1

Body

CF8M

Cold Working Pressure

6895kPa

MAX Working Temperature

200C

Disc

CF8M

Spring

316 Stainless Steel

Spring Cap

CF8M

Cap

CF8M

Joint Gasket

PTFE

Applications - Water, Oil, Gas, Chemicals, Corrosive Environment and Liquids

316 Stainless Steel 3 Piece Spring Check Valve

278

AAP CODE

IMPERIAL

SIZE

APPROX.

KG/PC

SS3CV15

1/2

24

77

0.4

SS3CV20

3/4

26

80

0.5

SS3CV25

30

84

0.78

SS3CV32

1 1/4

36

96

1.13

SS3CV40

1 1/2

45

104

1.58

SS3CV50

50

115

2.19

www.aapindustries.com.au

CHECK VALVES AND STRAINERS [19]

Forged Steel Piston Check Valve Class 800 (Socketweld)

Material List

Specifications

PART

MATERIAL

Design

ANSI B16.34

Body

ASTM A105

Socket weld

ANSI B16.11

Bonnet

ASTM A105

Cold Working Pressure

13800kPa

Gasket

Graphite

MAX Working Temperature

427C

Spring

316 Stainless Steel

Disc

SS410 (2Cr13)

Seat

H/F Stellite

Applications - Steam Oil and Petro Chemical

Industry

Forged Steel Piston Check Valve Class 800 (Socketweld)

AAP CODE

IMPERIAL

SIZE

APPROX.

KG/PC

VCP800SW15

1/2

90

60

1.6

VCP800SW20

3/4

110

78

VCP800SW25

127

88

4.3

VCP800SW32

1 1/4

150

92

5.6

VCP800SW40

1 1/2

180

108

10

VCP800SW50

210

145

16

Forged Steel Piston Check Valve Class 800 NPT

Material List

Specifications

PART

MATERIAL

Design

ANSI B16.34

Body

ASTM A105

Thread (NPT)

ANSI B1.20.1

Bonnet

ASTM A105

Cold Working Pressure

13800kPa

Gasket

Graphite

MAX Working Temperature

427C

Spring

316 Stainless Steel

Disc

SS410 (2Cr13)

Seat

H/F Stellite

Applications - Steam Oil and Petro

Chemical Industry

Forged Steel Piston Check Valve Class 800 NPT

AAP CODE

IMPERIAL

SIZE

APPROX.

KG/PC

VCP80015

1/2

90

60

1.6

VCP80020

3/4

110

78

VCP80025

127

88

4.3

VCP80032

1 1/4

150

92

5.6

VCP80040

1 1/2

180

108

10

VCP80050

210

145

16

www.aapindustries.com.au

279

[19] CHECK VALVES AND STRAINERS

Cast Steel Flanged Check Valve ANSI 150

Material List

Specifications

PART

MATERIAL

Design

ANSI B16.34

Body

WCB (ASTM A216)

Flange

ANSI B16.5

Bonnet

WCB (ASTM A216)

MAX Working Temperature

300C

Disc

410 (2Cr13)

Cold Working Pressure

1960kPa

Seat

H/F Stellite

Gasket

Graphite

Cast Steel Flanged Check Valve ANSI 150

IMPERIAL

SIZE

HOLE

DIAMETER

NO.

HOLES

APPROX.

KG/PC

VSC15050

203.2

135

20

19

VSC15065

2 1/2

215.9

147

20

26

VSC15080

241.3

178

20

31

VSC15094

292.1

222

20

51

VSC15096

355.6

314

22

85

VSC15098

495.6

350

22

148

VSC150X25

10

622.3

406

26

12

218

VSC150X30

12

698.3

445

26

12

345

AAP CODE

Cast Steel Flanged Check Valve ANSI 300

Material List

PART

Specifications

MATERIAL

Design

ANSI B16.34

Body

WCB (ASTM A216)

Flange

ANSI B16.5

Bonnet

WCB (ASTM A216)

MAX Working Temperature

440C

Cold Working Pressure

5100kPa

Disc

410 (2Cr13)

Seat

H/F Stellite

Gasket

Graphite

Cast Steel Flanged Check Valve ANSI 300

AAP CODE

280

IMPERIAL

SIZE

HOLE

DIAMETER

NO.

HOLES

APPROX.

KG/PC

VSC30050

266.7

160

20

25

VSC30080

317.5

189

22

44

VSC30094

355.6

210

22

68

VSC30098

533.4

418

12

26

197

www.aapindustries.com.au

CHECK VALVES AND STRAINERS [19]

Brass Y Strainer

Material List

Specifications

PART

MATERIAL

Thread

AS1722.2

Body

Brass

MAX Working Temperature

100C

Mesh

304 Stainless Steel

Cold Working Pressure

1600kPa

Applications - Filtering Fluid to Protect inline valving

Brass Y Strainer

AAP

CODE

IMPERIAL

SIZE

MESH

DIAMETER

MESH

CENTRE

TO CENTRE

APPROX.

KG/PC

VBY10

3/8

47

31

0.8

0.07

VBY15

1/2

65

34

0.8

0.23

VBY20

3/4

80

42

0.8

0.35

VBY25

96

48

0.8

0.59

VBY32

1 1/4

104

55

0.8

0.83

VBY40

1 1/2

116

66

0.8

1.19

VBY50

140

74

0.8

1.95

VBY65

2 1/2

168

85

0.8

2.38

Stainless Steel Y Strainer

Material List

Specifications

PART

MATERIAL

Thread

Body

CF8M

MAX Working Temperature

230C

Cap

CF8M

Cold Working Pressure

5500kPa

Gasket

PTFE

Mesh

316 Stainless Steel

AS 1722.1

Stainless Steel Y Strainer

AAP CODE

IMPERIAL

SIZE

MESH

CENTRE

TO

CENTRE

MESH

DIAMETER

APPROX.

KG/PC

SSY15

1/2

65

51

0.2

SSY20

3/4

80

60

0.33

SSY25

90

72

0.7

SSY32

1 1/4

105

77

0.9

SSY40

1 1/2

120

87

1.4

SSY50

140

103

2.4

SSY65

2 1/2

170

112

4.7

SSY80

195

129

7.3

www.aapindustries.com.au

281

[19] CHECK VALVES AND STRAINERS

Cast Iron Flanged Y Strainer Table E

Material List

Specifications

PART

MATERIAL

Flange

AS2129 T/E

Body

Cast Iron (epoxy coated)

Max Working Temperature

120C

Screen

304 Stainless Steel

Cold Working Pressure

1600kPa

Gasket

Graphite

Cover

Cast Iron

Plug

Malleable Iron

Effective Open Area

Applications - Water, Oil, Air

Size

Screen Openings

(% of Inlet Pipe)

50mm 150mm

1.5mm diam @

4.5mm spacing

33%

200mm 300mm

3mm diam @ 7.5mm

spacing

44%

Cast Iron Flanged Y Strainer Table E

IMPERIAL

SIZE

HOLE

DIAMETER

NO.

HOLES

APPROX.

KG/PC

VDIY50

225.4

144

18

10

VDIY65

2 1/2

273

176

18

14

VDIY80

292.1

195

18

19

VDIY94

352.4

246

18

33

VDIY95

416

300

18

50

VDIY96

470

320

22

55

VDIY98

543

397

22

99

VDIYX25

10

660.4

483

22

12

169

VDIYX30

12

762

560

26

12

245

VDIYX35

14

950

689

26

12

450

AAP CODE

Cast Iron Flanged Y Strainer (Table D)

Material List

Specifications

PART

MATERIAL

Flange

Body

Cast Iron (epoxy coated)

Max Working Temperature

120C

Screen

304 Stainless Steel

Cold Working Pressure

1600kPa

Gasket

Graphite

Cover

Cast Iron

Plug

Malleable Iron

AS2129 T/E

Effective Open Area

Applications - Water, Oil, Air

Size

Screen Openings

(% of Inlet Pipe)

50mm 150mm

1.5mm diam @

4.5mm spacing

33%

200mm 300mm

3mm diam @ 7.5mm

spacing

44%

Cast Iron Flanged Y Strainer Table D

282

AAP

CODE

IMPERIAL

SIZE

HOLE

DIAMETER

NO.

HOLES

APPROX.

KG/PC

VDIY94D

352.4

246

18

33

VDIYX25D

10

660.4

483

22

169

www.aapindustries.com.au

CHECK VALVES AND STRAINERS [19]

Brass Foot Valve

Material List

Specifications

PART

MATERIAL

Thread

AS1722.1

Body

Brass

MAX Working Temperature

100C

Gasket

NBR

Cold Working Pressure

965kPa

Applications - General, Irrigation, Rural services

Brass Foot Valve

AAP CODE

IMPERIAL

SIZE

APPROX.

KG/PC

VBF15

1/2

VBF20

3/4

61.5

26

0.16

68

31.5

0.2

VBF25

VBF32

76

38

0.25

1 1/4

93

47

0.42

VBF40

1 1/2

VBF50

103

53

0.59

114

65.6

0.92

VBF65

VBF80

2 1/2

125

85

1.2

140

95

1.59

VBF94

185

121

2.68

Stainless Filter

Material List

PART

Specifications

MATERIAL

Thread

Body

Nylon

Mesh

304 Stainless Steel

IS0 228

Stainless Filter

AAP CODE

IMPERIAL

SIZE

MESH

SIZE

APPROX.

KG/PC

VSS10

3/8

30

1200m

0.01

VSS15

1/2

30

1200m

0.01

VSS20

3/4

39

1200m

0.01

VSS25

45

1200m

0.01

VSS32

1 1/4

56

1200m

0.02

VSS40

1 1/2

64

1200m

0.03

VSS50

77

1200m

0.05

VSS65

2 1/2

98

2000m

0.09

VSS80

107

2000m

0.11

VSS94

117

2000m

0.13

www.aapindustries.com.au

283

Вам также может понравиться

- AV-C Butterfly ValveДокумент20 страницAV-C Butterfly ValveSopon SrirattanapiboonОценок пока нет

- Industrial Steam Tray ST5 PDFДокумент4 страницыIndustrial Steam Tray ST5 PDFKim Swee LimОценок пока нет

- Series 767FR Specification SheetДокумент4 страницыSeries 767FR Specification SheetFEBCOОценок пока нет

- Válvula de SeguridadДокумент8 страницVálvula de Seguridadmark_59Оценок пока нет

- WW 770-UДокумент4 страницыWW 770-UAhmad NasserОценок пока нет

- Feed Water Heater - Isolation System: Features & BenefitsДокумент9 страницFeed Water Heater - Isolation System: Features & BenefitsAkash PatilОценок пока нет

- Sewage Air ValveДокумент10 страницSewage Air ValveAhmed TalaatОценок пока нет

- SRC Alpha Version1 PDFДокумент26 страницSRC Alpha Version1 PDFRajat JainОценок пока нет

- Valves Guide: Types, Parts, Standards & SpecificationsДокумент141 страницаValves Guide: Types, Parts, Standards & SpecificationsrichardОценок пока нет

- 2007 Danfoss CatalogueДокумент40 страниц2007 Danfoss CatalogueMiroslav AleksicОценок пока нет

- Series 825Y Specification SheetДокумент2 страницыSeries 825Y Specification SheetFEBCOОценок пока нет

- 'C' Series Control ValvesДокумент12 страниц'C' Series Control Valvesابزار دقیق100% (1)

- RedvalvE 90 01Документ4 страницыRedvalvE 90 01Rizal FalevyОценок пока нет

- Series 825YD Specification SheetДокумент2 страницыSeries 825YD Specification SheetFEBCOОценок пока нет

- Lift Check ValvesДокумент4 страницыLift Check Valveslejyoner62Оценок пока нет

- DelugeДокумент4 страницыDelugeBogdan Axinte100% (1)

- C2Документ38 страницC2juanca_eduОценок пока нет

- Dual Plate Check Valve WeightДокумент1 страницаDual Plate Check Valve WeightbisworupmОценок пока нет

- T1002-PSV-1453 Type - 2600Документ2 страницыT1002-PSV-1453 Type - 2600Jonson CaoОценок пока нет

- Float Valves for Tanks and PipelinesДокумент28 страницFloat Valves for Tanks and PipelinescartarОценок пока нет

- Air Release Valve E-34 Series FireДокумент5 страницAir Release Valve E-34 Series FireUghojor ElohoОценок пока нет

- Anderson Greenwood - Pentair Series 400 Modulating Datasheet PDFДокумент4 страницыAnderson Greenwood - Pentair Series 400 Modulating Datasheet PDFSARATH KRISHNAKUMARОценок пока нет

- Book LayoutДокумент8 страницBook LayoutaamenaОценок пока нет

- Guide to Valve Types, Uses, Maintenance and ControlДокумент44 страницыGuide to Valve Types, Uses, Maintenance and Controlأحمد محمد قدريОценок пока нет

- Valvulas Diafragma InformacionДокумент4 страницыValvulas Diafragma InformacionCHRISTIANCHIROQUEОценок пока нет

- Turbine Bypass ValveДокумент12 страницTurbine Bypass ValveRam MohanОценок пока нет

- E4Документ14 страницE4juanca_eduОценок пока нет

- VALVULAS - Series2200, NORRISEALДокумент8 страницVALVULAS - Series2200, NORRISEALAndrea Hernández CarreñoОценок пока нет

- VNotchДокумент3 страницыVNotchThiruThirunavukkarasuОценок пока нет

- PVR-108-2 Fueling Model SheetДокумент2 страницыPVR-108-2 Fueling Model SheetLetycia RosalesОценок пока нет

- Alarm ValveДокумент6 страницAlarm ValveAnonymous ZPTCAz9Оценок пока нет

- Crane Engineering Data 1Документ56 страницCrane Engineering Data 1jerry666aОценок пока нет

- FlowCon EVS 15-25mm Plug-in Temperature Control InsertДокумент7 страницFlowCon EVS 15-25mm Plug-in Temperature Control InsertJeff Anderson CollinsОценок пока нет

- Pressure Releif ValveДокумент24 страницыPressure Releif Valvemtalha_loveОценок пока нет

- Apco Airvacuum Valves Avv Sales 601Документ8 страницApco Airvacuum Valves Avv Sales 601Jhony MedranoОценок пока нет

- HansenДокумент4 страницыHansenBruna MacedoОценок пока нет

- Valvula Reductora de Presion Bermad Area 675 720-ULДокумент4 страницыValvula Reductora de Presion Bermad Area 675 720-ULChristian FherОценок пока нет

- p177 02 PDFДокумент4 страницыp177 02 PDFJuan ZamoraОценок пока нет

- Flowserve Vlatb001Документ20 страницFlowserve Vlatb001Selva KumarОценок пока нет

- Eko4000-4100 WebДокумент4 страницыEko4000-4100 WebSubramanian SaravananОценок пока нет

- Hydraulic Concentrate Control ValveДокумент2 страницыHydraulic Concentrate Control ValveNandani MangaleeОценок пока нет

- Dual-Plate Check Valve DesignДокумент5 страницDual-Plate Check Valve Designmusaismail8863Оценок пока нет

- BHEL Valves PDFДокумент135 страницBHEL Valves PDFNitin Aggarwal100% (1)

- Ball Valve - Training Material (Compatibility Mode)Документ115 страницBall Valve - Training Material (Compatibility Mode)kart_rl80% (10)

- Type A Air Valves (WABCO) AVENTICSДокумент32 страницыType A Air Valves (WABCO) AVENTICSWILLIAM ROMERO100% (1)

- Iso 9001 CertifiedДокумент4 страницыIso 9001 CertifiedLuis R. Salas SotoОценок пока нет

- Apollo ValvesДокумент44 страницыApollo ValvesDevdatt WaghuleОценок пока нет

- Es Acv 1116FMДокумент4 страницыEs Acv 1116FMWattsОценок пока нет

- MC 162-163Документ2 страницыMC 162-163Brandon MarshallОценок пока нет

- Electri RelifДокумент18 страницElectri Relifsuleman247Оценок пока нет

- Ball Valve Seat Seal Injection SystemДокумент28 страницBall Valve Seat Seal Injection SystemmudrijasmОценок пока нет

- 07 ValvesДокумент33 страницы07 Valvesshiva_ssk17Оценок пока нет

- Gufmc 0138 UsДокумент8 страницGufmc 0138 Usmusaismail8863Оценок пока нет

- Valves & Controls: Crosby Safety Valves Style HSLДокумент12 страницValves & Controls: Crosby Safety Valves Style HSLeborresonОценок пока нет

- Combination Air Valves Guide for PipelinesДокумент4 страницыCombination Air Valves Guide for PipelinesFelipe OliverosОценок пока нет

- E 50 49 - FireДокумент2 страницыE 50 49 - FireJulio C. Sivira CallejaОценок пока нет

- SV 3 Safety ValveДокумент7 страницSV 3 Safety ValveWanderley FonsecaОценок пока нет

- Check Valves With Tilting DiscДокумент2 страницыCheck Valves With Tilting DiscSamir RawalОценок пока нет

- Report Project-Model 3D, Variasi Ducting Off, Variasi 1 Dan 2-1Документ12 страницReport Project-Model 3D, Variasi Ducting Off, Variasi 1 Dan 2-1Appleuk SudarОценок пока нет

- Pelatihan Teknik Dasar AcДокумент1 страницаPelatihan Teknik Dasar AcAppleuk SudarОценок пока нет

- Kumar 2018Документ17 страницKumar 2018Appleuk SudarОценок пока нет

- Fulton Oil HeaterДокумент16 страницFulton Oil HeaterarjmandquestОценок пока нет

- Conection Flange EconomizerДокумент3 страницыConection Flange EconomizerAppleuk SudarОценок пока нет

- Kumar 2018Документ17 страницKumar 2018Appleuk SudarОценок пока нет

- Purchase History ReportДокумент41 страницаPurchase History ReportAppleuk SudarОценок пока нет

- Research Issues On Water Disaster Management and CC - M. Syahril B. KusumaДокумент56 страницResearch Issues On Water Disaster Management and CC - M. Syahril B. KusumaAppleuk SudarОценок пока нет

- Stiker IntegraДокумент7 страницStiker IntegraAppleuk SudarОценок пока нет

- Northstart Meat Mercant Inc PDFДокумент22 страницыNorthstart Meat Mercant Inc PDFAppleuk SudarОценок пока нет

- Tas Pinggang Elbrus (Original) Bukan Kaleng - KalengДокумент1 страницаTas Pinggang Elbrus (Original) Bukan Kaleng - KalengAppleuk SudarОценок пока нет

- Kanji n3Документ203 страницыKanji n3Appleuk SudarОценок пока нет

- Pressure Test ProcedureДокумент6 страницPressure Test ProcedureAppleuk SudarОценок пока нет

- Gestra EquipmentДокумент42 страницыGestra EquipmentAppleuk SudarОценок пока нет

- Miniature Thermoelectric Power Plant PDFДокумент5 страницMiniature Thermoelectric Power Plant PDFAppleuk SudarОценок пока нет

- Maintain STEAM-MATIC FT boiler generatorДокумент3 страницыMaintain STEAM-MATIC FT boiler generatorAppleuk SudarОценок пока нет

- 274cat CT GBДокумент6 страниц274cat CT GBparijat50Оценок пока нет

- ValveДокумент1 страницаValveAppleuk SudarОценок пока нет

- Pid Legend PDFДокумент1 страницаPid Legend PDFSocMed Dtk UI0% (1)

- Compact Gas Burners Product GuideДокумент24 страницыCompact Gas Burners Product GuideAppleuk SudarОценок пока нет

- 08 CNC AdeДокумент1 страница08 CNC AdeAppleuk SudarОценок пока нет

- Stress in Steam Boiler Shells From Boiler PressureДокумент1 страницаStress in Steam Boiler Shells From Boiler PressureAppleuk SudarОценок пока нет

- Для Просмотра Статьи Разгадайте Капчу - 2Документ44 страницыДля Просмотра Статьи Разгадайте Капчу - 2Appleuk SudarОценок пока нет

- TemperatureДокумент10 страницTemperatureAli BastiОценок пока нет

- Lal 125Документ20 страницLal 125Zvonko TrajkovОценок пока нет

- Weishaupt Tweetraps WG30-WG40 - Instalation - Manual - AN PDFДокумент36 страницWeishaupt Tweetraps WG30-WG40 - Instalation - Manual - AN PDFpatitay03681740% (5)

- Research Issues On Water Disaster Management and CC - M. Syahril B. KusumaДокумент56 страницResearch Issues On Water Disaster Management and CC - M. Syahril B. KusumaAppleuk SudarОценок пока нет

- 2556 - P&ID Master IBSM Heavy OilДокумент1 страница2556 - P&ID Master IBSM Heavy OilAppleuk SudarОценок пока нет

- 2566 Technical Manual Ibsm FueloilДокумент29 страниц2566 Technical Manual Ibsm FueloilAppleuk SudarОценок пока нет

- XR77CX: Installing and Operating InstructionsДокумент5 страницXR77CX: Installing and Operating InstructionsVũ Hằng PhươngОценок пока нет

- Delta Ia-Mds Vfd-Ed Um en 20150910-1Документ280 страницDelta Ia-Mds Vfd-Ed Um en 20150910-1FahadОценок пока нет

- 2007 Bachu Etal CO2 Storage Capacity EstimationДокумент14 страниц2007 Bachu Etal CO2 Storage Capacity EstimationArindam Obzi GuptaОценок пока нет

- محطات الطاقةДокумент22 страницыمحطات الطاقةJoe LewisОценок пока нет

- Impulse Valve Operator Kit IV.1.09.01Документ2 страницыImpulse Valve Operator Kit IV.1.09.01eduardo gonzalezav0% (1)

- General Principles of Freeze Drying (The Lyophilization Process)Документ9 страницGeneral Principles of Freeze Drying (The Lyophilization Process)Shefali PawarОценок пока нет

- Caliber Modulo PCM PinoutДокумент7 страницCaliber Modulo PCM PinoutManuel Suarez100% (3)

- 3 Instant Ways To Make Money From People Around You: by Oluwatoyin OmotosoДокумент21 страница3 Instant Ways To Make Money From People Around You: by Oluwatoyin Omotosoobisesan phillipОценок пока нет

- Report 04.02.20Документ4 страницыReport 04.02.20Kartik SoniОценок пока нет

- KRYPTOSPHERE TechnologyДокумент20 страницKRYPTOSPHERE TechnologySoniale Sánchez GómezОценок пока нет

- MeasurementДокумент4 страницыMeasurementJemason100% (1)

- IGBC Annual Review 2011-2012Документ28 страницIGBC Annual Review 2011-2012Sourav SenОценок пока нет

- Air Cooler LeafletДокумент2 страницыAir Cooler LeafletSaad zubayr MОценок пока нет

- CV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)Документ5 страницCV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)toalok4723Оценок пока нет

- Design and Generating Energy As A Car Alternator TДокумент7 страницDesign and Generating Energy As A Car Alternator TJohnny TestОценок пока нет

- Ground Improvement TechniquesДокумент29 страницGround Improvement TechniquesMeEr AahilОценок пока нет

- Boundary Layer ThicknessДокумент23 страницыBoundary Layer ThicknessPridhar ThiagarajanОценок пока нет

- Classification ISO 8217 (2005)Документ5 страницClassification ISO 8217 (2005)Salah JallaliОценок пока нет

- O Engineers 3rd Issue Oct 2017Документ51 страницаO Engineers 3rd Issue Oct 2017arsalanhamidОценок пока нет

- Cause Effect Analysis of Oil Loss in Edible Oil IndustryДокумент60 страницCause Effect Analysis of Oil Loss in Edible Oil IndustrySaurabh RaiОценок пока нет

- Connection TableДокумент10 страницConnection TableBepdjОценок пока нет

- Pneumatic Slotting MachineДокумент3 страницыPneumatic Slotting MachineSwami NathanОценок пока нет

- Kaplan Turbine Working As A Propeller CFD InvestigДокумент11 страницKaplan Turbine Working As A Propeller CFD InvestigclaudehackerОценок пока нет

- Waste Water-Sewage PumpДокумент111 страницWaste Water-Sewage Pumpcharadeg100Оценок пока нет

- Master Plan 2021Документ172 страницыMaster Plan 2021Rajnish MishraОценок пока нет

- E PM 100Документ29 страницE PM 100masoudОценок пока нет

- Three-Phase Induction MotorДокумент21 страницаThree-Phase Induction MotorRajeev ValunjkarОценок пока нет

- Lumidor Minimax XTДокумент4 страницыLumidor Minimax XTPaky PakicОценок пока нет

- Dolphin by EnOcean enДокумент16 страницDolphin by EnOcean en刘嘉伟Оценок пока нет

- 39CQ Iom 06302014Документ20 страниц39CQ Iom 06302014Non Etabas GadnatamОценок пока нет