Академический Документы

Профессиональный Документы

Культура Документы

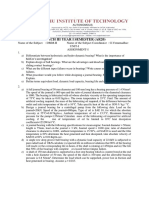

AT2351 Automotive Engine Components Design May - Jun 2014

Загружено:

pavanraneОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AT2351 Automotive Engine Components Design May - Jun 2014

Загружено:

pavanraneАвторское право:

Доступные форматы

Reg. No.

Question Paper Code : 51098

B.E./B.Tech. DEGREE EILAMINATION. MAY/JUNII 201 4

Sixth Semester

Automobile Engineering

AT 2351/AU 61/10122 AU

602 AUTOMOTI\T ENGINE COMPONE\ITS

DESIGN

(Regulation 2008/2010)

Time : Three hours

Maximum : 100 narks

Als*,et AJ-L questions.

PARTA-(10r

2 = 20

marks)

Give any trvo applications ofintederence frt.

W}}at is tolerance grade?

Under \j{hat force, the big end bolts and caps are designed?

Specifu the reason for use oftapered skirt for pistons.

Enumerate the design considerations for crank pin.

What is the net force acting on the crankshaft of an engine?

Define co-eficient of fluctuation of speed.

State the type ofstresses induced in a dm flywheel.

Why the area of the inlet valve port is made larger than the area of exhaust

valve port?

10.

What are the methods and materials used in the manufacture of cam shafts?

PARTB-(5x

11.

(a)

16 = 80

marks)

A meilium force frt on a 50 mm shaft lequires a hole tolerance of 0.025

mm and a shaft tolerance of 0.016 mm. The maximum interference is to

be 0.042 mm. How rvill you Dimension the hole and the shaft, if hole

deviation is I{?

Or

i2.

(b)

The maximum load on a petrol engine push rod 300 mm long is 1400 N'

It is hollow having the outer aliameter 1.25 times the inner diameter'

Spherical seated bearings are used for the push rod. The modulus of

elasticity for the matedal of the push lod is 210 kn-/mmr. Find a suitable

size for the push rod, taking a factor of safety of 2.5.

(a)

Design a connecting rod for an (engine fiom the following data

Piston diameter = 125 mm

Siroke 150 mm

Length of connecting rod = 300 mm

Maximum gas pressure at 5% of stroke = 5 n/mm2

Spped o[

engine

1200

rpo

Mass of reciprocating parts = 2 kg

Factor of safety = 5

Material steel = 35 Ni Cr 60.

Or

0)

A four stroke diesel engine has the folloiving specifrcations

Brake

power

5 kw

Speed = 200 rpm

Indicated rnean effective pressure = 0.3 N/mm2

Mechanical efficiency = 80%

Determine

(i)

(ii)

(iii)

13.

(a)

Bore and length ofthe cylinder;

Thickness of the cylincler heail; and

Size of studs for the cylinder head.

Design a single"throw, tlouble-view crank shaft made of forged steel for a

single cylinder, vertical IC engine having cylinder diameter of 120 mm

and stroke lelgth of 160 mm. The engine develops 10 kw at 300 mm The

explosion pressute is 2.5 N/mm2 gauge. The maximum torque is

developed when the crant shaft turns Through 25' from the TDC

position during the.expansion stroke. The burnt gas Pressure at that

moment is 2.0N/mm' . The cranl< thall main beadngs arc 320 mm apart'

Or

51098

(b)

Design an overhang cranh shaft $'ith_two nlain bearings for an IC. engine

\\ r'h ih" Follo\\ rnB ,1dra :

Cylinder bore = 250 m

Stroke length = 300 rnm

Flywheel weight = 27 KN

Ma\imum Ples.u.P =:.5 \/ mln

Maximum torque at crank roiation

309.

the prcssure at that

Instant 1.7 N/mm1.

1,1.

(a)

The iurning moment diagram for a multicylinder engine has been drawn

to a scale of l rnm = 1000 N-m and 1 mm=6'. The areas above and below

the mean turning moment Lne tckcn rn order ate 530, 330, 380, 470, 180,

360, 350 and 280 sq.mm. For the engine Find the diameter of the

flr'rvheel. The mean rpm, is 150 and the total fluctuation of Speed must

not exceed 3.5% of the mean. Determine a suitable cross_sectional area of

the Iim of the fl1'r,vheel, assuming the total energy of the fl,'wheel to be

15/14 that ofthe rim. The peripheral velocity ofthe flywheel is 15m/s'

Or

ft)

15. (a)

Design a fllr,vheel for a single-cyLinder, four'stroke Yertical cylinder diesel

engine aleveloping 4 Kw at 1500 rpm. Assume coeffrcient of speed

fluctuation, C" = 0.01.

Design a rocker arm of I_section made of cast steel for operating an

'exhaust valve of a gas engine. The effective length of the rocker arm is

250 mm and the angle behveen the arm is 135". The exhaust valve is

80 Drm in aliameter and the gas pressure when the valve begins to open is

0.4 N/mm2. The greatest suction pressure is 0.03 N/mm' below

atmospheric. The initial load maybe assumeal as 0 05 N/mm2 of valve

area anal the valve inertia and friction losses as 120 N. The ultimate

strength of cast steel is 750 Mpa The allowable bearlng pressure is

8 N/mm'z and the permissible stress in the material is 72-Mpa'

Or

(b)

The following data refer to a circular arc cam which operats flat faced

follower:

l-east radius 50 mm; Total Lift 25 mm; Flank radius 50 mm; Angle of lift

?0 Deglees ; Calculate the principal climensions of the cam aDd draw the

cam prollle.

51098

Вам также может понравиться

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- AECD QuestionsДокумент7 страницAECD QuestionssbkОценок пока нет

- IC Engine Componenets Design ProblemДокумент4 страницыIC Engine Componenets Design ProblemTamene TesfayeОценок пока нет

- Doec Question Bank: Ut 2 and Yt 2)Документ4 страницыDoec Question Bank: Ut 2 and Yt 2)Aditya DeshmukhОценок пока нет

- Determine The Dimensions of Cross-Section of The Connecting Rod For A Diesel Engine With TheДокумент1 страницаDetermine The Dimensions of Cross-Section of The Connecting Rod For A Diesel Engine With Theanurag kumarОценок пока нет

- AT8611 Lab QuestionsДокумент9 страницAT8611 Lab QuestionsChirpiОценок пока нет

- IC Engine PartsДокумент2 страницыIC Engine PartsSushil Kumar SinghОценок пока нет

- Supp Nov 2009Документ10 страницSupp Nov 2009prk74Оценок пока нет

- 3 Tutorial IC EngineДокумент3 страницы3 Tutorial IC EnginevattuОценок пока нет

- DMM Ii (2015)Документ35 страницDMM Ii (2015)gorijalaОценок пока нет

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringДокумент3 страницы1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishОценок пока нет

- Techno India: (Designing of Ic Engine Parts: Cylinder and Piston)Документ17 страницTechno India: (Designing of Ic Engine Parts: Cylinder and Piston)goutam kumarОценок пока нет

- Design of Transmission Systems 10Документ2 страницыDesign of Transmission Systems 10srajapratyОценок пока нет

- Dmm-II Assignment TestДокумент2 страницыDmm-II Assignment TestSai Srinivas BodapatiОценок пока нет

- Design of Transmission Systems 3Документ2 страницыDesign of Transmission Systems 3srajapratyОценок пока нет

- Akışkanlar Mek.Документ6 страницAkışkanlar Mek.Sai PranayОценок пока нет

- Projects For Lab BДокумент91 страницаProjects For Lab BPeter AshrafОценок пока нет

- Design of Machine Members II R5320305 Set 3Документ2 страницыDesign of Machine Members II R5320305 Set 3Ravi Kumar KamarthiОценок пока нет

- Iii Me Ii Sem Q.bank 2016-17Документ32 страницыIii Me Ii Sem Q.bank 2016-17Abhishek SakatОценок пока нет

- Diploma Board Examination - December 2020Документ2 страницыDiploma Board Examination - December 2020Pradeep AppuОценок пока нет

- DMM-2 3 1 Q&aДокумент6 страницDMM-2 3 1 Q&aAnand vinayОценок пока нет

- 50 - 20T X 29.5m DG Crane - R3Документ13 страниц50 - 20T X 29.5m DG Crane - R3Rv VaghasiaОценок пока нет

- 05-04 Machine Design & Cad-II (Me)Документ2 страницы05-04 Machine Design & Cad-II (Me)Abdul AhadОценок пока нет

- r05320305 Design of Machine Members IIДокумент11 страницr05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- MD-III - TUT - 5 and 6Документ5 страницMD-III - TUT - 5 and 6Sushil ThakkarОценок пока нет

- 07a6ec05 Designofmachinemembers IIДокумент11 страниц07a6ec05 Designofmachinemembers IIzahid_polyОценок пока нет

- Sathyabama University: Register NumberДокумент3 страницыSathyabama University: Register NumberSecret SecretОценок пока нет

- rr321401 Principles of Machine DesignДокумент8 страницrr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- Design of Machine ElementsДокумент3 страницыDesign of Machine ElementsHariharanAutoОценок пока нет

- Seventh Semester B.Tech. Degree Examination, June 2009 03-703: Design of Machine Elements - Ii (M)Документ3 страницыSeventh Semester B.Tech. Degree Examination, June 2009 03-703: Design of Machine Elements - Ii (M)Harish ChandranОценок пока нет

- S80 MCCДокумент236 страницS80 MCCAnonymous 8rb48tZS100% (1)

- Machine Design I TutorialДокумент3 страницыMachine Design I TutorialbngelotrОценок пока нет

- Progressive Cavity Pump (PCP) : Mohamed ElbadriДокумент46 страницProgressive Cavity Pump (PCP) : Mohamed Elbadrimohanned salah100% (3)

- DMM 2Документ6 страницDMM 2Shubham MahajanОценок пока нет

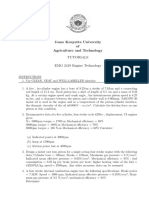

- Jomo Kenyatta University of Agriculture and Technology Tutorials EMG 2419 Engine TechnologyДокумент2 страницыJomo Kenyatta University of Agriculture and Technology Tutorials EMG 2419 Engine TechnologyEric MajaoОценок пока нет

- Md-Ii 2Документ11 страницMd-Ii 2Vishal ZalaОценок пока нет

- Machine Design - LДокумент2 страницыMachine Design - LNilesh Mistry (Nilesh Sharma)Оценок пока нет

- Dme Quest Ut-2Документ9 страницDme Quest Ut-2aadhithyarajasekaranОценок пока нет

- MD Coaching 1Документ31 страницаMD Coaching 1Jom BautistaОценок пока нет

- 21751-6838-Principles of Machine DesignДокумент8 страниц21751-6838-Principles of Machine DesignMacasaet Al-awnОценок пока нет

- 8th Sem - Assignment - MD II (2962108)Документ5 страниц8th Sem - Assignment - MD II (2962108)rishabhk28995Оценок пока нет

- Motores YaskawaДокумент56 страницMotores YaskawaLisa GarciaОценок пока нет

- R07-SUPPLY-DecemberJanuary 2014-15 - Design of Machine Members - IIДокумент2 страницыR07-SUPPLY-DecemberJanuary 2014-15 - Design of Machine Members - IIPraveen KumarОценок пока нет

- TE 2008 Mechanical Qp2013Документ56 страницTE 2008 Mechanical Qp2013avinash119870% (1)

- Design of FlywheelДокумент15 страницDesign of FlywheelGujar SnehaОценок пока нет

- Makalah GTWДокумент8 страницMakalah GTWfaisalОценок пока нет

- AAAAAAAAAAAAAAДокумент16 страницAAAAAAAAAAAAAASriramulu JaichandarОценок пока нет

- S 50 MCCДокумент270 страницS 50 MCCAnonymous 8rb48tZS100% (2)

- Ingersoll-Rand Compressors 15T2Документ2 страницыIngersoll-Rand Compressors 15T2Dedi Mulyana100% (1)

- 181505-181902-MD - IiДокумент2 страницы181505-181902-MD - IiSiddharth PanchalОценок пока нет

- Thermal Engineering I MANUALДокумент35 страницThermal Engineering I MANUALKalpit KauraseОценок пока нет

- Assignment 2Документ3 страницыAssignment 2sonawanepmsОценок пока нет

- Stress Analysis of Piston Using Pressure Load and Thermal LoadДокумент8 страницStress Analysis of Piston Using Pressure Load and Thermal LoadInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Submersible Pump Moter Core Design PDFДокумент7 страницSubmersible Pump Moter Core Design PDFIjabiОценок пока нет

- Diesel Locomotive Works: VaranasiДокумент29 страницDiesel Locomotive Works: VaranasiGaurav PandeyОценок пока нет

- Jeep Engine and Cam SpecsДокумент6 страницJeep Engine and Cam Specsmnlwood25580% (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiОт EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiОценок пока нет

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionОт EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionРейтинг: 4 из 5 звезд4/5 (1)

- Surface Hardening of Steels PDFДокумент319 страницSurface Hardening of Steels PDFHaydee VОценок пока нет

- ME6403 EMM - by Civildatas - Com 1Документ88 страницME6403 EMM - by Civildatas - Com 1pavanraneОценок пока нет

- AT17411 Lab ManualДокумент38 страницAT17411 Lab ManualpavanraneОценок пока нет

- AT 17503 - Automotive Electrical and Electronics: Session 16Документ15 страницAT 17503 - Automotive Electrical and Electronics: Session 16pavanraneОценок пока нет

- Conference On Automotive Electronics - AgendaДокумент3 страницыConference On Automotive Electronics - AgendapavanraneОценок пока нет

- AT 17503 AEE Session 27Документ18 страницAT 17503 AEE Session 27pavanraneОценок пока нет

- AT 17503 AEE Session 24Документ17 страницAT 17503 AEE Session 24pavanraneОценок пока нет

- AT 17503 AEE Session 29Документ15 страницAT 17503 AEE Session 29pavanraneОценок пока нет

- AT 17503 AEE Session 28Документ18 страницAT 17503 AEE Session 28pavanraneОценок пока нет

- AT 17503 AEE Session 1Документ43 страницыAT 17503 AEE Session 1pavanraneОценок пока нет

- AT 17503 - Automotive Electrical and Electronics: Session 23Документ17 страницAT 17503 - Automotive Electrical and Electronics: Session 23pavanraneОценок пока нет

- AT 17503 - Automotive Electrical and Electronics: Session 31Документ7 страницAT 17503 - Automotive Electrical and Electronics: Session 31pavanraneОценок пока нет

- AT 17503 AEE Session 5Документ20 страницAT 17503 AEE Session 5pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 38Документ32 страницыAT 17701 - Engine& Vehicle Management System: Session 38pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 39Документ24 страницыAT 17701 - Engine& Vehicle Management System: Session 39pavanraneОценок пока нет

- AT 17503 AEE Session 30Документ18 страницAT 17503 AEE Session 30pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 40Документ11 страницAT 17701 - Engine& Vehicle Management System: Session 40pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 42Документ11 страницAT 17701 - Engine& Vehicle Management System: Session 42pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 41Документ14 страницAT 17701 - Engine& Vehicle Management System: Session 41pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 37Документ8 страницAT 17701 - Engine& Vehicle Management System: Session 37pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 36Документ13 страницAT 17701 - Engine& Vehicle Management System: Session 36pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 35Документ15 страницAT 17701 - Engine& Vehicle Management System: Session 35pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 34Документ18 страницAT 17701 - Engine& Vehicle Management System: Session 34pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 2Документ15 страницAT 17701 - Engine& Vehicle Management System: Session 2pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 16Документ19 страницAT 17701 - Engine& Vehicle Management System: Session 16pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 8Документ10 страницAT 17701 - Engine& Vehicle Management System: Session 8pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 15Документ11 страницAT 17701 - Engine& Vehicle Management System: Session 15pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 3Документ17 страницAT 17701 - Engine& Vehicle Management System: Session 3pavanraneОценок пока нет

- AT 17701 - Engine& Vehicle Management System: Session 5Документ13 страницAT 17701 - Engine& Vehicle Management System: Session 5pavanraneОценок пока нет

- MBA - Updated ADNU GSДокумент2 страницыMBA - Updated ADNU GSPhilip Eusebio BitaoОценок пока нет

- Effects of Organic Manures and Inorganic Fertilizer On Growth and Yield Performance of Radish (Raphanus Sativus L.) C.V. Japanese WhiteДокумент5 страницEffects of Organic Manures and Inorganic Fertilizer On Growth and Yield Performance of Radish (Raphanus Sativus L.) C.V. Japanese Whitepranjals8996Оценок пока нет

- LICДокумент82 страницыLICTinu Burmi Anand100% (2)

- HP Sustainability Impact Report 2018Документ147 страницHP Sustainability Impact Report 2018Rinaldo loboОценок пока нет

- BSBOPS601 Develop Implement Business Plans - SДокумент91 страницаBSBOPS601 Develop Implement Business Plans - SSudha BarahiОценок пока нет

- Syed Hamid Kazmi - CVДокумент2 страницыSyed Hamid Kazmi - CVHamid KazmiОценок пока нет

- Health Informatics SДокумент4 страницыHealth Informatics SnourhanОценок пока нет

- Tracker Pro Otm600 1.5Документ19 страницTracker Pro Otm600 1.5Camilo Restrepo CroОценок пока нет

- CRC Implementation Code in CДокумент14 страницCRC Implementation Code in CAtul VermaОценок пока нет

- Department of Labor: 2nd Injury FundДокумент140 страницDepartment of Labor: 2nd Injury FundUSA_DepartmentOfLabor100% (1)

- INTERNSHIP PRESENTATION - Dhanya - 2020Документ16 страницINTERNSHIP PRESENTATION - Dhanya - 2020Sanitha MichailОценок пока нет

- Leeka Kheifets PrincipleДокумент6 страницLeeka Kheifets PrincipleAlexandreau del FierroОценок пока нет

- Economies and Diseconomies of ScaleДокумент7 страницEconomies and Diseconomies of Scale2154 taibakhatunОценок пока нет

- Science News Explores-June July 2023Документ36 страницScience News Explores-June July 2023Tobei AchimОценок пока нет

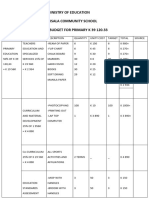

- Ministry of Education Musala SCHДокумент5 страницMinistry of Education Musala SCHlaonimosesОценок пока нет

- Sangeetahealingtemples Com Tarot Card Reading Course in UsaДокумент3 страницыSangeetahealingtemples Com Tarot Card Reading Course in UsaSangeetahealing templesОценок пока нет

- Remuneration Is Defined As Payment or Compensation Received For Services or Employment andДокумент3 страницыRemuneration Is Defined As Payment or Compensation Received For Services or Employment andWitty BlinkzОценок пока нет

- QG To AIS 2017 PDFДокумент135 страницQG To AIS 2017 PDFMangoStarr Aibelle VegasОценок пока нет

- Ethercombing Independent Security EvaluatorsДокумент12 страницEthercombing Independent Security EvaluatorsangelОценок пока нет

- Switch CondenserДокумент14 страницSwitch CondenserKader GüngörОценок пока нет

- Understanding Consumer and Business Buyer BehaviorДокумент47 страницUnderstanding Consumer and Business Buyer BehaviorJia LeОценок пока нет

- QuizДокумент11 страницQuizDanica RamosОценок пока нет

- Dr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Документ2 страницыDr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Najeebuddin AhmedОценок пока нет

- 1grade 9 Daily Lesson Log For Demo 1 4Документ5 страниц1grade 9 Daily Lesson Log For Demo 1 4cristy olivaОценок пока нет

- Revit 2019 Collaboration ToolsДокумент80 страницRevit 2019 Collaboration ToolsNoureddineОценок пока нет

- VoLTE KPI Performance - E2EДокумент20 страницVoLTE KPI Performance - E2EAnway Mohanty100% (1)

- Pilot'S Operating Handbook: Robinson Helicopter CoДокумент200 страницPilot'S Operating Handbook: Robinson Helicopter CoJoseph BensonОценок пока нет

- Electrical Estimate Template PDFДокумент1 страницаElectrical Estimate Template PDFMEGAWATT CONTRACTING AND ELECTRICITY COMPANYОценок пока нет

- ABB Price Book 524Документ1 страницаABB Price Book 524EliasОценок пока нет

- 0063 - Proforma Accompanying The Application For Leave WITHOUT ALLOWANCE Is FORWARDED To GOVERNMEДокумент4 страницы0063 - Proforma Accompanying The Application For Leave WITHOUT ALLOWANCE Is FORWARDED To GOVERNMESreedharanPN100% (4)