Академический Документы

Профессиональный Документы

Культура Документы

Sliding Pressure Operation

Загружено:

Carlos ToscanoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sliding Pressure Operation

Загружено:

Carlos ToscanoАвторское право:

Доступные форматы

Proceedings of the 5th IASME/WSEAS Int.

Conference on Heat Transfer, Thermal Engineering and Environment, Athens, Greece, August 25-27, 2007 299

Sliding pressure operation of large conventional

steam power units

GEORGE DARIE, HORIA PETCU,

GABRIEL NEGREANU, VIOREL GHERGHINA

Polytechnic University of Bucharest

Splaiul Independentei 313, Sector 6, Bucuresti, ROMANIA

geo@energy.pub.ro http://cceei.energ.pub.ro

Abstract: - New condition in the energy market imposed changes in conventional steam units load curve

coverage. From the classical base load this installations have been forced to migrate to semi base load. This

element imposed a new way to operate, more flexibly, steam power plants. Classical operation mode for the

existing sub critical parameter steam cycle is with constant live steam parameters (proper for base load curve

coverage). The paper compares main plant parameters for the two operating modes in the case on an existing

Romanian Power Plant. The paper is useful for the establishing of operating mode for existing conventional

power plants.

Key-Words: - Conventional Power Plant, Steam Turbine, Constant Live Steam Pressure, Sliding Live Steam

Parameters.

1 Introduction

Electric energy market liberation imposed a new

way to operate coal power plants units. The

tendency is to operate this units, not in base load

(with constant and close to nominal load), but in

semi base load (with important load variation). In

the electrical system coal plants are participating

more and more at primary and secondary tune. This

element brought the discussion about switching

constant live steam parameters operating to sliding

live steam operating mode.

In constant live steam pressure operation mode,

steams pressure is maintained constant trough

control stage admission section variation. In sliding

live steam operation mode, the quantitative and

qualitative control with control stages is aborted. In

this case, inlet turbine areas remain constant, and the

live steam pressures will naturally result, function of

the live steam flows (turbine loads).

Constant live steam parameter versus sliding live

steam parameters is an old problem. The main

theoretical advantages of the second operation mode

are [1]:

a) Pressure losses due to lamination disappear;

b) Steam turbines internal efficiencies (including

control stages) are high for different loads [2,3];

Function of the constructive types of analyzed

cycles, for some loads, running is more economic

with sliding parameters.

The switch from constant parameters to sliding

parameters operating modes can improve off design

runs for the units. For example LMZ under critical

parameter steam turbine K 210 130 run better

with sliding parameter operation, the heat

consumption being reduced with 1.6 %.

Another advantage of sliding parameter operating

mode is that efforts through high pressure

components of steam turbines are reduced [5]. On a

large scale of steam turbines loadings, complete

admission on control valves assures uniform

distribution of steam, and uniform temperatures on

control stage. Lamination into control valves will

induce high temperatures into control stages even

for low steam turbine loadings. Using sliding

parameter operating mode assure: greater flexibility,

faster transition between diverse loads then with

constant live steam operating mode, and metal

fatigue into acceptable limits [4, 5]. In these

conditions the steam turbines will be more adaptable

for semi base load politics.

Advantages of sliding live steam pressures have

influenced the last large steam turbine design. Table

1 present some examples of Europes units operated

in this way [6]. Similar operating models are present

in Japan and USA [3, 7].

This paper objective is sliding live steam

parameters operation mode analysis for one 330

MW, reheated, under critical, existing, steam turbine

unit, frequent in Romanian Power Plants.

Proceedings of the 5th IASME/WSEAS Int. Conference on Heat Transfer, Thermal Engineering and Environment, Athens, Greece, August 25-27, 2007 300

Table 1. Steam turbines

parameters operating modes.

units

with sliding

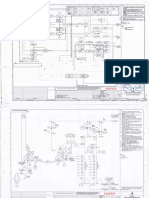

2 F1L 330 MW Steam Turbine

This steam turbine is a reheat, condensing, action

type, four cylinders, one shaft, and one condenser,

designed by RATEAU SCHNEIDER. High

pressure cylinder has 11 stages, the first one is the

control stage, intermediate pressure cylinder has 13

stages and the tow low pressure cylinders have tow

fluxes each, with 6 stages. Table 2 presents the main

parameters of this type of steam turbines and figure

1 present the simplified thermal circuit.

Figure 1 Simplified thermal scheme of the F1L 330

unit

SB steam boiler; HPC High pressure cylinder; IMC

intermediate pressure cylinder; LPC low pressure

cylinder; EP extraction pump; CTS Chemical

treatment station; RP reprise pumps; D Deaerator;

LPP low pressure feed water heater; FP main feed

water pump; HPP high pressure feed water heater; EG

electric generator.

Control stage steam feed is assured trough four

control valves, unaffected by the operating mode

(with or without sliding pressure), at design load

those valves are completely opened.

Tabele 2 F1L 330 steam turbine main parameters

In the case of constant live steam pressure

operating mode, at partial load, the control valves

are sequentially closed. The closing valve is

characterized by exergeic losses through lamination.

This process is shown in figure 2 (line 0 0). We

also see in figure 2 tow detention lines: one for the

completely opened valves (line 0 2) and one for

the closing valve (line 0 2). Enthalpy at the stage

end in the weighed mean between the tow processes.

3 Methodology

The sliding live steam parameter operation was

analyzed with a mathematical model witch allow

steam thermal circuit computation. The main

components of the model are [8]: turbine process

modeling, and feed water heating system calculus.

Control stage process was especially treated by

this model because it is the main difference between

the actual operating mode (constant live steam

pressure) and the purposed operating mode (sliding

live steam parameter operation).

In the case of sliding live steam parameter

operating mode, all control valves remain opened

for a large load range, lamination through valves

disappear and energy loses in control stages

diminish. In this case the detention line is 0 2 in

figure 2.

Steam detention process in the rest of the steam

turbine stages and the feed water preheat calculus

are similar in the two cases, being presented in [8].

Based on the mathematical model, specialized

software was developed. It admitted the analyses of

different operating regimes for the 330 MW units.

Proceedings of the 5th IASME/WSEAS Int. Conference on Heat Transfer, Thermal Engineering and Environment, Athens, Greece, August 25-27, 2007 301

Figure 2 Control stage expansion line

4 Results and conclusions

Regimes analyses in the constant live steam

pressure operation mode and, respectively, the

sliding live steam parameters operation mode were

completed in the following initial conditions

(encountered in the most Romanian sites): the unit

works with the complete feed water preheat system,

the main pump is steam drive, condenser cooling

water have 15 C, electrical output varies between

130 and 330 MW, and live steam temperature and

reheat temperature are constant and with design

values.

Figure 4 Pressure HPC stages isentropic expansion

efficiency load variation

4.1. Isentropic expansion efficiency of the

steam turbine

Control stage internal efficiency at sliding live

steam parameter operating mode is bigger then

constant live steam pressure operation mode. This

conclusion is a consequence of lamination process

that misses in the first case (especially for low

loads). See figure 3.

Figure 5 IPC stages isentropic expansion efficiency

load variation

Most of the analyzed domain shows that the rest

of HPC stages have greater efficiencies in the first

case. The same conclusion is valid for IPC and LPC

stages. See figures 4, 5, and 6.

Figure 6 LPC stage isentropic expansion efficiency

load variation

Figure 3 Control stage isentropic expansion

efficiency load variation

Proceedings of the 5th IASME/WSEAS Int. Conference on Heat Transfer, Thermal Engineering and Environment, Athens, Greece, August 25-27, 2007 302

4.2. Thermal efficiency of steam turbine

cycle

Thermal efficiency is influenced by the next two

factors in the sliding parameter case: live steam

parameter decrease and internal stages efficiencies

growth.

On the analyzed domain the two factors have

opposite effects on thermal efficiencies. There are

no substantial differences between the cases. We

underline the following: closely to the design

operating mode live steam pressures in almost the

same for the two variants. In the constant live steam

pressure case laminations induce a slight reduction

on efficiency because the last control valve does not

open completely.

Figure 8 Thermal efficiencies load variation

In the 200 310 MW range, live steam pressure

reduction effect (in the sliding parameter case) is

evident and thermal efficiency is bigger in the

constant live steam pressure case.

4.3. 35 C condenser cooling water case

In the under 200 MW range, lamination effect (in

the constant parameter case) is stronger then live

steam pressure reduction (in the sliding parameter

case). For this reason thermal efficiencies are greater

for sliding parameter.

At this cooling water temperature the steam

turbine is unable to produce 330 MW electrical

power. For this reason, on the following figures load

will not grow to 330 MW.

See figures 7 and 8 presents live steam load, and

thermal efficiency load variation.

Figure 7 Live steam flow load variation

The analyses were repeated for the 35 C

condenser cooling water case. (Figures 9 10).

Conclusions from previous analyses remain.

Figure 9 Live steam flow load variation (cooling

water temperature 35C).

Proceedings of the 5th IASME/WSEAS Int. Conference on Heat Transfer, Thermal Engineering and Environment, Athens, Greece, August 25-27, 2007 303

[5] S. Leibbrandt Markedly enhanced plant

performance, Siemens Power Journal on line,

2001.

[6] * * * - Unit Control MODAN, ABB, 2005.

[7] A.K. Pahva, M.W. Justice BT valve adapts

plant for sliding-pressure, Power Engineering,

December 1991.

[8] G. Darie, H. Petcu Methodology and software

for prediction of cogeneration steam turbines

performances, 17th European Symposium on

Computer Aided Process Engineering, ppg. 1103

1108, Elsevier 2007.

Figure 10 Thermal efficiency load variation (cooling

water temperature 35C)

4.4. Conclusions

Live steam sliding pressure operation mode

introduces two opposite effects on a conventional

steam unit thermal efficiency:

-

On one hand the thermal efficiency is

decreasing due to the reduction of the live

steam pressure.

On the other hand the thermal efficiency is

increasing due to the better behavior of the

steam turbine control stage.

As a conclusion, live steam sliding pressure

operation mode has not a major effect on the

thermal efficiency. More than that, there are loads

when this efficiency is even lower than in the case

with constant parameter operating mode.

However, sliding live steam parameter operation

mode assures better operation conditions for the

steam turbine. The metal stress will diminish and the

operation flexibility at partial loads will increase.

References:

[1] B.E. Kapelovici Steam turbine operation,

Energoatomizdat, Moscova, 1985.

[2]

www.cycle_tempo.nl/Apparatus/Steam_turbine.

pdf.

[3] H. Kimura, J. Matsuda, K. Sakai Latest

experience of coal fired supercritical sliding

pressure operation boiler and application for

overseas utility, www.bhk.co.jp.

[4] * * * - Energetica Revue No. 6 A, ppg. 286

287, Bucharest, 1996.

Вам также может понравиться

- Sliding Pressure OperationДокумент5 страницSliding Pressure Operationknsaravana100% (1)

- Sliding Pressure Operation of Large Conventional Steam Power UnitДокумент6 страницSliding Pressure Operation of Large Conventional Steam Power UnitKr SantoshОценок пока нет

- Sliding Pressure Operation of Large Conventional Steam Power UnitДокумент6 страницSliding Pressure Operation of Large Conventional Steam Power UnitKr SantoshОценок пока нет

- Sliding Pressure Operation of Large Conventional Steam Power UnitДокумент6 страницSliding Pressure Operation of Large Conventional Steam Power UnitUdhayakumar VenkataramanОценок пока нет

- Lect. 5Документ37 страницLect. 5Hashim AbadaОценок пока нет

- A New Linear Model of Fossil Fired Steam Unit For Power System Dynamic AnalysisДокумент8 страницA New Linear Model of Fossil Fired Steam Unit For Power System Dynamic AnalysisSara VooDoo HazeОценок пока нет

- BoilerДокумент8 страницBoilerbsiva9Оценок пока нет

- In Uence of Ambient Temperature On Combined-Cycle Power-Plant PerformanceДокумент12 страницIn Uence of Ambient Temperature On Combined-Cycle Power-Plant PerformanceHéctor Jorge Bravo PastorОценок пока нет

- ASME90 GT 335 BollandДокумент9 страницASME90 GT 335 Bollandank_mehraОценок пока нет

- Controlling Reheat Steam Temperature in Once Through BoilersДокумент8 страницControlling Reheat Steam Temperature in Once Through Boilersபிரசன்னகுமார் ஆனந்தன்Оценок пока нет

- Analysis of The Dynamic Characteristics of A Single-Pressure Combined-Cycle Power PlantДокумент10 страницAnalysis of The Dynamic Characteristics of A Single-Pressure Combined-Cycle Power PlantIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalОценок пока нет

- 27 Pozivil 2Документ3 страницы27 Pozivil 2Kristijan HorvatОценок пока нет

- Comparison of CCGT For System Stability StudiesДокумент7 страницComparison of CCGT For System Stability Studiesskthen72Оценок пока нет

- Development of A Dynamic Model and Control System For Load-Following Studies of Supercritical Pulverized Coal Power PlantsДокумент21 страницаDevelopment of A Dynamic Model and Control System For Load-Following Studies of Supercritical Pulverized Coal Power PlantsGaurav MirlekarОценок пока нет

- Thermodynamic Analysis of Rajby Industries Power and Boiler HouseДокумент20 страницThermodynamic Analysis of Rajby Industries Power and Boiler HouseSyed AhmedОценок пока нет

- V005t15a001 88 GT 150Документ13 страницV005t15a001 88 GT 150Antonio CilindroОценок пока нет

- 吴宇峰 Thermodynamics PaperДокумент10 страниц吴宇峰 Thermodynamics PaperPalmОценок пока нет

- Combined Cycle Power PlantДокумент11 страницCombined Cycle Power PlantPGPalomaОценок пока нет

- 1000 MW Ultra-Supercritical Turbine Steam Parameter Optimization PDFДокумент7 страниц1000 MW Ultra-Supercritical Turbine Steam Parameter Optimization PDFKrishnan SanthanarajОценок пока нет

- Chapter 8B - Gas Power Plant Brayton CycleДокумент17 страницChapter 8B - Gas Power Plant Brayton CycleBF3nobel100% (1)

- Boiler Riser TubesДокумент8 страницBoiler Riser TubesSachinОценок пока нет

- Power Generation Using Multi Component Working FluidsДокумент31 страницаPower Generation Using Multi Component Working FluidsaroontpeОценок пока нет

- Overview of Liquid Metal MHD Power SystemsДокумент6 страницOverview of Liquid Metal MHD Power SystemsdenisekrseОценок пока нет

- Steam Turbine Aux. Steam SystemДокумент29 страницSteam Turbine Aux. Steam SystemPrasanna Chikkamallaiah100% (1)

- THERMODYNAMICSДокумент32 страницыTHERMODYNAMICSp_k_soni_iit_physicsОценок пока нет

- Performance Analysis of Regenerative Feedwater Heaters in 210Mw Thermal Power PlantДокумент6 страницPerformance Analysis of Regenerative Feedwater Heaters in 210Mw Thermal Power Plantrsr ecОценок пока нет

- Gas Turbine Power Plant: Fig.1-2: Components of A Basic Gas Turbine EngineДокумент22 страницыGas Turbine Power Plant: Fig.1-2: Components of A Basic Gas Turbine Engineام البنين الرياني100% (1)

- Comparison of Gas-Turbine and Combined Cycle Models For System Stability StudiesДокумент7 страницComparison of Gas-Turbine and Combined Cycle Models For System Stability StudiesjmantОценок пока нет

- A Thermal Nonlinear Dynamic Model For Water Tube Drum BoilersДокумент16 страницA Thermal Nonlinear Dynamic Model For Water Tube Drum Boilersprabhuene1Оценок пока нет

- Boiler Control From Power Magazines InputДокумент11 страницBoiler Control From Power Magazines InputUdhayakumar VenkataramanОценок пока нет

- Heat Exchanger ExampleДокумент7 страницHeat Exchanger ExampleBrian MasonОценок пока нет

- PhysResInt 10 341016Документ10 страницPhysResInt 10 341016kannanmech87Оценок пока нет

- Dynamic Modeling of Compressors Illustrated by An Oil Flooded Twin Helical Screw Compressor 2011 MechatronicsДокумент8 страницDynamic Modeling of Compressors Illustrated by An Oil Flooded Twin Helical Screw Compressor 2011 MechatronicsTai Huu100% (1)

- Dostal - SUPERCRITICAL CARBON DIOXIDE CYCLE THERMODYNAMIC ANALYSIS AND COMPARISON PDFДокумент12 страницDostal - SUPERCRITICAL CARBON DIOXIDE CYCLE THERMODYNAMIC ANALYSIS AND COMPARISON PDFJahangir MalikОценок пока нет

- BTG Controls 73Документ8 страницBTG Controls 73Anil PandeyОценок пока нет

- Heat Recovery Steam GeneratorДокумент21 страницаHeat Recovery Steam GeneratorAbdullah AhmedОценок пока нет

- 1 s2.0 0029549393900439 MainДокумент17 страниц1 s2.0 0029549393900439 MainLyes AbbassenОценок пока нет

- Analysis - To - Determine - Optimum - Steam - Pressure - Before DeaeratorДокумент9 страницAnalysis - To - Determine - Optimum - Steam - Pressure - Before DeaeratorMas ZuhadОценок пока нет

- Comparison Between Single&multi Shaft Turbine PDFДокумент12 страницComparison Between Single&multi Shaft Turbine PDFcobrasrkОценок пока нет

- PGI2003 FastStartup&DesignForCyclingДокумент20 страницPGI2003 FastStartup&DesignForCyclingscarrion80100% (1)

- Development of A Free-Piston Linear Generator For Use in An Extended-Range Electric VehicleДокумент6 страницDevelopment of A Free-Piston Linear Generator For Use in An Extended-Range Electric VehicleCan AlОценок пока нет

- Condenser and Cooling Tower Performance PDFДокумент69 страницCondenser and Cooling Tower Performance PDFsasikumar r100% (1)

- Thermal Analysis & Testing On (Aw-Type) Hermetically Sealed Reciprocating Refrigerent CompressorДокумент10 страницThermal Analysis & Testing On (Aw-Type) Hermetically Sealed Reciprocating Refrigerent CompressorGuru MaheshОценок пока нет

- Christer Wik, Heikki Salminen Klaus Hoyer Christoph Mathey, Stefan Vögeli Panagiotis KyrtatosДокумент14 страницChrister Wik, Heikki Salminen Klaus Hoyer Christoph Mathey, Stefan Vögeli Panagiotis KyrtatosKapil PaganiОценок пока нет

- Two Stage Refrigeration Circuit SimulationДокумент7 страницTwo Stage Refrigeration Circuit SimulationDang Anh TuanОценок пока нет

- An Optimal Regulation Model For Steam Piping System of Large-Scale Steel EnterpriseДокумент4 страницыAn Optimal Regulation Model For Steam Piping System of Large-Scale Steel EnterpriseAnonymous PkeI8e84RsОценок пока нет

- Art 9Документ6 страницArt 9Hernan Camilo Vargas AcostaОценок пока нет

- Steam Power PlantДокумент10 страницSteam Power PlantJoel DaleОценок пока нет

- Preflash DrumДокумент27 страницPreflash DrumGarry David100% (1)

- Helixchanger Heat ExchangersДокумент7 страницHelixchanger Heat ExchangersAnonymous QSfDsVxjZОценок пока нет

- Steam Turbine Versus Pressure Reducing Valve OperationДокумент13 страницSteam Turbine Versus Pressure Reducing Valve OperationEmerson RwkОценок пока нет

- Process Control Unit 4 NotesДокумент21 страницаProcess Control Unit 4 NotesiamananujrОценок пока нет

- Igtc2003tokyo ts098Документ7 страницIgtc2003tokyo ts0981hass1Оценок пока нет

- Steam Turbine SimulatorДокумент4 страницыSteam Turbine SimulatorvasavakurupОценок пока нет

- The Steam Turbine: ObjectivesДокумент32 страницыThe Steam Turbine: Objectiveslifemillion2847100% (1)

- Steam TurbineДокумент32 страницыSteam Turbinelifemillion2847100% (3)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesОт EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesРейтинг: 1 из 5 звезд1/5 (2)

- LCF-HCF TutorialДокумент85 страницLCF-HCF TutorialCarlos ToscanoОценок пока нет

- Solid Particle Erosion and Mechanical DamageДокумент5 страницSolid Particle Erosion and Mechanical DamageCarlos ToscanoОценок пока нет

- GE Frame F Inspection ItemsДокумент4 страницыGE Frame F Inspection ItemsCarlos Toscano100% (1)

- Mechanical Inspection PDFДокумент34 страницыMechanical Inspection PDFSchwihdi ZakОценок пока нет

- Equation 1. Adiabatic Change For Ideal GasesДокумент1 страницаEquation 1. Adiabatic Change For Ideal GasesCarlos ToscanoОценок пока нет

- Juegos PPCДокумент8 страницJuegos PPCikro995Оценок пока нет

- AutoCAD Civil 3D Performance Optimization 2Документ5 страницAutoCAD Civil 3D Performance Optimization 2Renukadevi RptОценок пока нет

- Title To The ProjectДокумент14 страницTitle To The ProjectJatinChadhaОценок пока нет

- Hortors Online ManualДокумент11 страницHortors Online Manualtshepang4228Оценок пока нет

- Chapter 3 SampleДокумент12 страницChapter 3 Samplesyarifah53Оценок пока нет

- 3a. Systems Approach To PoliticsДокумент12 страниц3a. Systems Approach To PoliticsOnindya MitraОценок пока нет

- Section 12-22, Art. 3, 1987 Philippine ConstitutionДокумент3 страницыSection 12-22, Art. 3, 1987 Philippine ConstitutionKaren LabogОценок пока нет

- Reaching Different Learning Styles ThrouДокумент29 страницReaching Different Learning Styles ThrouKENNETH HERRERAОценок пока нет

- Lenovo Security ThinkShield-Solutions-Guide Ebook IDG NA HV DownloadДокумент10 страницLenovo Security ThinkShield-Solutions-Guide Ebook IDG NA HV DownloadManeshОценок пока нет

- High-Definition Multimedia Interface SpecificationДокумент51 страницаHigh-Definition Multimedia Interface SpecificationwadrОценок пока нет

- Magicolor2400 2430 2450FieldSvcДокумент262 страницыMagicolor2400 2430 2450FieldSvcKlema HanisОценок пока нет

- Morales v. Lockheed Martin, 10th Cir. (2000)Документ2 страницыMorales v. Lockheed Martin, 10th Cir. (2000)Scribd Government DocsОценок пока нет

- Profile Romblon IslandДокумент10 страницProfile Romblon Islandderella starsОценок пока нет

- Lecture Notes (Financial Economics)Документ136 страницLecture Notes (Financial Economics)americus_smile7474100% (2)

- Nature Hill Middle School Wants To Raise Money For A NewДокумент1 страницаNature Hill Middle School Wants To Raise Money For A NewAmit PandeyОценок пока нет

- Aermod - DRM - Course NotesДокумент25 страницAermod - DRM - Course NotesGhulamMustafaОценок пока нет

- Past Simple and Continuous - When - While Worksheet - Live WorksheetsДокумент4 страницыPast Simple and Continuous - When - While Worksheet - Live WorksheetsSaraí CaracúnОценок пока нет

- Chapter IДокумент38 страницChapter ITuyền PhạmОценок пока нет

- SecuritizationДокумент46 страницSecuritizationHitesh MoreОценок пока нет

- Attachment 05 - BFD, ELD and P&I Diagrams-PearlДокумент77 страницAttachment 05 - BFD, ELD and P&I Diagrams-Pearlum er100% (1)

- HANA Heroes 1 - EWM Lessons Learned (V2)Документ40 страницHANA Heroes 1 - EWM Lessons Learned (V2)Larissa MaiaОценок пока нет

- ABES Engineering College, Ghaziabad Classroom Photograph: (Ramanujan Block, First Floor)Документ21 страницаABES Engineering College, Ghaziabad Classroom Photograph: (Ramanujan Block, First Floor)Avdhesh GuptaОценок пока нет

- Invoice 1281595768Документ3 страницыInvoice 1281595768vikas9849Оценок пока нет

- Impact of Wrongful Termination On EmployeesДокумент4 страницыImpact of Wrongful Termination On EmployeesAvil HarshОценок пока нет

- Hydraulic Breakers in Mining ApplicationДокумент28 страницHydraulic Breakers in Mining ApplicationdrmassterОценок пока нет

- HK Magazine 03082013Документ56 страницHK Magazine 03082013apparition9Оценок пока нет

- Review of Financial Statements and Its Analysis: Rheena B. Delos Santos BSBA-1A (FM2)Документ12 страницReview of Financial Statements and Its Analysis: Rheena B. Delos Santos BSBA-1A (FM2)RHIAN B.Оценок пока нет

- Sowk-625 Iq Tool 4Документ22 страницыSowk-625 Iq Tool 4api-405320544Оценок пока нет

- Wi-Fi Planning and Design Questionnaire 2.0Документ12 страницWi-Fi Planning and Design Questionnaire 2.0Free Space67% (3)

- Point of View Task CardsДокумент7 страницPoint of View Task Cardsapi-660227300Оценок пока нет