Академический Документы

Профессиональный Документы

Культура Документы

Lube Oil Test

Загружено:

Vijay A0 оценок0% нашли этот документ полезным (0 голосов)

43 просмотров3 страницыgfgg

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документgfgg

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

43 просмотров3 страницыLube Oil Test

Загружено:

Vijay Agfgg

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

L.O COOLER LEAKAGE..

HOW DETECT AND

TESTING!

MEO SUCCESS

L.O Cooler Leak Detection

plate type l.o cooler

When we talk about L.O cooler, first thing comes to our mind that ok,

the cooling medium is Water.

Now General arrangement of water type L.O cooler (generally plate

type)

is that water enters the plates from one side and l.o from the other,

such that they both cross each other which ensures maximum

interaction (heat exchange).

Now suppose due to any factor, excessive sea water pressure or

corrosion, the water side gets corroded, then water will start to

release to the l.o.

This is a major danger!

Thus to combat this we have to keep a close track on the quality and

contamination level of Lub Oil (l.o).

Broadly, there are two hazards in L.O contamination..

Sea Water Ingress in L.O (main topic)

Microbiological Development (big enemy)

Sea Water Ingress in the L.O can be detected in many ways,

Onboard Lub Oil Tests

Shore Based Lub Oil Tests

Purifier Sludge tank filling too fast (easiest indication)

Purifier Sludge Tank definitely fills up faster if there is an water

ingress in l.o.

L.O Purifier separates out deposits and water content form the l.o

system that is circulated from the L.O sump of engine.

Now if there will be water ingress then more water will be separated

and the separated sludge goes to the L.O sludge tank.Thus its sudden

increasing level implies L.O Cooler Leakage!

Reasons to test L.O

To monitor the deterioration of quality of oil with time

To check for contamination with other oil, water and microbacterial attack

To avoid damage to the lubricating part of the machinery

To determine any leak or source of contamination of oil

Sampling Point For L.O

The sample to be tested (be it shore based or on board) must be

ensured to take after the L.O system with system in running

condition.

Some C/E ask to take samples before the system, but it is good

practice to take post system.

Also allow sample to cool to atmospheric temperature before use.

Shore Based L.O Testing at Lab

The sample is filled in the bottles provided by the lab (Visva Lab most popular).

Then a form is filled for information about the oil and its running hours.

Put all the things in a courier packet.

Later fill a removal report and submit it to agent for landing at next

port.

They will send a report in few weeks by email.

Onboard Lub Oil Tests

Certain tests are done to test water leakage.They are explained

further,

Water Ingress Test

5 ml of sample is taken inside digital water content meter mixed with 15 ml of

reagent containing paraffin or toluene. Before closing the lid of the digital meter, a

sealed sachet containing calcium Hydride is kept and container closed tight. The

meter is shaken by hand and the pressure rise due to the chemical reaction in the

test container is shown as water percentage in the digital display.

Testing its Viscosity

This test is performed by using a Flow stick in which two paths are provided for

flow of oil side by side. In one path fresh oil is filled and in other side path used

sample oil is filled. Now the flow stick is tilted allowing oil on both paths flowing in

the direction of the tilt due to gravity. A finish point is provided along with

reference points along the flow stick and the position of used oil is checked when

fresh oil reaches the finish point.

Spot Test

In this test a drop of lube oil is put on the blotter paper and it is then dried for

few hours. The dry spot is then compared with the standard spot available which

determines the insoluble components in lube oil.

Вам также может понравиться

- Jan & Feb Orals Question Chennai MMDДокумент90 страницJan & Feb Orals Question Chennai MMDVijay AОценок пока нет

- Safematic SteeringДокумент9 страницSafematic SteeringVijay A100% (1)

- Crankpin BearingДокумент1 страницаCrankpin BearingVijay AОценок пока нет

- Crankpin BearingДокумент1 страницаCrankpin BearingVijay AОценок пока нет

- Diff Between Sulzer and B&W Crosshead LubricationДокумент1 страницаDiff Between Sulzer and B&W Crosshead LubricationVijay A100% (3)

- Construction Materials For Marine Diesel EnginesДокумент5 страницConstruction Materials For Marine Diesel EnginesVijay AОценок пока нет

- Purpose of CrossheadДокумент1 страницаPurpose of CrossheadVijay AОценок пока нет

- Storm ValveДокумент2 страницыStorm ValveVijay AОценок пока нет

- Part7 Q A Marine EngineerДокумент6 страницPart7 Q A Marine EngineerVijay AОценок пока нет

- Marpol Suplement 2015Документ48 страницMarpol Suplement 2015CvitaCvitićОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- DBMS-LM Kavi With MinipjtДокумент56 страницDBMS-LM Kavi With Minipjtkavi_mithuОценок пока нет

- An Introduction To Error-Correcting Codes: The Virtues of RedundancyДокумент38 страницAn Introduction To Error-Correcting Codes: The Virtues of RedundancyKrish Cs20Оценок пока нет

- Diesel GateДокумент41 страницаDiesel Gateanon_934477879100% (1)

- Cs9152 DBT Unit IV NotesДокумент61 страницаCs9152 DBT Unit IV NotesNivithaОценок пока нет

- DPP Series 1 PDFДокумент1 страницаDPP Series 1 PDFsukainaОценок пока нет

- VirtualHost Examples - Apache HTTP ServerДокумент9 страницVirtualHost Examples - Apache HTTP ServerSaitejaTallapellyОценок пока нет

- Taking Your Pump System Efficiency To New Heights: CU 352 Multi-Pump ControllerДокумент4 страницыTaking Your Pump System Efficiency To New Heights: CU 352 Multi-Pump Controllersushant moreyОценок пока нет

- Canvera Photobook GuideДокумент16 страницCanvera Photobook GuideAnupam KumarОценок пока нет

- Pds Luxathane 5000 VocДокумент2 страницыPds Luxathane 5000 Vocmuthukumar100% (1)

- Lexus Brand BrochureДокумент40 страницLexus Brand Brochurejammypops100% (1)

- Ram Concrete AnalysisДокумент94 страницыRam Concrete AnalysisTom CurryОценок пока нет

- AULA 13 - RespondidoДокумент4 страницыAULA 13 - RespondidoRanyelle WanessaОценок пока нет

- Railway-4 Permanent Way & Alignment (Lecture-4)Документ17 страницRailway-4 Permanent Way & Alignment (Lecture-4)OBIDUR RAHMAN 1701085Оценок пока нет

- Lista Preturi Linhai 300 2014 PDFДокумент25 страницLista Preturi Linhai 300 2014 PDFSimonaVătafuОценок пока нет

- Brosur Hari GuruДокумент8 страницBrosur Hari GuruFitri SharifОценок пока нет

- Normas ISO TelecomunicacionesДокумент38 страницNormas ISO Telecomunicacionesjolao AlmeidaОценок пока нет

- 381Документ8 страниц381Nidya Wardah JuhanaОценок пока нет

- Career Development PlanДокумент5 страницCareer Development Planapi-317247630Оценок пока нет

- Water Tank Seat Slab DesignДокумент2 страницыWater Tank Seat Slab DesignMesfin Derbew100% (2)

- PC Platform Compilers For PSS®E - Smart Grid Solutions - SiemensДокумент2 страницыPC Platform Compilers For PSS®E - Smart Grid Solutions - SiemensSarah JenkinsОценок пока нет

- PQ070XF02SZH: Features Outline DimensionsДокумент4 страницыPQ070XF02SZH: Features Outline DimensionsJulio Cesar CastilloОценок пока нет

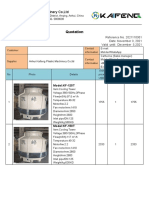

- KAIFENG Quotation For 150T Cooling TowerДокумент13 страницKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyОценок пока нет

- MD RAKIBUL ISLAM Update CVДокумент2 страницыMD RAKIBUL ISLAM Update CVনীল বেদনাОценок пока нет

- Individual: DR Winnie Louis LeeДокумент27 страницIndividual: DR Winnie Louis Leeedn_mj1645Оценок пока нет

- Solucionario Libro Infotech 4th EditionДокумент32 страницыSolucionario Libro Infotech 4th EditionGisella Espinoza BarberenaОценок пока нет

- ORF Issue Brief 309 SpaceLawДокумент12 страницORF Issue Brief 309 SpaceLawNitish KumarОценок пока нет

- 1743 LKWActrosXXXXXX 954frДокумент4 страницы1743 LKWActrosXXXXXX 954frgeothermal3102100% (1)

- Strategic Planning ToolkitДокумент19 страницStrategic Planning ToolkitStephen OliekaОценок пока нет

- CCI Control Valves For Fossil ApplicationsДокумент2 страницыCCI Control Valves For Fossil ApplicationsGabrieldiazОценок пока нет

- Dodge Journey 2017 - Owner's ManualДокумент510 страницDodge Journey 2017 - Owner's Manualandres camachin100% (1)