Академический Документы

Профессиональный Документы

Культура Документы

SPE 88797 Determination of Recovery and Relative Permeability For Gas Condensate Reservoirs

Загружено:

juan joseОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SPE 88797 Determination of Recovery and Relative Permeability For Gas Condensate Reservoirs

Загружено:

juan joseАвторское право:

Доступные форматы

SPE 88797

Determination of Recovery and Relative Permeability for Gas Condensate Reservoirs

Mohamed Al-Honi, SPE, and Abdulrazag Y. Zekri, SPE, Waha Oil Company

Copyright 2004, Society of Petroleum Engineers Inc.

This paper was prepared for presentation at the 11th Abu Dhabi Intgernational Petroleum

Exhibition & Conference held in Abu Dhabi, UAE, 1013 October 2004.

This paper was selected for presentation by an SPE Program Committee following review of

information contained in a proposal submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers is

prohibited. Permission to reproduce in print is restricted to a proposal of not more than 300

words; illustrations may not be copied. The proposal must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Abstract

Coreflood experiments on gas condensate flow behavior were

conducted for a Libyan gas condensate reservoir. The

objectives were to investigate the effects of rock and fluid

characteristics on critical condensate saturation (CCS), gas and

condensate relative permeabilitys, hydrocarbon recovery and

trapping by water injection, and incremental recovery by

subsequent blowdown and vaporization by dry gas injection.

The water/gas relative permeability data were generated

using implicit historical matching simulator which uses a

reverse history matching technique to generate a full suite of

relative permeability curves over the range of interest. The

results of the tests on the reduction in gas permeability due to

retrograde condensate accumulation demonstrated that, in

general, the effective permeability to gas decreased

significantly at pressures below the dew point pressure due to

the condensate trapping effect for all the stacks investigated in

this study. Permeability continues to drop at very low

pressures even though theoretically condensate should be revaporizing. The recoveries of the liquid condensate during the

vaporization by dry gas injection at pressures below the dew

point pressure were generally high. The recovery ranged from

66% to 70% for the high permeability core stack and 86% to

98% for the lower permeability core stack. In theory, it is

possible for all of the condensate to be revaporized into the

methane gas stream. However, in practice, the recovery is

usually less than 100% due to macroscopic sweep efficiency

limitations and mass transfer limitations within the rock

matrix.

Poor mobility ratio and viscous fingering during the methane

injection characterize the re-vaporization of gas condensate by

methane gas. This results in early breakthrough of the

methane gas and very high gas/liquid ratios during the test.

The volume of methane gas injection required to recover a

significant amount of the condensate liquid in the core is a

function of temperature, pressure, composition of the gas,

heterogeneity and especially the permeability of the core

sample.

Introduction

Gas condensate fields development and management require

good understanding of fluid flow behavior and techniques to

optimize the recovery. When the well bottom hole flowing

pressure falls below the dew point, condensate liquid builds up

around the well bore, causing a reduction in gas permeability

and well productivity. The liquid saturation may reach values

as high as 50 or 60 per cent, and the well deliverability may be

reduced by up to an order of magnitude Curtis et al.1 stated

that relative permeability effects in gas condensate reservoirs

can be classified into three categories: (1) near-well steadystate gas/condensate flow where saturation hysteresis is severe

throughout the life of a well experiencing hundreds of cycles

of complete or partial imbibitions and drainage; (2) in the bulk

of the reservoir far-removed from the wells, an imbibitions

process occurs throughout the life of the reservoir, where

liquid mobility is (practically) zero and only gas flows at a

somewhat reduced permeability; and (3) water encroachment,

where gas and/or retrograde condensate are trapped in

quantities from 15-40 saturation percent, and water

permeability can be significantly reduced. They presented an

engineering approach to treat gas-condensate relative

permeabilities describing near-well flow in gas condensate

wells. A good number of researchers suggest that gas

condensate relative permeabilities increase at high flow rates,

and that these changes can be correlated against the capillary

number2,3,4,5 The previous conclusion was based on evidence

obtained from laboratory core flood experiments The capillary

number is a dimensionless number which measures the

relative strength of viscous and capillary forces. The increase

in mobility at high capillary number is sometimes termed

velocity stripping.

Mott et al.6 developed a new method to measure gas

condensate relative permeabilities under conditions relevant to

the near well region. The new technique measures krg as a

function of krg/kro and capillary number; this is the most

important information for calculating gas condensate well

productivity.

Moctezuma-Berthier and Samaniego7 present a methodology

for the realization of laboratory representative studies of flow

in heterogeneous cores flowing with gas and condensate

equivalents fluids. The relative permeability curves are found

fitting the gas production and pressure drop experimental data

with a compositional simulator. This simulator was used to

have a detailed behavior of the fluids during the experiment.

Permeability reduction to the gas phase due to an increment in

the residual liquid saturation.

The reservoir pressure can be maintained above the

dewpoint pressure through injection of gas. Gas cycling or

(re)injection of lean gas is frequently applied, because dry,

methane-rich hydrocarbon gas has suitable physical properties.

Nitrogen is a potential alternative injection gas. It is available

everywhere because it can be produced from air at low costs

using cryogenic or membrane separation8. Economic

evaluations show that nitrogen injection is realistic, provided

that the gas condensate is sufficiently rich9,10. Nitrogen

injection has been applied, often in combination with gas

cycling, in several gas-condensate reservoirs11,12,13,14.

Description of Experiments

Apparatus and Materials

Core Flooding Apparatus. The schematic diagram of the

core flooding apparatus is shown in Fig.1. Two fluid

accumulators are connected to a variable rate injection pump.

The core holder is placed in a variable temperature oven.

Pressure and temperature transducers are connected at both

ends of the core inside the core holder. A chart recorder and a

digital pressure recorder are connected to the temperature

transducer and pressure transducer respectively.

Rock and Fluids. Stacked (composite) cores are constructed

to reduce experimental error by increasing the pore volume of

the porous media utilized for the experiment. End effect

errors can also be reduced by increasing the amount of rock

volume which possesses stabilized saturation apart from the

inlet and outlet phenomena. The longer core composed of

several shorter samples is constructed by mounting the core

end to end and placing wafers of thin porous fiber between the

samples to ensure capillary continuity between the rock faces.

To prepare the reservoir fluids by recombining the separator

condensate and synthetic separator gas, the gas is first

condensed into a high pressure cylinder for high pressure

applications. By immersing the target high pressure cylinder

in liquid nitrogen, the low pressure gas can be readily

transferred. Once the specified pressure drop has been

achieved on the source gas in the low pressure tank, the high

pressure cylinder is then heated to system temperature. To

increase the pressure to operating pressure mercury is injected

into the bottom of the cylinder which acts as a confining fluid.

In this manner any pressure can be achieved (up to 10,000 psi,

about 70,000 kPa) and a constant injection pressure can be

maintained. Table 1presents the physical properties of eight

core stacks.

Experimental Procedure

Wettability Restoration of Plugs

The samples were initially evacuated and then pressure

saturated to 100% water saturation. The samples were then

desaturated to irreducible water saturation by centrifuging

each individual sample under air. To mimic hydrocarbon

migration into place, gas samples from the studied reservoir

were displaced through these samples for an extended period

of time in an effort to restore these samples to their virgin

conditions. The restoration procedure was performed at

reservoir conditions of 315F and 7082 psig pore pressure

SPE 88797

with the application of net overburden pressure (4850 psig)

with the duration being four weeks. The results of restoration

indicated that the reservoir is a water wet system at reservoir

condition.

WaterGas (Condensate) Relative Permeability

Water-gas relative permeability tests were conducted on

reservoir core materials and fluids the studied gas condensate

reservoir. Routine air permeability and helium expansion

porosity tests were conducted on selected samples following

cleaning (to remove residual hydrocarbon) to aid in the

selection of representative core material for testing in all the

core stacks. Composite core samples are mounted and initial

displacement of humidified methane gas is conducted to

increase pore pressure to the desired reservoir internal pore

pressure. Displacement is then switched to retrograde

condensate gas from the selected reservoir until the effluent

GOR matches the live fluid gas-condensate ratio. Injection of

formation brine at a low rate followed until no additional gas

and/or retrograde condensate is produced. During this

displacement, measure the pressure drop across the core and

record the gas and water production rates to facilitate the

calculation of the saturation and permeability values.

Reduction in Gas Permeability Due to Retrograde

Condensate

In order to provide accurate material balance and to

minimize the end effect, each core stack consisted of four

plugs of similar permeability and porosity values. The core

samples were then restored to their native wettability using the

procedure mentioned above. Core flood tests were conducted

at the reservoir temperature of 315F, with a confining

pressure of approximately 12000 psig and a back pressure of

7082 psig. The experimental procedures involved first

mounting the core samples using specified reservoir

conditions. Then, initial displacement of gas was conducted to

increase internal pressure to the desired reservoir pore

pressure. Gas displacement continued until the effluent

gas/liquid ratio matched the initial gas/liquid ratio. The

pressure at the back pressure regulator (BPR) was reduced to

the dew point pressure of 6610 psig and the permeability to

gas was measured at the dew point pressure and the reservoir

temperature. The BPR was reduced again to 6320 psig (below

the dew point pressure) to allow a condensate saturation to

form uniformly in the pore system of the test sample. The

permeability to gas at 6320 psig and reservoir temperature was

measured. Subsequently, the BPR was reduced to 5763, 5263,

4763, 3763, 3263, 1000 and 100 psig, and the gas permeability

measured using equilibrium gas at each pressure step.

Condensate Vaporization by Dry Gas at Pressures Below

Dewpoint Pressure

Two composite core stacks (Table 2) were prepared for

the vaporization of condensate experiments. In order to

minimize the end effects, up to 12 plug samples were used in

each stack. These plug samples were arranged in a sequence

using the Huppler15 method such that the harmonic average

permeability between each core plug is as close as possible to

the overall average permeability for the whole stack. This

results in the core plugs having permeabilities closest to the

SPE 88797

overall permeability being located near the outlet end of the

core stack where the pressure gradient is greatest. Composite

core samples are mounted using specified reservoir conditions,

and initial displacement of methane gas is conducted to

increase pore pressure to the desired reservoir pore pressure.

Displacement is then switched to recombined condensate gas

from the selected reservoir until the effluent GOR matches the

reservoir GOR. Drop the back pressure regulator (BPR) to

6320 psig (below the dew point pressure of 6610 psig) to

allow a condensate saturation to form. Monitor gas and

condensate production during the pressure depletion. A dry

gas flood using methane gas is conducted at 6320 psig to

determine what portion of the residual condensate saturation is

vaporized by the dry gas. Collect relative permeability data

and effluent gas and condensate samples at every 0.5 pore

volume of dry gas injection. Analyze composition of both

gas and condensate samples and measure effective

permeability to dry gas at the end of the flood.

RESULTS AND DISCUSSION

Water-Gas (Condensate) Relative Permeability Tests

Eight core stacks were constructed using samples from the

selected gas condensate reservoir. Compositions of the

recombined reservoir fluid and the synthetic formation brine

are shown in Tables 3 and 4. Table 5 presents a summary of

the end point data from the waterflood relative permeability

tests for these core stacks. The relative permeability curves for

stacks 1to 8 are shown in Fig. 2 Residual trapped gas

saturations ranged from 10.7% to 30.9% for all core stacks and

averages about 27%. Gas recoveries ranged from 56.9% to

79.5% of hydrocarbon in place. On the average, breakthrough

of the injected water occurred after about 0.5 pore volume of

water injection.

Reduction in Gas Permeability

Prior to these relative permeability measurements, a

constant volume depletion experiment was conducted using

recombined reservoir fluid which indicated that the dew point

pressure of the reservoir fluid is at about 6610 psig. The

volume percentage of the retrograde condensate increased

rapidly at pressures below the dew point pressure to a

maximum of about 25 percent at a pressure of approximately

4000 psig after which further pressure results in more volatile

components of the condensate revaporazing back into the gas

phase. Some small vaporization of the retrograde condensate

can be observed at pressure below 4000 psig down to the

atmosphere pressure. Past experience indicates that significant

in-situ revaporization in the porous media will likely not occur

due to capillary pressure and mass transfer limitations. In our

work, significant reductions in permeability were observed as

the pore pressure was decreased. This is expected, of course,

due to the increase in condensate trapping effects with

decreased pore pressure. Permeability continued to drop at

pressures below 4000 psig even though theoretically

condensate should be re-evaporating. These observations are

likely caused by the mass transfer limitations during

multiphase flow in the core stack and the effect of the

increasing overburden pressure (matrix compressibility) as the

internal pore pressure of the reservoir is reduced. In addition,

some of the effective permeabilities measured at the saturation

pressure of 6610 psig were less than the air permeabilities

obtained from routine core analysis for the same core

materials. This is a common phenomenon that can be

attributed to a combination of the relative permeability effects,

Klinkenberg effects and overburden effects. Results of the

permeability reductions for all eight core stacks are shown in

Fig. 3.

Condensate Vaporization by Dry Gas Injection below

Dewpoint Pressure

For this test program, two long core stacks (12 samples

each) were constructed using core materials from the chosen

reservoir. The tests were conducted at two pore pressures: at

6320 psig and 5700 psig. A summary of the condensate

recoveries is shown in Table 6. The cumulative condensate

production curves expressed in percent of ICIP (InitialCondensate-In-Place) are shown in Fig. 4. Compositional

analyzes of the produced gas demonstrated that breakthrough

of the injected methane occurred at about 0.6 pore volume of

methane injection; however, a significant volume of

condensate continued to be produced after breakthrough. The

condensate recovery at breakthrough is at approximately 45

percent due mostly to the relatively high core permeability (50

md) which may allow channeling of the injection gas. Fig. 5

shows the molecular weight of the produced condensate liquid

as a function of methane gas injection for the higher

permeability stack #1. The data demonstrate an increasing

trend in the molecular weight of the produced condensate

liquid. This is a good indication of the vaporization of the

heavy hydrocarbons by multi-contact miscibility with methane

gas. Similar observations can be found in the molecular

weights of the heavier hydrocarbons such as Heptane-plus

(C7+) to Dodecane-plus (C12+) components (Fig. 6). In

addition, the mole fraction curve of the Dodecane-plus

components shows a significant increasing trend with the

volume of methane injection which again indicates multicontact miscibility with the methane gas. On the other hand,

the mole fractions of the Hexane-plus and Heptane-plus

components in the condensate production remain fairly

constant with time because the lighter hydrocarbon

components can be readily vaporized by first-contact

miscibility with methane gas. The amount of these lighter

hydrocarbons being recovered at later times becomes less and

less significant. The effective permeability to gas during the

revaporization of condensate tests was monitored. The results

show that, as more methane gas is injected, the effective

permeability to gas for the higher perm stack #1 increases

from about 4 percent before the start of methane injection to

about 50 percent after 3 pore volumes of methane gas have

been injected. This regain permeability is shown in Fig. 7.

The second core stack (#2) has a much lower average

permeability (3 mD) than stack #1; which had an average

permeability of 50 mD. The overall recovery of the condensate

from the dry gas displacement is very high at an average of

about 90 percent. The test parameters and coreflood test

results for this core stack are shown in Tables 59 to 65 and in

Compositional analyzes of the produced gas shows that

breakthrough of the injected methane occurred at between 0.6

to 0.75 pore volumes of methane injection and the production

of the condensate still continued afterwards. The condensate

recovery at breakthrough is slightly higher than 60 percent (of

initial condensate in place) depending on the pressure

conditions. This indicates a much more efficient gas flood

likely due to the low permeability and more homogeneous

nature of this core stack. Considering the scatter in the data,

the molecular weight, mole fraction and densities, we believe

that the mechanism of vaporization by first and multi-contact

miscibility between the heavy hydrocarbons with the methane

gas takes place as with the first core stack.

Effective gas permeability shows similar functionality for

the lower permeability stack #2, but the final permeability

attained was only about 2 percent of air permeability. This is

an indication that the finer pore structure/greater tortuosity of

the lower permeability stack have a limiting effect on the

effective permeability with residual fluids in place.

CONCLUSIONS

Based on the results of this study, the following conclusions

can be drawn:

1. The effective permeability to gas decreased significantly at

pressures below the dew point pressure due to the

condensate trapping effect for all the stacks investigated in

this study. Permeability continues to drop at very low

pressures even though theoretically condensate should be

re-vaporizing. In our experience, this phenomenon is most

likely due to mass transfer limitations during multi phase

flow in the core stack which practically limit the amount of

condensate which can be revaporized (due to diffusion

limitation). Also, as the pore pressure is decreased, the

net overburden pressure on the rock matrix will increase

as pore pressure continues to be reduced. This increase in

overburden will also tend to reduce the effective

permeability of the core matrix.

2. The recoveries of the liquid condensate during the

vaporization by dry gas injection at pressures below the

dew point pressure were generally high. The recovery

ranged from 66% to 70% for the high permeability core

stack and 86% to 98% for the lower permeability core

stack.

3. Poor mobility ratio and viscous fingering during the

methane injection characterize the re-vaporization of gas

condensate by methane gas.

This results in early

breakthrough of the methane gas and very high gas/liquid

ratios during the test.

4. Methane gas will be least efficient hydrocarbon based gas

that would be considered for revaporization, the gas from

the reservoir would be more effective and might be used in

the field since it will more richer.

5. The volume of methane gas injection required to recover a

significant amount of the condensate liquid in the core is a

function of temperature, pressure, composition of the gas,

heterogeneity and especially the permeability of the core

sample.

6. It is evident from the laboratory data that heavy

hydrocarbon components from hexane-plus up to

SPE 88797

dodecane-plus fractions can be revaporized by miscible

extraction at high pressure with methane gas.

Acknowledgment

The authors would like thank Waha Oil Company for

permission to publish the paper. All the laboratory work was

performed at Hycal Laboratories.

References

1. Whitson, C. H., Fevang, O., and Svareid, A.: Gas

Condensate Relative Permeability For Well Calculations,

paper SPE 56476 presented at presented in the 1999 SPE

Annual Techenical Conference and Exhibition held in

Houston, Texas 3-6 october 1999.

2. Henderson, G.D. et al.: Measurement and Correlation of

Gas Condensate Relative Permeability by the Steady-State

Method,SPEJ, June 1996.

3. Ali, J.K. et al.: The Effects of High-Velocity Flow and

PVT Changes near the Wellbore on Condensate Well

Performance,paper SPE 39823, presented at the SPE

Annual Technical Conference and Exhibition, San

Antonio, 5-8 October 1997.

4. Boom, W. et al: Experimental Evidence for Improved

Condensate Mobility at Near-Wellbore Flow Conditions,

paper SPE 30766, presented at the SPE Annual Technical

Conference and Exhibition, Dallas, 22-25 October 1995.

5. Kalaydijan, F. J-M. et al: Predicting Gas Condensate

Reservoir Performance: How Flow Parameters are Altered

when Approaching Production Wells, paper SPE 36715,

presented at the SPE Annual Technical Conference and

Exhibition, Denver, 6-9 October 1996.

6. Mott, R., Cable, A., and Spearing, M.: A New Method Of

Measuring Relative Permeabilities For Calculating GasCondensate Well Deliverability, paper SPE 56484

presented at the 1999 SPE Annual Technical Conference

and Exhibition held in Houston, Texas, 3-6 October 1999.

7. Moctezuma-Berthier, A., Samaniego, F. V.: Relative

Permabilities of Gas-Condensate Fluids in Heterogeneous

Porous Media, paper SPE 59049 presented at the 2000

SPE International Petroleum Conference and Exhibition in

Mexico held in Villahermosa, Mexico, 1-3 February 2000.

8. Evison, B. and Gilchrist, R.E.: New Developments in

Nitrogen in the Oil Industry, paper SPE 24313 presented

at the 1992 SPE Mid-Continent Gas Symposium, Amarillo,

Texas, 1314 April.

9. Donohoe, C.W. and Buchanan, R.D.: Economic Evaluation

of Cycling Gas-Condensate Reservoirs with Nitrogen,

JPT (February 1981) 263.

10 Hagoort, J., Brinkhorst, J.W., and van der Kleyn, P.H.:

Development of an Offshore Gas Condensate Reservoir

by Nitrogen Injection visa`-vis Pressure Depletion, JPT

(April 1988) 463.

11. Eckles, W.W. Jr., Prihoda, C., and Holden, W.W.:

Unique Enhanced Oil and Gas Recovery for Very HighPressure Wilcox Sands Uses Cryogenic Nitrogen and

Methane Mixture, JPT (June 1981) 971.

12. Wendschlag, D.D., Stephenson, R.E., and Clark, T.T.:

Fieldwide Simulation of the Anschutz Ranch East

SPE 88797

Nitrogen Injection Project with a Generalized

Compositional Model, paper SPE 12257.

13. Metcalfe, R.S., Vogel, J.L., and Morris, R.W.:

Compositional Gradients in the Anschutz Range East

Field, SPERE (August 1988) 1025; Trans., AIME, 285.

14. Huang, W.W., Bellamy, R.B., and Ohnimus, S.W.: A

Study of Nitrogen Injection for Increased Recovery From a

Rich Retrograde Gas/Volatile Oil Reservoir, paper SPE

14059.

15. Huppler, J. D.: Waterflood Relative Permeability in

Composite Cores, Journal of Petroleum Technology (May

1969) 539-540.

SPE 88797

Table 1. Coposite rock stacks properties

Core

Air

Core

Air

Stack

Plug sample

Permeability

Porosity

Stack

Plug

sample

I.D.

I.D.

(mD)

(fraction)

I.D.

I.D.

(mD)

(fraction)

P581

28.0

0.107

P101

92.0

0.129

P582

28.0

0.096

P5

91.0

0.128

P381

27.0

0.105

P156

91.0

0.139

P383

27.0

0.109

P222

95.0

0.142

P67

6.4

0.080

P135

8.5

0.106

P69

5.5

0.084

P142

9.0

0.095

P201

6.6

0.114

P77

9.0

0.120

P257

7.8

0.119

P141

8.0

0.096

P28

2.5

0.114

P270

19.0

0.102

P54

2.1

0.100

P265

22.0

0.101

P105

1.9

0.099

P200

19.0

0.126

P152

2.7

0.085

P181

20.0

0.145

P261

5.0

0.104

P56

30.0

0.124

P220

4.0

0.125

P65

71.0

0.135

P212

4.2

0.122

P118

37.0

0.114

P28

3.7

0.071

P33

47.0

0.102

Permeability

Porosity

Table 2. Composite core , condensate vaporization test

Core

Air

Core

Air

Stack

Plug

sample

Permeability

Porosity

Stack

Plug sample

Permeability

Porosity

I.D.

I.D.

(mD)

(fraction)

I.D.

I.D.

(mD)

(fraction)

P25

43

0.115

P241

3.0

0.080

P67

48

0.127

P225

2.2

0.116

P62

55

0.091

P187

3.1

0.113

P140

50

0.123

P191

2.9

0.124

P65

45

0.109

P158

3.3

0.085

P87

45

0.113

P230

2.5

0.115

P170

60

0.119

P159

2.2

0.062

P34

68

0.120

P73

3.7

0.087

P105

38

0.102

P95

2.4

0.099

P174

49

0.148

P63

2.7

0.084

P83

44

0.137

P49

2.3

0.101

P80

68

0.144

P72

3.3

0.081

51

0.121

2.8

0.096

SPE 88797

Table 3. Reservoir fluid composition

Table 4. Formation water composition

Composition

(mole %)

Cations/Anions

(mg/L)

N2

1.24

Na

56400

CO2

5.25

392

H2S

0.00

Ca

22200

C1

72.34

Mg

1560

C2

7.85

Ba

C3

2.46

Sr

IC4

0.65

Fe

700

C4

1.10

Cl

134000

IC5

0.46

Br

C5

0.45

C6

0.72

HCO3

C7+

7.48

SO4

2.9

TOTAL

100.00

CO3

OH

Pressure (psia)

6597

GOR

6030 scf/bbl

Total Dissolved

Solids

215255 mg/L

Brine Viscosity

0.329 cP

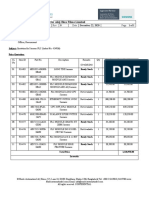

Table 5. Water-Gas relative permeability summary

Co

re Stack

I.D.

Air

Permeability

Range (mD)

Swi

(percent)

Initial

Permeability

to Gas

Recovery

(% PV)

Recovery

(% HCPV)

Residual

Gas

Saturation

Final

Permeability

to water

#1

27 28

7.1%

5.36 mD

64.6%

69.6%

28.3%

22.3 mD

#2

5.5 7.8

24.1%

1.84 mD

53.0%

69.9%

22.9%

0.64 mD

#3

1.9 2.7

28.4%

0.24 mD

40.7%

56.9%

30.9%

0.024 mD

#4

3.7 5.0

26.1%

0.106 mD

55.0%

74.5%

18.9%

0.077 mD

#5

91 95

16.2%

24.5 mD

56.2%

67.0%

27.6%

8.19 mD

#6

8.0 9.0

48.0%

0.94 mD

41.3%

79.5%

10.7%

0.37 mD

#7

19 22

19.9%

3.84 mD

57.6%

72.0%

22.5%

1.89 mD

#8

30 71

16.6%

19.5 mD

56.4%

67.6%

27.0%

3.30 mD

SPE 88797

Table 7. Summary of condensate recoveries

Core Stack #1

Initial Condensate

Saturation

(%PV)

Final Condensate

Saturation

(%PV)

% Revaporization

(% of Original

Condensate In Place)

@ 6320 psig

7.8

2.3

70.4

@ 5700 psig

13.8

4.6

66.4

@ 6320 psig

7.4

0.2

97.9

@ 5700 psig

12.3

1.8

85.8

Core Stack #2

BPR Pressure

To Vacuum

Pressure Transducer

Filter

Coreholder

Core

Backpressure

Valve

Wet Test Meter

Annular Pressure

Injection

Pressure

Annulus Pressure

Positive Displacement Pump

Figure 1. Schematic diagram of flooding apparatus.

SPE 88797

1

1

Relative Permeability

Krg

0.8

Krw

0.6

0.4

0.2

0.8

Krg

Stack 2

Krw

0.6

0.4

0.2

0

0

0

0.2

0.4

0.6

0.8

0.2

0.4

0.6

0.8

Water Saturation (fraction)

Water Saturation (fraction)

Krg

Stack # 3

0.6

Relative Permeability

0.8

Krw

0.4

0.2

0.8

0.2

0.4

0.6

0.8

Stack # 4

K rg

K rw

0.6

0.4

0.2

0.2

Water Saturation (fraction)

0.4

0.6

0.8

W ater Saturation (fraction)

1

Stack # 5

0.8

Relative Permeability

Relative Permeability

Krg

0.6

Krw

0.4

0.2

Stack # 6

0.8

Krg

0.6

Krw

0.4

0.2

0

0

0.2

0.4

0.6

0.8

Water Saturation (fraction)

0.2

0.4

0.6

0.8

Water Saturation (fraction)

Stack # 7

Krg

0.8

Relative Permeability

Relative Permeability

Relative Permeability

Relative Permeability

Stak # 1

Krw

0.6

0.4

0.2

Stack # 8

0.8

0.6

Krg

Krw

0.4

0.2

0

0

0

0.2

0.4

0.6

Water Saturation (fraction)

0.8

0.2

0.4

0.6

0.8

Water Saturation (fraction)

Figure 2. Gas condensate water relative permeabilities.

10

SPE 88797

60.0

Effective gas permeability,mD

50.0

S tac k 1

S tac k 2

40.0

S tac k 3

S tac k 4

S tac k 5

30.0

S tac k 6

S tac k 8

20.0

10.0

0.0

0

1000

2000

3000

4000

5000

6000

7000

P ore pres s ure ps ig

100%

80%

60%

Place)

Cumulative Condensate Production (% Original Liquid in

Figure 3. Permeability reduction for different core stacks.

40%

6 3 2 0 p s ig P o re P re s s u re

20%

5 7 0 0 p s ig P o re P re s s u re

0%

0

0 .5

1 .5

2.5

3 .5

C u m u l a t i ve D r y G a s In j e c t i o n ( P . V . )

Figure 4. Gas condensate recovery as function of cum gas injection.

SPE 88797

11

350

300

Molecular Weight

250

200

6320 psig Pore Pressure

150

5700 psig Pore Pressure

100

50

0

0

0.5

1.5

2.5

3.5

Cumulative Dry Gas Injection (P.V.)

Figure 5. Molecular weighr vs. cum dry gas injection.

1.2

C12+ Mole Fraction

0.8

Figure 5. Molecular weight of produced condensate.

0.6

6320 psig Pore Pressure

5700 psig Pore Pressure

0.4

0.2

0

0

0.5

1.5

2.5

3.5

Cumulative Dry Gas Injection (P.V.)

Figure 6. Stack #1 - Condensate Vaporization Test, C12+ Mole Fraction Profile

Regain Permeability (% of average Kair)

100%

90%

At 6320 psig

80%

At 5700 psig

70%

60%

50%

40%

30%

20%

10%

0%

0

0.5

1.5

2.5

3.5

Figure 7. Condensate vaporization Test, regain permeability versus Dry Gas injection.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 10 1 1 32 1809Документ9 страниц10 1 1 32 1809juan joseОценок пока нет

- 10 1 1 210 4793Документ14 страниц10 1 1 210 4793juan joseОценок пока нет

- $Документ10 страниц$juan joseОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 6 Spe26402Документ14 страниц6 Spe26402juan joseОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Characterization of Wettability From Spontaneous Imbibition MeasurementsДокумент8 страницCharacterization of Wettability From Spontaneous Imbibition Measurementsjuan joseОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- SPE SA (0526) : Estimating The Amount of Free Sand in The Yielded Zone Around Vertical and Horizontal Oil WellsДокумент14 страницSPE SA (0526) : Estimating The Amount of Free Sand in The Yielded Zone Around Vertical and Horizontal Oil Wellsjuan joseОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- SPE 104429 A New Methodology On Reservoir Modeling in The Fracture-Cavity Carbonate Rock of Tahe OilfieldДокумент9 страницSPE 104429 A New Methodology On Reservoir Modeling in The Fracture-Cavity Carbonate Rock of Tahe Oilfieldjuan joseОценок пока нет

- 2 Spe64753Документ6 страниц2 Spe64753juan joseОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Use of Pressure, P Squared or Chi in Reservoir GasДокумент9 страницUse of Pressure, P Squared or Chi in Reservoir Gase1mcОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- SPE 39972 Analysis of Linear Flow in Gas Well Production: Models and SolutionsДокумент12 страницSPE 39972 Analysis of Linear Flow in Gas Well Production: Models and Solutionsjuan joseОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- SPE 39972 Analysis of Linear Flow in Gas Well Production: Models and SolutionsДокумент12 страницSPE 39972 Analysis of Linear Flow in Gas Well Production: Models and Solutionsjuan joseОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- SPE 38653 A Procedure To Integrate Well Test Data, Reservoir Performance History and 4-D Seismic Information Into A Reservoir DescriptionДокумент16 страницSPE 38653 A Procedure To Integrate Well Test Data, Reservoir Performance History and 4-D Seismic Information Into A Reservoir Descriptionjuan joseОценок пока нет

- SPE 48880 The Integration of Geology and Well Testing For Improved Fluvial Reservoir CharacterisationДокумент8 страницSPE 48880 The Integration of Geology and Well Testing For Improved Fluvial Reservoir Characterisationjuan joseОценок пока нет

- SPE 38866 Analysis of Commingled Gas Reservoirs With Variable Bottom-Hole Flowing Pressure and Non-Darcy FlowДокумент13 страницSPE 38866 Analysis of Commingled Gas Reservoirs With Variable Bottom-Hole Flowing Pressure and Non-Darcy Flowjuan jose100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- AADE 01-NC-HO-27: State of The Art Positive Displacement Motors Enhance Vertical Drilling PerformanceДокумент6 страницAADE 01-NC-HO-27: State of The Art Positive Displacement Motors Enhance Vertical Drilling Performancejuan joseОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- (Blasingame) SPE 106308Документ13 страниц(Blasingame) SPE 106308juan joseОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- SPE 80474 Experience in Developing A Web Base Workflow To Enhance CompetencyДокумент11 страницSPE 80474 Experience in Developing A Web Base Workflow To Enhance Competencyjuan joseОценок пока нет

- SPE 166222 Pressure and Temperature Transient Analysis: Hydraulic Fractured Well ApplicationДокумент21 страницаSPE 166222 Pressure and Temperature Transient Analysis: Hydraulic Fractured Well Applicationjuan joseОценок пока нет

- UndergraduateGuide 019Документ40 страницUndergraduateGuide 019juan joseОценок пока нет

- New Well Completion and Stimulation Techniques Using Liquid Jet Cutting TechnologyДокумент7 страницNew Well Completion and Stimulation Techniques Using Liquid Jet Cutting Technologyjuan joseОценок пока нет

- Optimization of The Blueberry Debolt Oil Pools: Significant Production Increases For A Mature FieldДокумент11 страницOptimization of The Blueberry Debolt Oil Pools: Significant Production Increases For A Mature Fieldjuan joseОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 2 AADE 05 NTCE 05 - Howard FormatesДокумент10 страниц2 AADE 05 NTCE 05 - Howard FormatesPTОценок пока нет

- SPE 49090 Simplified Productivity Equations For Horizontal Wells Producing at Constant Rate and Constant PressureДокумент10 страницSPE 49090 Simplified Productivity Equations For Horizontal Wells Producing at Constant Rate and Constant Pressurejuan joseОценок пока нет

- 6 Spe26402Документ14 страниц6 Spe26402juan joseОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- 6 Spe-112355-MsДокумент13 страниц6 Spe-112355-Msjuan joseОценок пока нет

- (Blasingame) SPE 103204Документ27 страниц(Blasingame) SPE 103204juan joseОценок пока нет

- 10 1 1 32 1809Документ9 страниц10 1 1 32 1809juan joseОценок пока нет

- 7 SPE93992 (Full Permission)Документ6 страниц7 SPE93992 (Full Permission)juan joseОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- FS-1040 FS-1060DN: Parts ListДокумент23 страницыFS-1040 FS-1060DN: Parts List1980cvvrОценок пока нет

- The Essence of Technology Is by No Means Anything TechnologicalДокумент22 страницыThe Essence of Technology Is by No Means Anything TechnologicalJerstine Airah SumadsadОценок пока нет

- Third Party Risk Management Solution - WebДокумент16 страницThird Party Risk Management Solution - Webpreenk8Оценок пока нет

- Atmel 46003 SE M90E32AS DatasheetДокумент84 страницыAtmel 46003 SE M90E32AS DatasheetNagarajОценок пока нет

- Swelab Alfa Plus User Manual V12Документ100 страницSwelab Alfa Plus User Manual V12ERICKОценок пока нет

- Cameron International Corporation: FORM 10-KДокумент31 страницаCameron International Corporation: FORM 10-KMehdi SoltaniОценок пока нет

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Документ2 страницыLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulОценок пока нет

- Ce-Series - TK60981-ML-18 IM - Rev - 0 - 05-13Документ96 страницCe-Series - TK60981-ML-18 IM - Rev - 0 - 05-13VERDADE MUNDIAL GUERRAОценок пока нет

- A202 KBK3043 - Assignment Individual (20%) Review LiteratureДокумент5 страницA202 KBK3043 - Assignment Individual (20%) Review LiteratureAlfie AliОценок пока нет

- Functions of Theory in ResearchДокумент2 страницыFunctions of Theory in ResearchJomariMolejonОценок пока нет

- CycleMax IntroДокумент13 страницCycleMax IntroIslam AtefОценок пока нет

- Ilovepdf MergedДокумент503 страницыIlovepdf MergedHemantОценок пока нет

- Waves and Ocean Structures Journal of Marine Science and EngineeringДокумент292 страницыWaves and Ocean Structures Journal of Marine Science and Engineeringheinz billОценок пока нет

- English For Academic and Professional Purposes - ExamДокумент3 страницыEnglish For Academic and Professional Purposes - ExamEddie Padilla LugoОценок пока нет

- SAMPLE MCQuestions ByTopicsДокумент45 страницSAMPLE MCQuestions ByTopicsVeeru ManikantaОценок пока нет

- Exploring-Engineering-And-Technology-Grade-6 1Документ5 страницExploring-Engineering-And-Technology-Grade-6 1api-349870595Оценок пока нет

- Bone Surface MarkingsДокумент2 страницыBone Surface MarkingsNurul Afiqah Fattin AmatОценок пока нет

- "Tell Me and I Forget, Teach Me and I May Remember, Involve MeДокумент1 страница"Tell Me and I Forget, Teach Me and I May Remember, Involve MeBesufkad Yalew YihunОценок пока нет

- 2007 ATRA Seminar ManualДокумент272 страницы2007 ATRA Seminar Manualtroublezaur100% (3)

- Use of The Internet in EducationДокумент23 страницыUse of The Internet in EducationAlbert BelirОценок пока нет

- Electronic Diversity Visa ProgrambДокумент1 страницаElectronic Diversity Visa Programbsamkimari5Оценок пока нет

- IPA Smith Osborne21632Документ28 страницIPA Smith Osborne21632johnrobertbilo.bertilloОценок пока нет

- CHAPTER 2 Part2 csc159Документ26 страницCHAPTER 2 Part2 csc159Wan Syazwan ImanОценок пока нет

- Problem Solving No. 123Документ5 страницProblem Solving No. 123Christy Joy BarboОценок пока нет

- SievesДокумент3 страницыSievesVann AnthonyОценок пока нет

- Hitachi Vehicle CardДокумент44 страницыHitachi Vehicle CardKieran RyanОценок пока нет

- Technical Sheet Racloflex NTДокумент2 страницыTechnical Sheet Racloflex NTAnthony AngОценок пока нет

- 2010 - Howaldt y Schwarz - Social Innovation-Concepts, Research Fields and International - LibroДокумент82 страницы2010 - Howaldt y Schwarz - Social Innovation-Concepts, Research Fields and International - Librovallejo13Оценок пока нет

- CL Honours Report NamanДокумент11 страницCL Honours Report NamanNaman VermaОценок пока нет

- Week 3 Lab Arado, Patrick James M.Документ2 страницыWeek 3 Lab Arado, Patrick James M.Jeffry AradoОценок пока нет