Академический Документы

Профессиональный Документы

Культура Документы

Metal Dusting

Загружено:

glazetm0 оценок0% нашли этот документ полезным (0 голосов)

45 просмотров4 страницыMETAL DUSTING

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документMETAL DUSTING

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

45 просмотров4 страницыMetal Dusting

Загружено:

glazetmMETAL DUSTING

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

egesee

ee eee eccerene

BRC-CORP 37-74.F 167

Section 31. METAL DUSTING

Definition of

Metal dusting corrosion is a process whereby metal is removed by the

Teaction of hot process gas with the metal surface to form carbides, which

may Subsequently be oxidized and swept away in the process stream. ‘Carburization

is a pre-requisite for metal dusting corrosion, and is distinguished from it by

the deterioration it produces (see Section 6 on Carburization). Such a di

tinction has questionable merit, however, but has found common usage throughout

the industry. Metal dusting corrosion produces a wear appearance or distinct

pit formation. Figure 31-1 shows a localized wear pattern occurring adjacent

to a weld, in an Incoloy alloy 800 tube. Figure 31-2 shovs s general wall

thinning occurring in a tube of the same alloy where pitting is also observed.

Discussion of the Problem

Metal dusting corrosion can occur simply by formation of brittle

carbides at grain boundaries. These carbides can fracture, when subjected to

pesvice stresses (mechanical and thermal) or volume stresses, associated with

increased carbon concentration at the process stream surface. The process

stream can then sweep avay particles of metal, which have been loosened from

the tube wall by these fracture processes. The deterioration pattern is

related to localized carburization, susceptibility of the metal surface, and

flow characteristics of the process stream. The metal dusting corrosion

example shown in Figure 31-1 is somewhat more compley than eimpla carhurization,

as indicated by the micrograph of the tube wall shown in Figure 31-3. In this

case, the intergranular carbides initially formed (layer D) were oxidized

ayer C). Oxides have very low mechanical strength, and fracture quite

easily, permitting rapid metal particle removal in a high velocity strean.

The surface of Figure 31-3 consists of an iron-nickel solid solution (layer A)

where chromium has been removed to form carbides, and an oxide layer (layer

3). These pheses are alov canily reuuved from the tube wall during service.

Metal dusting corrosion usually occurs at temperatures above 649°C

(2200°F), although it hax been reported in piping exposed to temperaturee ac

low as 427°C (800°F). Efforts have been made to minimize carburization,

by sulfur and steam additions to the process stream. The subsequent effects

are not well documented.

Methods of Checking for the Problem

Metal dusting corrosion can be identified visually by the wear pattern

or pitted appearance it produces, along with metallographic examination.

Often, the finding of magnetic particles in adhering coke material is an

indicieion of metal dusting.

Methods of Eliminating the Problem

Metal dusting corrosion is characteristic of specific process

streams. Factors reducing carburization, such as increasing chromium, nickel

or silicon content, in austenitic alloys, can be helpful in reducing the rate

of metal dusting. ‘In general, the susceptibility to metal dusting will be

reduced when (ZCr) + 2x(%Si) > 24x, in iron-based alloys. Steam in the

Process stream also promotes a stable oxide film and reduces metal dusting

suscepesbilicy.

168 BRC-CORP 37-74.

Employment of austenitic stainless alloys where the silicon content

is in excess of 2.5 percent can promote formation of the detrimental eigna~

Phase (see Section 35).

Because the conditions causing metal dusting are only poorly

defined, solutions will not be the same for each occurrence. Each problen must

be carefully studied to determine the most effective and economical moat

that will be compatible vith the process stream.

Figure 31-4

Localized metal Dusting Aajecent to te Weld In an Incoloy 800 Tube

Magnification: 4X.

Po cccccccccccccce

BRC-CORP 37.74.

ie

Figure 31.2

‘Metal Dusting Corrosion of Incoloy 800 Tube

[Note general wall tninning ang prting

‘Magnification: 1X.

eo ©0000 OCOEEOO

BRC-CORP 37-745

eoeee socscceest

Figure 31.3

Photomicrograph of # Cross Section Through the Wall of an Incoloy

Alloy 800 Tube Attacked by Metal Dusting

Note that four distinct layers may be seen,

Magnification: 40X.

ccePoccccccccccccccest

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Understanding API SIRE Reading 1 Part 2 of 2Документ54 страницыUnderstanding API SIRE Reading 1 Part 2 of 2glazetmОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Kelly HandbookДокумент20 страницKelly HandbookglazetmОценок пока нет

- Tank in Service Inspection ChecklistДокумент8 страницTank in Service Inspection ChecklistAhmadiBinAhmad100% (3)

- Casio Manual fx-9860GII - Soft - EN PDFДокумент473 страницыCasio Manual fx-9860GII - Soft - EN PDFglazetmОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Understanding API SIRE Reading 1 Part 2 of 2Документ54 страницыUnderstanding API SIRE Reading 1 Part 2 of 2glazetmОценок пока нет

- Weld DefectsДокумент18 страницWeld Defectsisaacthib100% (2)

- TI-Nspire CX-HH GettingStarted EN PDFДокумент114 страницTI-Nspire CX-HH GettingStarted EN PDFglazetmОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- 571 Book Rust Busters1Документ231 страница571 Book Rust Busters1glazetm100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Grinding CracksДокумент3 страницыGrinding CracksglazetmОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Hydrogen BlisteringДокумент7 страницHydrogen BlisteringglazetmОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- 571 Book Rust Busters1Документ231 страница571 Book Rust Busters1glazetm100% (1)

- Caltex Process Plant CorrosionДокумент161 страницаCaltex Process Plant Corrosionglazetm100% (3)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- API - RP-571 - Damage Mech. SummaryДокумент28 страницAPI - RP-571 - Damage Mech. SummaryglazetmОценок пока нет

- Caltex Materials of ConstructionДокумент51 страницаCaltex Materials of ConstructionglazetmОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Stainless SteelДокумент8 страницStainless Steelsamitha505Оценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- C067Документ49 страницC067Gato Sesa0% (1)

- Synthetic AmphetamineДокумент57 страницSynthetic Amphetaminelumik123475% (4)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Rake AngleДокумент2 страницыRake AnglezidaaanОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- GB - T 8163-2018Документ8 страницGB - T 8163-2018Dung HDОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Chloride Attack On Stainless SteelДокумент7 страницChloride Attack On Stainless Steelpravin_koyyanaОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- SOR 15-16 GujДокумент229 страницSOR 15-16 Gujmtdby29% (7)

- RT ProcedureДокумент18 страницRT Procedure1339979Оценок пока нет

- Steel Grades HandbookДокумент6 страницSteel Grades Handbookbhavin178Оценок пока нет

- SOM-BMT Lab Manual FinalДокумент48 страницSOM-BMT Lab Manual FinalHarish T S Gowda100% (1)

- Dross ControlДокумент8 страницDross Controlkhuzafa100% (1)

- Landing GearДокумент6 страницLanding GearMureithi SamОценок пока нет

- BrazingДокумент16 страницBrazingbalamurugan_me100% (3)

- Nitriding & Nitrocarburising: Mikael Fällström Bodycote AGI NEEДокумент51 страницаNitriding & Nitrocarburising: Mikael Fällström Bodycote AGI NEEPushparaj Vignesh100% (1)

- BS en 10244-1-2009 Steel Wire and Wire Products - Non-Ferrous Metallic Coatings On Steel Wire - Part 1 General PrinciplesДокумент10 страницBS en 10244-1-2009 Steel Wire and Wire Products - Non-Ferrous Metallic Coatings On Steel Wire - Part 1 General Principlesazher03100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Dry Electrodes SystemДокумент8 страницDry Electrodes SystemhamoudabiОценок пока нет

- Industrial Cleaning Source BookДокумент58 страницIndustrial Cleaning Source Bookshiel175Оценок пока нет

- Spot WeldingДокумент37 страницSpot WeldingSabhari Natarajan100% (1)

- Astm Volume 0101 PDFДокумент4 страницыAstm Volume 0101 PDFPrasanna UmapathyОценок пока нет

- 800 10121Документ3 страницы800 10121slymnОценок пока нет

- FIPA G Magnetgreifer en USДокумент3 страницыFIPA G Magnetgreifer en UStushar7000Оценок пока нет

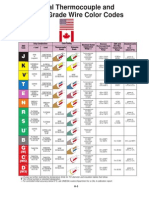

- International Thermocouple and Extension Grade Wire Color CodesДокумент6 страницInternational Thermocouple and Extension Grade Wire Color CodesEdguitar TheLonelyОценок пока нет

- AISC Propiedades y Pesos v14 - TOTALДокумент77 страницAISC Propiedades y Pesos v14 - TOTALAlex RiosОценок пока нет

- Unit 3 BasicsДокумент76 страницUnit 3 BasicsamarparimiОценок пока нет

- SA Roofing Cladding Section 3 PDFДокумент37 страницSA Roofing Cladding Section 3 PDFharishram123456Оценок пока нет

- Roman Dagger StanjelДокумент12 страницRoman Dagger StanjelMiroslav VujovicОценок пока нет

- Chapter 3 Datasheets Roof PanelsДокумент16 страницChapter 3 Datasheets Roof PanelsMladen BilincОценок пока нет

- Serie A Ba Que AnglaisДокумент3 страницыSerie A Ba Que AnglaisAnkur BhargavaОценок пока нет

- Buildning Materials:: Reinforcing SteelДокумент17 страницBuildning Materials:: Reinforcing SteelNitin RaoОценок пока нет