Академический Документы

Профессиональный Документы

Культура Документы

Giao Trinh Nen Mong Xe

Загружено:

NguyễnMinhNghĩaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Giao Trinh Nen Mong Xe

Загружено:

NguyễnMinhNghĩaАвторское право:

Доступные форматы

NATIONAL UNIVERSITY OF CIVIL ENGINEERING

DIVISION OF SOIL MECHANICS AND FOUNDATION ENGINEERING

FOUNDATION ENGINEERING

(FOR THE ENGLISH COURSE)

NGUYEN BAO VIET

LE THIET TRUNG

HA NOI - 2013

National University of Civil Engineering

CONTENTS

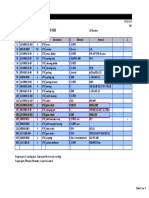

CONTENTS .....................................................................................................................i

LIST OF FIGURES ....................................................................................................... iii

PREFACE ........................................................................................................................v

CHAPTER 1:

INTRODUCTION ................................................................................1

CHAPTER 2:

SHALLOW FOUNDATIONS ............................................................. 3

2.1

Introduction ..................................................................................................3

2.2

Main Components of Shallow Foundations ................................................5

2.3

Contact Pressure Distribution beneath Base of Footing .............................. 7

2.3.1 Contact Pressure Distribution of Spread Footing ........................................9

2.3.2 Contact Pressure Distribution of Wall Footing .........................................10

2.3.3 Net Load Applied on Footing Base ........................................................... 10

2.3.4 Vertical Stress Increase ..............................................................................10

2.4

Ultimate Bearing Capacity of Shallow Foundation ...................................12

2.4.1 General .......................................................................................................12

2.4.2 Terzaghis Bearing Capacity Theory .........................................................13

2.4.3 The General Bearing Capacity Equation ...................................................17

2.4.4 General Bearing Capacity Equation in Practice ........................................19

2.4.5 Safety Factor and Allowable Load-Bearing Capacity ............................... 20

2.4.6 Bearing Capacity of Layered Soils: Stronger Soil underlain by Weaker

Soil .............................................................................................................20

2.5

Shallow Foundation Design .......................................................................21

2.5.1 Introduction ................................................................................................ 21

2.5.2 Design Procedure for Shallow Foundation. ...............................................21

2.5.3 Geotechnical Analyses and Design............................................................ 22

2.5.4 Structural Footing Design ..........................................................................25

CHAPTER 3:

SOIL IMPROVEMENT .....................................................................30

3.1

Sand Replacement ......................................................................................31

3.2

Sand Compaction Piles ..............................................................................32

3.2.1 Characteristics of Sand Compaction Piles .................................................34

3.2.2 Sand Compaction Pile Working Procedure ...............................................35

3.2.3 Applied Assumptions in Calculation of Sand Compaction Piles ..............36

Foundation Engineering

CONTENTS

National University of Civil Engineering

ii

3.2.4 Principle of Sand Compaction Pile Analyses ............................................36

3.2.5 Plan layout and Distance of Sand Compaction Pile ..................................37

3.2.6 Estimation of Improved Soil Properties ....................................................41

3.3

Vibroflotation ............................................................................................. 42

3.4

Blasting ......................................................................................................44

3.5

Precompression .......................................................................................... 44

3.6

Stone Columns ........................................................................................... 45

3.7

Dynamic Compaction ................................................................................46

3.8

Jet Grouting ................................................................................................ 48

3.9

Recommendation of Improvement Methods for Soils............................... 49

CHAPTER 4:

4.1

PILE FOUNDATIONS ......................................................................50

Definitions and classifications ...................................................................50

4.1.1 Definitions..................................................................................................50

4.1.2 Classifications of piles ...............................................................................52

4.1.3 Advantages and disadvantages of different pile material .......................... 58

4.2

Constitution of a Prefabricated Reinforced Concrete Pile .........................62

4.3

Bearing Capacity of a Single Pile .............................................................. 66

4.3.1 Definitions..................................................................................................66

4.3.2 Pile axial bearing capacity. ........................................................................66

4.4

Design of Low Pile Cap Foundation .........................................................74

4.4.1 Design hypotheses .....................................................................................74

4.4.2 Material selection for pile and pile cap ......................................................74

4.4.3 Pile dimension selection and pile load capacity calculation ......................75

4.4.4 Pile quantity and pile arrangement ............................................................ 75

4.4.5 Verification of load applied to pile ............................................................ 76

4.4.6 Verification of the resistance of bearing stratum .......................................77

4.4.7 Calculation of pile foundation settlement ..................................................78

4.4.8 Pile cap height ............................................................................................ 78

4.4.9 Verification of pile when transportation and positioning .......................... 81

4.4.10 Selection of hammer for driven piles .........................................................82

REFERENCES ..............................................................................................................83

Foundation Engineering

CONTENTS

National University of Civil Engineering

iii

LIST OF FIGURES

Figure 2-1 (a) Strip foundation under a wall (b) Strip foundation under columns

(c) Spread foundation (d) Mat foundation. (1) Footing (2) Wall (3)

Column ...................................................................................................... 3

Figure 2-2 Examples of spread foundations .................................................................... 3

Figure 2-3 Examples of shallow foundations (a) Combined footing; (b) combined

trapezoidal footing; (c) cantilever or strap footing; (d) octagonal

footing; (e) eccentric loaded footing with resultant coincident with

area so soil pressure is uniform. ................................................................ 4

Figure 2-4 Examples of mat foundations (a) Flat plate; (b) plate thickened under

columns; (c) beam-and-slab; (d) plate with pedestals; (e) basement

walls as part of mat. ................................................................................... 4

Figure 2-5 A typical cross section of spread footing....................................................... 5

Figure 2-6 Reinforcement of a spread footing ................................................................ 6

Figure 2-7 Behavior of foundations with connecting beams .......................................... 6

Figure 2-8 Ground beam and footing reinforcements ..................................................... 7

Figure 2-9 Settlement profile and contact pressure in sand: (a) flexible

foundation; (b) rigid foundation ............................................................. 8

Figure 2-10: Settlement profile and contact pressure in clay: (a) flexible

foundation; (b) rigid foundation ................................................................ 8

Figure 2-11: Linear distribution of contact pressure ....................................................... 9

Figure 2-12 2:1 method of finding stress increase under a foundation ......................... 11

Figure 2-13 Nature of bearing capacity failure in soil: (a) general shear failure:

(b) local shear failure; (c) punching shear failure. .................................. 12

Figure 2-14 Bearing capacity failure in soil under a rough rigid continuous (strip)

foundation ................................................................................................ 14

Figure 2-15 Bearing capacity of a strip foundation on layered soil ............................. 20

Figure 2-16 Two-way shear calculation ........................................................................ 26

Figure 2-17 Wide-beam shear calculation ..................................................................... 27

Figure 2-18 Flexure reinforcement calculation ............................................................. 28

Figure 3-1 (a) Completed sand replacement (b) Partial sand replacement ................... 31

Figure 3-2 Sand compaction pile test of Basore and Boitano (1969): (a) Layout of

the compaction piles; (b) Standard penetration resistance variation

with depth and S ..................................................................................... 33

Figure 3-3 Sand compaction pile mandrel tip ............................................................... 34

Figure 3-4 Characteristic of sand compaction piles for a spread footing ...................... 35

Figure 3-5 Sand compaction pile working procedure ................................................... 36

Figure 3-6 Principle of sand compaction pile analyses ................................................. 37

Figure 3-7 Compaction area for (a) strip footing and (b) spread footing ...................... 38

Figure 3-8 Plan layout of sand compaction piles (a) equiangular triangle (b)

Square ...................................................................................................... 40

Foundation Engineering

LIST OF FIGURES

National University of Civil Engineering

iv

Figure 3-9 Vibroflotation unit ....................................................................................... 42

Figure 3-10 Compaction by the vibroflotation process ................................................. 43

Figure 3-11 Principles of precompression ..................................................................... 44

Figure 3-12 Sand drain .................................................................................................. 45

Figure 3-13 Prefabricated vertical drain (PVD) ............................................................ 45

Figure 3-14 (a) Stone columns in a triangular pattern; (b) stress concentration due

to change in stiffness ............................................................................... 46

Figure 3-15 Rig of Dynamic compaction ...................................................................... 47

Figure 3-16 Dynamic compaction, working procedure ................................................. 47

Figure 3-17 Effects of soil Improvement by Dynamic compaction &

Vibroflotation .......................................................................................... 48

Figure 3-18 Jet grouting ................................................................................................ 49

Figure 3-19 Site improvement methods as a function of soil grain size ....................... 49

Figure 4-1: Low pile cap foundation High pile cap foundation ................................. 52

Figure 4-2: Steel pile cross section ................................................................................ 53

Figure 4-3: End bearing pile .......................................................................................... 54

Figure 4-4: Friction or Cohesion pile ............................................................................ 54

Figure 4-5: under-reamed base enlargement to a bore-and-cast-in-situ pile ................. 55

Figure 4-6: Concrete driven piles system ...................................................................... 56

Figure 4-7: Drilling auger types: short section single flight double flight .............. 57

Figure 4-8: Bored pile phasing: Site preparation Positioning Excavation

Rebar installation Conrete pouring Pile completion. ........................ 58

Figure 4-9: Different cross section of piles ................................................................... 63

Figure 4-10: Detailed design of prefabricated reinforced concrete pile ........................ 63

Figure 4-11: Cross section of a square pile ................................................................... 64

Figure 4-12: Stirrup bar: separate bar and spriral bar ................................................... 64

Figure 4-13: Details of pile toe ...................................................................................... 64

Figure 4-14: Steel grid at pile top Hook rebar............................................................ 64

Figure 4-15: Steel plate at the pile top........................................................................... 65

Figure 4-16: Details of pile connection ......................................................................... 65

Figure 4-17: sc khng bn qci v sc khng mi qcn trong th nghim CPT ............... 68

Figure 4-18 Typical static load test arrangement showing instrumentation ................. 70

Figure 4-19: Two P-S curves types (a, b) and T-S curve (c)......................................... 71

Figure 4-20: Piles arrangement in side view. ................................................................ 75

Figure 4-21: Piles arrangement in plan view ................................................................. 76

Figure 4-22: Equivalent raft .......................................................................................... 77

Figure 4-23: damage pile cap by column ...................................................................... 79

Figure 4-24: damage of pile cap by pile reaction .......................................................... 80

Figure 4-25: Rebar area calculation schemas ................................................................ 81

Figure 4-26: Pile transportation verification ................................................................. 81

Figure 4-27: Pile positioning verification...................................................................... 82

Foundation Engineering

LIST OF FIGURES

National University of Civil Engineering

PREFACE

Soil mechanics and foundation engineering have developed rapidly during the last

fifty years. Intensive research and observation in the field and the laboratory have

refined and improved the science of foundation design.

This text book of Foundation Engineering is edited for undergraduate civil

engineering students, who have passed the soil mechanics course, which is a

prerequisite for the foundation engineering course. The text is composed of four

chapters with examples and problems, and an answer section for selected problems.

The chapters are mostly devoted to the geotechnical aspects of foundation design and

briefly described as follows

Chapter 1 of introduction gives an overview of foundation engineering

Chapter 2 presents on the concept of shallow foundation and focus analyses and

design of spread footing and wall trip footing on several types of sub-soils. The

structural design of footing according to the Vietnamese codes also mentioned in detail

in this chapter.

Chapter 3 introduces various types of soil improvement in that sand cushion and

sand compaction piles are concentrated in analyses and design also.

Chapter 4 is dedicated for deep foundation of prefabricated piles. The estimation

of geotechnical and in structural bearing capacity of piles is mentioned based on both

theories and practices. Structural pile-cap design is an important content in this

chapter.

After this course, the students can get the basic knowledge in foundation

engineering. They could calculate and design foundation in some simple cases. This is

the first step for an engineer in geotechnical and foundation engineering.

Thanks are due to all members of Geotechnical and Foundation Engineering

Division of National University of Civil Engineering for their help and

encouragements during the preparation of this text.

I am also grateful for several helpful suggestions of Prof. Vu Cong Ngu and

Assoc. Prof. Pham Quang Hung.

The Authors

Dr. Nguyen Bao Viet

Dr. Le Thiet Trung

Foundation Engineering

PREFACE

National University of Civil Engineering

CHAPTER 1:

INTRODUCTION

All structures resting on the earth must be carried by an interface element called

foundation. A foundation is the lowest part of a structure that transmits to, and into, the

underlying soil or rock all loads of the super-structure and also its self-weight.

The term super-structure is commonly used to describe the engineered part of the

system bringing loads to the foundation, or substructure especially for buildings and

bridges. However, foundations also may carry only machinery, support industrial

equipment (pipes, towers, and tanks) act as sign base, and the like. Therefore it is

better to describe a foundation as a part of the engineered system that interfaces the

load-carrying component to the ground.

It is evident that a foundation is the most important part of the structures or

engineering system.

The design of foundations of structures such as buildings, bridges, and dams

generally requires knowledge of such factors as:

(a) The load that will be transmitted by the superstructure to the foundation

system,

(b) The requirements of the local building code,

(c) The behavior and stress-related deformability of soils that will support the

foundation system, and

(d) The geological conditions of the soil under consideration.

To a foundation engineer, the last two factors are extremely important because

they concern soil mechanics.

The geotechnical properties of a soil such as its grain-size distribution, plasticity,

compressibility, and shear strength can be assessed by proper laboratory testing. In

addition, recently emphasis has been placed on the in situ determination of strength

and deformation properties of soil, because this process avoids disturbing samples

during field exploration.

However, under certain circumstances, not all of the needed parameters can be or

are determined, because of economic or other reasons. In such cases, the engineer must

make certain assumptions regarding the properties of the soil. To assess the accuracy

of soil parameters whether they were determined in the laboratory and the field or

whether they were assumed the engineer must have a good grasp of the basic

principles of soil mechanics. At the same time, he or she must realize that the natural

soil deposits on which foundations are constructed are not homogeneous in most cases.

Thus, the engineer must have a thorough understanding of the geology of the area that

is, the origin and nature of soil stratification and also the groundwater conditions.

Foundation engineering is a clever combination of soil mechanics, engineering

geology, and proper judgment derived from past experience. To a certain extent, it

may be called an art. When determining which foundation is the most economical, the

engineer must consider the superstructure load, the subsoil conditions, and the desired

tolerable settlement.

Foundation Engineering

INTRODUCTION

National University of Civil Engineering

In general, foundations of the structures may be divided into two major categories:

(1) Shallow foundations.

(2) Deep foundations.

Spread footings, wall footings, and mat foundations are all shallow foundations. In

most shallow foundations, the depth of embedment can be equal to or less than three to

four times the width of the foundation. Pile and drilled shaft foundations are deep

foundations. They are used when top layers have poor load-bearing capacity and when

the use of shallow foundations will cause considerable structural damage or instability.

The separation is not strict but in the point of view of a foundation engineer, in

analysis and design of a shallow foundation, vertical friction between the foundation

and soils is neglected.

Foundation Engineering

INTRODUCTION

National University of Civil Engineering

CHAPTER 2:

SHALLOW FOUNDATIONS

2.1 Introduction

Shallow foundations, often called footings, are usually embedded about a meter or

so into soil. One common type is the spread footing which consists of strips or pads of

structural materials which transfer the loads from walls and columns to the soil or

bedrock.

Another common type of shallow foundation is the slab-on-grade foundation

where the weight of the building is transferred to the soil through a concrete slab

placed at the surface. Slab-on-grade foundations can be reinforced mat slabs, which

range from 25 cm to several meters thick, depending on the size of the building.

Concrete is almost universally used for footings because of its durability in a

potential hostile environment and for economy.

Figure 2-1 shows some shallow foundations including strip footings (a) and (b);

spread footing (c); and mat foundation (d). Furthermore, in Figure 2-2 there are several

common types of spread footing consist of constant footing (a); stepped footing (b);

and sloped footing (c).

Figure 2-1 (a) Strip foundation under a wall (b) Strip foundation under columns (c)

Spread foundation (d) Mat foundation. (1) Footing (2) Wall (3) Column

Figure 2-2 Examples of spread foundations

Various types of shallow foundation which could be used in practice such as combined

or connected footings and mat foundations are illustrated in Figure 2-3 and Figure 2-4.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

Figure 2-3 Examples of shallow foundations (a) Combined footing; (b) combined

trapezoidal footing; (c) cantilever or strap footing; (d) octagonal footing; (e) eccentric

loaded footing with resultant coincident with area so soil pressure is uniform.

Figure 2-4 Examples of mat foundations (a) Flat plate; (b) plate thickened under

columns; (c) beam-and-slab; (d) plate with pedestals; (e) basement walls as part of

mat.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

2.2 Main Components of Shallow Foundations

A shallow foundation basically consists of the following components:

- Leveling concrete

- Footings (single, strip, and mat)

- Ground beams

- Vertical supported structures such as columns, walls.

Figure 2-5 show a typical reinforced concrete footing. The concrete used for

foundation should not be less than B20 and reinforcement should not be less than 10.

Just based on soil, leveling concrete is the lowest layer with at least 100mm thick.

Leveling concrete creates a clean flat platform so that concrete work for the

foundations could be carried out fluently. The concrete used for leveling normally is

B7.5 with course aggregate of 4x6 rock.

Footings would be flat, step or slope as shown in Figure 2-2 with the minimum

thickness would be required as 150mm but 200mm is preferred in practice. Footing

reinforcements shown in Figure 2-5 to resist tensile stress induced in the footing. For

spread and wall strip footing, basically upper (top) reinforcement, hairpin and chair bar

are not necessary.

A rebar spacer is a device that secures the reinforcing steel is assembled in place

prior to the final concrete pour so that cover depth normally of 50mm is assured. The

spacers are left in place for the pour to keep the reinforcing in place, and become a

permanent part of the structure. Rebar spacer would be made of concrete or plastic.

Figure 2-5 A typical cross section of spread footing

Figure 2-6 illustrates rebar placement for a spread footing and supported column.

It should be noted that in case of stepped or sloped footing, footings neck would be

required. The neck should be normally enlarged about 50mm for every directions of

the column. Sometimes column rebars need a hook so that they could stand on the

lower (bottom) reinforcements layer.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

Figure 2-6 Reinforcement of a spread footing

Figure 2-7 Behavior of foundations with connecting beams

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

Figure 2-8 Ground beam and footing reinforcements

Generally, it is useful to place connecting beams at the foundation because they

carry the horizontal shear forces and prevent damage from differential settlements.

Connecting beam is also called ground beam because of the location the beams placed.

Figure 2-7 shows the behavior of spread footings tied together with ground beams.

Reinforcement for ground beam and footings are shown in Figure 2-8.

2.3 Contact Pressure Distribution beneath Base of Footing

The stress distribution under even symmetrically loaded footing is not uniform

following researches of Schultze (1961), Barden (1962) and Borowicka (1963). The

actual stress distribution depends on both footing rigidity and subsoil. For footing on

loose sand the grains near to edge tend to displace laterally, whereas interior soil is

relatively confined. Figure 2-9 shows the general diagram of the stress distribution for

both flexible and rigid shallow foundation on granular soil.

The theoretical pressure distribution for the general case of rigid footing on

cohesive soils is shown on Figure 2-10(b). The high edge pressure may be explained

by considering that edge shear must occur before any settlement can take place. Since

soil has low rupture strength, and most of footings are of intermediate rigidity, it is

very not likely that high edge shear stresses are developed.

The pressure distribution beneath most footings will be rather indeterminate

because of the interaction of the footing rigidity with the soil type, state, and time

response to stress. For this reason it is common practice to use linear pressure

distribution of Figure 2-11 beneath foundations whose rigidity are large enough such

as spread footings and strip footings under wall. Some of field measurements reported

indicated this assumption is adequate.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

Figure 2-9 Settlement profile and contact pressure in sand: (a) flexible foundation;

(b) rigid foundation

Figure 2-10: Settlement profile and contact pressure in clay: (a) flexible foundation;

(b) rigid foundation

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

9

N

hm

Y

pmin

pmax

pmax

Figure 2-11: Linear distribution of contact pressure

2.3.1 Contact Pressure Distribution of Spread Footing

A footing carrying a single column is called spread footing, since its function is to

spread the column load laterally to the soil so that the stress intensity is reduced to a

value that soil can safely carry. These members sometimes called single or isolated

footings. Since the footings are subjected to moments in addition to vertical load, as

shown in Figure 2-11, distribution of the contact pressure by the foundation on soil is

not uniform. The nominal distribution of the pressure is:

Where:

Eq. 2-1

|

Eq. 2-2

|

Eq. 2-3

N is vertical axial force at footing level;

N0 is vertical axial force at the ground level;

, weight of footing and soil above footing

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

10

=20kN/m3 (approximate), average unit weight of footing material

(concrete) and soil above footing.

Mx, My are moments at footing level;

l, b are dimensions of spread footing.

2.3.2 Contact Pressure Distribution of Wall Footing

Wall footings serve a similar purpose of spreading the wall load to the soil.

Because of their long shape (ratio of length (l) to width (b) greater than 7), the footings

theoretically are considered as one-way structure. In reality, when the wall is high

enough so its internal resistance moment of the long axis is large then the bending of

the wall and also the footing could be ignored.

The distribution of the contact pressure is:

Eq. 2-4

| |

Eq. 2-5

| |

Where:

Eq. 2-6

N is vertical axial force distributed for 1m long at footing level;

N0 is vertical axial force distributed for 1m long at the ground level;

, weight of footing and soil above footing for 1m long;

M is moments distributed for 1m at footing level;

b is width of footing wall.

2.3.3 Net Load Applied on Footing Base

The net load applied on footing base is determined as the total stress at the footing

base level extract the geostatic (over-burden) stress at the base level.

Eq. 2-7

Where

tb = effective unit weight of soils above footing base level.

2.3.4 Vertical Stress Increase

2.3.4.1 Method based on Boussineq Equation.

One of the most common methods to estimate stress increase at a depth under a

foundation from the net applied load ( p) is Boussineq Equation based on Theory of

Elasticity which have been mentioned at chapter 4 of the Soil mechanics text book. To

obtain the result, the load is assumed act on a homogenous, isotropic, weightless, and

elastic half-space of soil.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

11

Certainty the increase stress, , is varies from point to point in the soil space but

in the engineering point of view, in conservative side, at each level should be

considered at the center of the foundation where it gets maximum value. To deal this

problem, an equivalent uniform distribution of load of p should be used as net

applied load. General equation based on chapter 4 of soil mechanics text book to get

the increase stress is

Eq. 2-8

Where k = loading factor depending on the shape of foundation base and the

depth of considered point.

2.3.4.2 Simple Equivalent Method (2:1Method).

Figure 2-12 2:1 method of finding stress increase under a foundation

Foundation engineers often use an approximate method to determine the increase

in stress with depth caused by the construction of a foundation. The method is referred

to as the 2:1 method (See Figure 2-12). According to this method, the increase in stress

at depth z is

for spread footing

Eq. 2-9

for strip footing

Eq. 2-10

Eq. 2-9 and Eq. 2-10 are based on the assumption that the stress from the

foundation spreads out along lines with a vertical-to-horizontal slope of 2:1.

Some authors have proposed the slope angle be anywhere from 30o to 45o. In

Vietnam, 30o is default for that angle. It should be noted that 2:1 method is widely

used over the world because of simplicity and conservative result.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

12

2.4 Ultimate Bearing Capacity of Shallow Foundation

2.4.1 General

To perform satisfactorily, shallow foundations must have two main characteristics:

1. They have to be safe against overall shear failure in the soil that supports

them.

2. They cannot undergo excessive displacement, or settlement. (The term

excessive is relative, because the degree of settlement allowed for a

structure depends on several considerations.)

The load per unit area of the foundation at which shear failure in soil occurs is

called the ultimate bearing capacity, which is the subject of this part.

p

pgh

p

pgh(1)

pgh

pgh(1)

pgh pgh

Figure 2-13 Nature of bearing capacity failure in soil: (a) general shear failure: (b)

local shear failure; (c) punching shear failure.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

13

Consider a strip foundation with a width of b resting on the surface of a dense sand

or stiff cohesive soil, as shown in Figure 2-13(a). Now, if a load is gradually applied to

the foundation, settlement will increase. The variation of the load per unit area on the

foundation p with the foundation settlement is also Figure 2-13 failure in the soil

supporting the foundation will take place, and the failure surface in the soil will extend

to the ground surface. This load per unit area is usually referred to as the ultimate

bearing capacity of the foundation. When such sudden failure in soil takes place, it is

called general shear failure.

If the foundation under consideration rests on sand or clayey soil of medium

compaction Figure 2-13 (b), an increase in the load on the foundation will also be

accompanied by an increase in settlement. However, in this case the failure surface in

the soil will gradually extend outward from the foundation, as shown by the solid lines

in Figure 2-13 (b). When the load per unit area on the foundation equals movement of

the foundation will be accompanied by sudden jerks. A considerable movement of the

foundation is then required for the failure surface in soil to extend to the ground

surface (as shown by the broken lines in the figure). The load per unit area at which

this happens is the ultimate bearing capacity, pgh. Beyond that point, an increase in

load will be accompanied by a large increase in foundation settlement. The load per

unit area of the foundation, pgh(1), is referred to as the first failure load (Vesic, 1963).

Note that a peak value of p is not realized in this type of failure, which is called the

local shear failure in soil.

If the foundation is supported by a fairly loose soil, the loadsettlement plot will

be like the one in Figure 2-13 (c). In this case, the failure surface in soil will not extend

to the ground surface. Beyond the ultimate failure load, pgh, the loadsettlement plot

will be steep and practically linear. This type of failure in soil is called the punching

shear failure.

2.4.2 Terzaghis Bearing Capacity Theory

Terzaghi (1943) was the first to present a comprehensive theory for the evaluation

of the ultimate bearing capacity of rough shallow foundations. According to this

theory, a foundation is shallow if its depth, (Figure 2-14), is less than or equal to its

width. Later investigators, however, have suggested that foundations with equal to 3 to

4 times their width may be defined as shallow foundations.

Terzaghi suggested that for a continuous or strip foundation (i.e., one whose width

to length ratio approaches zero), the failure surface in soil at ultimate load may be

assumed to be similar to that shown in Figure 2-14. (Note that this is the case of

general shear failure, as defined in Figure 2-14a.) The effect of soil above the bottom

of the foundation may also be assumed to be replaced by an equivalent surcharge,

(where is a unit weight of soil). The failure zone under the foundation can be separated

into three parts (see Figure 2-14):

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

14

1. The triangular zone ACD immediately under the foundation

2. The radial shear zones ADF and CDE, with the curves DE and DF being arcs

of a logarithmic spiral

3. Two triangular Rankine passive zones AFH and CEG

hm

q = .hm

Figure 2-14 Bearing capacity failure in soil under a rough rigid continuous (strip)

foundation

The angles CAD and ACD are assumed to be equal to the soil friction angle .

Note that, with the replacement of the soil above the bottom of the foundation by an

equivalent surcharge q, the shear resistance of the soil along the failure surfaces GI

and HJ was neglected.

Using equilibrium analysis, Terzaghi expressed the ultimate bearing capacity in

the form

Eq. 2-11

c = cohesion of soil

= unit weight of soil

q = hm

N , Nq, Nc = bearing capacity factors that are non-dimensional and

are functions only of the soil friction angle, .

The bearing capacity factors N , Nq, Nc are defined by

Where:

Eq. 2-12

Eq. 2-13

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

15

Eq. 2-14

Where

Kp = passive pressure coefficient.

The variations of the bearing capacity factors defined by Eq. 2-12, Eq. 2-13, and

Eq. 2-14 are given in Table 2-1

Table 2-1 Terzaghis Bearing Capacity Factors

To estimate the ultimate bearing capacity of square and circular foundations, Eq.

2-11 may be respectively modified to

for square foundation

Eq. 2-15

for circular foundation

Eq. 2-16

In Eq. 2-15, b equals the dimension of each side of the foundation; in Eq. 2-16, b

equals the diameter of the foundation.

For foundations that exhibit the local shear failure mode in soils, Terzaghi

suggested the following modifications to Eq. 2-11, Eq. 2-15, and Eq. 2-16:

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

16

for strip foundation

Eq. 2-17

for square foundation

Eq. 2-18

for circular foundation

Eq. 2-19

N , Nq, and Nc, the modified bearing capacity factors, can be calculated by

using the bearing capacity factor equations (for N , Nq, and Nc, respectively) by

replacing by = tan-1(2/3tan). The variation of and with the soil friction angle

is given in Table 2-2.

Table 2-2 Terzaghis Modified Bearing Capacity Factors

Terzaghis bearing capacity equations have now been modified to take into

account the effects of the foundation shape depth of embedment and the load

inclination. This is given in the next section. Many design engineers, however, still use

Terzaghis equation, which provides fairly good results considering the uncertainty of

the soil conditions at various sites.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

17

2.4.3 The General Bearing Capacity Equation

The ultimate bearing capacity Eq. 2-11, Eq. 2-15, and Eq. 2-16 are for continuous,

square, and circular foundations only; they do not address the case of rectangular

foundations. Also, the equations do not take into account the shearing resistance along

the failure surface in soil above the bottom of the foundation (the portion of the failure

surface marked as GI and HJ in Figure 2-14). In addition, the load on the foundation

may be inclined. To account for all these shortcomings, Vesic (1973) suggested the

following form of the general bearing capacity equation:

Eq. 2-20

In this equation:

c = cohesion;

q = effective stress at the level of the bottom of the foundation;

= unit weight of soil;

b = width of foundation (= diameter for a circular foundation);

s(.) = shape factors;

d(.) = depth factors;

i(.) = load inclination factors;

b(.) = tilted base inclination factors;

g(.) = ground inclination factors;

N , Nq, and Nc = bearing capacity factors.

The equations for determining the various factors given in Eq. 2-20 are described

briefly in the sections that follow. Note that the original equation for ultimate bearing

capacity is derived only for the plane-strain case (i.e., for continuous foundations). The

shape, depth, load inclination, tilted base inclination, and ground inclination factors are

empirical factors based on experimental data.

The basic nature of the failure surface in soil suggested by Terzaghi now appears

to have been borne out by laboratory and field studies of bearing capacity (Vesic,

1973). It can be shown that

(

(

)

(

Eq. 2-21

Eq. 2-22

Eq. 2-23

It should be noted that Nc was originally derived by Prandtl (1921); Nq was

presented by Reissner (1924). Caquot and Kerisel (1953) and Vesic (1973) gave the

relation for N.

Shape, Depth, load Inclination, tilted Base inclination, and Ground inclination

Factors

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

18

{

Where

Q0 = shear force at column base level

N0 = axial force at column base level

F = foundation base area

cg = cohesion between footing base and the soil under.

cg (0.6 ~ 1.0)c

Where:

is angle between foundation base to horizontal (positive

since the angle opposite to combination of axial

force N0 and shear force Q0).

{

Where:

Foundation Engineering

is angle between the grounds surface to horizontal.

SHALLOW FOUNDATIONS

National University of Civil Engineering

19

Table 2-3 Bearing capacity factors for the general equations

2.4.4 General Bearing Capacity Equation in Practice

In practice, most of shallow foundations based on flat ground with base inclination

equal zero, for simplicity Eq. 2-20 can be reformed into the following equation in that

factors of depth, load inclination might be neglected.

Eq. 2-24

Where sc, sq, q are shape factors as mentioned above but for simplicity,

some engineers have used following alternative relations

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

20

2.4.5 Safety Factor and Allowable Load-Bearing Capacity

Calculating the gross allowable load-bearing capacity, [p], of shallow foundations

requires the application of a factor of safety (FS) to the gross ultimate bearing

capacity, or

Eq. 2-25

The factor of safety, FS, should be 2~3 in most cases.

2.4.6 Bearing Capacity of Layered Soils: Stronger Soil underlain by Weaker Soil

The bearing capacity equations presented in the above section involve cases in

which the soil supporting the foundation is homogeneous and extends to a

considerable depth. The cohesion, angle of friction, and unit weight of soil were

assumed to remain constant for the bearing capacity analysis. However, in practice,

layered soil profiles are often encountered. In such instances, the failure surface at

ultimate load may extend through two or more soil layers, and a determination of the

ultimate bearing capacity in layered soils can be made in only a limited number of

cases. This section features the procedure for estimating the bearing capacity for

layered soils in which stronger soil underlain by weaker soil.

Figure 2-15 shows a strip foundation supported by a stronger soil layer, underlain

by a weaker soil that extends to a great depth. The physical parameters of the two soil

layers are also written down in the Figure.

In this case, the stronger soil could be failed cause of contact foundation ptb, and

on the other hand, the weaker soil could be failed by the load just above that layer at

depth of hm_t.

ptb

hm

1

bt=b+H

hm_t =hm+H

ptb_2

Figure 2-15 Bearing capacity of a strip foundation on layered soil

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

21

Bearing capacity of foundation at footing base level (the stronger soil) could be

calculated easily by the normal approaches described in the above sections (Eq. 2-11,

Eq. 2-15, and Eq. 2-16 or Eq. 2-20 or Eq. 2-24). On the other hand, bearing capacity of

the weaker soil could be done by the same way with an equivalent foundation of

footing dimensions are extended follows 2:1 method and the embedded depth is

calculated as

hm_t = hm + H

Where:

Eq. 2-26

hm_t = embedded depth of equivalent foundation

hm = embedded depth of foundation

H = Thickness of the soil from footing level to the weaker soil

2.5 Shallow Foundation Design

2.5.1 Introduction

To perform satisfactorily, shallow foundations must have three main

characteristics:

1. The soil they laid on must be in safe of strength. It means that the foundation

satisfies condition of bearing capacity.

2. They cannot undergo excessive displacement, or settlement. (The term

excessive is relative, because the degree of settlement allowed for a

structure depends on several considerations and generally the amplitudes of

allowable settlement are list in the codes)

3. Foundation structure needs to be available for both conditions of strength and

serviceability.

2.5.2 Design Procedure for Shallow Foundation.

a) Soil base design

1. Choose embedded depth of footing;

2. Determine dimensions of footing;

3. To calculate the contact pressure;

4. Check for bearing capacity and economy conditions;

5. To calculate settlement and differential settlement;

6. Serviceability condition check;

b) Structural footing design

7. Choose structural materials for footing (type of concrete and

reinforcement)

8. Determine thickness of footing base, h;

9. Check for bearing capacity of shear;

10. Flexural design for footing base;

11. Technical drawings.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

22

2.5.3 Geotechnical Analyses and Design

2.5.3.1 Strength design of the Subsoil

a) Embedded depth of footing

Embedded depth of footing would be decided based on the following guidelines:

1. The footing must be laid on a steady strong soil and should be above

underground water level.

2. The shallower the better for the construction work of foundation but it should

be deep enough for satisfying architect requirements.

Depth of footing depends on soil strata it lay on. Basically, there are three types of

soil strata and see how to deal with each case.

(a) All soil layers are strong;

This case is most easy and convenient to give a decision. The footing depth

normally is about 1.0~1.5m since the lateral load is small the depth may be lesser.

(b) Weak soil of upper layer and strong soil of the lower;

When the weak layer is small (less than 3m) the most common method is eliminate

the weak soil replace them by a strong material such as sand and set the footing on

that. Since the thickness is larger (3~5m) the improvement of the soil such as soil

replacement, sand compaction piles should be applied.

(c) Strong soil at first, then weak layer and finally strong soil again at the lowest.

If the first strong layer is thick enough then this case is similar to the (a) case.

When the first strong layer is not so thick then the footing might place on the first but

the depth should be as small as possible. In this case bearing capacity of foundation

must be carefully considered for both strong and weak layers. In bad way, if the first

soil is thin then it becomes near case (b).

b) Dimensions of footing

To determine the footing dimensions play an important role in the foundation

design procedure. The size of footing affect significantly to the strength and

serviceability design of the foundation. The size should be large enough to satisfy the

technical requirements but not so large to agree with economic condition.

Firstly, an arbitrary value of foundation width, b0, should be chosen. That is entire

of the first step for strip footing but for spread footing, the length (l0 >b0) must be

assumed also. Normally l0 follows the larger of the bending moments and may be

estimated by relation l0 = b0 where =Mx/My 2. For example, in Figure 2-11 l0 (L)

is in Y direction according to case of Mx > My. In case of unique moment, l0 = b0

where = (1+e ~(1+2e) and e is a ratio of the moment, M, to axial force, N; (e= M/N).

c) Calculation of contact pressure

According to load and action codes, a structure must sustain several types of

loading such as static load, live load, wind load, earthquake load, flood load, and so

on. Basically, nominal loads are decided on the code. To determine the loads applying

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

23

on a structure component (foundation, in this case) a combination process must be

carried out, of course, according to the code instruction. The loads can be divided into

two categories as follows

- Un-factored loads combined with no factors are based on the nominal values

only. For foundation design un-factored loads are used for bearing capacity check and

also for settlement estimation.

The un-factored loads normally displayed by symbol of tc for example

,

. Hence the contact pressure under footing comes from un-factored

combination, ptb, pmax, pmin are obtained from Eq. 2-1 to Eq. 2-6 in that

,

are replaced by

,

respectively.

- Factored loads combination in which the nominal values are multiplied with the

factors in the code. These combinations are applied for structural foundation design.

The stresses used for structural footing design must be based on factored load

combinations, but due to the self-balance the weight of footing and the soil above

footing are not involved in the calculation. If factored loads are

,

then

tb

max

min

the pressure under footing comes from factored combination, p0 , p0 , p0 are

computed from the equations modified from section 2.3

For spread footings:

Eq. 2-27

|

Eq. 2-28

Eq. 2-29

For strip footings:

Eq. 2-30

|

Eq. 2-31

|

Eq. 2-32

d) Check for technical and economic conditions

The contact pressures, ptb, pmax, pmin must be satisfied technical conditions

Eq. 2-33

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

24

On the other hand, the contact pressures, ptb, pmax, pmin must be also satisfied one

of the following economic conditions:

Eq. 2-34

If one of the technical conditions in Eq. 2-33 especially the first two are not passed

then dimensions of footing in step (2) must be redone with advised larger dimensions.

In case both conditions of Eq. 2-34 are not satisfied, works in the step (2) should

be done again with advised smaller dimensions. It should be noted that, in practice,

20% is completely acceptable instead of 5% of idealization.

2.5.3.2 Serviceability conditions of the Soil

a) Stress induced Settlement

Stress induced settlement, pgl, is the net applied stress on soil of the un-factored

combination loads. Based on Eq. 2-7, the expression as follow

Eq. 2-35

Where

ptb is contact pressure obtained from Eq. 2-1 or Eq. 2-4 with unfactored combination loads.

tb = effective unit weight of soils above footing base level.

b) To calculate settlements

The approaches to estimate settlement of soil under the load have been described

in detail on the Soil mechanics book or any text books of geotechnical engineering. A

review is presented as follows

Settlement for homogenous soil strata

If net applied load is small, the relation of pS is linear, hence using the

assumption that the soil medium is an elastic, homogeneous, isotropic, and semiinfinite medium. In practice, since a soil stratum is homogenous, the theory of elastic

would be applied.

For rectangular foundation:

Eq. 2-36

Where

const influenced by shape of footing l/b (rigid foundation);

b = width of footing;

0 = Poissons ratio;

E0 = Elastic modulus of the soil.

pgl = Net applied load of the un-factored combination.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

25

Settlement of multi-layers soil strata

For multi-layers soil strata, settlement of footing is estimated by accumulating

settlement of appropriate soil layers in the effective depth. The settlement calculation

is expressed as follow:

Where

Eq. 2-37

Si = settlement of a sub-layer which could be calculated based on

results of oedometer test. Refer to section 5.3 of the Text book

of Soil mechanics.

c) To calculate differential settlements

The differential settlements between two points (center of footings) are defined as

follow

|

Where

Eq. 2-38

Si, Si+1 = settlement of footing number i and i+1.

Li~i+1 = distance between the two points.

d) Serviceability condition check

The estimated settlements and differential settlements must be in range required in

the code. The relations could be expressed as

Eq. 2-39

The allowable settlement, [S], and allowable differential settlements, [ S] of

framed building of reinforced concrete are 8.0cm and 0.002 respectively, according to

the Vietnamese code. If material for the frame is steel then the allowable ones are

12.0cm and 0.004. For detail, refer to TCVN 205-1998, appendix H.

2.5.4 Structural Footing Design

Dimensions of a footing are controlled by the allowable soil pressure. On the other

hand, footing thickness h is usually decided by shear stresses. In addition, footing must

have strength to resist the bending moment induced by contact pressure of soil.

2.5.4.1 Shear strength design of footing

Footing must be considered in both ways: (1) shear forces of two-way action and

(2) wide-beam. Two-way action shear always controls the depth for centrally loaded

square footing. Wide-beam shear may control the depth for rectangular footings when

l/b ratio is greater than about 1.2 and may control for other l/b ratios when there are

overturning or eccentric loadings.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

26

a) Two-way action shear

A shear force acting on edge faces of the frustum in the Figure 2-16 of two-way

action based on the equilibrium theory.

Eq. 2-40

Where

ltb = min { lc+h0; 0.5(lc+l) };

btb = min { bc+h0; 0.5(bc+l) };

bc,lc = dimensions of column according to b, l of footing.

N0tt = Axial force at column base level of factored combinations;

p0tb is calculated by Eq. 2-27 or Eq. 2-30.

Figure 2-16 Two-way shear calculation

Shear strength of footing must be strong enough to resist the shear force of twoway action. Normally structural footing design uses no reinforcement for shear

therefore footing need an enough thickness for shearing.

Eq. 2-41

Where

utb = 2( ltb+btb ), average of top and bottom surface perimeter of the

frustum;

h0 = h a, effective height of footing;

h = thickness of footing;

a = concrete cover, normally equals of 50mm;

Rbt = allowable tension strength of footing concrete.

b) Wide-beam shear

When a footing sustains an eccentric load then wide-beam shear must be

considered. The shear force acting on the surface of shear section in Figure 2-17 could

be calculated in conservative side by the following expression

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

27

Eq. 2-42

Where

lt = 0.5(l - lc);

b = width of foo`ting;

p0max, p0min are determined in part c) of section 2.5.3.1

Figure 2-17 Wide-beam shear calculation

The thickness of footing also must suit with wide beam shear condition. In

practice, the following equation is usually used to.

Eq. 2-43

Where

btb = min { bc+h0; 0.5(bc+b) };

h0 = effective height of footing;

Rbt = tension strength of footing concrete.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

28

Note for wall strip footing

Thickness of a wall strip footing is controlled by wide-beam shear in the short

direction. Calculation process would be carried out by the same way as that described

above. Actually, this is plane strain problem then to analyze a wall strip footing, a unit

length of the footing would be consider. Thickness of the wall works as short

dimension of column bc, and in the long direction, dimension of the wall and

dimension of footing all are unit (1.0).

c) Thickness footing design procedure

-

Chose a value of footing thickness, h;

Determine concrete cover, a then calculate effective height h0 = h a;

Types of concrete and reinforcement used for footing should agree with

suggestions in section 2.2

The effective thickness h0 must be satisfied the shear conditions expressed by

Eq. 2-41 and Eq. 2-43; if not, a larger value of footing thickness, h, is advised.

The thickness must not so close to the minimum thickness based on shear

check because the thicker of footing the more rigid and lesser reinforcement of

foundation.

2.5.4.2 Flexural strength design of footing

Figure 2-18 Flexure reinforcement calculation

Flexural reinforcements of footing are calculated based on a console beam model

fixed at the edge of column sustain the soil reactions pressures. Reinforcements in the

long and short direction are computed by the bending moment at section I-I, II-II

respectively.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

29

According to reinforcement concrete code for flexural structures, the

reinforcement could be calculated by the following simplified equation.

Eq. 2-44

h0 = the effective height of footing;

Rs = allowable tensile strength of reinforcement;

M = the bending moment.

In case of no moment action then the soil pressures are uniform and the bending

moments could be calculated by the following equations:

Where

Where

lco = lng = 0.5( l - lc ) console span in long direction;

lco= bng =0.5( b-bc ) console span in short direction;

Eq. 2-45

Since the footing subjected moments, M, as shown in Figure 2-18, the soil

pressures are distributed in trapezoid then the bending moments could be calculated by

the following equations:

Eq. 2-46

Where

Note that the bending moments and reinforcement areas calculated for just one

unit of length only. The total reinforcement area normally shown in the drawings for

an isolated footing is determined by multiplied with length of the according footing

edge.

For strip footing, the reinforcement for the short direction is calculated in the same

way as that of spread footing. The difference is the reinforcement in the long direction

is set according to the minimum requirement of the codes.

Having obtained the required reinforcement area, an engineer should be place the

reinforcements into the footing by indicate size and distances of them. Note that, the

minimum reinforcement ratio and size, distance of reinforcement bars are basically

stipulated in the codes.

All the information of footing must be described in drawings detailed so that site

engineer could do construction work without any additional comments of designer

except some of extraordinary works.

Foundation Engineering

SHALLOW FOUNDATIONS

National University of Civil Engineering

CHAPTER 3:

30

SOIL IMPROVEMENT

In many areas of Vietnam especially in coastal Hong River and Me Kong delta,

certain soils make the construction of foundations extremely difficult. For example,

expansive or collapsible soils may cause high differential movements in structures

through excessive heave or settlement. Foundation engineers must be able to identify

difficult soils when they are encountered in the field. Although not all the problems

caused by all soils can be solved, preventive measures can be taken to reduce the

possibility of damage to structures built on them. This chapter outlines introduce some

methods for soil improvement before construction of foundations.

Function of a foundation is to transfer the structural loads from a building safely

into the ground. A backyard tool shed may need only wooden skids to spread its load

across an area of ground surface, whereas a house would need greater stability and

consequently its foundation should reach the underlying soil that is free of organic

matter. A larger and heavier building of masonry, steel, or concrete would require its

foundations to go deeper into earth such that the soil or the rock on which it is founded

is competent to carry its massive loads; on some sites, this means going a hundred feet

or more below the surface. Because of the variety of soil, rock, and water conditions

that are encountered below the surface of the ground and the unique demands that

many buildings make upon the foundations, foundation design is a highly specialized

field of geotechnical engineering.

The soil at a construction site may not always be totally suitable for supporting

structures such as buildings, bridges, highways, and dams. For example, in granular

soil deposits, the in situ soil may be very loose and indicate a large elastic settlement.

In such a case, the soil needs to be densified to increase its unit weight and thus its

shear strength. Sometimes the top layers of soil are undesirable and must be removed

and replaced with better soil on which the structural foundation can be built. The soil

used as fill should be well compacted to sustain the desired structural load. Compacted

fills may also be required in low-lying areas to raise the ground elevation for

construction of the foundation.

Soft saturated clay layers are often encountered at shallow depths below

foundations. Depending on the structural load and the depth of the layers, unusually

large consolidation settlement may occur. Special soil improvement techniques are

required to minimize settlement. Improving in situ soils by using additives is usually

referred to as stabilization.

Various techniques are used to

1. Reduce the settlement of structures

2. Improve the shear strength of soil and thus increase the bearing capacity of

shallow foundations

3. Increase the factor of safety against possible slope failure

4. Reduce the shrinkage and swelling of soils

Foundation Engineering

SOIL IMPROVEMENT

National University of Civil Engineering

31

This chapter discusses some of the general principles of soil improvement, such as

compaction, vibroflotation, precompression, sand drains, wick drains, stabilization by

admixtures, jet grouting, and deep mixing, as well as the use of stone columns and

sand compaction piles in weak clay to construct foundations.

3.1 Sand Replacement

There are basically two types of soil replacement methods: (1) removal and

replacement, and (2) displacement. The first method is the most common approach and

it consists of the removal of the compressible soil layer and replacement with

structural fill during the grading operations. Usually the removal and replacement

grading option is only economical if the compressible soil layer is near the ground

surface and the ground water table is below the compressible soil layer or the ground

water table can be economically lowered.

In case soil strata have weak soil of upper layer and strong soil of the lower and

when the weak layer is small (less than 3m) or the upper layer is not so weak, the most

common method is eliminate all or part of the weak soil then replace them by strong

material such as sand. Footings are set on the strong replacement.

Leveling concrete

100

h1

hm

2

1

hy

b

0.5h

0.5h

weak

soil

bt=b+h

Sand cushion

(a)

stiff

soil

h1

weak

soil

1

1~1.5

(b)

Figure 3-1 (a) Completed sand replacement (b) Partial sand replacement

The filled soils normally compacted by layers of 300~500mm to ensure the quality

as designed request. Sands from small to medium are widely used as replacement

materials so in Vietnam this method is also called sand cushion. The properties of

filled sand listed as follow would be easily achieved with not so hard effort of

compaction.

- Natural weight unit, = 18kN/m3

Foundation Engineering

SOIL IMPROVEMENT

National University of Civil Engineering

32

- Internal friction angle, =30o

- Deformation modulus, E0 = 16MPa

The filled sand must be thick enough to reduce the pressures at the footing to a

bearable pressure of the weak soil at the end of sand cushion. The problem requires the

bearing capacity consideration of layered soils mentioned at section 2.4.6. Note that

the sand cushion is taken into account as the stronger layer and the soil underneath the

sand cushion is the weaker layer. The pressure acting on the weaker layer consists of

two components (1) total vertical overburden (geostatic) pressure mentioned in the

Soil mechanics text book (2) vertical stress increment described in section 2.3.4.

On the other hand, with the thick enough of sand cushion, foundation settlement

could be reduced significantly. The settlement must satisfy at least the serviceability

conditions discussed in section 2.5.3.2.

It should be noted that in construction work of soil replacement, the original soil

would be removed by excavation therefor the engineer should estimate the soil slope

of the excavation. The slope could be predicted empirically, approximately vertical to

horizontal ratio, m = 1:1 to 1.5:1 is applied.

3.2 Sand Compaction Piles

Compaction piles are displacement piles can be driven into the ground in order to

increase the density of the soil. The soil is densified by both the actual displacement of

the soil and the vibration of the ground that occurs during the driving process. In

addition, there must be relatively close spacing of the piles in order to provide

meaningful densification of soil between the piles.

Sand compaction piles are one of compaction piles. They can be used in sites to

improve stability, control liquefaction, and reduce the settlement of various structures.

Built in soft clay, these piles can significantly accelerate the pore water pressuredissipation process and hence the time for consolidation.

Sand piles were first constructed in Japan between 1930 and 1950 (Ichimoto,

1981). Large-diameter compacted sand columns were constructed in 1955, using the

Compozer technique (Aboshi et al., 1979). The Vibro-Compozer method of sand pile

construction was developed by Murayama in Japan in 1958 (Murayama, 1962).

Sand compaction piles are constructed by driving a hollow mandrel with its

bottom closed during driving (see Figure 3-3). On partial withdrawal of the mandrel,

the bottom doors open. Sand is poured from the top of the mandrel and is compacted

in steps by applying air pressure as the mandrel is withdrawn. The piles are usually

0.40 to 0.76m in diameter and are placed at about 1.5 to 3m center to center. The

pattern of layout of sand compaction piles is shown as Figure 3-2(a) for equiangular

triangle. Sometimes, square layout is used for the sand piles.

Basore and Boitano (1969) reported a case history on the densification of a

granular subsoil having a thickness of about 9 m at the Treasure Island Naval Station

in San Francisco, California, using sand compaction piles. The sand piles had

diameters of 356 mm. Figure 3-2(a) shows the layout of the sand piles. The spacing,

Foundation Engineering

SOIL IMPROVEMENT

National University of Civil Engineering

33

S, between the piles was varied. The standard penetration resistances, N60, before and

after the construction of piles are shown in Figure 3-2(b) (see location of SPT test in

Figure 3-2(a)).

From this figure, it can be seen that the effect of densification at any given depth

decreases with the increase in S (or S/D). These tests show that when S/D exceeds

about 4 to 5, the effect of densification is practically negligible.

Figure 3-2 Sand compaction pile test of Basore and Boitano (1969): (a) Layout of the

compaction piles; (b) Standard penetration resistance variation with depth and S

Foundation Engineering

SOIL IMPROVEMENT

National University of Civil Engineering

34

Figure 3-3 Sand compaction pile mandrel tip

To improve soil by sand compaction piles, the engineer needs to consider:

- Diameter of the piles

- Length of the piles

- Plan layout and distance among the piles

- Determine the improved soil properties

3.2.1 Characteristics of Sand Compaction Piles

Sand compaction piles are circular with diameter of 400 600mm, 400mm is

widely used in Viet Nam;

Length of the piles, L, must be deep enough in order to improve the soils

influenced by loading. When the effective depth Hn of soil is deeper than that of weak

soil then the pile length should be controlled by depth of the weak soil hy. In the other

case, L should be controlled by Hn. The length L could be expressed as follow (see

Figure 3-4).

{

Eq. 3-1

Properties of the sand compacted piles would be collected as sand replacement

methods mentioned above as follows

- Natural weight unit, = 18kN/m3

- Internal friction angle, =30o

- Deformation modulus, E0 = 16MPa

Foundation Engineering

SOIL IMPROVEMENT

National University of Civil Engineering

35

Sand blanket

hy

500

500

weak

soil

L=Hn +500

Hn

L=hy- hm+500

300

hm

weak

soil

stiff

soil

Sand compaction

piles

stiff

soil

bnc=1.4b

0.2b

Compaction

Area, Fnc

0.2b

0.2b

0.2b

lnc=l+0.4b

Figure 3-4 Characteristic of sand compaction piles for a spread footing

3.2.2 Sand Compaction Pile Working Procedure

Sand compaction piles are driven into soils by the following steps:

Setting the casing at working point, keep casing bottom at ground level and

keep sand level gauge and depth gauge at 0;

Put casing into ground by hammer, hit with checking current gauge and depth

gauge;

When casing inserted 5m from ground level, hold sand level gauge 3m from

ground level. When depth gauge indicate exact central, brake the hammer

winch, hold casing input;

Put sand in casing with open dump valve of hopper;

Foundation Engineering

SOIL IMPROVEMENT

National University of Civil Engineering

36

Figure 3-5 Sand compaction pile working procedure

Keep sand level gauge in working;

Start casing put out, and check sand level indicator going down;

Put casing 2m in ground (with checking depth level gauge);

Stop casing out when sand level gauge indicate 1.5m;

Put sand inside with sand level plumb winding up;

Keep sand level gauge down again;

Take out of casing with check sand level indicator (standard 3m)

Repeat step 7; 8 and 9

When depth gauge indicate 1m from ground level, open pressure valve in

casing and stop air jet close exhaust valve Put out casing slowly and

stop the hammer

3.2.3 Applied Assumptions in Calculation of Sand Compaction Piles

-

The void ratio of soil decreases the same at everywhere in the space between

the piles;

The decrease volume are the void decrease, soil particle volume are constant;

Water content is constant through the compaction process;

Soil does not move upward out of ground surface.

3.2.4 Principle of Sand Compaction Pile Analyses

Consider a footing with effect area of F which consists of two components area of

soil particle, Fh, and area of void Fr. See Figure 3-6(a). Following expressions show

the relations among them and initial void ratio, eo:

Foundation Engineering

SOIL IMPROVEMENT

National University of Civil Engineering

eo

Fr

Fh

Fh

1

F

1 eo

37

Fr

eo

F

1 eo

Eq. 3-2

Now after improving, sand piles have occupied area of Fc replacement of the void

only then improved void ratio, etk and area of the piles Fc could be shown in two ways:

Eq. 3-3

Eq. 3-4

The Eq. 3-3 used to determine improved void ratio in case of knowing sand

compaction piles information. Eq. 3-4 on the other hand is applied to get the required

area of sand piles if a void ratio, enc, already prescribed.

Fr

Fr

Fh

Fh

(a)

(b)

Fc

Figure 3-6 Principle of sand compaction pile analyses

3.2.5 Plan layout and Distance of Sand Compaction Pile

a) Conventional compaction area for footing

The conventional compaction area, Fnc, for strip footing and spread footing are

shown in Figure 3-7 by expand out from the edges of footing to all directions a

distance of 0.2b, where b = width of the footing.

For strip footing with 1m length in the long direction

Eq. 3-5

For spread footing

Eq. 3-6

Foundation Engineering

SOIL IMPROVEMENT

National University of Civil Engineering

38

bnc=1.4b

0.2b

0.2b

1m

(a)

Sand compaction piles

bnc=1.4b

0.2b

Compaction

Area, Fnc

0.2b

0.2b

0.2b

lnc=l+0.4b

(b)

Figure 3-7 Compaction area for (a) strip footing and (b) spread footing

b) Requirement of Number of Sand compaction piles for a Footing

In order to get an expected void ratio, etk, after soil improvement, a volume of sand

compaction piles should be installed into the soil. This volume of sand depends on the

compaction area, Fnc, the decrease of void ratio e=e0-etk, diameter of the sand pile, .

Having obtained the volume of sand compaction pile by Eq. 3-4, the required