Академический Документы

Профессиональный Документы

Культура Документы

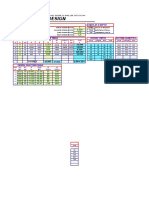

Checklist Inspeccion de Taladros

Загружено:

Adolfo AnguloАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Checklist Inspeccion de Taladros

Загружено:

Adolfo AnguloАвторское право:

Доступные форматы

Rig Inspection Checklist

NOTE: The following Rig Inspection Checklists are not a complete listing of requirements. They

were developed to assist employers and workers with training, equipment and documentation

requirements in rigging.

Training Requirements Rig Inspection Checklist

1.

2.

Derrick man must be trained and demonstrate proficiency to use

the emergency escape system installed on the rig; the escape

system must be inspected on a frequency as required by

regulation, by a qualified person and the inspection recorded and

records available.

Simulated Derrick rescue once a year and documented

3. 2 crew members with ENFORM RIG RESCUE training on tower

at all times

OHS Regulation/

WC Act

23.39.2 (4)(c)

23.39.3(3)(a)(b)

23.39.3(4)(a)(b)

4.14(3)

32.2(2)

32.2(1)

4. All crew members should have ENFORM FALL PROTECTION

training

11.2(6)

5. CAODC FALL PROTECTION MANUAL on location

11.3(2)

6. Hearing test once a year and within 6 months of being hired

7.8(1)(a)(b)

7. Fit testing for all respirators SCBAs and mask respirators

8.40

8. ETS no smoking in well site shack/camp/vehicles

designated safe outside areas only

4.81

9. No equipment located under escape buggy line 50 feet

10. Slings and attachments must be visually inspected each shift and

before use / removed from service if defective

11. Address hazards when rigging up working over 3 Meters above

grade / proper anchor points

23.39.2(2)

23.39.3(2)

15.25,15.43(wire rope)

15.54 (synthetic)

11.2, 11.6

12. Forklift/Mobile equipment training CSA Standard for lift trucks &

Manufacturers recommendations

4.3, 16.4, 16.7

13. Training of workers conducting rigging and slinging operations Definition of qualified - OHS Regulation Part 1

15.2

1.1

14. Driver training GODI ENFORM Training Program or equivalent

23.22

1

Revised April 2009

Equipment Requirements Rig Inspection Checklist

OHS Regulation/

WC Act

1.

2.

3.

4.

5.

6.

7.

Suitable Self Retracting Lifeline

(a) Floor to Crown

(b) Crown to racking board

(c) Soft line to Retract SALA Block Line when not in use (Reel)

optional

(d) Additional anchor point and assemblies for working lifelines

Equipped with an Emergency escape system from the racking

board that meets the requirements of 23.39.2 or 23.39.3

Location of escape equipment to allow unimpeded exit from

racking board (refer to CAODC RP #9 Derrick Egress)

Fall Restraint system for the roof of the doghouse or any other

area over 3 meters

Rig Rescue Equipment inspected and maintained in good

working order

Lock-out Station / Board ( locks / tags / scissor hasps)

11.5, 11.6

23.39.1

4.14(2)

23.39.2(1)(a)

11.2

11.9

10.1

10.4

23.36

CSA 94-4

4.55(a)

8.

4 Positive pressure (no donning switch) SCBA on site - 2 units at

two different locations / 4 spare bottles

Safety chain across V door

9.

Cat head spools removed or covered

23.20

10. Crown saver in place / functioned each day

23.49(2)(3)

11. Risk assessment done for eye washing facilities/emergency shower

12. Oil based mud system coveralls being cleaned at employers

expense / hand wash/ shower available

13. 15 meter clear area under the end of the escape buggy line

14. Rigging, fittings & slings have Manufactures ID / Working Load

Limit (WLL) attached

15. Stairs with 4 or more risers must have handrails

16. DSTs, underbalanced drilling & oil based mud systems require

2

2

L.E.L / H S / O detectors in an enclosed substructure or adequate

ventilation. Size of ventilation openings, mechanical ventilation, and

cold weather provisions

17. Signs under overhead power lines identifying location

18. Degasser vents lines use appropriate fittings

5.88

8.8, 5.85

23.39.2(2)

15.5(1)

4.62

23.43

19.5

23.13(1)

19. Exhaust fan in mud mixing room

5.64, 5.65

20. BOP requirements different than Alberta 1850 Meters and deeper

require gut line

**REFER TO Drilling & Production Regulation (Oil & Gas

Commission)

21. Coordination of Multiple Employer workplaces

22. Control of Static Electricity-grounding and Bonding

23. Fire hazards No Smoking or open flames within 25 meters

4.1

23.4 & WCA 118

23.6, 5.28

23.7

24. Control of Ignition Sources BC Electrical Code

23.8(1)(a)

25. Control of Ignition Sources Positive Air Shutoffs for Diesel Engines

23.8(1)(b)

23.8(2)

23.9

26. Flare Pits & Flare Lines lighting, safe access

27. Fire Extinguishers 4 X 40-BC

23.10

28. Air Operating Systems Alcohol restrictions

23.11

29. Pipelines, fittings & valves standards, safe work procedures

23.12

2

Revised April 2009

Equipment Requirements (contd) Rig Inspection Checklist

30. Hose Connections design, service

OHS Regulation/

WC Act

23.13

31. Pumps positive displacement, PSV

23.14

32. PSV when required (Boiler & Pressure Vessel Act)

23.15

33. PSV installation discharge pressure, valves, restrictions,

shear pins

34. Pipe Racks loads, level surface, pins and spacers

23.16

35. Handling Pipe nubbins, movement, deck pins, loading

23.18

36. Kelly hose safety lines, clamps, shock hoses

23.19

37. Rigging up signals, rigging, tag lines, location of worker, winching

23.21

38. Horizontal static line & walkway when derrick is laid down

39. Steep slopes engineering, written plan, snubbing & yo-yoing

23.17

11.2

4.3, 23.23(2)

40. Roads comply with OHSR Part 26

23.24

41. Size of work area emergency response, loads, safely moved

23.31

42. Inspection & Repair RPs 1.0/1.0A/2.0/3.0/4.0 CAODC log book

23.32

43. Rig Moves lifting points, raising & lowering the derrick

44. Manufactures or PEng Identification and Instructions for the

assembly and disassembly of the drilling or Service rig

45. BOPS installing, slinging

23.33 (2)

3.3(c),

14.3(1)(2)(3)

14.12(2)

23.37

46. Spudding in guards in place, platforms/stairways installed, escape

line

47. Draw works controls identified, guarded, locking devices

23.38

48. Stabbing boards dimensions, securing, fall protection

23.41

49. Derrick enclosures weather, climbing on, exits

23.42

50. Pits & Tanks sources of ignition, adequate ventilation

23.44

51. Hoisting lines 5 wraps on the draw works drum

23.48

52. Securing fingers unsupported ends on the monkey board

23.54

53. Weight indicators required, safety line

23.56

54. Brakes tested, automatic feed, hold down chain

23.57

55. Guarding of the rotary table and Kelly

12.2

56. Rotary tongs preventing uncontrolled movement

23.60

57. Guy lines installation, testing spec plate, documentation

23.63

58. Drill Stem Testing - requirements

23.64

59. Swabbing at night lighting, sand line depth meter, flags, wind

direction

60. Air intakes 6 meters from rig tank, tank truck loading

23.65

61. Flow piping anchored, restricted areas, pressure testing

23.69

62. Pressure testing 10% rule, documentation of tests, bleeding air

23.72

63. Hot oiling vent line 10 meters from source of ignition

23.73

3

Revised April 2009

23.40

23.68

Documentation Requirements Rig Inspection Checklist

OHS Regulation/

WC Act

WCA 115(2)(f)

1. BC WCB OHS Regulations on site

2. CAODC Fall Protection Manual on site (fall protection plans)

3. Accident Reporting Kit

11.3

WCA 172

4. Derrick climbing procedure posted

11.3

5. Racking board rescue procedures posted

4.13(3)

6. Noise level survey done and posted

7.3

7. Boiler certification on site (BOILER & PRESSURE VESSEL ACT)

4.1

8. Respirable air quality documentation on site tested every 12

months CSA Z180.1 M85

9. Fit testing documentation on site

8.37

10. SCBA inspection and maintenance records

8.44

8.44

11. List of weights of all items which can be lifted or winched

Critical or Tandem life procedures available followed

12. Emergency Escape system inspection and documentation as per

Requirements of system used i.e.; weekly, monthly or each time

Erected (Manufacturers instructions)

13. Simulated derrick rescue performed and documented once a year

23.34, 14.36(1)

14.42(1)(2)(3)

14.42.1(1-5)

23.39.2(4)(c)

23.39.3(3)(a)(b)

4.14(3), 32.2(2)

14. Safe work procedures for all jobs available for all workers

23.5

15. All certification for rig equipment (mast, substructure, BOPs, etc)

available on site

16. CAODC log book available on site

23.32

17. Monitoring and Sampling results when drilling with Non-Water Based

Drilling and Completions/Well Servicing Fluids (IRP#14), Exposure

Control monitoring conducted and Exposure Control Plan developed

and implemented according to Industrial Hygiene principals

18. Casing Bowl Welding-Done in accordance with ASME,CSA and API

Standards, welds NDT tested (dye testing) and pressure tested,

casing bowl Installation procedures followed and available for review

Comments:

4

Revised April 2009

23.32(2) (3)

5.27(LEL)

5.48, 5.54, 5.55

(OELs)

4.1

4.3(1)(a)(b)

23.72(1)

Вам также может понравиться

- Supplemental Manual: TopicsДокумент20 страницSupplemental Manual: TopicsKurniadi WibowoОценок пока нет

- Ad4401a ManualДокумент100 страницAd4401a ManualSeptian H ShОценок пока нет

- Caol Clay Core Reassessment - ISSUEДокумент13 страницCaol Clay Core Reassessment - ISSUEDavid Thomson100% (1)

- Sharland MC Chart 1Документ1 страницаSharland MC Chart 1Septriandi ChanОценок пока нет

- Geo SoltexДокумент1 страницаGeo SoltexWaleed Barakat MariaОценок пока нет

- Edta 4na MsdsДокумент7 страницEdta 4na MsdsManoj ChaudhariОценок пока нет

- Chapter 5 Formation EvaluationДокумент28 страницChapter 5 Formation EvaluationDeniz AkoumОценок пока нет

- Optimization Drilling Parameters Performance During Drilling in Gas WellsДокумент8 страницOptimization Drilling Parameters Performance During Drilling in Gas WellsOmotayo Akinpelumi100% (1)

- Saes Q 004Документ24 страницыSaes Q 004tariqueОценок пока нет

- GEOREPORT Mudlogging ExampleДокумент2 страницыGEOREPORT Mudlogging ExampleCarmen Ibeth Olivos PradaОценок пока нет

- DrilplexДокумент6 страницDrilplexLoganBohannonОценок пока нет

- 12 Saes-Q-009.Документ5 страниц12 Saes-Q-009.engr.sulaiman0016Оценок пока нет

- Coiled Tubing Calculation: Sws - Career Development System (Phase - I) Coiled Tubing Service Class Room TrainingДокумент16 страницCoiled Tubing Calculation: Sws - Career Development System (Phase - I) Coiled Tubing Service Class Room TrainingNardo AvalosОценок пока нет

- Case History Hydraulics Modeling Software Helps Optimize Drilling and ECD Control With High Degree of Accuracy On Deep, Hot Gulf of Mexico Shelf WellДокумент9 страницCase History Hydraulics Modeling Software Helps Optimize Drilling and ECD Control With High Degree of Accuracy On Deep, Hot Gulf of Mexico Shelf WellElias GonzalezОценок пока нет

- 1.basic Formulas PDFДокумент30 страниц1.basic Formulas PDFKevin AtochaОценок пока нет

- Apparatus and Method To Test Drilling Fluid Stability (Barite Sag Tester)Документ2 страницыApparatus and Method To Test Drilling Fluid Stability (Barite Sag Tester)Jarjis MohammedОценок пока нет

- WO2019209312A1.Polyamine Polyethers As Nonemulsifier ComponentsДокумент34 страницыWO2019209312A1.Polyamine Polyethers As Nonemulsifier ComponentsLê Công100% (2)

- Section - 10 Lost CirculationДокумент16 страницSection - 10 Lost CirculationIbrahim DewaliОценок пока нет

- Api Casing Design: Design Parameters Loads at A DepthДокумент2 страницыApi Casing Design: Design Parameters Loads at A DepthChak AlGhazelОценок пока нет

- Grading Analysis Sheet: Std. Ref. Standards Descriptor Question SummaryДокумент1 страницаGrading Analysis Sheet: Std. Ref. Standards Descriptor Question SummarySachin SahooОценок пока нет

- Workboat International Dmcco: Appendix 1.0A Drill/Training Form Drill/Training Records FormДокумент1 страницаWorkboat International Dmcco: Appendix 1.0A Drill/Training Form Drill/Training Records FormJeet SinghОценок пока нет

- Well Control Incident Response Plan: N A Le RTДокумент76 страницWell Control Incident Response Plan: N A Le RTChristian Olascoaga MoriОценок пока нет

- Reservoir Management - 03 (W Solutions)Документ39 страницReservoir Management - 03 (W Solutions)Ashraf SeragОценок пока нет

- Bentonite Clay-Acid Activation Studies: K. Suresh, R. Samant, S.K. Jatty and H. BambhaniaДокумент5 страницBentonite Clay-Acid Activation Studies: K. Suresh, R. Samant, S.K. Jatty and H. BambhaniaminingnovaОценок пока нет

- 2 Spe 96798 HPWBM - HodderДокумент12 страниц2 Spe 96798 HPWBM - HodderPT100% (1)

- Red Stripe Mud LightnerДокумент6 страницRed Stripe Mud LightnerChris SniderОценок пока нет

- Rheological Models For Drilling FluidДокумент16 страницRheological Models For Drilling FluidModesty Ekeh100% (1)

- SLB PowerPak Handbook 2004Документ216 страницSLB PowerPak Handbook 2004casda73Оценок пока нет

- SPE Pando x1Документ15 страницSPE Pando x1Fernando Mostajo RocaОценок пока нет

- Deepwater Well ControlДокумент2 страницыDeepwater Well ControlJayaprakash Gopala KamathОценок пока нет

- Spe 135704 MS PDFДокумент9 страницSpe 135704 MS PDFKd FaОценок пока нет

- UBDPRO - Underbalanced Drilling Hydraulics SoftwareДокумент2 страницыUBDPRO - Underbalanced Drilling Hydraulics SoftwarePegasus Vertex, Inc.Оценок пока нет

- Extended Abstract of Petroleum Systems of Iraqi OilfieldsДокумент6 страницExtended Abstract of Petroleum Systems of Iraqi Oilfieldsياسر جواد كاضمОценок пока нет

- Redback Operations ManualДокумент11 страницRedback Operations ManualDon BraithwaiteОценок пока нет

- Study On Rice Husk As Lost Circulation MaterialДокумент52 страницыStudy On Rice Husk As Lost Circulation MaterialMuhammad Nursalam100% (1)

- 1B - Drilling Cost and Drilling RateДокумент37 страниц1B - Drilling Cost and Drilling RateTu Dang TrongОценок пока нет

- Rig Stuck Pipe Assessment FormДокумент13 страницRig Stuck Pipe Assessment FormBalkis FatihaОценок пока нет

- Formation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsДокумент6 страницFormation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsJamalОценок пока нет

- Formation Eval & Well LoggingДокумент40 страницFormation Eval & Well Loggingisa rahmani100% (1)

- SPE 68504 Jet Drilling Tool: Cost-Effective Lateral Drilling Technology For Enhanced Oil RecoveryДокумент9 страницSPE 68504 Jet Drilling Tool: Cost-Effective Lateral Drilling Technology For Enhanced Oil RecoveryAnonymous VNu3ODGavОценок пока нет

- WarpДокумент12 страницWarpGT GuidoОценок пока нет

- FazeproДокумент8 страницFazeproMaria Fernanda Zenteno CastilloОценок пока нет

- Fishing & StucksДокумент51 страницаFishing & Stucksمحمد العراقيОценок пока нет

- Hycalog HydraulicsДокумент1 страницаHycalog HydraulicsMiguel RodriguezОценок пока нет

- Pilot Test: ScientificДокумент12 страницPilot Test: ScientificHomam MohammadОценок пока нет

- Well Kick Data: Sheet No. 2Документ2 страницыWell Kick Data: Sheet No. 2Raul Dolo QuinonesОценок пока нет

- BG - Well Integrity HandbookДокумент9 страницBG - Well Integrity Handbookwalter.tajuОценок пока нет

- Hydraulics - Summary: Including Cutting Weight & Tool JointДокумент17 страницHydraulics - Summary: Including Cutting Weight & Tool Jointmsu6383Оценок пока нет

- Dikhanov Drill Off TestДокумент19 страницDikhanov Drill Off TestjalalОценок пока нет

- What Is Fishing Operation - Drilling Formulas and Drilling CalculationsДокумент12 страницWhat Is Fishing Operation - Drilling Formulas and Drilling CalculationsAmine MimoОценок пока нет

- Basic DrillingДокумент65 страницBasic DrillingAboZaidОценок пока нет

- 01 Samss 041 PDFДокумент14 страниц01 Samss 041 PDFFAPM1285Оценок пока нет

- Maximum Allowable Mud Weight Before Kick: Well Data 4Документ5 страницMaximum Allowable Mud Weight Before Kick: Well Data 4Sachin SahooОценок пока нет

- Re Entry WorkДокумент3 страницыRe Entry WorkAnilОценок пока нет

- Polymer Support FluidДокумент2 страницыPolymer Support FluidhamsarajshettyОценок пока нет

- Tesco Corporation: Unit #: Date: Operating DaysДокумент1 страницаTesco Corporation: Unit #: Date: Operating Daysboy tryadiОценок пока нет

- Iptc 11234 MS PДокумент12 страницIptc 11234 MS PDanian PrimasatryaОценок пока нет

- Settling Plug Mixing ProcedureДокумент8 страницSettling Plug Mixing ProcedureKamel TouahriaОценок пока нет

- PRO-4.5-0001-1-01 Permit To Work: MS&L ProcedureДокумент27 страницPRO-4.5-0001-1-01 Permit To Work: MS&L ProcedureIsaac ShaulОценок пока нет

- RP554 ManualДокумент3 страницыRP554 ManualAdolfo Angulo100% (1)

- User Manual RAM BOPДокумент102 страницыUser Manual RAM BOPAdolfo Angulo100% (1)

- Pre-Recorded Information: X X X X XДокумент3 страницыPre-Recorded Information: X X X X XOscar BustosОценок пока нет

- 12 - WellSharp Subsea Study GuideДокумент2 страницы12 - WellSharp Subsea Study GuideAdolfo AnguloОценок пока нет

- HydrilДокумент46 страницHydrilAdolfo AnguloОценок пока нет

- Hoja de Control de Pozos Metodos de CirculacionДокумент2 страницыHoja de Control de Pozos Metodos de CirculacionAdolfo AnguloОценок пока нет

- 19 - IWCF Homework Answers Day 2 - 1blankДокумент53 страницы19 - IWCF Homework Answers Day 2 - 1blankAdolfo Angulo100% (2)

- Presentation H2S New WWWДокумент21 страницаPresentation H2S New WWWAdolfo AnguloОценок пока нет

- Transition Answers 16mar2015 IADCДокумент4 страницыTransition Answers 16mar2015 IADCAdolfo AnguloОценок пока нет

- 02 - WellSharp Drilling Supervisor - Day 1 Pre - CourseДокумент5 страниц02 - WellSharp Drilling Supervisor - Day 1 Pre - CourseAdolfo Angulo100% (1)

- Fundamentals of Petroleum Engineering WELL COMPLETION AND STIMULATION Mohd Fauzi Hamid Wan Rosli Wan Sulaiman Department of Petroleum Engineering Faculty of Petroleum & Renewable EnginДокумент29 страницFundamentals of Petroleum Engineering WELL COMPLETION AND STIMULATION Mohd Fauzi Hamid Wan Rosli Wan Sulaiman Department of Petroleum Engineering Faculty of Petroleum & Renewable Enginqazim786Оценок пока нет

- 150k Quick Jack Brochure Revised July 05Документ15 страниц150k Quick Jack Brochure Revised July 05Adolfo AnguloОценок пока нет

- Stuck Pipe Nov 2011Документ5 страницStuck Pipe Nov 2011Adolfo Angulo100% (1)

- Subsurface Safety Valve BasicsДокумент33 страницыSubsurface Safety Valve BasicsPun Chee100% (4)

- Cudd Well Control News Fall08Документ4 страницыCudd Well Control News Fall08Adolfo AnguloОценок пока нет

- Slickline OperationsДокумент97 страницSlickline Operationsasset_kulmagambetov100% (2)

- Stuck Pipe PreventionДокумент64 страницыStuck Pipe PreventionmmbatainehОценок пока нет

- Stuck Pipe Freeing WorksheetДокумент1 страницаStuck Pipe Freeing WorksheetAdeel NenseyОценок пока нет

- Petroleum Engineering 406: Lesson 7 Well Control Shallow Gas and Subsea Well ControlДокумент10 страницPetroleum Engineering 406: Lesson 7 Well Control Shallow Gas and Subsea Well ControlAdolfo AnguloОценок пока нет

- CTS EnglishДокумент4 страницыCTS EnglishAdolfo AnguloОценок пока нет

- The Access Training Program: Creating Petrotechnical Experts For TomorrowДокумент8 страницThe Access Training Program: Creating Petrotechnical Experts For TomorrowAdolfo AnguloОценок пока нет

- 03 Coil Tubing Pressure Control EquipmenДокумент5 страниц03 Coil Tubing Pressure Control EquipmenAdolfo AnguloОценок пока нет

- The Implications of Housing Density: Force, Chaired by Leading Architect Richard Rogers, Was Appointed To ConsiderДокумент8 страницThe Implications of Housing Density: Force, Chaired by Leading Architect Richard Rogers, Was Appointed To ConsiderSingleAspectОценок пока нет

- PSOДокумент66 страницPSOAsad Mazhar91% (11)

- Cat Manual c18Документ104 страницыCat Manual c18John Suarez100% (8)

- Manual BookДокумент354 страницыManual BookKurniawan100% (4)

- Iccec CCCДокумент22 страницыIccec CCCpdanishОценок пока нет

- C-6327 Data SheetДокумент2 страницыC-6327 Data Sheetahugandkiss77071Оценок пока нет

- Biodiesel Appleseed Reactor PlansДокумент6 страницBiodiesel Appleseed Reactor PlansLivreinatural Arkairis100% (2)

- Rototherm Group - Product Catalogue 2017 (Rev. 3 - Low Res)Документ42 страницыRototherm Group - Product Catalogue 2017 (Rev. 3 - Low Res)Rahul KumarОценок пока нет

- Safari: Your Necessity. Our CreationДокумент8 страницSafari: Your Necessity. Our CreationShama KapasiОценок пока нет

- Oil Grades and Capacities PDFДокумент1 страницаOil Grades and Capacities PDFAlin ŞovăialăОценок пока нет

- Clean Air ActДокумент9 страницClean Air Act지창욱Оценок пока нет

- Manual 120 K CatДокумент727 страницManual 120 K CatSavio Fernandes91% (45)

- 丢失文件名的文件Документ368 страниц丢失文件名的文件313934753Оценок пока нет

- Trouble Shooting Carb and Compression BRIGGS & STRATTONДокумент1 страницаTrouble Shooting Carb and Compression BRIGGS & STRATTONvulpinor100% (1)

- Industrial Training: Submitted by Mamta 15001005020 B.Tech (4 Yr) Chemical EngineeringДокумент19 страницIndustrial Training: Submitted by Mamta 15001005020 B.Tech (4 Yr) Chemical EngineeringMamta BamniyaОценок пока нет

- Technical Bulletin Ltb00566v6Документ8 страницTechnical Bulletin Ltb00566v6Ян ПавловецОценок пока нет

- Yamaha - Service Manual - F300aДокумент572 страницыYamaha - Service Manual - F300aJorge Lopes100% (1)

- 7 Control RegulationДокумент351 страница7 Control RegulationtruongОценок пока нет

- Spares Part HIMSEN UsedДокумент4 страницыSpares Part HIMSEN UsedPaulo MandingaОценок пока нет

- Yamaha F150FET Owners ManualДокумент92 страницыYamaha F150FET Owners ManualNur Fadly Ryzqy0% (1)

- Caterpillar Vane Pump PDFДокумент24 страницыCaterpillar Vane Pump PDFManuel Carvallo0% (1)

- Graco EcoQuip Brochure - December 28 2014Документ7 страницGraco EcoQuip Brochure - December 28 2014AshwinОценок пока нет

- Control Boxes (Pilih)Документ18 страницControl Boxes (Pilih)Shihabudin QolyubiОценок пока нет

- Accumulators PDFДокумент88 страницAccumulators PDFThiyagu SundaramОценок пока нет

- Combustion Stages of CI Engine and Factors Affecting ItДокумент15 страницCombustion Stages of CI Engine and Factors Affecting ItAbdul RehmanОценок пока нет

- Hydraulic Brain TeasersДокумент7 страницHydraulic Brain TeasersabhijitmukhОценок пока нет

- ARIES Drill Parts ManualДокумент202 страницыARIES Drill Parts ManualFernando Nunez100% (1)

- RC Datasheet PDFДокумент20 страницRC Datasheet PDFRicardo BarrosОценок пока нет

- TechOne - Automatic Transmissions Chapter 23,28Документ21 страницаTechOne - Automatic Transmissions Chapter 23,28don krtek100% (1)