Академический Документы

Профессиональный Документы

Культура Документы

6

Загружено:

Mohamed ElmakkyАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

6

Загружено:

Mohamed ElmakkyАвторское право:

Доступные форматы

Printed in U.S.A., Copyright 2000.

Penton

Media, Inc. All rights reserved. Machine Design (ISSN 0024-9114) is published semimonthly by Penton Media, Inc., 1100 Superior Ave., Cleveland, OH 44114-2543. Copies

not qualified for domestic requester circulation: one year, $105; two years, $165. Permission to photocopy is granted for users registered with the Copyright Clearance Center

(CCC) Inc. to photocopy any article, with the

exception of those for which separate ownership is indicated on the first page of the article, provided that the base fee of $1.25 per

copy of the article, plus $.60 per page is paid

to CCC, 222 Rosewood Dr., Danvers, MA

01923 (Code No. 0024-9114/00 $1.25 + .60).

Permission to reprint: Barbara LoSchiavo; Purchased reprints: Judy Dustman

(216-696-7000, ext. 9607); Advertising Materials: Advertising Dept., Machine Design,

1100 Superior Ave., Cleveland, OH 441142543, 216-696-7000. Inserts should be sent

to Machine Design, Penton Press, 680 N.

Rocky River Dr., Berea, OH 44017-1691.

Packaging/Material handling

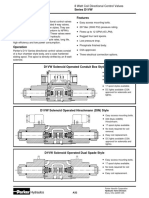

Bus-box kit simplifies

pneumatics control

System brings DeviceNet capability to

stand-alone in-line valves

and vacuum

generators.

anufacturers of packaging and

handling machinery are turning to fieldbus networks to

simplify designs and add functionality. A recently introduced Valve Bus Box offers control of standalone, in-line pneumatic valves and vacuum

generators using DeviceNet protocol, which

is growing in popularity in conveyor, handling, and packaging applications.

The system is from Festo Corp., Hauppauge, N.Y., which previously offered products in the mid to upper range of DeviceNet

compatible pneumatics. Festos introduction of the Valve Bus Box (VBB) adds a diverse group of low-cost solutions for singleunit DeviceNet-controlled pneumatics

where applications require directional

valves and/or vacuum generators.

The VBB kit includes a universal electronic module packaged to mechanically attach to a wide array of Festo CPE, Midi,

and Tiger 2000, 5/2 and 5/3 single and double-acting valves, and various configurations of vacuum generators. Assembly involves mounting the electronics module to

one side of the pneumatic component using

DIN rail technology with standard, supplied hardware.

The bus box represents a breakthrough

in pneumatics, since it marks the first time

that a single vacuum generator, under the

S74

MACHINE DESIGN

control of a DeviceNet protocol, has been

commercially available. The kit design provides flexibility when integrating the companys DeviceNet-compatible electronics

with standard valves and vacuum devices,

forming a compact and space-efficient single assembly.

Another advantage is that the modular

design permits isolation of the pneumatic

section (including solenoids) from the controlling electronics, thus making replacement of either fast, easy, and cost effective.

All electrical connections are made with

IP-65 compatible plugs and connectors, and

the VBB units are completely hardware

configurable. No software is required.

The VBB is CE compliant and meets

DeviceNet Specification (Version 2.0). The

inputs and outputs (type pnp) are optically

isolated for protection from overcurrent and

short circuit. The output is designed with

an electronic fuse (1.5-A trigger after

350 msec) which resets automatically when

a fault condition is removed. Supply voltage

is 24 Vdc, and the normal operating temperature range is 5 to 50C.

The Valve Bus Box is currently operating

in air-conveyor systems and pharmaceutical applications.

Information for this story provided by Festo

Corp., Hauppauge, N.Y.

FEBRUARY 8, 2001

www.machinedesign.com

The Valve Bus

Box is the first

commercially

available system

that permits

DeviceNet

control of a

single vacuum

generator.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- GuitarДокумент9 страницGuitarHarun Ünüvar100% (6)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Midway Basic RulesДокумент26 страницMidway Basic RulesRickОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Psalm 23 Sheet Music - Bing Images1Документ4 страницыPsalm 23 Sheet Music - Bing Images1Ed MillareОценок пока нет

- A Rich Man's Secret - Hen Roberts - 205Документ485 страницA Rich Man's Secret - Hen Roberts - 205kuky6549369100% (1)

- A321 Generic CCOMДокумент696 страницA321 Generic CCOMMustafa Direk100% (3)

- How Has Chuck Close Influenced Society and Evolved His Style - A Hypertexutal Research and Analysis of Chuck Close and His ArtworksДокумент10 страницHow Has Chuck Close Influenced Society and Evolved His Style - A Hypertexutal Research and Analysis of Chuck Close and His Artworksapi-355753458Оценок пока нет

- Vibration NotesДокумент95 страницVibration NotesHaitham Youssef100% (1)

- Esperanto Picture DictionaryДокумент118 страницEsperanto Picture DictionarymcmassiaОценок пока нет

- +A Touch of Jazz - Nick Ayoub - SATB (Sax Ensemble)Документ8 страниц+A Touch of Jazz - Nick Ayoub - SATB (Sax Ensemble)John SuskeyОценок пока нет

- 3 VR Input DevicesДокумент47 страниц3 VR Input DevicesFENGDA WUОценок пока нет

- 2015-T041 - SH222 Hose Summary Test ReportДокумент9 страниц2015-T041 - SH222 Hose Summary Test ReportMohamed ElmakkyОценок пока нет

- HelpfulEngineeringInfo PDFДокумент28 страницHelpfulEngineeringInfo PDFMohamed ElmakkyОценок пока нет

- 2015-T021 - GH466 Hose Summary Test ReportДокумент16 страниц2015-T021 - GH466 Hose Summary Test ReportMohamed ElmakkyОценок пока нет

- Agency Approvals Braided 2651 - LRДокумент2 страницыAgency Approvals Braided 2651 - LRMohamed ElmakkyОценок пока нет

- Pressure Transmitters: Tronic LineДокумент4 страницыPressure Transmitters: Tronic LineMohamed ElmakkyОценок пока нет

- DVC 99wierДокумент2 страницыDVC 99wierMohamed ElmakkyОценок пока нет

- Hpi Pumps General CatalogueДокумент1 страницаHpi Pumps General CatalogueMohamed ElmakkyОценок пока нет

- Crimp 1Документ4 страницыCrimp 1Mohamed ElmakkyОценок пока нет

- Aztech HW550-3G OEM DataSheet PDFДокумент2 страницыAztech HW550-3G OEM DataSheet PDFMohamed ElmakkyОценок пока нет

- DVC 99wierДокумент2 страницыDVC 99wierMohamed ElmakkyОценок пока нет

- Denison A - T6DDSДокумент3 страницыDenison A - T6DDSMohamed ElmakkyОценок пока нет

- 514 205Документ2 страницы514 205Mohamed ElmakkyОценок пока нет

- DVC 99straightwayДокумент2 страницыDVC 99straightwayMohamed ElmakkyОценок пока нет

- Kawasaki Check Valve C1001Документ5 страницKawasaki Check Valve C1001Mohamed ElmakkyОценок пока нет

- Hyd RexДокумент2 страницыHyd RexMohamed ElmakkyОценок пока нет

- 2502 A 002Документ10 страниц2502 A 002Mohamed ElmakkyОценок пока нет

- PowerPoint Is A Highly Innovative and Versatile Program That Can Ensure You A Successful Communication Whether YouДокумент3 страницыPowerPoint Is A Highly Innovative and Versatile Program That Can Ensure You A Successful Communication Whether YouJenjen BautistaОценок пока нет

- Macromechanics of A LaminateДокумент45 страницMacromechanics of A LaminateAvinash ShindeОценок пока нет

- Anti Aging TipsДокумент15 страницAnti Aging TipsArietta Pieds NusОценок пока нет

- PalestineДокумент5 страницPalestinebrettОценок пока нет

- 1819187-Kobold TrapsДокумент4 страницы1819187-Kobold Trapsjustin.callОценок пока нет

- Antenna Vsat Maintenance ProposalДокумент11 страницAntenna Vsat Maintenance ProposalRachmat HidayatОценок пока нет

- Prison Break WorksheetДокумент6 страницPrison Break Worksheetr_116862476Оценок пока нет

- Specification Sheet: WG-4000-B WG-4500-B WG-5000-B WG-5500-BДокумент1 страницаSpecification Sheet: WG-4000-B WG-4500-B WG-5000-B WG-5500-BAlexander George Madden PavónОценок пока нет

- Muslim Architecture in JaunpurДокумент33 страницыMuslim Architecture in JaunpurAnkit Gupta50% (2)

- PE 10 Q 1 MODULE 1 (Dagyaw) 2Документ31 страницаPE 10 Q 1 MODULE 1 (Dagyaw) 2uteОценок пока нет

- iconBiT XDS1003DT2 - UM - EN - RU PDFДокумент66 страницiconBiT XDS1003DT2 - UM - EN - RU PDFVasia DeminОценок пока нет

- Purple Parrot Menu at AtlantisДокумент8 страницPurple Parrot Menu at AtlantisClarita BernardinoОценок пока нет

- György Sándor LigetiДокумент2 страницыGyörgy Sándor LigetiviriОценок пока нет

- 2021-05-20 - RDSO SPN TC 65 2021 Version 6Документ78 страниц2021-05-20 - RDSO SPN TC 65 2021 Version 6Chaitanya Ram Nimmagadda100% (1)

- Plus D or Disciple: Multiface 128 - ManualДокумент4 страницыPlus D or Disciple: Multiface 128 - Manuallolo12345Оценок пока нет

- NEERJA 7th April 2016 Pre Shoot Draft PDFДокумент120 страницNEERJA 7th April 2016 Pre Shoot Draft PDFMuhammad Amir ShafiqОценок пока нет

- Gatewise Releases New Online Management Portal For Multifamily CommunitiesДокумент2 страницыGatewise Releases New Online Management Portal For Multifamily CommunitiesPR.comОценок пока нет

- Jah Heavy LoadДокумент1 страницаJah Heavy LoadMijail MijailОценок пока нет

- AutoCAD Checklist PRAGATHI COMPUTERSДокумент2 страницыAutoCAD Checklist PRAGATHI COMPUTERSBidyutОценок пока нет

- Insight Link 1 - Dictation - PDFДокумент16 страницInsight Link 1 - Dictation - PDFHeejin LeeОценок пока нет