Академический Документы

Профессиональный Документы

Культура Документы

Mixing Succeed at Scale Up

Загружено:

icingrockАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mixing Succeed at Scale Up

Загружено:

icingrockАвторское право:

Доступные форматы

.

ot,l

Succeed at Scale Up

Scale-up

problems in

industrial reactor

mixing can be

costly, but are

all too common.

Here's a proven

procedure that

avoids them.

Douglas E. Leng,

Jal

haif

on

'er

lac

~ion

eeds,

i'

The Dow Chemical Co.

ailure to properly scale up mixing in

batch and continuously stirred ves

sels remains a persistent problem in

the process industries. Numerous

causes of difficulty exist, but a pattern is

evident: A lack of understanding of the pro

cess undermines many efforts. Mixing prob

lems are seldom recognized, in part because

they are not well understood, but also

because they are not examined as quantita

tively as other unit operations.

Correcting errors in scaling mixing

operations is costly and sometimes impos

sible. Errors can cause losses of productivi

ty, quality, and profit, and they also can

lead to safety problems such as reactive

chemical incidents. Although technical

problems cause most failures, nontechnical

reasons also contribute to difficulties.

Scale up of mixing can be easy or com

plex. Most difficulties arise when potential

problems have not been well thought out.

Hardest of all are multiphase processes in

which the chemistry depends on condition

of the phases.

Good quantitative tools and measures of

performance are required to solve such

problems. (See the accompanying article

by Tatterson for an examination of these

needs.) My 25 years of experience with

industrial mixing and scale-up problems

has led me to identify some general trou

blespots and to develop a procedure for

successful scale up.

First of all, the engineer" must clearly

understand the role of the mixing. Is rapid

attainment of uniformity critical to process

success? The following are typical chemi

cal processes that depend on rapid attain

ment of uniformity:

chemical reactors/polymerizers in

which reaction kinetics are equal to or

faster than the ratc of mixing:

competing chemical reactions where

poor mixing affects yields;

crystallizers thai depend on uniform

mixing to promote the growth of large uni

form crystals; and

reactions dependent on mass transport.

such as coalescing and redispersing of liq

uid-liquid and gas-liquid mixtures.

For such processes. desired results can

be achieved more easily in small equip

ment than in large equipment.

Contrast those with applications that are

less sensitive to the needs of uniform mix

ing. These include:

heat transfer:

blending of miscible fluids:

reactors inyolved with slow chemical

reactions;

suspension of solids.

These foul can be considered noncritical

applications, i.e.. they can usually be scaled

up with few difficulties.

Many engineers are most familiar with

the latter, noncritical applications.

Unfortunately. they get the impression that

mixing is simple and can be treated casual

ly. Thus. it is not surprising that so many

scale-up problems occur.

Avoiding problems

For successful scaleup of mixing in

industrial processes, a designer should fol

low six distinct steps:

1. define the process need;

2. identify all of the operational

parameters;

3. review the process history:

4. select the imponant process

parameters;

S. choose an initial equipment design

vessel design, impellers. impeller location.

bal'fles. and points of feed and exit

~treams: and

6. test the design relative to the process

needs and assumptions and then fine tUlle it

to meet the needs of the most important

variables.

Many scale-up failures can he traced

directly to the omission of one or more of

CHEMICAL ENGINEERING PROGRESS

JUNE 1991

23

MIXING

I!1

thesl! six steps. We will consider

each of the steps in turn and provide

ex:ampJes of problems.

Defining the .process need

the impeller 10 distrihute the S,.uper

heated hydrocarhon vapor. The

impeller was supposed. to disperse

the vapor into buhhles to prtwide

mass transfer for the liberation of

ammonia. driving the reaction (0 the

right to form the dimer (2 Al.On

start-up, however, solids accumulat

ed at the base of the vessel. causing

the plant to shut down. The scale up

had been based on invalid criteria,

which led to inadequate mixing for

suspension of the solid.

. The design/~cale-up. process

should start with a thorough exami

nation of all process needs.

Requirements are often straightfor

ward. Sometimes. however. they

may he complex and even contlict

ing: For example. it might be neces

sary to exceed minimum shear to sat- .

isfy dem;)nds for flow and

uniformity.

Vapor to

Typical process needs

Condenser

include:

supplying a uniform slurry

385hp Drive

to feed another processing

step;

facilitating a controlled

chemical reaction;

Feed from

providing for mass or heat

Second

Stage

transfer:

Reactor

dispersing liquid drops for

a suspension polymerization

or extraction;

assuring continuous mixing

of added reactants or

Isopar Vapor

from

monomers.

Petrochem

Avoid the temptation to

Superheater

quickly accept the obvious

without evaluating Jess obvious needs. For instance,

solids must be kept in sus

Identifying all of the

pension. but sometimes that Figure 1. Sparged, lOO,OOO-gallon cofltinuously-stirred

operational parameters

may not be enough, as tank reactor containing 45% solids.

List and then prioritize the

shown in the following

reasons for mixing. These

example.

The major mistake was thinking

may include requirements for mixing

A complex, three-phase, continu

time (blending). micromixing, heat

that adequate suspension of solids

was sufficient to produce desired

transfer, shear. solids suspension.

ous-stirred-tank-reactor system was

being scaled up from test data

production rates. The suspension

mass transfer (including liquid-liq

derived in 3,SOO-gal vessels. The

problem was solved by doubling the

uid, liquid-solid. and gas-liquid 1.

reaction was an equilibrium dimer

power per unit volume, as suggested

introduction of gas into liquid, reac

in tests, but that necessitated trans

tants, chain terminators, initiators.

ization, described by:

ferring the original drive to a stand

2 A (solid) ~ (2 A) (solid) + 2 NH.

and reflux return.

(gas)

.'

by SO,OOO-gal reactor. As the

Textbooks on mixing note that

revised plant got back in production,

The reactor was the last stage of a

these operational parameters do not

tests revealed good solids suspen

scale up equally. Oldshue (I) illus

three-stage train. see Figure I, and

sion was provided in all regions of

contained reacting solids suspended

trates this for scale up from a :::O-gal

the smaller SO.OOO-gal reaclor. The

in a light hydrocarbon. Melt from the

to a 2,SOO-gal \essel: If the power

second stage entered the 100,000-gal

productivity, however, was only

per unit volume (PlY) is held con

about 2S% of the projected rate for

stant, circulation lime increases

stirred reactor and snliditled immedi

that size of vessel. The reaction rate

ately to form a fasl-:-;ettling slurry

threefold, tip speed by 70%, and th\.'

was an important problem that had

containing 4S% solids. Agitation was

impeller Reynolds number by a fac

not heen solved, Further tests also

provided by a single. four-blade, 4So

tor of 8.S. I f processes reqUire both

constant PlY and shear to be main

-pi lched-blade turhine 16 ft in diam

revealed that sparging the superheat

ed hydrm.:arhon was not effective in

lained, condition;. of geomelric simi

eler operated at 26 rpm and driven

removing the ammonia, although

by a 38S-hp motor. A large, bell

larity need to he n:laxeJ.

shaped distributor \\as located under

~H.'ceptahlc reaction rates had heen

In miniplanh. nonsill1ilar geol11\.'

I,~\

I

'

I

1i

1111

achieved by sparging gas into a

3,SOO-gal pilot-plant reactor.

Finally. it was shown 'that condi

tions had been different in the pilot

plant vessel. Sparging was accom

plished by pas~ing nitrogen into the

slurry of suspended solids in miner

ai oil. Nitrogen bubbles had provid

ed the mass transfer needed to

remove the ammonia in the small

reactor, but, in the plant reactor, cal

culations ot heat transfer from the

buobles to the surrounding fluid

indicated tpat all bubbles had

collapsed due to condensa

tion. The liberated heat from

condensation was transported

to the surface by convection.

where it caused the top layer

to boil. Mixing, therefore,

also had to rapidly circulate

reacting solids through the

boiling surface layer to

remove ammonia. Many

mixing designs were pro

posed. several were tested

45' psr Impeller

and pro\'ided improvements,

but none was sufficiently

effective to permit continu

ing to operate the plant.

Fortunately, problems of

Vapor Distributor

such magnitude occur

infrequently.

24

JUNE 1991

CHEMICAL ENGINEERING PROGRESS

II

try is used to simulate mix

2.0()()-gal semiworb plant.

Input Intensity=1.0

if'!!. in a large-scale reaclor:

howe\cr. agglomerates and

), example, when blend

small lumps of polymer

tIme i, critical. miniplant

formed. which necessitated

.;tudies can be done in a

'in-line product filtration.

reactor having a smaller

Oth~r problems al~() appeared

impeller diameterltank diam

but were controllable.

eter (OIT) ratio.

The full-scale plant was an

Identifying all of the key

g,OOO-gal multi-pitch-blade

Intensity=20

parameters is, admittedly, not

turbine installation. which

always easy, but the prob

included an elaborate recycle

lems that can be caused by

system through heaters and

Intensity=5

skimping on the analysis can

coolers arranged in parallel.

be tougher. For instance,

Problems greatly increased at

Intensity=1

incomplete parameter identi

this scale and were unman

fication led to the following

ageable even with the instal

lation of large in-line filters.

problem:

Intensity=O.2

Production of a fine

Calculations showed that

chemical was' being scaled

the energy per unit volume , /

up from a miniplant to a

was 120 hplLOOO gal at the'7

3,500-gal reactor. Agitation

5-L s,cale and decreased

was believed to be needed ill Figure 2. Schematic oj local relative turbulence

almost linearly to 3 hpll,OOO

intensities.

for solids movement equiva

gal in the production reactor.

lent to the just-suspended

Meanwhile. product contin

state. In reality, the reaction rates

ued

to

coarsen

as larger vessels were

Reviewing the process history

depended on several factors, per

used. Since the initiator half-life was

only a fraction of a second, the sizes

haps the most important of which

A process is often scaled up in

incremental stages to meet growing

was mass transfer between the two

of particles were established virtually

product-development needs. This

coalescing liquid phases. The pro

instantaneously when the monomers

iuction facility was sized according

provides an opportunity to observe

entered the reactor.. Intense

,~ reaction rates observed in mini

the development of problems due to

micromixing in the small vessel dis

plant vessels. Production rates

persed the monomers much more

scale up and can help minimize risk.

determined after plant start-up were

Problems can be subtle, as seen in

rapidly as polymerization proceeded.

the following example:

found to be more than an order of

A nonaqueous dispersion was

magnitude less than expected.

being developed from laboratory

At small scale, high shear and

through a mini plant, pilot plant,

rapid circulation led to a dispersion

. D. E. lENG is a senior research .

controlled environment and small

semiworks plant, and, finally, fuIl

scientist ill the Central

drops with a large interfacial area.

scale production. The product was to

Research Engineering

contain a certain fraction of solids in

At the large scale, shear rates were

laboratory of The Dow

lower and circulation was slower,

the form of micron-sized polymer

Chemical Co., Midland, MI

with both factors contributing to

particles. The procedure developed

(517/636-3387; Fax.: 517/638

was to continuously feed initiated

conditions classified as coalescence

9674). He has worked for Dow

monomers into a vigorously agitated

controlling. This led to large drops

at Midland for 35 years.

and much less interfacial area.

hot fluid to rapidly disperse the

During the last 25 years, he

Because the kinetics were controlled

monomers and provide uniformity

has been involved primarily in

and heat transfer. The rate of poly

by mass transfer, the change from

mixing and multiphase

merization was governed by the rate

dispersion dominance to coalescence

research, applications, prob- ,

of the addition of monomer, which

dominance explained the unexpected

lem solving, and engineering

behavior on scale up.

contained free-radical initiators with

administration. He obtained a

The scale-up problem might have

a half-life of less than a second at the

BSc and an MSc from Queen's

temperatures in the reactor.

been anticipated if the agitator had

Univ., Kingston, Ont., and a

1

Superior product was obtained in

been stopped during early laborato

PhD from Purdue Univ. A fel- .{

S-L glass reactors with the desired

ry work so that very rapid coales

low of the AIChE and a mem-j

viscosity, particle sizes, and percent

cence could have been seen. The

ber of the American Chemical l

problem was greatly eased by

age of solids. The results were not

Society, he was the chairman, '.

adding a second impeller, which

quite as good in the next size reac

of the Engineering Foundation

tors, but cerlainly good enough to

):ncreased the overall circulation

Conference on Mixing (1981) .. ';.i

maintain enthusiastic support from

rates and provided an additional

.'

;,',?..;,":

management and customcrs. In the

region ror drop dispersion.

,tii

"-. '1

CHEMICAL ENGINEERING PROGRESS JUNE 1991

25

,.

I

1., ;

J!

I!

11 '

MIXING

In larg('r s..:alc vessels. the

kl.' rthe mass transfer coeffi

mixing intensity was two

cient). it is the interfacial

orders of magnitude less. so

area. a"that is atTected in k1u

the dispcr;.ion of the

measurements, Hen(;c kl.a is

a function of the superfi(;i:l

monomer \\'a~ 'slow relative

to the rat(' of reaction. This

gas velocity and PIV. the

r('sulted in a big difference in

power per unit volume,

InterfaciaI

For example. consider the

the Damkohler number.

Vortex

Clearly. increasing the

scaleup of a microbial fer

total power to the level pro

mentation. The role of mix

vided in laboratory-scale

ing was to provide gas dis ,

work \\'as not a dable solu

persion, supply nutrient

tion. Instead. attention was

blending, keep solids in

Baffles

turned to assessing what

suspension. and maintai'l

could be done to improve

reI ati ve \y low shear. Th:

the mixing intensity at the

broth became rheologically

monomer inlet without

more non-Newtonian with

increasing the overall mix

time. The scale up was to

ing energy. The location of

provide correlations for 80

the monomer inlet was at a

m 3 vessels in which the

Figure 3. Improper geometry for the dispersion of

region of low turbulence,

desired dissolved oxygen

,

monomer ill water.

and local energy-dissIpation

could be maintained by a

rates in agitated vessels are

combination of impeller

attaining uniformity generally do not

known to be highly nonuniform.

speed and gas rate. The criticn

Recently published studies (2,3)

scale up well.

scale-up variable was selected to be

Mixing time was used as a crite

have shown that regions close to

the kLa, so that equivalence in kLa

rion for the scale up of a polymer

the impeller gave dissipation rates

could provide similar dissolved

20 times greater than the average in

ization process in which a block

oxygen levels at corresponding

the reactor as a whole. Figure 2

copolymer was being produced.

stages in the fermentation.

shows schematically that regions

Polymerization rates were fairly

Studies were conducted in 30-L

fast, and locally poor mixing gave

near the impeller provide more

and 2S0-L laboratory vessels. The

intense energy dissipation. Adding

inferior results, leading to a product

kLa measurements were made by the

the monomer through a cooled inlet

with a broad distribution of side

steady-state method: oxygen con

pipe directly to the impeller dis

chain lengths. Calculations indicat

sumption was determined from the

charge stream worked so well at the

ed what mixing times could be

difference between the inlet and out

production scale that filtration was

achieved reasonably in the planned

let oxygen concentrations and the

obviated.

production reactors, and miniplant

airflow rate. Probes measured the

Thus, careful observation and

conditions were chosen that would

dissolved oxygen in the liquid phase.

analysis gave warning that a prob

duplicate these conditions. Tests

The relationship between the two

lem, could occur, Fortunately, the

were then conducted in the mini

sizes of fennenters suggested a cor

solution was fairly simple to imple

plant to determine whether the

relation of the fonn:

k aa.(PAl: 14(S )oAfi(lI)

product quality was sensitive to

ment and worked well.

L

r~'

agitation rates above and below the

where S~ is the superficial gas veloci

ty. It was necessary to correlate kL

calculated rate based on equal mix

Selecting the important pro

ing time. In this case. scale up was

from a determination of the zero

cess parameters

Textbooks generally treat mixing

successful. due in part to the recog

shear viscosity (11) of broth sampled

as a series of topics that have little in

nition that mixing time was a criti

from the fermenter. The correlation

common. These topics can, however.

cal fac.tor for product quality.

proved to be accurate, provided

Ga.~-liquid mixing usually

impeIler flo\\' was sufficient to

lead to an orderly checklist for

relates to phenomena su(;h as gas

selecting parameters that are impor

entrain gas buhbles to the regions

below the impeller,

tant to the mixing process.

holdup, interfacial area (kiP, the

Blending of lIliscihlt! liquids deals

mass-transfer coefficient and inter

Many published studies on

facial area). and the ratio of power

gas-liquid mixing have been done ;11

with topics related to design and

while gassing to power for the

impeller and vessel dimensions, and

low gassing rates. conditions under

which mixing is fairly straightfor

generally ends up with a discussion

ungassed state (P /PIf~)' The latter is

expressed as a ru'netion of the aera

ward. Gas rates. however. arc usually

about mixing time. 8 m , A process is

seldom scaled up oy holding mixing

tion number QIND\ where Q is the

much highcr in industrial mixing

gassing rate, N is the impeller

time constant because this generally

often I to 3 \'olumcs of gas per vol

requires high power commitments.

speed. and D is the impeller diame

ume of liquid pcr minute - and can

ter. Sin(;e mixing has lillie effect on

lead to impclkr cavitation. Wh~'n

Processes that d.::pend on rapidly

II

II

~ !

26

JUNE 1991

CHEMICAL ENGINEERING PROGRESS

that happens. impeller discharge

)lWS diminish and the distribution

,)j" ga~ in the vessel can change dra

matically from fairly uniform to

poor. .-\5 discharge rates decrease.

impeller flow can no longer entrain

gas and carry it to all regions. The

region below the impeller near the

tank bottom is usually the first to

become void of bubbles. Under

flooded conditions. the impeller can

often only distribute gas radially to

regions above it. The ratio PIPIt~

falls to less than 0.5 under these

conditions.

Liqllid-liquid dispersiolls are

commonly associated with drop dis

persion and the generation of inter

facial area. Various mechanisms

have been proposed for drop disper

sion. usually relating fluid forces

(laminar or turbulent shear) to drop

surface forces. The fluid forces can

arise from impact at the walls. or

rotational, dilational or turbulent

shear. Resistance forces are com

monly those due to interfacial ten

sion or surface viscosity. The drop

breaks

when fluid forces exceed

,

cohesi\e forces.

The process of forming the dis

persion is also important. but it has

recehed little attention. Consider

two separated liquid phases. A and B.

of diiferent density with A on top

and B below. To create a dispersion

of B in A, an impeller must be placed

in A. For the reverse. the impeller

must be placed in B. This sounds

simple and logical. but its impor

tance was learned the hard way:

A suspension polymerization was

being scaled up from 3,500-gal to

lO.OnO-gal size. All factors about the

vessel geometry were similar, The

process technology had been estab

lished for many years in the smaller

reactor. Therefore. a prototype

10.OOO-gal vessel was to be tested

first: if it was successful, the remain

ing pl)lymerizers would be installed.

Agitation at both scales was provid

ed by a single. three-blade. retreat

cuneo glussed-steel impeller located

at the bottom of the reactor. The

polymerizers had two finger baffles

placed 1800 apart.

)

The polymerizer had to sequen

tially mix the phm;es (waler with sus

pl'nding agl'nt. and monomers with

catalYSt). form a suspension of

monomer drops in water. heat to

polymerize. polymerize. and finally

cool, The monomers were more

dense and initially formed the bot

tom layer. while water and suspend

ing agent formed the top layer.

Agitation begun, and heat-transfer

coefficients were calculated online

by the latest instrumentation. As the

polymerizer began its first run. the

heat-transfer coefficient feli from 50

to less than 2 Btu/h/ftC/oF. reactor

temperatures went out of control. and

emergency venting to a condenser

was activated to provide evaporative

cooling and avoid serious reactive

chemicals problems.

The monomer layer, instead of the

water layer, had become the continu

ous phase. and heating had initiated

polymerization - resulting in a

mess. Similar results were produced

in two further runs. The problem was

solved by placing a second impeller

in the upper. water layer, which

caused monomer to be thrown up

into that layer. Laboratory mixing

tests showed that the single lower

impeller created a large interfacial

vortex that allowed water from the

upper layer to reach the impeller and

become dispersed, as shown in

Figure 3 , The problem was not

apparent in the 3,500-gal vessel, pos

sibly because relatively lower tan

gential velocities existed, resulting in

a shallower interfacial vortex that did

not reach the impeller.

Coalescence of drops occurs upon

collisions with other drops, or

between drops and solid surfaces

such' as baffles. vessel \\alls. and

impellers. Conditions of shear lead to

drop collisions, High local shear

rutes also leud to drop di'persion. In

a coalescing and dispersing system.

coalescence occurs principally in

regions of low shear. v.hile disper

sion occurs in regions of high shear

near the impeller. An agitated disper

sion is both dynamic and periodic,

Large-scale eddies appear. disappear,

and reappear from time to time. sug

gesting highly transient behavior.

Colliding pairs of drops coalesce if

the forces pressing them together

endure long enough for drainage and

thinning of the continuous phase to

occur between them. If insufficient

drainage occurs. the drop pair will

separate as fluid forces diminish.

Other factors. such as the mobility of

the liquid-liquid interface. the defor

mation of the drops upon impact, and

foreign matter collected at the sur

face. also playa role in the drainage.

Our current ability to scale up liq

uid-liquid dispersions depends on

whether the system is coalescing or

noncoalescing. Coalescing systems

are extremely difficult to scale up if

equal interfacial area or drop-size

distribution must be maintained.

NOllcoalescillg systems often

involve suspension-polymerization

processes employing a water-soluble

protective polymer that collects at

the drop surfaces and prevents coa

lescence. Mixin'g for these systems ~)

need only provide for dispersion and !

suspension because coalescence is I"~

virtually absent. Figure -+ shows that

mean drop sizes become smaller and

suspension

line, drops

are suspended

Log

Drop

Size

.....f - - - - - - _ l _ Dispersion:

drops above

the dispersion

line are

dispersed.

Log Impeller Speed

Fi~llre

-I. Dispersioll-suspensio/l relations/ri/ls ill slispensioll poIYllleri:.atio/l.

CHEMICAL ENGINEERING PROGRESS JUNE 1991

27

MIXING

------.---~~--------------------------~~~---------------------------

drops arc hetter slispenued as

impeller speed" increase. Decreasing

the agilalor spe\.:d uo\.:s the opposite,

The drop sile eorn.:sponciing. to the

inter.scctipn Ill' the dispersion and

suspension line" is the largest mean

drop size that can he produced under

those specific conditions. The aver

age size of drops depends on either

turbulent or laminar shear. while

suspension depends on drop sizes.

density differences. and agitation

parameters (-J.).

Another factor to consider is that

the time to reach a completely dis

persed condition is short in small

equipment but long in large equip

ment. A light-transmission apparatus

for measuring interfacial area was

placed on a I.OOO-gal suspension

polymerizer to measure the time

required for complete dispersion. The

noneoalescing drops were still being

dispersed after 24 h of agitation.

Becaus.e proUllCliol1 schedules

usually do no! allow for allain111ent

of "complete" dispersion. scale up

becomes more complicated. One

ends up comparing completely dis

perscd drops made in sillall equip

ment with partly dispersed drops

produced in large polymerizers.

Therefore. agilation speed has to be

increased in the large vessel to pro

duce drop size:.. equivalent to those

made in the miniplant polymerizer.

Coalescing systems are, by com

parison. complicated to scale up

for a number of reasons. Rates of

chemical reactions often depend on

the interfacial area, which in turn

hinges on two dynamic factors:

coalescence and dispersion. Other

important points for these systems

are as follows:

1. Dispersion is localized near

the impeller in regions of high

shear; practically no dispersion

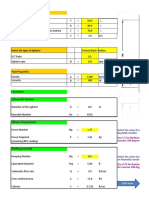

Table 1. Rules for scaling-up similar vessels under

turbulent conditions

NDX =Constant

Value of X

Rules

Processes

Constant tip speed,

constant torque/volume

Same maximum shear,

simple blending

0.85

Solids suspension

Used in Zweitering

equation for Nis, for

easily suspended solids

0.75

Solids suspension

Scale-up of average solids

suspensions

0.S7

Power/volume

Suspension of fast-settling

slurries, turbulent

dispersion, gas-liquid

operations where kLa's

must be scaled,

refctions requiring

micromixing

0.5

Constant Reynolds

number

Similar heat transfer,

equal viscous/inertial

forces

0.0

Constant speed

Equal mixing time, fast

reactions

..

Note: Using these rules for scale-up requires a Reynolds number greater than 10',

and geometry of similar proportions.

28

JUNE 1991

CHEMICAL ENGINEERING PROGRESS

occurs elsewhere. except initiallv.

2. Coalescence occurs e,ery

where drop colli~ions can OCCllr.

3. Circulation times increase

greatly in large 'e,sels.

The net effect of these three f~\Ctr)r\

is that dispersion dominates in sma! l

scale equipment and coalescem:c

dominates in large-scale. commer

cial equipment.

.

Solid-liquid dispersiolls com

monly involve the suspension of

solids' that are more dense than the

suspending phase. A reliable way to

predict how much agitation is need

ed to suspend solids is provided b:

the Zweitering equation (5;:

i.;N = [5 VO I d ~.: (g/).nlpp4~ X<),I3] I

.

.-DO.X5

"Iiu

where: N., represents revolutions per

second; isa constant that depends

on the selected impeller, its diameter

ratio. and bottom clearance: v is the

~ kinematic viscosit,. m 2/sec; d is the

~' mean particle size, m; D "is tht

impeller diameter. m; X is the per

centage of solids: (gt::.plp) is the

gravitational constant times the den

sity difference di\ided by the liquid

density. mlsec:::'

The just-suspended criterion is

good for dissolving solids. but it is

inadequate if homogeneity is

required; see Table 1 for recommen

dations for homogeneous suspension.

A more difficult. and less studied.

problem is the one of predicting the

N for solids less dense than the sus

pgnding fluid. In this case, the free

surface does not provide efficient

geometry for flow reversal compared

to the curved bottom of a tank. An

effective solution for the case of

floating solids is to place a second

impeller close to the free surface to

help disperse tloating solids. This ini

tiates suspension. and the second

impeller provides needed unifonnity.

An example for !loating solids is

a process to produce foaming-in

place beads. The process involved

adding cylindri,'ai thermoplastic

polymer granules ll1 hOI water con

taining an antil'oagulanl. A foaming

or blowing agent was added. and the

contents were heated to above the

glass-transition temperature. The

granules changed from cylindrical to

spherical particlc~ during the heating

:'1

:I

en'le. Batches were cooled to ambi

tcmperatures. vented to remove

C " , ; flammable blowing agen!.

;lIll. ,11en inspected prior to being

!ran~ferred out of the rolymerizeL

In~pcction~ provided a rough quality

l'heck. Suspension conditions in the

reactor were never ideal. as evi

denced by c~usting on the walls. baf

tle. impeller. and shaft.

On one occasion. conditions at the

end of the cycle were different. and

the beads were stickier than usual.

As the operator began his customary

inspection. he was greeted with a

surge of water, beads. and blowing

agent coming out of the manway. A

spark of unknown origin ignited the

tlammable mixture. and the entire

plant was engulfed in flames.

Fortunately. no one was hun. but the

process was never operated again.

A suspension failure had

occurred. causing massive agglomer

ation to take place. This agglomerat

ed material formed a solid layer

bridging the top surface of the liquid.

as shown in Figure 5. Venting had

only reduced pressure in the head

<-'tee above the crust layer, not

bw it. As the crust layer broke,

pressure from below forced the con

tents out through the opening.

Agitation had failed to provide ade

quate surface movement to assist in

stabilization of the panicles. The

impeller and baffle designs were

inadequate for this application.

Research showed that beads near

the top surface needed to be kept in

motion. to constantly wet and renew

the suspending agen!. When stag

nant conditions existed. water

drainage and agent suspension

occurred and led to interbead adhe

sion. In this prolonged plasticized

condition. the integrity of the beads

was lost. and a continuous polymer

bridge was formed across the sur

face of the contents. The level of liq

uid above the impeller is very criti

cal in marginal cases of floating

suspensions. and it may have been

the cause of the failure. although this

is not certain.

Agitation requirements in crystal

lization processes involve suspend

'g solids in liquids, providing low

lear (so as not to fral..'llIre the crys

tals). and supplying sufficient blend-

the entry point for diluent addition.

If diluenh are intniduccd near the

intake of the impeller. uniformity

can often be reachl.'d in time, ,hort

enou!!h to allow crystal !.!rowth to

domi~ate over nucl~ati(ln~ Because

one of the biggest unknowns is

shear and its effect on cry~tah. vari

able-speed drives are commonly

used for tank crystallizers.

Coagulated

layer of beads

C;ll

V

V

'\

-- ,

'

-,"

...,J

Choosing an initial equipment

design

i

Figure 5. Conditioll of suspellsion

failure caused by poor surface mixing.

ing to minimize concentration and

temperature gradients. Process

needs are specific to the system.

The usual objective in scale up of

tank crystallizers is to produce

large. uniform crystals that can be

easily separated and washed.

Conditions of uniformity are more

difficult to attain in large vessels,

which tend to produce a broader,

finer population of crystals. This

makes subsequent processing more

difficult. If nonsolvents are used {O

"salt out" the crystals. the same

mixing phenomena are encountered.

There is one important difference

the rate of approach to uniformity

can be influenced by the location of

Approximately 75% of all new

installations use contoured or hydro

foil impellers because they produce

axial tlow and develop a more order

ly circulation pattern. create low

shear. and require less power than

traditional impellers. The effects on

flow pattern produced by these

hydrofoils are ,shown in Figure 6.

Most processes require these fea-,

tures. Installations needing high~

shear mixing often couple a high

shear turbine with a hydrofoil

impeller. thereby maintaining good

circulation while providing high

shear/turbulence.

The position of the impellers is

important. in part because the total

volume of liquid may change (usual

ly increase) during many processes.

More than one impeller can be used,

even for normally shaped vessels,

i.e.. where the ratio of tank height to

tank diameter (HIT) is 1.2. In partic

ular, paired hydrofoils offer advan

45 PST

,/

\ /

t, ,j

I

j.

. I

J

FOil/"

u0

Guv

Figllre 6. Dijlerences ill ol'em/lfloll' pallerlls hetweell a ./5_

pitclted-blade turbi/le al/{I a 1t,I'dmflJiI.

CHEMICAL ENGINEERING PROGRESS JUNE 1991

29

,,

I

MIXING

~--------------------~----~~

Big Eddies

tages - their di~charge pallerns

match rather than conflict. as in other

designs. A second impeller is helpful

for solids suspension to provide mix

ing even while draining the contents

of the vessel. The upper impeller of a

dual-impeller systel11 ,hould be posi

tioned at a diswnce of about half an

impeller diameter (Dl from the liquid

surface while introducing solids, and

even for entraining gas into the sys

tem. Normally. the upper turbine is

placed about one impeller diameter

from the surface.

The selection of the ratio of the

impeller diameter to diameter of the

tank (Din is also important. In

industrial applications. ratios from

0.25 to 0.65 are used for common

impellers, while larger ratios are

used for anchors, gates. and helical

types of impellers. If the process

requires flow rather than turbulence,

DfT ratios of 0.4 to 0.6 are chosen.

For micromixing and processes

requiring turbulence. DfT ratios of

0.25 to 0.35 would be selected and

impellers would be operated at high

er speeds than when flow is required.

The trend in solids suspension has

been to use smaller. higher speed

hydrofoil impellers. These produce a'1

coherent jet of liquid that impinges (

on the bottom of the tank. resulting

in effective suspension of solids and

resuspension of settled solids.

Although the Rushton turbine is

commonly referred to in publica

tions, it is rarely used now for new

industrial gas-liquid installations.

An improved design is the concave

disk, which resembles a Rushton but

has six concave, semicylindrical

blades facing the direcliun of move

ment. This provides excellent gas

dispersion. can handle much more

gas before flooding. and lIses less

power than the Rushton turbine. A

new hydrofoil with three wide blades

is also useful. It disperses gas effec

tively and has little tendency to

flood. even at high gas tllnv rales.

The four-blade, 45 c -pilch-blade

turbine is still used for systems of

moderately high viscosity. e.g .. those

up to 40.000 cPo It pnnides more

local shear than the ncw wide-blade

hydrofoil designs: the latll..' 1'. howev

er. supply more flow and a beller

pattern and u~c less energy. At sti 11

J

30

JUNE 1991

Vortex

Figure 7. Typical surface conditiolls: (A) Turbulellt large eddies promote good

surface mixi/lg; (B) Laminar conditiolls with large ce1ltral vortex - good for addi

tion; (C) Flat surface, IlOt recommended for chemical additions.

higher viscosities, particularly where

heat transfer is a problem, special

impellers - including anchor, gate.

nelical. and double-helical types

should be used. In cases where peri

odic sweeping by blades of vessel

walls facilitates heat transfer, these

impellers can be designed to come

very close to the walls (or, in some

cases. to actually scrape the walls).

Some detail is given by Ulbrecht and

Patterson (6).

Fluids up to 3,000-4,000 cP

require some degree of baffling. The "

standard configuration calls for four ~

baffles 90 apart with a width of

Til 0 or Til 2 and located T172 from

the tank wall. This arrangement

works well unless the presence of

solids or non-Newtonian behavior

leads to regions of stagnation.

Baffles placed midway between the

impeller tip and the vessel wall help

to eliminate problems of stagnation.

particularly for thixotropic slurries. ~

Full-length baffles sometimes lead to

problems because they create a rela

tively quiet. vortex-free surface- (

making it more difficult to entrain

solids, liquids, and even gases.

Baffles placed below the surface

allow the fOf-mation of a free vortex. ~

which assists the transfer of materi- :)

als into the vessel.

Careful consideration must be

given to locations or the entries and

exits in stirred vessels. Materials

arc often added directly to the free

surface to avoid using dip pipes.

whit.:h can beconle plugged. Ir the

reaction is fast, the free surface

must be turhulent to adequately

cope with reaction kinetics. To fore

CHEMICAL ENGINEERING PROGRESS

stall such problems. it generally is

preferable to add feed streams close

to the impeller inlet. Feed can some

times be added to the bottom of the

reactor where an impeller is usually

located. In continuous processing.

avoid placing the feed and exit

points near each other because this

leads to bypassing and distorts the

residence-time distribution.

Designs often make use of steady

bearings to help a\'oid mechanical

problems associated with the use of

long, thin shafts. If steady bearings

cannot be tolerated, however. an

alternative is to U$e a shorter. thicker

shaft and place the drive at the bot

tom of the vessel. Using bottom

drives eliminates clutter at the top of

the vessel and allo\\s more options.

Motionless (or in-line) mixers

should be considered as an alterna

tive to stirred vessel designs for cer

tain types of applications. Fast chem

ical reactions often are ideal

applications for motionless mixers.

Also. such mixers excel for applica

tions in which competing reactions

take place and backmixing must be

avoided. In-line mixers are also used

to improve heat transfer to exchang

ers and pipe walls. Simple distribu

tive mixing depends on the length of

the mixer and the number of ele

ments. Dispersive mixing. such as

drop sizing. depends not only on the

number of elements but also the

pressure drop and !low rate, which

rclate to energy dissipation.

An advantage of motionless mix

ing over stirred-\essel mixing is the

elimination of bypassing. All Iluids

pass through regions of uni form

I.

radial and axial mixing. whereas

lr

" in stirred vessels is random.

l~;i,,~'I'l11nOW can lead to a problem

. the process requires the intense

,;[xing found only in regions near

.he impeller. These differences

rn)hubly account for why in-line

mhers invariably scale up success

fulh. unlike stirred vessels, which

are ~)ften fraught with problems.

),lotionless mixers come in a

\'ariety of designs and are usually

made to fit inside standard pipe

,iZe5. Systems can be designed for

~ither laminar or turbulent mixing

applications.

Designs for in-line mixers are

based on the degree of nonmixing in

the feed and the desired degree of

mixing required for the product.

The quality of mixing is usually

expressed as the ratio of the stan

dard deviation (of unmi xedness of

an added species) in the feed to the

average composition. Mixing is

generally considered to be complete

","'hen this ratio is 0.05. This is

equhalent to the "95% mixed" con

di';(m often referred to in stirred

\ )1 technology. The length need

ed for the motionless mixer depends

on the type of mixer selected, the

initial state. and the final uniformity

specified. A comparison of types

can be found in Hamby et af. (5),

along with the design procedure. It

is also important to take pressure

drop into account. Efficient mixers

that appear to require ~port lengths

might also demand an excessive

pressure drop.

Testing the design

It is important to check all of the

process requirements to see how well

each has been met by the proposed

design. The checklist would include

the power to be used. the speed, the

gear box. and the ability to achieve

the required process result. Using

common sense also helps. An

impeller will certainly be inadequate

if it cannot produce sufficient upflow

velocity to overcome the solids set

tling velocity.

An opportunity exists til the time

('. '\ant st~rt-up to me~sure and doc

,

f.:t performance. 01 course, there

often is a ~lrong desire to begin pro

duction as Sl)on as possinle. If oper

aling management can be persuaded

to permit the validation of the

design. however. this will add to the

knowledge base and pay big divi

dends for future operation and

design. Routine testing is done with

water in the vessel. Speed, vibration.

and power draw (using a wattmeter)

are the first things to check.

An inspection of the liquid sur

face tells how effective the baffling

is and how easily materials can be

added to the surface of the fluid.

Figures 7A-C show typical surface

conditions. Large-scale. high-energy

eddies, Figure 7A, promote large

surface waves. A large central vortex

is shown in Figure 7B, while static

conditions are shown in Figure 7C.

Conditions in Figures 7A and Bean

be used effectively for adding reac

tants; faster mixing is achieved by

adding reactants to the impeller

region. Conditions shown in Figure

7C should never be used to add reac

tants to a vessel. A camcorder can

help to record motion, which can

serve as a valuable future reference.

Mixing times can be measured

by a conductivity probe placed

inside the vessel. The probe is con

nected to a high-speed recorder to

monitor changes in conductance

(and, hence, concentration). A trac

er, often salt water, is injected

while the vessel is in operation and

the conductivities are recorded, if

appropriate. Tests can be repeated

at different water levels and agita

tor speeds.

Draining the vessel is important

to see if mechanical problems occur

as the liquid passes through the

plane of the impeller.

geneous liquids). however. can often

be treated via rules. If truly simple

systems are involved in scale up.

consider the rules given in Table I.

which have proven succe\\ful in

our work.

2. Acceptance (~r eXiSlil1!{ condi

tions: Energy is often wasted when

scale up is based on undefined needs.

In the case of a fermentation process.

it was found that reducing the original

mixing energy by 60% did not change

the process performance.

3. Undue secrecy: Honest. com

petent equipment vendors can ,serve

as important resources in helping

you choose the most suitable mixer

design. if they are given adequate

information. Secrecy is important,

but harm can result when only

selected information is provided.

4. Rigidity about flexibilit}:

System demands sometimes are too

broad for anyone design to handle

well. For instance, a single \es.sel

may have to serve as a blend tank. a

polymerizer, a devolatilizer. and

even a crystallizer. It would be

remarkable if any design could serve

each of those requirements equally

well. Therefore, it is essential to

assess the trade-offs between flexi

bility

and

performance.

Occasionally, particularly at small,

remote sites, multi task designs must

be used regardless of consequences.

Mixing is still largely an art. but

it is becoming more scientific. In the

future. quantitative tools such as

computational fluid dynamics

should provide a better link between

8D

design and performance.

Literature Cited.

"

Other pitfalls

Engineers also should guard

against the following common traps

for the unwary in the scale up of

mixing.

1.

Reliance

on

rules:

Preoccupation with scale-up rules

e.g.. "constant tip speed." "constant

power per unit volume," or "constant

torque per unit volume" - usually

means the engineer wanls an easy

answer. Depending on rules often

creates problems because rules trun

cate thinking. Simple mixing (slich

as the blending of nnnrc:li.ting homo

",-,'J

1. Oldshue; J. y.P."Fluid Mixing',

Technology," p.191, .;!,Vt.cGraw-HiIl, Ne~ ~~

York (1983).

.,:,:".J . . '.. .,

'2. Cutter,

A.,

p. 35~

L.

AiChllJ.. 12;

'(1966).

.

.:;1\'"

.; .' iij

.3. Angst, W., J. R~ Bourne, and P.",'

Dell'ava, Chem. Eng:.Sci .. 39

335,~

(1984).

~l~;,~.:.. . .

.

'. :~

4. Leng, D. E., and G. J~. Quarderer, 'i

Chern. Eng. Commun.,.. ~4, p. 177 (982).:;;

S. Hamby, N., M. F; Edwards, and A.;:

W. Nienow, "Mixing in the Proces(~

Industries," p. '226. 306. Bulterworths.~

Woburn. MA (1985). ;i,i

,

.l'~

.~ ,: Ulbrecht. J. J., a~d G. K. Patterson;'~

'. UMixing of Liquids 'by Mechanical ..;

. Agitation." p. 93, Goro,o", & Breach. New::!

_ '~'A

. York (I985)..,.,~" .

p:

CHEMICAL ENGINEERING PROGRESS JUNE 1991

31

Вам также может понравиться

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsОт EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilОценок пока нет

- Batch and Semi-batch Reactors: Practical Guides in Chemical EngineeringОт EverandBatch and Semi-batch Reactors: Practical Guides in Chemical EngineeringОценок пока нет

- August 2013Документ62 страницыAugust 2013ceshesolОценок пока нет

- Best Practice For Pilot Plant LayoutДокумент10 страницBest Practice For Pilot Plant LayoutRashesh ShahОценок пока нет

- The Unexpected Benefits of Testing Custom Mixers and BlendersДокумент4 страницыThe Unexpected Benefits of Testing Custom Mixers and BlendersJoshua JohnsonОценок пока нет

- Chemical Engineering Magazine, March 2015Документ104 страницыChemical Engineering Magazine, March 2015altamirano21Оценок пока нет

- Scaba Kevero enДокумент12 страницScaba Kevero enSuphi YükselОценок пока нет

- Reactor Design Scale UpДокумент9 страницReactor Design Scale UpMarcel ChevalierОценок пока нет

- Chemical Reactor DesignДокумент620 страницChemical Reactor DesignBellota03100% (2)

- Scale UpДокумент53 страницыScale UpAnonymous thMg61100% (1)

- Reactor DesignДокумент27 страницReactor Designcheckmeout803100% (3)

- Fraser Papers Solves Sludge Problems with Bubbling Fluidized Bed BoilerДокумент6 страницFraser Papers Solves Sludge Problems with Bubbling Fluidized Bed BoilermagtrolОценок пока нет

- Scale Up of Chemical ReactorsДокумент51 страницаScale Up of Chemical ReactorsMilton MizrainОценок пока нет

- Mixing CalculationДокумент31 страницаMixing CalculationTubagus100% (1)

- Film Evaporation TechnologyДокумент12 страницFilm Evaporation TechnologyAditya Bayu SalaksaОценок пока нет

- Reactor Design Scale UpДокумент9 страницReactor Design Scale UpEntropay UserОценок пока нет

- February 2014Документ68 страницFebruary 2014jpsi6Оценок пока нет

- May 2016 - International PDFДокумент104 страницыMay 2016 - International PDFBánh Cuốn Tôm ThịtОценок пока нет

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7От EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Оценок пока нет

- Scaled Up Process DirectlyДокумент8 страницScaled Up Process DirectlyAnonymous 1XHScfCIОценок пока нет

- Vacuum System: Plant Engineer OleochemicalДокумент55 страницVacuum System: Plant Engineer OleochemicalMahendra Puguh100% (2)

- Plant Engineers Guide To Agitation Design and FundamentalsДокумент33 страницыPlant Engineers Guide To Agitation Design and FundamentalsMark MacIntyre100% (1)

- Flexitallic Products PDFДокумент108 страницFlexitallic Products PDFNguyễn Xuân NamОценок пока нет

- FILTRATION MODELS AND EQUIPMENTДокумент66 страницFILTRATION MODELS AND EQUIPMENTCana DeОценок пока нет

- Design of Stirred Batch ReactorДокумент39 страницDesign of Stirred Batch ReactorSyahir Safarudin100% (3)

- Design Principles for Robert EvaporatorsДокумент16 страницDesign Principles for Robert EvaporatorsHede HödöОценок пока нет

- Unsteady CSTRs and Semibatch ReactorsДокумент8 страницUnsteady CSTRs and Semibatch ReactorssiegherrОценок пока нет

- Chemical Reactor Analysis and Applications for the Practicing EngineerОт EverandChemical Reactor Analysis and Applications for the Practicing EngineerОценок пока нет

- Wood BoilerДокумент59 страницWood BoilerRoberto ScheferОценок пока нет

- Manufacturing Process Scale-Up in The Personal Care Industry Problems and Solutions PDFДокумент4 страницыManufacturing Process Scale-Up in The Personal Care Industry Problems and Solutions PDFNindya IndahОценок пока нет

- Agitated Vessel Heat Transfer (K.J. Carpenter)Документ9 страницAgitated Vessel Heat Transfer (K.J. Carpenter)Clarence AG Yue100% (2)

- Small Mistakes Can Mean Big Success in Mixing Scale-UpДокумент39 страницSmall Mistakes Can Mean Big Success in Mixing Scale-UpSteve Wan100% (1)

- Ion Exchange TechnologyОт EverandIon Exchange TechnologyF. C. NachodОценок пока нет

- Pyrolysis of Mixed Polymers ReviewДокумент21 страницаPyrolysis of Mixed Polymers ReviewDoug OhnemusОценок пока нет

- (Marko Zlokarnik) Scale-Up in Chemical EngineeringДокумент9 страниц(Marko Zlokarnik) Scale-Up in Chemical EngineeringakilaprabuОценок пока нет

- How To Minimise Scaleup DifficultiesДокумент6 страницHow To Minimise Scaleup Difficultieskishore.charuОценок пока нет

- (2006, DUGAS) - Dissertação BaseДокумент145 страниц(2006, DUGAS) - Dissertação BaseSuênia FernandesОценок пока нет

- Refining Process HBДокумент296 страницRefining Process HBsomucdm6023Оценок пока нет

- Reactor Geometry and Agitator SelectionДокумент26 страницReactor Geometry and Agitator SelectionChemical Engineering100% (2)

- Turbulence in Mixing Operations: Theory and Application to Mixing and ReactionОт EverandTurbulence in Mixing Operations: Theory and Application to Mixing and ReactionRobert BrodkeyОценок пока нет

- Turflow Heat Exchanger High Efficiency Heat Transfer Solution-Sales BrochureДокумент8 страницTurflow Heat Exchanger High Efficiency Heat Transfer Solution-Sales BrochurePablo Angel ToiaОценок пока нет

- Design and Scheduling of Batch Processess PDFДокумент23 страницыDesign and Scheduling of Batch Processess PDFjokishОценок пока нет

- Chemical Process Equipment Selection and DesignДокумент7 страницChemical Process Equipment Selection and DesignMohammad KhОценок пока нет

- Computational Multiphase Flow ThesisДокумент299 страницComputational Multiphase Flow ThesisDeepak K NambiarОценок пока нет

- CheIng - June 2010 PDFДокумент68 страницCheIng - June 2010 PDFErvin WatzlawekОценок пока нет

- Enthalpy of Dilution of AcidsДокумент1 страницаEnthalpy of Dilution of AcidswidhisaputrawijayaОценок пока нет

- Chapter 4 Reactor DesignДокумент16 страницChapter 4 Reactor DesignAli AhsanОценок пока нет

- Mixing - Succeed at Scale UpДокумент9 страницMixing - Succeed at Scale UpVivian Fam100% (1)

- Agitation & Mixing of FluidsДокумент20 страницAgitation & Mixing of Fluidsmarkbene69Оценок пока нет

- Unit Operations Thumb RulesДокумент9 страницUnit Operations Thumb RuleshibhavuОценок пока нет

- Heat Transfer in Agitated VesselsДокумент33 страницыHeat Transfer in Agitated VesselsGanesh.Mahendra100% (1)

- Simulated Moving Bed Technology: Principles, Design and Process ApplicationsОт EverandSimulated Moving Bed Technology: Principles, Design and Process ApplicationsОценок пока нет

- Process Plant Equipment: Operation, Control, and ReliabilityОт EverandProcess Plant Equipment: Operation, Control, and ReliabilityРейтинг: 5 из 5 звезд5/5 (1)

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОт EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОценок пока нет

- P1499 104Документ0 страницP1499 104hasn5Оценок пока нет

- Pack Column Hetp PDFДокумент29 страницPack Column Hetp PDFMayurShindeОценок пока нет

- Top 21 Papers-TalkДокумент38 страницTop 21 Papers-Talklaser67Оценок пока нет

- Dimple Jacket Heat Transfer EstimationДокумент3 страницыDimple Jacket Heat Transfer EstimationicingrockОценок пока нет

- Minimize Scaleup Difficulties PDFДокумент6 страницMinimize Scaleup Difficulties PDFWillaОценок пока нет

- Dimple Jacket Heat Transfer Estimation PDFДокумент3 страницыDimple Jacket Heat Transfer Estimation PDFicingrockОценок пока нет

- Moshe Article PDFДокумент16 страницMoshe Article PDFicingrockОценок пока нет

- Chemical Engineering World - February 2016Документ64 страницыChemical Engineering World - February 2016icingrock100% (1)

- Selecting Right ImpellerДокумент7 страницSelecting Right Impellericingrock100% (2)

- Chemical Engineering MagazineДокумент11 страницChemical Engineering MagazineicingrockОценок пока нет

- Helical Ribbon ReactorДокумент17 страницHelical Ribbon ReactoricingrockОценок пока нет

- Power Requirement With HR AgitatorДокумент8 страницPower Requirement With HR AgitatoricingrockОценок пока нет

- ch3Документ55 страницch3icingrockОценок пока нет

- What Does Well Mixed MeanДокумент26 страницWhat Does Well Mixed MeanicingrockОценок пока нет

- A01 269Документ11 страницA01 269icingrockОценок пока нет

- Using Density 12MFДокумент3 страницыUsing Density 12MFM Ahmed LatifОценок пока нет

- Mechanical Design Aspects for High-Performance Agitated ReactorsДокумент11 страницMechanical Design Aspects for High-Performance Agitated ReactorsgpcshfОценок пока нет

- Moshe Article PDFДокумент16 страницMoshe Article PDFicingrockОценок пока нет

- Impeller TrimmingДокумент1 страницаImpeller TrimmingicingrockОценок пока нет

- Chm055a PDFДокумент314 страницChm055a PDFicingrockОценок пока нет

- Chemical Engineering Jun 2013 120, 6 ProquestДокумент4 страницыChemical Engineering Jun 2013 120, 6 ProquesticingrockОценок пока нет

- ch1Документ20 страницch1icingrockОценок пока нет

- A01 269Документ11 страницA01 269icingrockОценок пока нет

- Head Loss in Piping Systems: The Laws of NatureДокумент6 страницHead Loss in Piping Systems: The Laws of Natureqasim zaheerОценок пока нет

- Multi Stage BlowersДокумент12 страницMulti Stage BlowersicingrockОценок пока нет

- Air Leak TestДокумент5 страницAir Leak TestKiran KrishnanОценок пока нет

- Spencer CompressorДокумент20 страницSpencer Compressoricingrock100% (1)

- Protect Centrifugal Pumps From Low Flows PDFДокумент12 страницProtect Centrifugal Pumps From Low Flows PDFicingrockОценок пока нет

- Designing Piping For Gravity Flow PDFДокумент4 страницыDesigning Piping For Gravity Flow PDFicingrock100% (2)

- Assessing Student Learning OutcomesДокумент20 страницAssessing Student Learning Outcomesapi-619738021Оценок пока нет

- Agitators: Robert L. Bates, President Chemineer, IncДокумент24 страницыAgitators: Robert L. Bates, President Chemineer, InctenshinomiyukiОценок пока нет

- Digital Burner Controller: Tbc2800 SeriesДокумент4 страницыDigital Burner Controller: Tbc2800 SeriesSUDIP MONDALОценок пока нет

- Analogue Lab Manual AL7212 V2.1-Panduan Praktek DSR Elektronika-DikonversiДокумент235 страницAnalogue Lab Manual AL7212 V2.1-Panduan Praktek DSR Elektronika-DikonversiAl-FarabiОценок пока нет

- Hematology NotesДокумент3 страницыHematology NotesFarisa Jane BanggoОценок пока нет

- Larong Lahi Week 15 18Документ7 страницLarong Lahi Week 15 18CJAY SOTELOОценок пока нет

- Rumi and ReligionДокумент2 страницыRumi and ReligionJustin LiewОценок пока нет

- Hearing God Through Biblical Meditation - 1 PDFДокумент20 страницHearing God Through Biblical Meditation - 1 PDFAlexander PeñaОценок пока нет

- Perbandingan Penggunaan Refrigeran R22 Dengan R407 Pada Performa ACДокумент15 страницPerbandingan Penggunaan Refrigeran R22 Dengan R407 Pada Performa ACYuli RahmawatiОценок пока нет

- Joy Difuntorum-Ramirez CVДокумент2 страницыJoy Difuntorum-Ramirez CVJojoi N JecahОценок пока нет

- Vivaldi - Genuis of BaroqueДокумент279 страницVivaldi - Genuis of Baroqueilcanto100% (4)

- ENVPEP1412003Документ5 страницENVPEP1412003south adventureОценок пока нет

- IntegrityДокумент5 страницIntegrityPritam Kumar100% (1)

- Uc 3525 AДокумент17 страницUc 3525 AespaguetesОценок пока нет

- Ips 350:400:450:500:600 07:05 PDFДокумент124 страницыIps 350:400:450:500:600 07:05 PDFRandall PettersonОценок пока нет

- Money MBA 1Документ4 страницыMoney MBA 1neaman_ahmed0% (1)

- 3 - 6consctructing Probability Distributions CG A - 4 - 6 Lesson 2Документ24 страницы3 - 6consctructing Probability Distributions CG A - 4 - 6 Lesson 2CHARLYN JOY SUMALINOGОценок пока нет

- Liugong 938 Wheel Loader Parts ManualДокумент20 страницLiugong 938 Wheel Loader Parts Manualjonathan100% (49)

- Fancy YarnsДокумент7 страницFancy Yarnsiriarn100% (1)

- Differentiation SS2Документ88 страницDifferentiation SS2merezemenike272Оценок пока нет

- AWS S3 Interview QuestionsДокумент4 страницыAWS S3 Interview QuestionsHarsha KasireddyОценок пока нет

- Pankaj Screener 10 Oct 2014Документ127 страницPankaj Screener 10 Oct 2014Sadul Singh Naruka100% (1)

- PoiconverterДокумент2 страницыPoiconvertertaco6541Оценок пока нет

- Applied Physics Mini Launcher Lab ReportДокумент12 страницApplied Physics Mini Launcher Lab ReportTalharashid RamzanОценок пока нет

- Readme cljM880fw 2305076 518488 PDFДокумент37 страницReadme cljM880fw 2305076 518488 PDFjuan carlos MalagonОценок пока нет

- PSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipДокумент4 страницыPSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipAfees OlajideОценок пока нет

- Timoshenko Beam TheoryДокумент8 страницTimoshenko Beam Theoryksheikh777Оценок пока нет

- Introduction To Managerial Accounting Canadian 5th Edition Brewer Solutions ManualДокумент25 страницIntroduction To Managerial Accounting Canadian 5th Edition Brewer Solutions ManualMaryJohnsonsmni100% (57)

- LaQshya Labour Room Quality Improvement InitiativeДокумент2 страницыLaQshya Labour Room Quality Improvement InitiativeHimanshu SharmaОценок пока нет

- MEC332-MA 3rd Sem - Development EconomicsДокумент9 страницMEC332-MA 3rd Sem - Development EconomicsRITUPARNA KASHYAP 2239239Оценок пока нет