Академический Документы

Профессиональный Документы

Культура Документы

Corrosion Behavior of Materials in RO Water Containing 250-350 PPM Chloride

Загружено:

jperdigon9634Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Corrosion Behavior of Materials in RO Water Containing 250-350 PPM Chloride

Загружено:

jperdigon9634Авторское право:

Доступные форматы

Desalination 196 (2006) 149159

Corrosion behavior of materials in RO water containing

250350 ppm chloride

A.U. Malika*, I. N. Andijania, M. Mobina, S. Ahmadb

a

Research & Development Center, Saline Water Conversion Corporation,

P.O.Box 8328, Al-Jubail 31951, Saudi Arabia

Tel. +966 (3) 3433477; Fax +966 (3) 3431615; email: rdc@swcc.gov.sa

b

SABIC Technology Center, Al-Jubail, Saudi Arabia

Received 24 October 2005; accepted 5 December 2005

Abstract

Reverse osmosis (RO) water constitutes about 22% of total desalinated water produced in the world. The rest of

the desalinated water is almost entirely from thermal distillation, such as multistage flash (MSF) evaporation and

multi-effect desalination (MED) techniques. The RO permeate is more corrosive than water produced by thermal

distillation due to its high dissolved salts (TDS) level, particularly chlorides. As the RO water is transported through

cementitious or polymer lined pipelines, steel components like pumps, valves and pipes are likely to corrode, if

proper material selection is not made. Not much information is available regarding the corrosion behavior of RO

water towards the metallic materials particularly steels which forms the bulk of constructional materials. A study

has been conducted to investigate the corrosion behavior of some structural materials which include carbon steel

1018, electroless nickel plated carbon steel 1018 ENP, austenitic stainless steel AISI 304, and martensitic stainless

steels AISI 410, AISI 420 and AISI 431 in RO water. These materials have been the main constructional materials

used in metallic components of pipelines in Saudi Arabia. Studies have been carried out under dynamic conditions

(impingement under flow), static conditions (crevice formers) and in presence of an inhibitor (phosphate) using a

dynamic test loop. High chromium steels (>15% Cr) appear to provide good resistance where as low chromium

steels (<15% Cr) exhibit generally poor resistance under the above mentioned test conditions.

Keywords: Reverse osmosis; Multistage flash evaporation; Stainless steels; Corrosion; Internally lined steel pipe;

Impingement; Crevice former; Phosphate dosing

*Corresponding author.

Presented at the IDA World Congress on Desalination and Water Reuse, September 11-16, 2005, Singapore.

0011-9164/06/$ See front matter 2006 Elsevier B.V. All rights reserved.

doi:10.1016/j.desal.2005.12.010

150

A.U. Malik et al. / Desalination 196 (2006) 149159

1. Introduction

The multistage flash (MSF) process, involving

multistage distillation of seawater at low pressure,

and reverse osmosis (RO) based on the separation

of fresh water from seawater through a semi-permeable membrane under high pressure, are the

two main industrial processes used for the desalination in the Middle East. The materials on the

inlet side of the RO module are exposed to seawater feed with a total dissolved solids (TDS) in

excess of 45,000 ppm, while those on the outlet

side are exposed to a product water stream with a

TDS of about 500 ppm and a reject brine stream

containing TDS around 60,000 ppm. This high

TDS RO product water is much more corrosive

than MSF product water which has a TDS of about

10 ppm. The chloride content in water plays a predominant role in imparting corrosivity. The desalinated water which is used as the potable water

is transported through a network of internally

cement lined or polymer coated pipelines. The RO

product water in pipelines, when comes into contact with pumps, valves or other metallic components, has the capability to corrode these components. A survey of the literature indicates that

although numerous references are available on

corrosion-resistant materials related to MSF product

water but only limited references are available on

such materials related to RO product water [17].

Therefore, a study concerning with the corrosion

behavior of RO product water containing high

TDS with chloride content up to 350 ppm, is important for selecting the right material for pipelines

transporting RO product water.

A wide variety of constructional materials have

been used in the pumps, valves and other equipment in a recently built 450 km long internally

cement lined steel pipeline transporting RO product water. In this study, tests have been carried

out on six typical materials which are mainly used

in the construction of pipeline and water pumping

equipment. The materials include: carbon steel

1018 (CS 1018), electroless nickel plated carbon

steel containing 30 m thick plating of Ni metal

(1018 ENP), austenitic stainless steel AISI 304

SS and martensitic stainless steels, AISI 410 SS,

AISI 420 SS and AISI 431 SS. The experimental

studies include: (i) Corrosion resistance test under

operating conditions (ii) Corrosion resistance test

under shutdown conditions and (iii) Effect of

phosphate dosing.

2. Experimental procedures

CS 1018, 1018 ENP, martensitic chromium

stainless steels namely AISI 410 SS, AISI 420 SS

and AISI 431 SS and austenitic stainless steel AISI

304 SS were used during the experiment. The chemical composition of the alloys used in the testing

program is given in Table 1.

Tests were carried out on 4 types of de-aerated

water, namely (a) LLW (lower limit water) and

(b) ULW (upper limit water); representing lower

and upper limits of dissolved solids in water, respectively and (c) and (d) the waters containing

zinc hexameta phosphate (ZHMP) in LLW and

ULW, respectively. The composition of LLW and

ULW is shown in Table 2.

Electrochemical polarization studies were carried

out using a computer controlled EG&G model 273

EG&G Potentiostat. The experiments were carried

out using corrosion cell (model K0047) with saturated calomel, graphite and epoxy mounted metal

sample as reference, counter and working electrodes, respectively. The details of the experimental set up are given previously [8]. After stabilization of rest potential (Ecorr), the scan was taken

at the rate of 10 mV/min in the range of 250 mV

to +200 mV vs. Ecorr. From each curve, the rest

potential, Ecorr, the potential at which the current

passed through a value of zero during the sweep

and bc, the Tafel slope of cathodic hydrogen part

of the curve were recorded automatically.

Multiple crevice assemblies which were used

in the present test had a 30 mm OD and 20 mm

ID, thus producing a 5 mm annular crevice site.

The whole assembly was torqued to 10 N/mm2

force between crevice former assembly and the

sample.

A.U. Malik et al. / Desalination 196 (2006) 149159

151

Table 1

Chemical composition of the alloys used in testing program

S..# Alloy

AISI type UNS No.

%C

% Cr

% Ni

Carbon steel

CS 1018

0.25 max.

0.5 max.

Electroless nickel plated carbon

steel*

Austenitic stainless steel

Martensitic chromium stainless

steel

Martensitic chromium stainless

steel

Martensitic chromium stainless

steel

1018 ENP

0.5 max. Cu 0.3 max.

Si 0.6 max.

304SS

410SS

S30400

S41000

0.08 max.

0.15 max.

1820

11.513.5

812

420SS

S42000

0.350.45 max. 1214

0.5 max.

431SS

S43100

0.2 max.

1.252.5

3

4

5

6

J2503

1517

Other elements

*30 m thick plating of Nickel metal on carbon steel

Table 2

Composition of RO waters used in testing program

Parameters

RO waters

LLW

ULW

Sodium (ppm) 160

Chloride (ppm) 250

Sulfate (ppm)

14

pH

8.5

225

350

20

8.5

Jet impingement test (JIT) was performed

using a Cortest jet impingement test apparatus

(JITA). Using JITA, samples were tested simultaneously using 2 numbers of plenums. The samples were attached to the plenums (Fig. 1). Each

plenum chamber consists of 12 nozzle ports with

1 mm diameter orifice, thus allowing 24 numbers

of samples to be tested in each test. The plenums

were constructed totally from titanium. During the

test the plenums were submerged in test solution

tank with a capacity of 100 L. The test solution

Fig. 1. Photographs of plenum used for testing of samples in JITA.

152

A.U. Malik et al. / Desalination 196 (2006) 149159

temperature was controlled by a heater-chiller unit

provided with JITA. Table 3 shows conditions

under which JIT were carried out. After completion of JIT the plenums were taken out from

the test solution; the samples were detached from

the plenums and subjected to thorough examination. The corrosion rates of the alloys were measured by weight loss technique using standard formula [7]. The radius of impingement (RI) and

depth of impingement (DI) were measured using

a calibrated microscope.

A close circuit re-circulation dynamic test loop

(DTL) was used to carry out the tests as per ASTM

designation G 31-72 (re-approved 1990) for weight

loss under dynamic conditions. Flow diagram of

DTL system is shown in Fig. 2. Five samples were

fixed at a time in each coupon holder. The test

velocity was varied by varying the test coupon

holder diameter and flow rate of loop. The test

loop had a facility to monitor inlet and outlet pressures, temperature and flow rate on continuous

basis. Online data monitoring of the system was

carried out. Coupons were fixed in the two holders

for 14 and 28 day duration tests, respectively. The

corrosion rate was calculated following weight

loss technique [7]. Table 4 lists the parameters

which were maintained during the operation of

DTL.

Table 3

Test conditions for jet impingement tests

Test Test medium

No.

1

2

3

Temperature

(C)

ULW

35

ULW

50

ULW+2 ppm ZHMP 35

Velocity

(m/s)

No. of samples

Test period

(d)

10

10

10

2 sets of 12 each

2 sets of 12 each

2 sets of 12 each

14 and 28

14 and 28

14 and 28

Fig. 2. Flow diagram of dynamic test loop. CH = coupon holder; PG = pressure gauge; FM = flow meter; TI = temperature

indicator; V = valve; P = pump.

A.U. Malik et al. / Desalination 196 (2006) 149159

153

Table 4

Dynamic test loop operation

Test #

Mean temperature

(C)

Inlet pressure

(bar)

Average flow rate

(m3/h)

Average velocity

(m/s)

ZHMP

(ppm)

1

2

3

39.6

43.5

43.8

2.0

2.0

2.0

68.5

68.4

68.4

4.0

4.0

4.0

0

2

15

Table 5

JIT results

Alloy

Test

solution

Temp.

(C)

CR

(mpy)

Test

solution

Temp.

(C)

CR

(mpy)

Test

solution

Temp.

(C)

CR

(mpy)

1018

ULW

50

29

ULW

35

28.0

35

6.0

1018 ENP

304 SS

410 SS

420 SS

431 SS

1.3

0

5.3

1.7

0

1.1

0

4.8

1.1

0

ULW +

2% ZHMP

1.0

0

0.4

0.1

0

3. Results and discussion

3.1. Testing under dynamic conditions

To generate data relevant to corrosion resistance under operating conditions, JIT was carried

out. In the JIT, a flow induced localized corrosion

would occur when metals and alloys are subjected

to water jets of specified velocity. Velocity has a

major role in inducing corrosion. During JIT, the

corrosion process is accelerated by the removal

of protective corrosion products layer on the metal

surface by the action of shear stress and turbulence

of fluid flow. This would result in direct exposure

of base metal to environmental agent and accelerate the metal dissolution. Tests were carried out

at two temperatures namely, 35C and 50C (the

temperature range expected in the transmission

lines) and at a velocity of 10 m/s representing

velocity of flow normally encountered at the

immediate vicinity of pump outlets of transmission lines. The alloys 304 SS and 431 SS did not

show any corrosion at both the temperatures and

test period of 14 and 28 days. CS 1018 showed

the highest corrosion rate followed by 410 SS,

420 SS and ENP 108. The corrosion rates of the

alloys after 28 day tests were found higher than

those tested for 14 days. The increase of temperature from 35C to 50C slightly increased the corrosion rates of the alloys (Table 5).

The effect of velocity was analyzed in terms

of extent of corrosion by the measurement of depth

of impingement attack (DI) as a function of radius

of impingement (RI). The results indicate that only

carbon steel was susceptible to impingement corrosion (Table 6), however, the extent of corrosion

was not significant. Other materials were free from

impingement corrosion. All materials did show

impingement mark by way of stains and except

carbon steel none of the materials had any evidence of material loss due to erosion corrosion

(depth of impingement attack = 0).

The effect of phosphate dosing on the corrosion

154

A.U. Malik et al. / Desalination 196 (2006) 149159

Table 6

Radius of impingement (RI) and depth of impingement (DI) data in RO waters

Test media temp. ULW 50C

parameter

ULW 35C

ULW + 2 ppm phosphate

35C

Alloy

RI (mm)

DI (mm)

RI (mm)

DI (mm)

RI (mm)

DI (mm)

1018

1018 ENP

304 SS

410 SS

420 SS

431 SS

35

25

20

30

1

15

0.31

0

0

0

0

0

30

30

30

15

1

20

0.6

0

0

0

0

0

15

16.5

1

1

1

1

0

0

0

0

0

0

rates of carbon steel and 410 SS was quite pronounced. The corrosion due to impingement was

significantly lowered because of the inhibitive

effect of phosphate.

3.2. Testing under shut down conditions

The studies were carried out to determine the

corrosion resistance of the materials under shut

down condition when water is stagnant in the

pipeline. Two methods were employed to investigate corrosion resistance under shut down condition namely, electrochemical polarization and crevice corrosion test using multiple crevice assembly.

Potentiodynamic cyclic polarization tests have

been successfully used to determine the materials

pitting susceptibility on the basis of pitting potential, Epit and protection potential, Eprot. Epit is the

potential at which a consistent increase in current

density occurs, indicating the initiation of nonrepassivating pits. Eprot is defined as the potential

where the forward and reverse scan cross or current reaches a value of 2 A/cm2 and considered

as most active potential at which pit propagation

can occur. A noble value of pitting potential is

taken to indicate a high resistance of material to

pitting. Tests were carried out at 20C and 45C.

Typical Tafel plots are shown in Figs. 36. There

are two important features of the Tafel plots: on

inhibition, corrosion current, Icorr was shifted to

lower value and corrosion potential, Ecorr was

shifted to more noble value indicating the positive

role played by the phosphate in inhibiting the

corrosion reaction. Figs. 79 show some typical

cyclic polarization curves for steels in presence

of ULW water with or without addition of phosphate. In general, Epit shifts to more negative (or

active) potential with increase in chloride concentration (Table 7). Cyclic polarization curves for

1018 ENP do not exhibit a well defined Epit in

LLW or ULW but addition of phosphate provided

inhibiting effect by showing improved pitting resistance (Fig. 7). The pitting susceptibility is generally observed for rest of the materials. The most

resistant material was found to be 304 SS in all

test media (Table 7). Out of the three martensitic

chromium steels (namely, 410 SS, 420 SS and 431

SS), 431 SS had shown highest resistance to pitting followed by 420 SS and 410 SS in water containing no phosphate. Apart from 1018 ENP, the

inhibitive effect of phosphate appears to be negative, vis--vis Epit in all the alloys except 420 SS

in LLW and 431 SS in ULW.

Crevice exposure tests were carried out in stagnant solution to generate data on crevice corrosion

susceptibility of materials. In crevice exposure

tests, the susceptibility to crevice attack was determined in terms of maximum pit depth after exposure to crevices. The resistance to crevice attack

by different alloys in water containing different

amount of chloride was also evaluated by maxi-

A.U. Malik et al. / Desalination 196 (2006) 149159

155

Inhibited

inhibited

LLW

Uninhibited

LLW

ULW

LLW

Fig. 4. Tafel plots of carbon steel in LLW solution at 20C

with and without corrosion inhibitor.

Fig. 3. Tafel plots of carbon steel in two different test

solutions at 20C.

20 oC

20o

45

C

Inhibited

LLW

inhibited

Uninhibited

LLW

45 C

Fig. 5. Tafel plots of SS 410 in LLW solution at 20 and

45C.

Fig. 6. Tafel plots of SS 420 in LLW solution at 20C

with and without corrosion inhibitor.

Table 7

Results obtained from cyclic polarization test under shut down conditions. Test solution pH = 8.5, at 45C in de-aerated

LLW and ULW with and without 2.0 ppm ZHMP

Alloys

410 SS

420 SS

431 SS

304 SS

1018 ENP

LLW, 45C

LLW, 45C + ZHMP

ULW, 45C

ULW, 45C + ZHMP

Ecorr

Epit

Eprot

Epit Eprot

Ecorr Epit

Eprot

Epit Eprot

Ecorr Epit

Eprot

Epit Eprot

Ecorr Epit

Eprot Epit

Eprot

783

802

748

765

485

12

185

390

465

20

590

582

531

315

195

578

767

921

780

175

771

790

738

753

448

594

600

532

331

334

534

803

884

764

662

793

799

762

788

440

619

533

456

242

583

593

719

580

791

809

764

780

325

625

600

447

326

60

203

352

433

153

36

60

263

388

22

36

61

425

344

259

589

539

872

670

156

A.U. Malik et al. / Desalination 196 (2006) 149159

Fig. 7. Cyclic polarization curves of 1018-ENP in deaerated ULW solutions with and without inhibitor at 45C.

Fig. 9. Cyclic polarization curves of SS 431 in de-aerated ULW solution with and without inhibitor at 45C.

mum pit depth. Multiple crevice assembly has

been used in the tests. Four types of water were

used in the crevice test at 45C for 30 days: (i)

ULW, (ii) LLW, (iii) ULW containing 2 ppm of

phosphate and (iv) LLW containing 2 ppm phosphate. The procedures followed in the tests were

as per ASTM G 7889 for crevice testing.

The alloys 304 SS and 1018 ENP did not show

any pitting and appeared to be free from crevice

corrosion attack in LLW and ULW (Table 8). The

Fig. 8. Cyclic polarization curves of 304 SS in de-aerated ULW solutions with and without inhibitor at 45C.

carbon steel showed high corrosion rates in both

LLW and ULW but in LLW there was no pitting.

It appeared that in high chloride medium, carbon

steel underwent pitting and showed significant

local attack. Alloy 420 SS showed maximum

pitting with highest pit depth in all the test

solutions; this was followed by 410 SS. The effect

of phosphate dosing is quite pronounced on the

corrosion behavior of carbon steel in both ULW

and LLW. The presence of phosphate in general,

had considerably reduced the overall corrosion

rates. Apart from CS 1018, alloys 304 SS, 431 SS

and 1018 ENP were found to be free from crevice

attack in phosphate medium. The alloy 420 SS

showed highest number of pits, however, depth

of attack was lower when compared to test without

phosphate addition (Table 8).

3.3. Effect of phosphate dosing (dynamic condition)

The effect of phosphate dosing on the corrosion

behavior of high chloride water (ULW) under dynamic conditions was studied using a recirculation

DTL as per ASTM designation G 3172 (reapproved 1990). The test solution, ULW, was

dosed sequentially with 0, 2 and 15 ppm ZHMP

with a flow velocity of 4 m/s. The duration of the

A.U. Malik et al. / Desalination 196 (2006) 149159

157

Table 8

Crevice test results at 45C

Alloy

Test solution

CR (mpy)

No. of pits

Max. pit depth (mm)

1018

1018 ENP

304 SS

410 SS

420 SS

431 SS

1018

1018 ENP

304 S

410 SS

420 SS

431 SS

1018

1018 ENP

304 SS

410 SS

420 SS

431 SS

1018

1018 ENP

304 SS

410 SS

420 SS

431 SS

ULW

LLW

ULW + 2 ppm phosphate

LLW + 2 ppm phosphate

16.5

3.1

0.0

2.1

1.25

0.0

17.2

2.3

0.0

19.5

0.35

1.0

5.0

1.0

0.0

0.8

0.5

0.0

4.2

0.5

0.0

0.5

0.8

0.0

16

0

0

21

26

1

0

0

0

27

37

1

24

39

15

35

0.16

1.2

1.4

0.3

0.45

1.4

0.6

0.2

0.3

1.2

0.1

1.2

test was 14 and 28 days and the temperature was

maintained at 403C.

Exposure of CS 1018, 410 SS, 420 SS and

431 SS resulted in the growth of loose thick brown

scales of iron oxides. The scales were easily removable. CS 1018 showed a uniform metal loss,

410 SS showed large number of pits over the edges

whereas in 420 SS and 431 SS coupons no pitting

was observed. Exposure of CS 1018 coupons to

ZHMP dosed ULW resulted in the formation of

brownish grey adherent scales which appeared to

be protective irrespective of the duration of exposure.

The corrosion rate of CS 1018 without ZHMP

addition was highest followed by 410 SS and 1018

ENP, respectively. The alloys 420 SS and 431 SS

showed negligible corrosion rates (Table 9).

Addition of 2 ppm ZHMP decreased the corrosion

rate of CS 1018 by one third and further addition

up to 15 ppm ZHMP lowered down the corrosion

rate by one fifth (Table 9 and Fig. 10). The maximum efficiency of the inhibitor was noted in the

CS coupons. The addition of 2 ppm inhibitor showed

an efficiency of 75% while on increasing the

inhibitor concentration to 15 ppm, its efficiency

marginally increased to about 80%. However, an

increase in the number of pits was observed when

the inhibitor concentration was increased from 2

to 15 ppm. The number of pits in CS coupons

also increased with increase in the exposure period

in the presence of the inhibitor.

158

A.U. Malik et al. / Desalination 196 (2006) 149159

Table 9

Corrosion rate and efficiency of phosphate inhibitor (ZHMP) from the dynamic test loop

ZHMP

(ppm)

0

2

15

Materials

Carbon steel

1018 ENP

410 SS

420 SS

431 SS

CR

(mpy)

% efficiency CR

(mpy)

% efficiency CR

(mpy)

% efficiency CR

(mpy)

% efficiency

114.1

37.9

22.2

0

66.8

80.6

0

26.0

65.2

0

23.6

25.1

0

100

100

2.3

1.7

0.8

3.4

2.6

2.6

0

0

0

Fig. 10. Graphs showing the variation of corrosion rates of CS-1018, 410 SS and 420 SS after 14 and 28 day exposures.

4. Conclusions

(a) Under jet impingement test conditions, in

high chloride water containing 350 ppm chloride

CS 1018 corroded significantly; this was followed

by 1018 ENP and 410 SS which showed only marginal effect. The alloys 304 SS and 431 SS showed

no or very little corrosion from impingement under all test conditions. The effect of phosphate

dosing on impingement induced corrosion on CS

1018 was very positive reducing the corrosion rate

by one order of magnitude.

(b) Under shut down conditions, the alloys 304

SS and 1018 ENP did not show any pitting and

appeared to be free from crevice corrosion attack.

The susceptibility of different materials to crevice

corrosion in test waters was found to be in the

following order: 304 SS > 431SS > 420 SS > 410

> ENP 1018 > CS 1018.

(c) Addition of phosphate reduces the corrosion rate significantly for CS 1018, 1018 NP and

410 SS. Alloys 420 SS, 431 SS and 304 SS showed

no change in corrosion rates on inhibitor addition.

In general, the phosphate dosing annuls the effect

A.U. Malik et al. / Desalination 196 (2006) 149159

of crevices in carbon steel, ferritic and austenitic

steels in test waters. The effect of phosphate concentration on its inhibition efficiency was only

marginal.

References

[1] J.W. Oldfield and B. Todd, Desalination, 55 (1985)

261.

[2] S. Nordin and J. Olsson, Desalination, 62 (1987)

235.

159

[3] A.M. Hassan and A.U.Malik, Desalination, 74

(1989) 157.

[4] J. Nordstrm and J. Olsson, Desalination, 97 (1994)

213.

[5] J.W. Oldfield and B. Todd, Desalination, 108 (1996)

27.

[6] A. Al-Odwani, M. Al-Tabtabaei and A. Abdul Nabi,

Desalination, 120 (1998) 73.

[7] M.G.. Fontana, Corrosion Engineering, McGrawHill International Edition, Singapore, 1987, p. 14.

[8] A.U. Malik, N.A. Siddiqui, S. Ahmed and I.N.

Andijani, Corrosion Sci., 33 (1992) 1809.

Вам также может понравиться

- Key Issues Related To Modelling of Internal Corrosion of Oil and Gas Pipelines-A ReviewДокумент16 страницKey Issues Related To Modelling of Internal Corrosion of Oil and Gas Pipelines-A ReviewsanaamikhailОценок пока нет

- Corrosion Engineering: CO Corrosion of N-80 Steel at 71 C in A Two-Phase Flow SystemДокумент8 страницCorrosion Engineering: CO Corrosion of N-80 Steel at 71 C in A Two-Phase Flow SystemGabriel BustosОценок пока нет

- Corrsion P110 Casing CO2 Saturated (2015)Документ14 страницCorrsion P110 Casing CO2 Saturated (2015)Alex VianaОценок пока нет

- 12 - Comparison - On The Cracking SusceptiДокумент8 страниц12 - Comparison - On The Cracking SusceptiKAWAI LAWОценок пока нет

- Hong 2002Документ12 страницHong 2002googley71Оценок пока нет

- Corrosion Failures of AISI Type 304 Stainless Steel in A Fertiliser PlantДокумент11 страницCorrosion Failures of AISI Type 304 Stainless Steel in A Fertiliser PlantAndrea CalderaОценок пока нет

- Hydrodynamic Effects On The CO Corrosion Inhibition of X-120 Pipeline Steel by Carboxyethyl-ImidazolineДокумент15 страницHydrodynamic Effects On The CO Corrosion Inhibition of X-120 Pipeline Steel by Carboxyethyl-ImidazolineMahdi HeidaryОценок пока нет

- Stainless Steels and Drinking Water Around The WorldДокумент12 страницStainless Steels and Drinking Water Around The WorldVizit31Оценок пока нет

- Effect of Water Content On The Corrosion Behavior of Carbon Steel in Supercritical CO2 PhaseДокумент15 страницEffect of Water Content On The Corrosion Behavior of Carbon Steel in Supercritical CO2 PhaseFrancois BornmanОценок пока нет

- 654SMO Vs C276Документ16 страниц654SMO Vs C276陳維中Оценок пока нет

- Characteristics o F Corrosion Scales o N Pipeline Steel in CO 2 - Saturated NaCl Brine SolutionДокумент4 страницыCharacteristics o F Corrosion Scales o N Pipeline Steel in CO 2 - Saturated NaCl Brine SolutionjifarinaОценок пока нет

- Control Techniques of Scaling and Corrosion in Geothermal FluidsДокумент9 страницControl Techniques of Scaling and Corrosion in Geothermal FluidsHobokela MikaelОценок пока нет

- Corrosion Failure Analysis of L485 Natural Gas Pipeline in CO2 EnvironmentДокумент7 страницCorrosion Failure Analysis of L485 Natural Gas Pipeline in CO2 EnvironmentRagerishcire KanaalaqОценок пока нет

- Ijct 16 (3) 216-220 PDFДокумент5 страницIjct 16 (3) 216-220 PDFrapidremi100% (1)

- Corrosion Resistance of Steels Used in Beet Sugar Processing JuicesДокумент9 страницCorrosion Resistance of Steels Used in Beet Sugar Processing JuicesFarouq AliОценок пока нет

- Corrosion and Electrochemical Behavior of 316L Stainless Steel in Sulfate-Reducing and Iron-Oxidizing Bacteria SolutionsДокумент6 страницCorrosion and Electrochemical Behavior of 316L Stainless Steel in Sulfate-Reducing and Iron-Oxidizing Bacteria SolutionsPredrag VasiljevićОценок пока нет

- Materials 13 02836 v2Документ14 страницMaterials 13 02836 v2UMERОценок пока нет

- Thermal Aging Effect on Oxide Films in Dissimilar Metal WeldsДокумент9 страницThermal Aging Effect on Oxide Films in Dissimilar Metal WeldsOscarCastilloNavaОценок пока нет

- Effect of Post Weld Surface Treatments on Corrosion Resistance of Duplex Stainless Steel WeldsДокумент14 страницEffect of Post Weld Surface Treatments on Corrosion Resistance of Duplex Stainless Steel WeldsdevangmajithiaОценок пока нет

- Fouling and Scale Control 2009Документ31 страницаFouling and Scale Control 2009kikokalazo0% (1)

- Hydrochloric Acid HandbookДокумент15 страницHydrochloric Acid HandbookSachikanta PradhanОценок пока нет

- Electrochemical Corrosion Resistance Evaluationof Ferritic Stainless Steelin HCLДокумент13 страницElectrochemical Corrosion Resistance Evaluationof Ferritic Stainless Steelin HCLparv serviceОценок пока нет

- Characterization of The Rust Formed On Weathering Steel Exposed To Qinghai Salt Lake AtmosphereДокумент7 страницCharacterization of The Rust Formed On Weathering Steel Exposed To Qinghai Salt Lake Atmosphereroscarlos1936Оценок пока нет

- How Aqueous Silica Impacts Iron Corrosion and Red Water ProblemsДокумент11 страницHow Aqueous Silica Impacts Iron Corrosion and Red Water ProblemsAngga RisesОценок пока нет

- Factors Affecting Selection of Tubes of Heat ExchangerДокумент6 страницFactors Affecting Selection of Tubes of Heat ExchangerKvvPrasadОценок пока нет

- Corrosion Behavior of Carbon Steel in Oxygenated Sodium Sulphate Solution Under Different Operating ConditionsДокумент11 страницCorrosion Behavior of Carbon Steel in Oxygenated Sodium Sulphate Solution Under Different Operating ConditionsSEP-PublisherОценок пока нет

- Corrosion KitДокумент4 страницыCorrosion KitBalRam DhimanОценок пока нет

- Understanding Pitting Corrosion BehaviourofX-65CarbonSteelinCO2SaturatedEnvironmentsДокумент29 страницUnderstanding Pitting Corrosion BehaviourofX-65CarbonSteelinCO2SaturatedEnvironmentspurnawanОценок пока нет

- Engineering Failure Analysis: Qaioguo Wu, Xuedong Chen, Zhichao Fan, Defu Nie, Renchao WeiДокумент9 страницEngineering Failure Analysis: Qaioguo Wu, Xuedong Chen, Zhichao Fan, Defu Nie, Renchao WeiMahsaОценок пока нет

- Sea Water CorrosionДокумент16 страницSea Water CorrosionPrabath Nilan GunasekaraОценок пока нет

- Performance of Some Thiophene Derivatives As Corrosion Inhibitors For 304 Stainless Steel in Aqueous SolutionsДокумент21 страницаPerformance of Some Thiophene Derivatives As Corrosion Inhibitors For 304 Stainless Steel in Aqueous SolutionsNguyễn Minh ThôngОценок пока нет

- Corrosion Behavior of Ni Steels in Aerated 3.5-Wt.% Nacl Solution at 25ºc by Potentiodynamic MethodДокумент12 страницCorrosion Behavior of Ni Steels in Aerated 3.5-Wt.% Nacl Solution at 25ºc by Potentiodynamic MethodHassen LazharОценок пока нет

- Sacrificial Anode Cathodic Protection of Low Carbon Steel in Sea WaterДокумент11 страницSacrificial Anode Cathodic Protection of Low Carbon Steel in Sea WaterÂngela CruzОценок пока нет

- Farelas - Effect of CO2 Phase - H2O and SO2Документ24 страницыFarelas - Effect of CO2 Phase - H2O and SO2Andy ChoОценок пока нет

- Sweet Corrosion in PipelineДокумент8 страницSweet Corrosion in PipelinedgkmurtiОценок пока нет

- Engineering Failure Analysis: C.M.B. Martins, J.L. Moreira, J.I. MartinsДокумент7 страницEngineering Failure Analysis: C.M.B. Martins, J.L. Moreira, J.I. Martinspaneisan100% (1)

- Corrosion in High Pressure CO2-Equipment For Water Solubility MeasurementsДокумент4 страницыCorrosion in High Pressure CO2-Equipment For Water Solubility MeasurementstheijesОценок пока нет

- Corrosion Behavior of T91 and Type AISI 403 Stainless Steel in Supercritical WaterДокумент8 страницCorrosion Behavior of T91 and Type AISI 403 Stainless Steel in Supercritical WaterSai dineshОценок пока нет

- International Journal of Pressure Vessels and Piping: SciencedirectДокумент12 страницInternational Journal of Pressure Vessels and Piping: SciencedirectArturo CervantesОценок пока нет

- Influence of Hydrogenation On Residual Stresses ofДокумент10 страницInfluence of Hydrogenation On Residual Stresses ofNia KurniaОценок пока нет

- Amine Type Inhibitor Effect On Corrosion-Erosion Wear in Oil Gas PipesДокумент4 страницыAmine Type Inhibitor Effect On Corrosion-Erosion Wear in Oil Gas PipesSyakir YepОценок пока нет

- Fundamental Study On The Effectiveness of Sacrificial Point Anode For Corrosion Prevention of Steel Bars in Chloride Contaminated ConcreteДокумент11 страницFundamental Study On The Effectiveness of Sacrificial Point Anode For Corrosion Prevention of Steel Bars in Chloride Contaminated ConcreteRahmita Sari RafdinalОценок пока нет

- 3,4-Dimethoxybenzaldehydethiosemicarbazone As CorrosionДокумент11 страниц3,4-Dimethoxybenzaldehydethiosemicarbazone As CorrosionFernando HenriqueОценок пока нет

- Corrosion Science: Shuan Liu, Huyuan Sun, Lijuan Sun, Huiji FanДокумент8 страницCorrosion Science: Shuan Liu, Huyuan Sun, Lijuan Sun, Huiji FanVanessa Rios NolayaОценок пока нет

- Caustic Corrosion in Boiler Waterside Tube Root Cause & MechanismДокумент9 страницCaustic Corrosion in Boiler Waterside Tube Root Cause & Mechanismعزت عبد المنعمОценок пока нет

- Introduction To Swas Steam and Water Analysis SystemДокумент41 страницаIntroduction To Swas Steam and Water Analysis SystemvaishnaviОценок пока нет

- EIS Studies of A Corrosion Inhibitor Behavior Under Multiphase Ow ConditionsДокумент12 страницEIS Studies of A Corrosion Inhibitor Behavior Under Multiphase Ow Conditionsgoogley71Оценок пока нет

- Effect of Inoculant On The Degradation Behaviour of Multi Layered Mild Steel/Al-Cr Plate in Psidium Guajava Leaf ExtractДокумент7 страницEffect of Inoculant On The Degradation Behaviour of Multi Layered Mild Steel/Al-Cr Plate in Psidium Guajava Leaf ExtractAZOJETE UNIMAIDОценок пока нет

- Jurnal Kelompok 1Документ10 страницJurnal Kelompok 1Agy RandhikoОценок пока нет

- Engineering Failure Analysis: Zhihong Wang, Chaoyue Yang, Lin ZhuДокумент8 страницEngineering Failure Analysis: Zhihong Wang, Chaoyue Yang, Lin ZhuwhoismeОценок пока нет

- Design & Calculation Cathodic Protection Impressed Cureent SystemДокумент107 страницDesign & Calculation Cathodic Protection Impressed Cureent Systemmtuanlatoi9704Оценок пока нет

- PDFДокумент30 страницPDFMihai RomulusОценок пока нет

- Electrocoagulation (With Iron Electrodes) As A Pre-Treatment Part of Brackish Groundwater Desalination SystemДокумент13 страницElectrocoagulation (With Iron Electrodes) As A Pre-Treatment Part of Brackish Groundwater Desalination SystemijasrjournalОценок пока нет

- Corrosion of marine carbon steel by electrolyzed ballast waterДокумент7 страницCorrosion of marine carbon steel by electrolyzed ballast waterswapneel_kulkarniОценок пока нет

- Correlation between heat treatment, microstructure and properties of TRIP-assisted steelsДокумент6 страницCorrelation between heat treatment, microstructure and properties of TRIP-assisted steelsShaheer Ahmed Khan0% (1)

- Offshore CorrosionДокумент16 страницOffshore CorrosionpkannanОценок пока нет

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesОт EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášОценок пока нет

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeОт EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeОценок пока нет

- Advances in Solid Oxide Fuel Cells XОт EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffОценок пока нет

- Manual Ultrasonic Inspection of Thin Metal WeldsДокумент16 страницManual Ultrasonic Inspection of Thin Metal WeldsSimon LeeОценок пока нет

- Near-Field Characteristics of Circular Piston Radiators PDFДокумент8 страницNear-Field Characteristics of Circular Piston Radiators PDFjperdigon9634Оценок пока нет

- Near-Field Characteristics of Circular Piston RadiatorsДокумент8 страницNear-Field Characteristics of Circular Piston Radiatorsjperdigon9634Оценок пока нет

- Stress Corrosion Cracking of Gas Pipelines - Effect of Surface Roughness, Orientations and FlatteningДокумент13 страницStress Corrosion Cracking of Gas Pipelines - Effect of Surface Roughness, Orientations and Flatteningjperdigon9634Оценок пока нет

- Strong Exploration of A Cast Iron Pipe Failure ModelДокумент12 страницStrong Exploration of A Cast Iron Pipe Failure Modeljperdigon9634Оценок пока нет

- Local Heat Treatment ServiceДокумент3 страницыLocal Heat Treatment Servicejperdigon9634Оценок пока нет

- Effect of Cooling Rate On Structure and Properties of An Ultra-Low Carbon HSLA-100 Grade SteelДокумент7 страницEffect of Cooling Rate On Structure and Properties of An Ultra-Low Carbon HSLA-100 Grade Steeljperdigon9634Оценок пока нет

- Stability of Thin-Walled High-Pressure Cylindrical Pipes With Non-Circular Cross-Section and Variable Wall Thickness Subjected To Non-Homogeneous CorrosionДокумент10 страницStability of Thin-Walled High-Pressure Cylindrical Pipes With Non-Circular Cross-Section and Variable Wall Thickness Subjected To Non-Homogeneous Corrosionjperdigon9634Оценок пока нет

- Evaluation of The Effect of Corrosion Defects On The Structural Integrity of X52 Gas Pipelines Using The SINTAP Procedure and Notch TheoryДокумент9 страницEvaluation of The Effect of Corrosion Defects On The Structural Integrity of X52 Gas Pipelines Using The SINTAP Procedure and Notch Theoryjperdigon9634Оценок пока нет

- Failure Analysis of A Leak-Off Oil Pipe From Injection Valves of An Off-Shore Operating Diesel EngineДокумент13 страницFailure Analysis of A Leak-Off Oil Pipe From Injection Valves of An Off-Shore Operating Diesel Enginejperdigon9634Оценок пока нет

- Stability Loss of Thin-Walled Cylindrical Tubes, Subjected To Longitudinal Compressive Forces and External CorrosionДокумент4 страницыStability Loss of Thin-Walled Cylindrical Tubes, Subjected To Longitudinal Compressive Forces and External Corrosionjperdigon9634Оценок пока нет

- Passive Cooling of The PBMR Spent and Used Fuel TanksДокумент9 страницPassive Cooling of The PBMR Spent and Used Fuel Tanksjperdigon9634Оценок пока нет

- Use of Topographic Polymeric Replica To Characterize Electric Corrosion FailureДокумент5 страницUse of Topographic Polymeric Replica To Characterize Electric Corrosion Failurejperdigon9634Оценок пока нет

- Strong Exploration of A Cast Iron Pipe Failure ModelДокумент12 страницStrong Exploration of A Cast Iron Pipe Failure Modeljperdigon9634Оценок пока нет

- Corrosive Effects of Salt Hydrate Phase Change Materials Used With Aluminium and CopperДокумент8 страницCorrosive Effects of Salt Hydrate Phase Change Materials Used With Aluminium and Copperjperdigon9634Оценок пока нет

- Acoustical Physics 2009 V55 N01 Dispersion of The Signal of A Parametric Array in Shallow WaterДокумент5 страницAcoustical Physics 2009 V55 N01 Dispersion of The Signal of A Parametric Array in Shallow Waterjperdigon9634Оценок пока нет

- Structural Integrity Evaluation of X52 Gas Pipes Subjected To External Corrosion Defects Using The SINTAP Procedure PDFДокумент13 страницStructural Integrity Evaluation of X52 Gas Pipes Subjected To External Corrosion Defects Using The SINTAP Procedure PDFjperdigon9634Оценок пока нет

- The Effect of Advanced Treatment On Chlorine Decay in Metallic PipesДокумент10 страницThe Effect of Advanced Treatment On Chlorine Decay in Metallic Pipesjperdigon9634Оценок пока нет

- The Use of Radiography For Thickness Measurement and Corrosion Monitoring in PipesДокумент6 страницThe Use of Radiography For Thickness Measurement and Corrosion Monitoring in Pipesjperdigon9634Оценок пока нет

- Acoustical Physics 2009 V55 N01 Nonlinear Standing Waves, Resonance Phenomena, and Frequency Characteristics of Distributed SystemsДокумент28 страницAcoustical Physics 2009 V55 N01 Nonlinear Standing Waves, Resonance Phenomena, and Frequency Characteristics of Distributed Systemsjperdigon9634Оценок пока нет

- The Function of Sulfate-Reducing Bacteria in Corrosion of Potable Water MainsДокумент4 страницыThe Function of Sulfate-Reducing Bacteria in Corrosion of Potable Water Mainsjperdigon9634Оценок пока нет

- Acoustical Physics 2009 V55 N01 Modal Time Reversal of Waves For Shallow-Water SeaДокумент11 страницAcoustical Physics 2009 V55 N01 Modal Time Reversal of Waves For Shallow-Water Seajperdigon9634Оценок пока нет

- Acoustical Physics 2009 V55 N01 Effect of Initial Stress On Love Waves in A Piezoelectric Structure Carrying A Functionally Graded Material LayerДокумент7 страницAcoustical Physics 2009 V55 N01 Effect of Initial Stress On Love Waves in A Piezoelectric Structure Carrying A Functionally Graded Material Layerjperdigon9634Оценок пока нет

- Acoustical Physics 2009 V55 N01 Intensity Variations of High-Frequency Sound Pulses Due To The Motion of Shallow-Water Internal SolitonsДокумент8 страницAcoustical Physics 2009 V55 N01 Intensity Variations of High-Frequency Sound Pulses Due To The Motion of Shallow-Water Internal Solitonsjperdigon9634Оценок пока нет

- Acoustical Physics 2009 V55 N01 Calculation of Acoustic Energy Trapping in Resonators Based On Isotropic and Nanoceramic MaterialsДокумент7 страницAcoustical Physics 2009 V55 N01 Calculation of Acoustic Energy Trapping in Resonators Based On Isotropic and Nanoceramic Materialsjperdigon9634Оценок пока нет

- Acoustical Physics 2009 V55 N01 Amplitude Dependent Internal Friction and Generation of Harmonics in Granite ResonatorДокумент8 страницAcoustical Physics 2009 V55 N01 Amplitude Dependent Internal Friction and Generation of Harmonics in Granite Resonatorjperdigon9634Оценок пока нет

- Acoustical Physics 2009 V55 N01 Diagnostics of Residual Stress in Metals With Wideband Surface Acoustic PulsesДокумент7 страницAcoustical Physics 2009 V55 N01 Diagnostics of Residual Stress in Metals With Wideband Surface Acoustic Pulsesjperdigon9634Оценок пока нет

- Acoustical Physics 2009 V55 N01 Acoustic Studies of Melting and Crystallization of Sodium Nitrite Nanocrystals in The Pores of Mesoporous Silicate MatricesДокумент6 страницAcoustical Physics 2009 V55 N01 Acoustic Studies of Melting and Crystallization of Sodium Nitrite Nanocrystals in The Pores of Mesoporous Silicate Matricesjperdigon9634Оценок пока нет

- Faster Class II Cabinet UltraSafeДокумент2 страницыFaster Class II Cabinet UltraSafeahamad1Оценок пока нет

- Joint Filler & Bearing Pads - Sparkton Const. Supplies, IncДокумент2 страницыJoint Filler & Bearing Pads - Sparkton Const. Supplies, IncKaren IsananОценок пока нет

- The Health of The St. Croix Estuary - Vol. 1 Executive SummaryДокумент19 страницThe Health of The St. Croix Estuary - Vol. 1 Executive SummaryART'S PLACEОценок пока нет

- B SC M SC Biotechnology 2010 2011Документ51 страницаB SC M SC Biotechnology 2010 2011avi_281993Оценок пока нет

- Calcium Aluminate Cement ConcreteДокумент6 страницCalcium Aluminate Cement ConcreteGandhi HammoudОценок пока нет

- Api 510 Exam: Api576 Questions - 01Документ3 страницыApi 510 Exam: Api576 Questions - 01korichiОценок пока нет

- Electrolytes, Acids, Bases, and pH GuideДокумент9 страницElectrolytes, Acids, Bases, and pH GuideMariaPaulaGonzalezRojasОценок пока нет

- Plastic Film - Wikipedia, The Free EncyclopediaДокумент2 страницыPlastic Film - Wikipedia, The Free Encyclopediadidodido_67Оценок пока нет

- Biology - MitochondriaДокумент9 страницBiology - MitochondriaAJ IzaguirreОценок пока нет

- Ordering Information:: Back To Piping StudyДокумент3 страницыOrdering Information:: Back To Piping StudyShankar JhaОценок пока нет

- Klinger Ballostar KHE: 2-Piece Ball Valves DN 15 - 200 (1/2" - 8")Документ11 страницKlinger Ballostar KHE: 2-Piece Ball Valves DN 15 - 200 (1/2" - 8")Zain AliОценок пока нет

- Glassfibre Reinforced Concrete Principles, Production, Properties and Applications by Professor Peter J. M. BartosДокумент209 страницGlassfibre Reinforced Concrete Principles, Production, Properties and Applications by Professor Peter J. M. Bartoscelso100% (1)

- EastmanДокумент37 страницEastmanKrishnananth SajuОценок пока нет

- BHELДокумент17 страницBHELSumit KumarОценок пока нет

- Spectroscopy Problems Part 1Документ49 страницSpectroscopy Problems Part 1Partha Samanta100% (1)

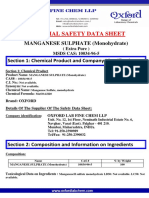

- MANGANESE SULPHATE (Monohydrate) (Extra Pure)Документ8 страницMANGANESE SULPHATE (Monohydrate) (Extra Pure)Bima KurniawanОценок пока нет

- Chemical KineticsДокумент52 страницыChemical KineticsdhananjaylandgeОценок пока нет

- 11 CR-CB Data SheetДокумент2 страницы11 CR-CB Data SheetJLZ972Оценок пока нет

- Design of Process EquipmentДокумент175 страницDesign of Process EquipmentAravind MadhuОценок пока нет

- Brochure WL110 enДокумент10 страницBrochure WL110 enAndrei BuragaОценок пока нет

- Zainal (2001) - Prediction of Performance of A Downdraft Gasifier Using Equilibrium Modeling For Different Biomass MaterialsДокумент17 страницZainal (2001) - Prediction of Performance of A Downdraft Gasifier Using Equilibrium Modeling For Different Biomass MaterialsAbraham AvОценок пока нет

- Process Synthesis: Uni Ersity of Wisconsin Madison, W Sconsin 53706Документ8 страницProcess Synthesis: Uni Ersity of Wisconsin Madison, W Sconsin 53706Pardon MungwariОценок пока нет

- Earth and Life Science - q2 - LasДокумент177 страницEarth and Life Science - q2 - LasKim Charlotte Balicat-Rojo Manzori82% (11)

- Bro Composite-Glazing enДокумент20 страницBro Composite-Glazing enJane SweetОценок пока нет

- 0271.SAS-BR-Inorganics Siral Siralox WEBДокумент16 страниц0271.SAS-BR-Inorganics Siral Siralox WEBMrutunjay PatraОценок пока нет

- Match! Phase Analysis Report: Institute of Technology Sepuluh November (ITS), Department of Physics Sample: 0,5 BarДокумент3 страницыMatch! Phase Analysis Report: Institute of Technology Sepuluh November (ITS), Department of Physics Sample: 0,5 BarnovernandoОценок пока нет

- BITSAT Sample Paper: Bitsat Set 1 Bitsat Set 1Документ37 страницBITSAT Sample Paper: Bitsat Set 1 Bitsat Set 1SRI RAMОценок пока нет

- Safety Data Sheet: Product Name: MOBILGEAR 600 XP 68Документ11 страницSafety Data Sheet: Product Name: MOBILGEAR 600 XP 68م.حسين العامريОценок пока нет

- Chapter 1Документ40 страницChapter 1aRe_an90100% (2)

- Cady B - Synthesis of A Copper Oxide LabДокумент4 страницыCady B - Synthesis of A Copper Oxide Labapi-298329103Оценок пока нет