Академический Документы

Профессиональный Документы

Культура Документы

Boiler Automation PDF

Загружено:

Harshada DeokateИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Boiler Automation PDF

Загружено:

Harshada DeokateАвторское право:

Доступные форматы

PLC Scada Based Boiler Control Operation

PLC SCADA BASED BOILER CONTROL OPERATION

1

GOWTHAM. N, 2JAYANDHAN.V.K, 3KARTHIK.K

1,2,3

B.E., III Year Department of Mechanical Engineering Velammal Engineering College, Chennai.

Abstract- This paper outlines the various stages of operation involved in the conversion of manually operated boiler towards

a fully automated boiler. Over the years the demand for high quality, greater efficiency and automated machines has

increased in this globalised world The initial phase of the paper focuses on passing the inputs to the boiler at a required

temperature, so as to constantly maintain a particular temperature in the boiler. The Air preheater and Economizer helps in

this process. And the paper mainly focuses on level, pressure and flow control at the various stages of the boiler plant. Thus

the temperature in the boiler is constantly monitored and brought to a constant temperature as required by the power plant.

The automation is further enhanced by constant monitoring using SCADA screen which is connected to the PLC by means

of communication cable. By means of tag values set to various variable in SCADA the entire process is controlled as

required. At the automated power plant, the boiler is controlled by Variable Frequency Drive (VFD) to put in action the

required processes to be carried out at the boiler .Thus the entire cycle is carried out as a paper and at various stages each

phase is detailed out .This paper has proved to be very efficient practically as the need for automation grows day by day.

Keywords- Automation, PLC-SCADA, Boiler, VFD

I.

system that collects raw data, processes it and

presents it in values which can be verified and

compared with the standard values. In the coding

process of this implementation with micro-controller,

it requires a fast and efficient processing which on the

other part depends on the length and sub-routines of

the coding process. Thus it provides a real challenge

with systems involving.

INTRODUCTION

Over the years the demand for high quality, greater

efficiency and automated machines has increased in

the industrial sector of power plants. Power plants

require continuous monitoring and inspection at

frequent intervals. There are possibilities of errors at

measuring and various stages involved with human

workers and also the lack of few features of

microcontrollers. Thus this paper takes a sincere

attempt to explain the advantages the companies will

face by implementing automation into them. The

boiler control which is the most important part of any

power plant, and its automation is the precise effort of

this paper.

III.

All the values can be filled up by the introduction of

the automation technique into the power plants. The

automation technique involving the automatic control

of all the processes which includes the monitoring

and inspection needs provides for a very efficient

system. The automation process helps the company

having the power plant to reduce the amount of errors

that occur , reduction in the human resources,

increased efficiency, and most importantly very cost

effective.

In order to automate a power plant and minimize

human intervention, there is a need to develop a

SCADA (Supervisory Control and Data Acquisition)

system that monitors the plant and helps reduce the

errors caused by humans. While the SCADA is used

to monitor the system, PLC (Programmable Logic

Controller) is also used for the internal storage of

instruction for the implementing function such as

logic, sequencing, timing, counting and arithmetic to

control through digital or analog input/ output

modules various types of machines processes.

Systems are used to monitor and control a plant or

equipment in industries such as telecommunications,

water and waste control, energy, oil and gas refining

and transportation.

II.

METHODS

IV.

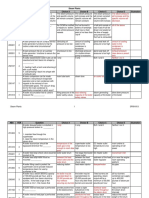

CRITICAL CONTROL PARAMETERS

IN BOILER

A. Level Control

Steam Drum level, De-aerator level and hot well level

B. Pressure Control

Force draft pressure, Induced draft pressure, Steam

drum pressure, Deaerator pressure, Turbine inlet

steam pressure, balanced draft pressure

DRAWBACK OF CONVENTIONAL

SYSTEM

C. Flow Control

Air flow, Steam flow, Water flow.

Conventional equipment systems are prone to errors

due to the involvement of humans in the data

collection and processing using complicated

mathematical expressions. Thus what we require is a

D. Temperature Control

Deaerator temperature, Steam drum temperature,

Underbed boiler temperature, Turbine inlet steam

temperature, Flue gas temperature.

Proceedings of 11th IRF International Conference, 15th February-2015, Bengaluru, India, ISBN: 978-93-84209-90-2

46

PLC Scada Based Boiler Control Operation

Control, PID control, Operator control, Signaling and

listing, Coordination and communication.

AUTOMATION

Delegation of Human Control to technical Equipment

aimed towards achieving.

B. How PLC works

Basics of a PLC function are continual scanning of a

program. The scanning process involves three basic

steps.

Advantages

Higher productivity, Superior quality of end product,

efficient usage of raw materials and energy, improved

safety in working condition.

Step 1: Testing input status

First the PLC checks each of its input with intention

to see which one has status on or off. In other words

it checks whether a switch or a sensor etc., is

activated or not. The information that the processor

thus obtains through this step is stored in memory in

order to be used in the following steps.

A. History of Control and Automation

PLC

ELECTRICAL CONTROL

WITH LOGIC GATES

WITH LOGIC GATES

MANUAL CONTROL

Step 2: Programming execution

Here a PLC executes a program instruction by

instruction based on the program and based on the

status of the input has obtained in the preceding step,

and appropriate action is taken. The action might be

activation of certain outputs and the results can be put

off and stored in memory to be retrieved later in the

following steps.

Manual Control

In this, the Control and Automation are done by

Manual Operations.

Drawbacks:

Human Errors subsequently affect quality of

end product.

Hard Wired Logic Control

In this, Contractor and relays together with

timers and counters were used in achieving

desired level of automation.

Bulky and complex wiring, Involves lot of

rework to implement changes in control

logic, the work can be started only when the

takes is fully defined and this leads to longer

project time.

Step 3: Checking and Correction of output status

Finally, a PLC checks up output signals and adjust it

has needed. Changes are performed based on the

input status that had been read during the first step

and based on the result of the program execution in

step two following execution of step three PLC

returns a beginning of the cycle and continually

repeats these steps.

Scanning time = Time for performing step 1+ Time

for performing step 2+ Time for performing step 3.

Electronics Control with Logic Gates

In this, Contactor and Relays together with timers and

counters were replaced with logic gates and

electronic timers in the control circuits.

V.

ALLEN BRADLEY PLC

Programmable Logic Controller or PLC is an

intelligent system of modules, which was introduced

in the control, & instrumentation industry for

replacing relay based logic. Over a period of time,

better I/O handling capabilities and more

programming elements have been added along with

improvement in communication.

Advantages

Reduced space requirements, energy saving,

less maintenance and hence greater

reliability.

The Major Drawbacks

Implementation of changes in the control

logic as well as reducing the project leadtime was not possible.

PLC Working

At the beginning of each cycle the CPU brings in all

the field input signals from the input signals from the

module and store into internal memory as process of

input signal. This internal memory of CPU is called

as process input image (PII).

Programmable Logic Controller

In this, instead of achieving desired control and

automation through physical wiring of control

devices, it is achieving through program say software.

User program (Application) will be available in CPU

program memory. Once PII is read, CPU pointer

moves in ladder program from left to right and from

top to bottom. CPU takes status of input from PII and

processes all the rungs in the user program. The result

of user program scan is stored in the internal memory

Advantages

Reduced

Space,

Energy

saving,

Modular

Replacement, Easy trouble shooting, Error

diagnostics programmer, Economical, Greater life

and reliability, The Compatibilities of PLCS, Logic

Proceedings of 11th IRF International Conference, 15th February-2015, Bengaluru, India, ISBN: 978-93-84209-90-2

47

PLC Scada Based Boiler Control Operation

of CPU. This internal memory is called process

output image or PIQ. At the end of the program run

i.e., at the end of scanning cycle, the CPU transfers

the signal states in the process image output to the

output module and further to the field control.

B. Interfacing

Fig. 2, Interfacing of PLC and SCADA

I/O driver (SCADA) picks up PII and PIQ and

transfers the image to database and this image is

called driver image. This driver image available in

SCADA database is used for graphical view of

process monitoring from operator station (OS) in the

central control room.

C. Connecting to the PLC

Open a SCADA application

Create a tag of type I/O discrete, select the

type as discrete

Select read only if you dont want to force

values to PLC. Selecting read and write

allows to the SCADA to read and force

values to the PLC.

Type an access name.

The access name can visualized as a

gateway for a group of resources.

Most of PLC drivers communicate with

SCADA package using DDE, DDE requires

three parameters namely name of the DDE

server, topic name and item name. In case of

reading a number of items from a particular

PLC driver application name topic name are

common, so this application name that is

name of the DDE server and Topic name

combine to form an access name. Access

name is required to be defined only once

then other items of driver can be accessed by

using the Access name and item name.

These details will be provided by the driver

vendor or developer.

Click ok, the access name will be listed

finally click done, then type the item name,

click save to save the I/O tags. Go to run

time to communicate with PLC.

A. Features of Allen Bradley PLC

Using Allen Bradley 1000PLC Micrologix 1000PLC

has 20 digital outputs. The left side of the screen

shows that eh project tree while the right side of the

screen is the programming area. Either area can be

increased in size, minimized, or closed by left

clicking the mouse on the appropriate symbol.

VI.

SCADA

SCADA stands for Supervisory Control and Data

Acquisition. As the name indicates, it is not a full

control system, but rather focuses on the supervisory

level.

Fig. 1, I/O Pin Configuration of AB PLC

Proceedings of 11th IRF International Conference, 15th February-2015, Bengaluru, India, ISBN: 978-93-84209-90-2

48

PLC Scada Based Boiler Control Operation

What is SCADA? It is used to monitor and control

plant or equipment. The control may be automatic or

initiated by operator commands. The data acquisition

is accomplished firstly by the RTUs scanning the

field inputs connected to the RTU (it may be also

called a PLC programmable logic controller.). This

is usually at a fast rate. The central host will scan the

PTUs (usually at a slower rate). The data is

processed to detect alarm conditions, and if an alarm

is present, it will be displayed on special alarm lists.

of steam is generated. The generated steam

temperature may be greater or lesser than the desired

temperature. So depending on the situation the

generated steam is then passed through primary

heater followed by secondary heater. The secondary

temperature is monitored.

Here we consider three main cases:

1. If the secondary heated temperature is

greater than the desired temperature then by

using PID controller, approximate control

signal is sent to the control valve 3 of the

super heater tank, to reduce the temperature,

by spraying chilled water from de-aerator

tank.

2. If the output of the secondary heated

temperature is lesser than the desired, using

a PID controller approximate control signal

is sent to bunker valve to control fuel flow.

3. If the output of the secondary heated

temperature equals the desired temperature,

no control action is needed, the stem is taken

out.

A. Basics

A SCADA system consists of a number of

components.

The RTUs.Remote telemetry or

terminal units.The central SCADA master system.

Field Instrumentation

The SCADA RTU is a (hopefully) small ruggedized

computer, which provides intelligence in the field,

and allows the central SCADA master to

communicate with the field instruments. It is a standalone data acquisition and control unit. Its function is

to control process equipment at the remote site,

acquire data from the equipment, and transfer the data

back to the central SCADA system.

FIX32 software enables you to configure a system

environment that provides:

Supervisory control, batch processing, data

acquisition, continuous control, and statistical process

control for industrial applications.

VII. BOILER OPERATION

Water plays a major part in the generation of steam.

Inlet water to the steam drum should be in purified

form, for that, PH value of the water should be

maintained, and stored in de-aerator tank. Feed water

pump is switched ON by using feed water pump

switch. The water from the de-aerator tank is allowed

to pass through two parallel pipes. In one pump the

flow rate is maintained at 130% and in another it is

5%. Thus the failure of any one pipe does not affect

the boiler operation. The water is passed through

economizer, thus the heat in the outgoing gases is

recovered, by transferring its heat to the water. Then

the heated water is made to flow through steam and

water drum. In this, water should be maintained at

least at 50%. For sensing water level we use PID

controller in AB PLC. When the level is lesser than

or greater than 50%, PID controller senses the level

change and sends the appropriate control signal to the

feed water valve 1 or valve 2. Thus, in spite of any

changes in disturbance variable, the water level can

be maintained at 50% by proper turning of PID

controller.

Fig. 3, PID Controller in SCADA

A. Flowchart

The operation is summarized as flowchart as below

Water in the water drum is maintained at more than

75%. This water is circulated back to steam and water

drum, due to difference in temperature, high amount

Proceedings of 11th IRF International Conference, 15th February-2015, Bengaluru, India, ISBN: 978-93-84209-90-2

49

PLC Scada Based Boiler Control Operation

CONCLUSION

The most important aspect of any power plant is the

boiler control. Several techniques can be

implemented to control the boiler in power plant. The

method that has to be used relies on varied objectives

like superior quality, increased efficiency, high profit

and other such points depending upon the purpose of

the company that implies it. With the prime objective

of catering to these necessities and the needs of the

industrial sector, significance has been given here to

automation. This paper presented here has kept in

mind, the ceaseless changes that are relentlessly

taking place in the contemporary scenario of the

industrial segment. Emphasis has been given to the

automation process that is now rapidly taking its

place in all the power plants across the globe. The

Paper has furnished itself to study the integral parts of

the entire process involved, their implementation and

the problems that may show up have also been given

their due importance. The future work deals with the

purification of water to the boiler and the air

circulation for the boiler to burn the fuel using same

automation technique.

RESULT

Fig.4, Flow chart of Boiler Operation

REFERENCES

[1]. Control of Bolier operation using PLC-SCADA ,

shankar,k.gowri,

Jan

2008

source:International

Multiconference of engineers and computer scentist

[2]. Control of Bolier operation using PLC-SCADA , H.P.Patil,

C.K.Satpute, March 2014 , International Journal for

technology reasearch in enginnering ISSN(online)- 23474718

[3]. Boyer, Stuart SCADA: Supervisory Control and Data

Acquisi-tion, Instrument Society of America, Research

Triangle, NC. 1993.

[4]. Dale E.Seborg,Thomas F.Edgar,Duncan A.Mellichamp

and

Francis

J.Doyle

Process Dynamics and

Control, Process Automation, 2011.

[5]. M.V. Radhakrishnan Modern Boiler Design, ISA Trans.,

2000

[6]. Textbook on Thermal Engineering by R.K.Rajput.

Fig.4, Flow chart of Boiler Operation

Proceedings of 11th IRF International Conference, 15th February-2015, Bengaluru, India, ISBN: 978-93-84209-90-2

50

Вам также может понравиться

- PLC Automation of Steam TurbineДокумент5 страницPLC Automation of Steam TurbineWinarsita Gilang100% (1)

- Boiler Control OverviewДокумент4 страницыBoiler Control OverviewMAS98Оценок пока нет

- Automation of Boiler Control SystemsДокумент12 страницAutomation of Boiler Control SystemsHaseeb Ur Rehman0% (1)

- Final Report - Boiler AutomationДокумент62 страницыFinal Report - Boiler Automationdhirajsingh_avit90% (10)

- DC Motor ControllerДокумент7 страницDC Motor ControllerJan MicahОценок пока нет

- Ys 1700 SettingsДокумент4 страницыYs 1700 SettingsvjОценок пока нет

- Combustion Control System For A Marine BoilerДокумент2 страницыCombustion Control System For A Marine Boilermavericksailor100% (2)

- Air Compressor On A ShipДокумент2 страницыAir Compressor On A ShipBhalchandra ChandakkarОценок пока нет

- User ManualДокумент32 страницыUser ManualAljun LumbaoОценок пока нет

- Boiler Start-Up and Operational Procedures - 660MW DHIДокумент44 страницыBoiler Start-Up and Operational Procedures - 660MW DHIHemendra VermaОценок пока нет

- Fuel Oil Forwarding System TrainingДокумент11 страницFuel Oil Forwarding System TrainingMohammed Ibrahim AsifОценок пока нет

- Determine flow rate and calculate gas billДокумент4 страницыDetermine flow rate and calculate gas billbrianОценок пока нет

- Lab Name: Demonstration and Operation of 5KW Steam Power PlantДокумент14 страницLab Name: Demonstration and Operation of 5KW Steam Power PlantFarhan EdwinОценок пока нет

- AhmadJavaid (TZIDC ABB Positioner)Документ17 страницAhmadJavaid (TZIDC ABB Positioner)ahmedОценок пока нет

- Inert Gas SystemДокумент3 страницыInert Gas Systemmehedi2636Оценок пока нет

- Drum Level CompensationДокумент8 страницDrum Level CompensationSmriti PrasadОценок пока нет

- Engine Testing ShopДокумент5 страницEngine Testing ShopSri Ram VikasОценок пока нет

- 6.8 Temperature Level Monitoring and Automatic Control in BoilerДокумент5 страниц6.8 Temperature Level Monitoring and Automatic Control in BoilerPushpa Mohan Raj100% (1)

- Evaluating Boiler Efficiencies Using Direct and Indirect MethodsДокумент52 страницыEvaluating Boiler Efficiencies Using Direct and Indirect MethodsdebelaОценок пока нет

- Steam Plant FundamentalsДокумент228 страницSteam Plant FundamentalsMark Allen San Antonio100% (1)

- Ignition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionДокумент8 страницIgnition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionthinhklОценок пока нет

- Ammonia Refrigeration Cycle AnalysisДокумент44 страницыAmmonia Refrigeration Cycle AnalysisAntonio Di FioreОценок пока нет

- Continuum Mechanics For EngineersДокумент53 страницыContinuum Mechanics For Engineersshushant kumarОценок пока нет

- AALBORG Boiler ControlДокумент185 страницAALBORG Boiler ControlBatuhan ZerenerОценок пока нет

- Jacket Water SystemДокумент2 страницыJacket Water SystemJitendra KumarОценок пока нет

- U of I Facilities Standards - Control ValvesДокумент25 страницU of I Facilities Standards - Control Valvesforevertay2000Оценок пока нет

- Build Basic Refrigeration CircuitsДокумент8 страницBuild Basic Refrigeration CircuitsMuhammad HafeezОценок пока нет

- Experiment - 2: AIM: To Study The Characteristics of Pelton Turbine and Plot GraphsДокумент8 страницExperiment - 2: AIM: To Study The Characteristics of Pelton Turbine and Plot GraphsNishant JainОценок пока нет

- Displacer Type Level SwitchДокумент10 страницDisplacer Type Level SwitchKarthik Chockkalingam100% (1)

- CPU Structure and Function: Arithmetic Logic Unit Control Unit Control Registers DatapathДокумент47 страницCPU Structure and Function: Arithmetic Logic Unit Control Unit Control Registers DatapathSuhaila NajibОценок пока нет

- Commissioning Manual DH-6155: Descon Engineering LTDДокумент102 страницыCommissioning Manual DH-6155: Descon Engineering LTDHammad AhmedОценок пока нет

- ABB's PMS prevents multi-million dollar shutdownsДокумент5 страницABB's PMS prevents multi-million dollar shutdownsdennisraj1Оценок пока нет

- 2013 Catalog Ferroli Pompe de CalduraДокумент152 страницы2013 Catalog Ferroli Pompe de CalduraMatei JelecuteanuОценок пока нет

- Lesson 06 - Feed & CondensateДокумент38 страницLesson 06 - Feed & CondensatehafezyakoutОценок пока нет

- 3 Element Drum Level ControlДокумент3 страницы3 Element Drum Level ControlSriteja JosyulaОценок пока нет

- Boiler Control SystemsДокумент64 страницыBoiler Control SystemsSridhar DineshОценок пока нет

- Energy Efficiency Solutions: Tackling The Energy Challenges ThroughДокумент16 страницEnergy Efficiency Solutions: Tackling The Energy Challenges ThroughHadrien FaryalaОценок пока нет

- What Is CogenerationДокумент3 страницыWhat Is CogenerationmuthuОценок пока нет

- Boiler fouling and slagging prevention with intelligent sootblowingДокумент8 страницBoiler fouling and slagging prevention with intelligent sootblowingSuganya LokeshОценок пока нет

- Cold Junction Compensation PDFДокумент10 страницCold Junction Compensation PDFAbhayy DevОценок пока нет

- Boiler Drum Level Measurement and ControlДокумент13 страницBoiler Drum Level Measurement and ControlasdmoomОценок пока нет

- CS2024 Coal Feeder SpecsДокумент41 страницаCS2024 Coal Feeder SpecsRiaz AhmedОценок пока нет

- 11 ShipCtrlsystems 3020Документ12 страниц11 ShipCtrlsystems 3020Rajan BhandariОценок пока нет

- Operation Manual CS6 GasДокумент17 страницOperation Manual CS6 Gasmind2008Оценок пока нет

- HGU ManualДокумент15 страницHGU ManualGarvit ChopraОценок пока нет

- Controller Design For Controlling Water Level Control MechanismДокумент24 страницыController Design For Controlling Water Level Control MechanismKasehun Getinet KitilaОценок пока нет

- Mini PLC projects for conveyor belt painting and bulk material fillingДокумент3 страницыMini PLC projects for conveyor belt painting and bulk material fillingAhmed Samy El GoharyОценок пока нет

- Boiler Level ControlДокумент20 страницBoiler Level Controltinuvalsapaul100% (1)

- Boiler Control Using SCADAДокумент9 страницBoiler Control Using SCADAAdarsh Sunkad0% (1)

- Control Boiler Operation PLC-SCADAДокумент26 страницControl Boiler Operation PLC-SCADAKannan S100% (2)

- Control of Boiler Operation Using PLC - SCADAДокумент6 страницControl of Boiler Operation Using PLC - SCADAvikyarifОценок пока нет

- Control of Boiler Operation Using Plc-ScadaДокумент4 страницыControl of Boiler Operation Using Plc-ScadaSiddhantОценок пока нет

- Power Plants InspectionДокумент2 страницыPower Plants InspectionRamkumar KrishnamurthyОценок пока нет

- Color Making and Mixing Process Using PLCДокумент5 страницColor Making and Mixing Process Using PLCmubashirОценок пока нет

- Color Making and Mixing Process Using PLCДокумент5 страницColor Making and Mixing Process Using PLCInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- PLC Full ReportДокумент10 страницPLC Full ReportJian Jie0% (1)

- Ia TheoryДокумент7 страницIa Theoryravi KumarОценок пока нет

- Paper Mill Operation and TheoryДокумент85 страницPaper Mill Operation and TheoryS Bharadwaj Reddy50% (2)

- Automation of Chemical Process PlantДокумент4 страницыAutomation of Chemical Process PlantRajeshОценок пока нет

- VFR by Michael AshamДокумент8 страницVFR by Michael AshamHany Elsawy AbdelrahmanОценок пока нет

- DT90 Digital Room ThermostatДокумент8 страницDT90 Digital Room ThermostatAbdullah YÜKSELОценок пока нет

- ClassNK - MEPC80 SummaryДокумент5 страницClassNK - MEPC80 SummaryPereira JenОценок пока нет

- BOQ - SIPIL GI 150 KV RAJAPAKSIДокумент14 страницBOQ - SIPIL GI 150 KV RAJAPAKSIReinhard Jesaya SimbolonОценок пока нет

- Freefall Lifeboats: in Maritime EquipmentДокумент4 страницыFreefall Lifeboats: in Maritime Equipmentbernardinodino100% (1)

- Electrical, Electronic and Logic ComponentsДокумент29 страницElectrical, Electronic and Logic ComponentsJomer JuanОценок пока нет

- Introducing The GEK Gasifier Systems - Rev3Документ18 страницIntroducing The GEK Gasifier Systems - Rev3ettypasewangОценок пока нет

- Third Quarter-Module 4: Week 4Документ11 страницThird Quarter-Module 4: Week 4SHERLA PERENAОценок пока нет

- Installation Instructions: MFP RangeДокумент12 страницInstallation Instructions: MFP RangeSoheil GhasemiОценок пока нет

- Proximity Probe Mounting OptionsДокумент6 страницProximity Probe Mounting OptionstoilalongОценок пока нет

- TCL ProductCatalogueДокумент24 страницыTCL ProductCatalogueSarah Shibu ThomasОценок пока нет

- Structure of Atom Key ConceptsДокумент22 страницыStructure of Atom Key ConceptsMeersОценок пока нет

- Brake System Design For A Single Seater VehicleДокумент27 страницBrake System Design For A Single Seater VehicleAshraf Zulkafli100% (1)

- 03 VESPR and PolarityДокумент5 страниц03 VESPR and PolarityNursalfarinah BasirОценок пока нет

- Energy Revision Summary Key PointsДокумент8 страницEnergy Revision Summary Key PointsyuhОценок пока нет

- Free Surface Flow Simulation With ACUSIM in The Water IndustryДокумент8 страницFree Surface Flow Simulation With ACUSIM in The Water IndustryKhiladi PujariОценок пока нет

- Grove RT700E: Product GuideДокумент20 страницGrove RT700E: Product GuideLuis Miguel Rivera SoplopucoОценок пока нет

- Mitsubishi Electric PLFY-P VBM-E Service Manual EngДокумент44 страницыMitsubishi Electric PLFY-P VBM-E Service Manual Engengenharia proclimaОценок пока нет

- Golden rules of work permitsДокумент18 страницGolden rules of work permitsRusihan HSEОценок пока нет

- Installation, Operation and Maintenance Instructions: Penberthy Model Tme MixerДокумент4 страницыInstallation, Operation and Maintenance Instructions: Penberthy Model Tme MixerGuillermo MartinezОценок пока нет

- CEB1061Документ6 страницCEB1061oscar horacio floresОценок пока нет

- XFP100E CB1 50HZ pump curvesДокумент6 страницXFP100E CB1 50HZ pump curvesDanilo RochaОценок пока нет

- Brosur Wasion HyMeter 300 PT. OthoДокумент4 страницыBrosur Wasion HyMeter 300 PT. OtholuwiceОценок пока нет

- Extraction of Betalain Dye From Beetroot and Preparation of Organic DSSCДокумент4 страницыExtraction of Betalain Dye From Beetroot and Preparation of Organic DSSCrobel kassawОценок пока нет

- Hydraulic Calculations MudpumpДокумент1 страницаHydraulic Calculations MudpumpSudish BhatОценок пока нет

- GM Part List - D79 D69 Autres - D3908 DR PDFДокумент14 страницGM Part List - D79 D69 Autres - D3908 DR PDFAbderrahmane AbdoОценок пока нет

- IEEE C57-117 Guide For Reporting Failure Investigation Transformer-ReactorДокумент29 страницIEEE C57-117 Guide For Reporting Failure Investigation Transformer-ReactorSukant Bhattacharya100% (1)

- HEC Pakistan Syllabus For B.S. & M.S.physics 2005Документ75 страницHEC Pakistan Syllabus For B.S. & M.S.physics 2005Jehan Zaib Ali Khan100% (2)

- 05Документ17 страниц05Andreas StathatosОценок пока нет

- PLC-controlled Stepper Motor Drive For NC PositionДокумент10 страницPLC-controlled Stepper Motor Drive For NC PositiondeoarshiОценок пока нет