Академический Документы

Профессиональный Документы

Культура Документы

Reuse of Char Waste As Road Material

Загружено:

ychodneker0 оценок0% нашли этот документ полезным (0 голосов)

26 просмотров1 страницаAbstract

Оригинальное название

Reuse of Char Waste as Road Material

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документAbstract

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

26 просмотров1 страницаReuse of Char Waste As Road Material

Загружено:

ychodnekerAbstract

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

Reuse of Char waste as Road Material

Dr. K G Guptha* Yeshwant V. Prabhu Chodnekar #

Present study deals with understanding the material produced in Goa Sponge and Power Ltd(GSPL) about its

suitability related to Asphalt Concrete Performance in Pavements. A set of performance-related aggregate tests for

evaluating aggregates for use in HMA pavements. Pavement performance indicators assumed to be related to these

laboratory aggregate tests were permanent deformation because of traffic loading (both with and without stripping),

fatigue cracking, and surface defects (e.g., raveling, popouts, and potholes).The performance relationships were

developed based on laboratory tests.

The study on Reuse of Char waste as Road Material recommends the use of Char aggregates in wearing coat,

bitumen macadam, and wet mix macadam in road construction. Char waste is a processed solid waste of sponge iron

industry. This is selected as a road material in view of its expected scope of application, available quantities and

accessibility throughout the whole country. Its availability in India is around 193.4lakh tones and in Goa about

1.9lakhs tones. Various physical parameters, chemical tests, combination of Char aggregates with conventional

aggregates, binding parameters of it with the bitumen were evaluated through laboratory tests as per relevant IS

Code and MoRTH (Ministry of Road Transport and Highway) specifications.

The objective of conducting physical and chemical tests were to get a better idea about the material properties,

suitability of the material, and if it satisfies or qualifies the code requirements. Bitumen moulds were casted for Char

aggregate and for combinations with conventional aggregate for various layers with different bitumen content. This

was carried out to verify the strength or the load it can take and to find its flow value using Marshall Stability test.

Since naturally occurring aggregates are scarce compared to the present and future demand, Char waste can be used

as better substitute. It is an eco friendly material. Looking at the grading of the Char waste, it can be comfortably

adopted for WMM, BM and AC. Since Char is used and handled at lower temperature compared to conventional

aggregates, it results in precious energy points saving. As it requires less compaction there is less fuel consumption.

Tests have shown that it is highly durable material. Considering Char waste from quantum wise, quality wise and

economy wise it is a positive promising road material..

KEY WORDS: Char waste, MoRTH, Binder, Macadam, Pavement, Marshal Stability

Вам также может понравиться

- LinksДокумент1 страницаLinksychodnekerОценок пока нет

- DSR 2012Документ448 страницDSR 2012jagadees21100% (2)

- CBRT Syllabus for Assistant Professor Civil EngineeringДокумент2 страницыCBRT Syllabus for Assistant Professor Civil EngineeringychodnekerОценок пока нет

- Ayurveda PhysicianДокумент1 страницаAyurveda PhysicianKirankumar MutnaliОценок пока нет

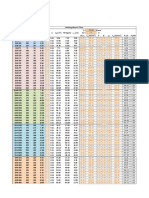

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Goa College of Engineering Old Q PaperДокумент2 страницыGoa College of Engineering Old Q PaperychodnekerОценок пока нет

- Inspirational Words FarewellДокумент2 страницыInspirational Words FarewellychodnekerОценок пока нет

- Syllabus Lecturer ElectricalДокумент1 страницаSyllabus Lecturer ElectricalychodnekerОценок пока нет

- Theory QuestionsДокумент1 страницаTheory QuestionsychodnekerОценок пока нет

- Panasonic ACДокумент36 страницPanasonic ACychodnekerОценок пока нет

- Design For Flexure Is 800 2007Документ2 страницыDesign For Flexure Is 800 2007ychodnekerОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Input: kN L= mm E= k= Section = ISHB 400 at 77.4 kg /m mm mm mm mm A= α = P= N/mm f = N/mmДокумент4 страницыInput: kN L= mm E= k= Section = ISHB 400 at 77.4 kg /m mm mm mm mm A= α = P= N/mm f = N/mmychodnekerОценок пока нет

- Design of Concentric Compression Member IS 800 - 2007 PDFДокумент1 страницаDesign of Concentric Compression Member IS 800 - 2007 PDFychodnekerОценок пока нет

- EMI Calculator For Home Loan, Car Loan & Personal Loan in IndiaДокумент6 страницEMI Calculator For Home Loan, Car Loan & Personal Loan in IndiaychodnekerОценок пока нет

- Presents: Concrete-Techgroup Indian Guide To Quality ConcreteДокумент2 страницыPresents: Concrete-Techgroup Indian Guide To Quality ConcreteychodnekerОценок пока нет

- SPSHAHДокумент4 страницыSPSHAHychodnekerОценок пока нет

- Calculation Sheet: Job No. Sheet Rev. Job. Title Date Checked by DateДокумент1 страницаCalculation Sheet: Job No. Sheet Rev. Job. Title Date Checked by DateychodnekerОценок пока нет

- Hydrodynamic Analysis of TLPДокумент8 страницHydrodynamic Analysis of TLPychodnekerОценок пока нет

- Aerodynamics of Wind TurbinesДокумент69 страницAerodynamics of Wind Turbinesangelgabri12Оценок пока нет

- Reuse of Char Waste As Road MaterialДокумент1 страницаReuse of Char Waste As Road MaterialychodnekerОценок пока нет

- Goa Engineering College Civil Engineering SyllabusДокумент7 страницGoa Engineering College Civil Engineering SyllabusychodnekerОценок пока нет

- (ANSYS AQWA) Study On Mooring System Design of Floating Offshore Wind Turbine in Jeju Offshore AreaДокумент9 страниц(ANSYS AQWA) Study On Mooring System Design of Floating Offshore Wind Turbine in Jeju Offshore AreaychodnekerОценок пока нет

- LCorrections in Is 800 2007Документ4 страницыLCorrections in Is 800 2007Naveen ParthasarathyОценок пока нет

- IS 10262 - 2009 - RevisionДокумент18 страницIS 10262 - 2009 - RevisionSampathKumara Swamy K100% (4)

- Offshore Structural DesignДокумент36 страницOffshore Structural Designmesserklinge100% (1)

- DNV Code ListДокумент3 страницыDNV Code Listychodneker100% (1)

- The World's Oceans: A Guide to Earth's Major Bodies of Saline WaterДокумент1 страницаThe World's Oceans: A Guide to Earth's Major Bodies of Saline WaterychodnekerОценок пока нет

- Wind Turbine Power CalculationДокумент5 страницWind Turbine Power CalculationRavi Acharya100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Helical Twisted Roots Pump E00636Документ10 страницHelical Twisted Roots Pump E00636Ade Bagus SetiawanОценок пока нет

- Report Filed by The APPCBДокумент30 страницReport Filed by The APPCBhcbbОценок пока нет

- Philippines Pharmacy Act PenaltiesДокумент6 страницPhilippines Pharmacy Act PenaltiesOdyОценок пока нет

- ICARUS' Trunnion Mounted Ball Valve Design GuideДокумент36 страницICARUS' Trunnion Mounted Ball Valve Design GuidezayerirezaОценок пока нет

- Brochure Nuwind General Purpose CentrifugesДокумент28 страницBrochure Nuwind General Purpose CentrifugesMarco Antonio Lopez BalderasОценок пока нет

- IrelДокумент29 страницIrelvarghis_k_thomasОценок пока нет

- Microalgae To Biofuels Promising' Alternative and Renewable EnergyДокумент13 страницMicroalgae To Biofuels Promising' Alternative and Renewable EnergyJeevan KumarОценок пока нет

- 41 42Документ4 страницы41 42alfa alfaОценок пока нет

- Concrete Repair and Structure StrengtheningДокумент5 страницConcrete Repair and Structure StrengtheningAidaJalaluddinОценок пока нет

- Characterization and Reuse of Kiln Rollers Waste in The Manufacture of Ceramic Floor TilesДокумент7 страницCharacterization and Reuse of Kiln Rollers Waste in The Manufacture of Ceramic Floor Tilesmap vitcoОценок пока нет

- Selectividad Ingles 2011-2012Документ2 страницыSelectividad Ingles 2011-2012sergiosanroОценок пока нет

- Keystone Butterfly PDFДокумент12 страницKeystone Butterfly PDFCésar AugustoОценок пока нет

- Criteria air pollutants: Sources, health effects and control of particulate matterДокумент8 страницCriteria air pollutants: Sources, health effects and control of particulate matterSumaiya ImamОценок пока нет

- BIO130 Sec2 - Lec1and2 - 1pptДокумент38 страницBIO130 Sec2 - Lec1and2 - 1pptlemonpartymanОценок пока нет

- Materials Finer Than 75 - : Standard Test Method For M (No. 200) Sieve in Mineral Aggregates by WashingДокумент3 страницыMaterials Finer Than 75 - : Standard Test Method For M (No. 200) Sieve in Mineral Aggregates by WashingLuis Alejandro Sánchez LópezОценок пока нет

- Synthesis and Reactivity in Inorganic and Metal-Organic ChemistryДокумент18 страницSynthesis and Reactivity in Inorganic and Metal-Organic ChemistryYoselin GomezОценок пока нет

- Analysis of Amino Acids in Spinach and AppleДокумент1 страницаAnalysis of Amino Acids in Spinach and AppleSilwanus ManaoОценок пока нет

- India refinery configurations-Meeting future demand & regulationsДокумент9 страницIndia refinery configurations-Meeting future demand & regulationsphantanthanhОценок пока нет

- Choose The Correct. (Marks: 50)Документ37 страницChoose The Correct. (Marks: 50)AmaanОценок пока нет

- Step 1 BiochemistryДокумент12 страницStep 1 Biochemistrylotusnelum7100% (2)

- Jak1 Aur El DWG A 0 9035 (D)Документ1 страницаJak1 Aur El DWG A 0 9035 (D)Budi HahnОценок пока нет

- TS - X Chemistry All DCEB Papers Chapter Wise Academic Standard Wise Prefinal - I & 2 QuestionsДокумент40 страницTS - X Chemistry All DCEB Papers Chapter Wise Academic Standard Wise Prefinal - I & 2 Questionsc18180707Оценок пока нет

- Spredox D 364 For Solvent Based InkjetДокумент9 страницSpredox D 364 For Solvent Based InkjetPravin TandelОценок пока нет

- Creating an Eco-Friendly Fiber SheetДокумент66 страницCreating an Eco-Friendly Fiber SheetDosirt VisdaОценок пока нет

- Sci 9 DLL Q2 W1Документ6 страницSci 9 DLL Q2 W1Nomar Maigue DarОценок пока нет

- Pressure Operated Water Valve Types WVFX and WVS: Data SheetДокумент11 страницPressure Operated Water Valve Types WVFX and WVS: Data SheetДаниіл ЩигельськийОценок пока нет

- NDA Chemistry MCQs For PracticeДокумент9 страницNDA Chemistry MCQs For Practicekumar HarshОценок пока нет

- Cooling Tower AnalysisДокумент6 страницCooling Tower AnalysisACОценок пока нет

- Production of MTBE (Methyl Tertiary Butyl Ether) From Methanol and Butylene by Catalytic ConversionДокумент11 страницProduction of MTBE (Methyl Tertiary Butyl Ether) From Methanol and Butylene by Catalytic ConversionAsim RafiqueОценок пока нет

- Crack Control for Concrete Masonry VeneersДокумент10 страницCrack Control for Concrete Masonry VeneersAdam JonesОценок пока нет