Академический Документы

Профессиональный Документы

Культура Документы

A Biologically Inspired Hydrophobic Membrane For Application in Pervaporation PDF

Загружено:

JH BJОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A Biologically Inspired Hydrophobic Membrane For Application in Pervaporation PDF

Загружено:

JH BJАвторское право:

Доступные форматы

Article

pubs.acs.org/Langmuir

A Biologically Inspired Hydrophobic Membrane for Application in

Pervaporation

Nora Jullok,*,, Rodrigo Martnez, Christine Wouters, Patricia Luis, Mara Teresa Sanz,

and Bart Van der Bruggen

Department of Chemical Engineering, Process Engineering for Sustainable Systems (ProcESS), KU Leuven, W. de Croylaan 46,

B-3001 Heverlee, Belgium

Department of Chemical Engineering, University of Burgos, 09001 Burgos, Spain

School of Bioprocess Engineering, Universiti Malaysia Perlis, Kompleks Pusat Pengajian Jejawi 3, 02600 Arau, Perlis, Malaysia

ABSTRACT: An articial polydimethylsiloxane/polyphenylsulfone (PDMS/PPSU)

membrane, which emulates the hydrophobic behavior of natural membranes, was

synthesized. Hydrophobicity was achieved by coating the membrane surface sublayer

using conventional silicon material, which imitates the character of epicuticular wax (EW)

of Prunus laurocerasus L. leaves. It was then applied as a separation medium in

pervaporation (PV) of diluted mixtures of ethyl acetate and aroma compounds. The

membranes biomimetic characteristics were evaluated using surface morphology analyses,

that is, Fourier transform infrared (FTIR), water contact angle measurements, and SEM

imaging. A comparison of properties of the membranes synthesized in this work against

selected hydrophobic plant leaves indicated a good agreement. PV using these biologically

inspired articial membranes demonstrated preference for the permeation of ethyl acetate.

Besides intrinsic characteristics, it was also observed that the chemical potential is highly

inuential in activating sorption, diusion, and desorption of a specic compound.

cuticle are called epicuticular waxes.3 Jetter et al. further

explained that wax lms from P. laurocerasus consist of a

mixture of alkanes with dierent chain lengths and other

compound classes.4 Typical wax morphologies include thin

lms and three-dimensional structures such as massive crusts,

granules, plates, platelets, laments, rods, and tubules with

hollow center.3 According to several other studies, cuticles

serve as an ecient transport barrier in controlling dehydration

by transpiration, besides managing the plantpathogen

interactions.3,59 Water movement across plant cuticles is

similar to its movement across membranes, which can be

quantied using the rst Ficks Law. Cuticular water

permeability is highly dependent on the cuticular/water

partition coecient, porosity, membrane thickness, tortuosity

factor, self-diusion, and the hindrance factor.10 On the basis of

these ndings, it can be concluded that membranes exhibiting

these curticular properties are extremely useful for industrial

applications, especially for organic traces removal in aqueous

solution through pervaporation. This work aims to transfer

these cuticular wax properties found in plants by introducing

and synthesizing a composite polymer-based membrane.

Polydimethylsiloxane (PDMS) membranes have been frequently used in PV to recover organic solvents from aqueous

mixtures,1113 and also for gas separation.14 As a support

material, a third member of the polysulfone family,

polyphenylsulfone (PPSU), with better properties than

1. INTRODUCTION

Nature has inspired various inventions and technological

solutions to overcome limitations of mankind in life. Various

improved materials, tools, structures, mechanisms, processes,

algorithms, and methods resulted from the understanding of

nature and its phenomena. Flying, for instance, was inspired by

the mechanism used by birds, while divers ns were replicated

from semiaquatic creatures such as seals.1 The word

biomimetics, which rst appeared in Websters dictionary in

1974, is dened as the study of the formation, structure or

function of biologically produced substances and materials (as

enzymes or silk) and biological mechanisms and processes (as

protein synthesis or photosynthesis) especially for the purpose

of synthesizing similar products by articial mechanisms, which

mimic natural ones.2 Biomimetic research resulted in the

understanding of various phenomena such as wettability and

the self-cleaning eect found in natural leaves such as Nelumbo

nucifera gaern (Lotus leaf), Oryza sativa L. (Rice leaf), Colocasia

(Taro leaf), Prunus laurocerasus L. leaves (Cherry laurel), and

Setcreasea purpurea boom (purple setcreasea). Recently, studies

discovered that leaves in general are laminated with organic

lms containing C, H, and O elements. Others believed that the

majority of lower and higher-altitude plants (e.g., owers,

leaves, fruits, stems) consist of a continuous extracellular

membrane known as cuticle, which covers the outer layer of the

epidermal cell.3 In general, cuticles are cutin-based composite

materials with integrated and superimposed lipids known as

waxes. Plant waxes embedded into the cuticle are called

intracuticular waxes, whereas waxes superimposed onto the

2013 American Chemical Society

Received: October 24, 2012

Published: January 16, 2013

1510

dx.doi.org/10.1021/la3050253 | Langmuir 2013, 29, 15101516

Langmuir

Article

Table 1. Physicochemical Properties of the Seven Selected Aroma Compoundsa

properties

formula

functional group

MW, g/mol

SG @ 25 C

boiling point, C

Psat (26 C), Pa

solubility in water @ 20 C, g/L

CH3CO2C2H5

ROCOR

88.1

0.901

77.1

13 045

80

C5H10O

RHCO

86.1

0.803

92.5

7035

15

C5H8O2

ROCCOR

100.1

0.957

108

2918

60

C6H12O

RHCO

100.2

0.814

128.3

1540

IS

C5H10O

ROH

86.1

0.839

114.4

1348

IS

C8H16O

ROH

128.2

0.83

8485

65

IS

C6H5CHO

RHCO

106.1

1.046

179

181

0.3

1 = ethyl acetate, 2 = 3-methylbutyraldehyde, 3 = 2,3-pentanedione, 4 = hexanal, 5 = 1-penten-3-ol, 6 = 1-octen-3-ol, 7 = benzaldehyde, IS =

insoluble, SG = specic gravity.

W (%) = solute 100%

Wsolution

polysulfone (PSf) and polyethersulfone (PES) in terms of

chemicals and temperature resistance was utilized.15 PPSU is

considerably a new membrane material, which potentially

serves as an alternative for other commercially available PV

membranes. Others have studied PPSU as a support to

polymeric liquids in the recovery of aromatic compounds from

wastewater,16 PPSU/PBNPI blend membranes for hydrogen

separation,17 and as a proton-conducting fuel cell membrane.18

Because PPSU has been proven to be very robust,18 this study

explores the use of such material in combination with PDMS.

This investigation also analyzes the eect of operating

conditions by means of solutes concentration and feed

temperature on the permeating components. Structure and

morphologies of the fabricated membranes are analyzed using

contact angle measurements, FTIR, and SEM imaging. Finally,

these synthesized biomimetic membranes are applied in the

pervaporation (PV) process for permeation of hydrophobic

compounds (ethyl acetate, 3-methylbutyraldehyde, 2,3-pentanedione, hexanal, 1-penten-3-ol, 1-octen-3-ol, benzaldehyde).

(1)

After thorough mixing, agitation in the solution was lowered to

reduce the amount of air intake. Bubbles present in the PDMS

solution were removed using vacuum deairing, prior to cooling at

room temperature. The synthesized at sheet PPSU was circularly cut

and capped on one side of a cylinder. Next, the PDMS solution was

carefully poured onto the surface of the membrane, while swirling the

capped cylinder for an even coating distribution. Finally, these coated

PDMS/PPSU membranes were ready for use upon oven-curing for 45

min at 105 C, denoted as M1, M2, and M3 for 5, 10, and 15 wt %

PDMS, respectively.

2.3. Membrane Characterization. 2.3.1. Wettability. Contact

angle measurements were conducted using a standard contact angle

apparatus (KRU SS GmbH Germany, model DSA 10-Mk2) to

determine the degree of wettability. The measurement was performed

using a drop-shape analysis software to study the video images of the

pendant drops. A syringe plunger was utilized for drop depositions on

the surface of the membrane under study.

2.3.2. Microscopy Study of Natural and Synthetic Surface. The

surface and cross-sectional area of lotus leaf, lotus ower, taro leaf, and

the PDMS/PPSU membranes were obtained using SEM (Philip XL30

ESEM FEG, The Netherlands). To analyze PDMS/PPSU as a

function of polymer concentration, the membranes were split during

liquid nitrogen immersion to enable accurate cross-section imaging.

Magnications up to 2500 were obtained at 20 kV.

2.3.3. Analysis of Samples. The compositions of aroma compounds

permeating through the membranes were analyzed using head space

gas chromatography (HS-GC). HS-GC consists of a gas chromatography (Perkim Elmer autosystem) and a headspace sampler (Perkim

Elmer HS16). The GC column was a cpSil8CB 50 m 0.32 mm. The

injector and ame ionization detector temperatures were set at 180

and 250 C, respectively. The oven was operated at temperatures

ranging from 40 to 180 C, while helium with purity of 99.99% was

used as carrier gas.

2.4. Application of Nature-Inspired Membrane in Pervaporation. Besides regulating water content in plants, epicuticular wax

serves as the rst and main barrier to the penetration of agriculturally

important chemicals. Similarly, this concept is applied in this work.

The penetration of seven dierent synthetic chemicals with distinct

physicochemical properties through the membrane was studied: ethyl

acetate, 3-methylbutyraldehyde, 2,3-pentanedione, hexanal, 1-penten3-ol, 1-octen-3-ol, and benzaldehyde. Their physicochemical properties

are summarized in Table 1.

For this investigation, three feed concentrations were used: 1, 5, and

10 ppm in water, containing equal amounts of the seven compounds

while varying the feed temperature from 25 to 45 C. To achieve

equilibrium, the tested membrane was mounted onto the membrane

test cell, and feed was circulated overnight. Because of the dense

structure of the membrane surface, the sorption of liquid into the

dense layer to reach equilibrium between membrane and feed mixture

normally takes a long time at ambient conditions. Thus, overnight

immersion may ensure that both membrane and feed solution are in

equilibrium prior to PV experiments. Vacuum was not employed on

2. MATERIALS AND METHODS

2.1. Materials. Polyphenylsulfone (PPSU, Radel R-5000) with an

average molecular weight of 50 000 g mol1 was obtained from Solvay

Advanced Polymer Belgium. Polydimethylsiloxane (PDMS, Sylgard

184), which consists of two-part liquid component kits (part A/part B

to be mixed in 10:1 ratio by weight), was purchased from Dow

Corning Belgium, while N-methyl-pyrrolidone (NMP, 99%), 1-octen3-ol (98%), 3-methylbutyaldehyde (98%), and 2,3-pentenedione

(97%) were purchased from Acros Organics (Geel, Belgium). Hexanal

(98%) and 1-penten-3-ol (99%) were obtained from Sigma Aldrich

Chemie GmbH (Steinhem, Germany). Ethyl acetate (EtOAc) (HLPC

grade, >99%) was purchased from Fischer Scientic (Loughborough,

UK), benzaldehyde (99+%) was from Avocado Research Chemicals

Limited (Lancs, UK), and n-hexane was from Chem-Lab NV

(Zedelgem, Belgium).

For the synthesis of hydrophilic sublayer membrane, a hydrophilic

PPSU sublayer is rst produced prior to the hydrophobic coating. The

preparation of the hydrophilic sublayer was performed by immersion

precipitation. First, the polymer solution was cast on a glass plate and

immersed in a nonsolvent bath for a few minutes. It was then removed

from the water bath and rinsed with demineralized water. Next, the

membrane was immersed in another clean water bath to allow removal

of excess solvents. Details of this synthesis have been described in

previous work,19 where a membrane with 25 wt % PPSU was used as

sublayer. This composition was chosen due to its proven high ux in

PV dehydration of acetic acid and water solution.19

2.2. Preparation of PDMS/PPSU Membrane. The PDMS

coating was prepared using Sylgard 184 silicone elastomer kit, which

consists of two parts: the lot-matched base (A) and the curing agent

(B). Parts A and B are mixed in a ratio of 10 to 1, by weight. Three

dierent wt % PDMS solutions were prepared, 5, 10, and 15 wt %

PDMS in hexane solution, according to eq 1:

1511

dx.doi.org/10.1021/la3050253 | Langmuir 2013, 29, 15101516

Langmuir

Article

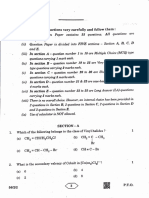

Figure 1. Top layers of synthesized PPSU and PDMS membranes at lower to higher polymer concentration: (a) 25 wt % PPSU, thickness 0.55

m; (b) 27.5 wt % PPSU, thickness 0.25 m; (c) 30 wt % PPSU, thickness = 0.32 m; (d) 5 wt % PDMS, thickness = 1.4 m; (e) 10 wt % PDMS,

thickness = 2.74 m; and (f) 15 wt % PDMS, thickness = 4.37 m. Panels ac were reprinted with permission from ref 19. Copyright 2011 Elsevier.

E

P

P

= exp x

l

RT

l

the permeate side during this period. A detailed procedure can be

found in our recent investigation.19

The membrane ux (J) was determined experimentally through

gravimetrical weighing of collected PV permeate samples over time.

These sample weights, measured with an accuracy of 104 g, then

enable ux calculation using eq 2:

J=

m

P

= (ioLxiLoPisat

o yio Pi l)

At

l

where P/l is the permeance, (P/l) is the pre-exponential factor of the

permeance, R is the gas constant (J/mol.K), T is the temperature (K),

and Ex is the activation energy (kJ/mol).

3. RESULTS AND DISCUSSION

3.1. Biomimetics of Leaves in the Synthesis of PDMS/

PPSU. Mass transfer during membrane formation occurs

through two mechanisms: delayed demixing and instantaneous

demixing.23 The demixing time delay critically determines the

membrane morphology. Van de Witte et al. have demonstrated

that the nucleation and growth in the polymer poor phase are

responsible for pore generation,22 which allows obtaining a leaflike morphology. In addition, a low polymer concentration

results generally in high membrane porosity, approaching a

porosity that can be found as stomas in the leaf and stem

epidermis areas used for gaseous exchange. In this study, an

instantaneous lm formation was observed once the polymer

solution was brought in contact with the nonsolvent, indicating

a rapid demixing process. Thus, a very thin top layer and

sublayer with large amounts of macrovoids was obtained. This

membrane top layer is expected to contain nodular structures,

and consequently to exhibit some degree of porosity. On the

contrary, increasing the concentration of the polymer solution

results in a decreased membrane porosity, resulting in a denser

and thicker top layer (Figure 1ac) due to interconnectivity of

pores at the inception of demixing.23

Application of a denser membrane with a thicker top layer in

separation typically results in a low membrane permeability.

(2)

where m is the weight of collected permeate (kg), t is the duration of

the experiment (h), A is the eective area of the membrane (0.001963

m2), Lio and xLio are the activity coecient and mole fraction in the feed

liquid, yio is the mole fraction in the permeant vapor, Psat

io is the vapor

pressure of the pure component i, and Pil is the total pressure in the

permeate side. P is the membrane permeability (molm/m2hbar). For

an unknown membrane thickness, l (m), the membrane permeance,

P/l (mol/m2hbar), also known as the component ux normalized

driving force, can be used.

The membrane performance in terms of enrichment factor is

dened as the ratio of concentration in the permeate to the feed:

i =

Wi ,p

Wi ,f

(4)

(3)

where Wi,p and Wi,f are the weight fractions of component i in

permeate and feed, respectively. In the recovery of aroma compounds,

the solvent enrichment factor is close to unity. Therefore, the

enrichment factors of aroma can be assumed to be equal to the

corresponding separation factors, the ratio between permeability or

permeance of components i and j.19 The membrane ux and

permeance were given in molar terms to allow direct result

comparison between PV and the larger body of gas permeation.20

The temperature dependence of the permeance was then analyzed

using an Arrhenius equation (eq 4):21

1512

dx.doi.org/10.1021/la3050253 | Langmuir 2013, 29, 15101516

Langmuir

Article

Table 2. Characterization of Natural Leaves and Articial Membrane Using DSLR and SEMa

SEM gure of cherry laurel was adapted from the work of Koch and Ensikat.3

reported that the three hydrophobicities of the Homo sapiens

(human skin) with contact angles of 100 18 (underarm skin

washed with water), 76 20 (underarm skin washed with

soap), and 104 16 (underarm skin washed with ethanol) are

potentially comparable to this synthesized membrane.

3.2.2. FTIR Studies: Natural Leaves versus Articial

Membrane. Measured FTIR spectra for the cherry laurel,

lotus leaf, taro leaf, and the M1 membrane are shown in Figure

3, indicating spectrum similarities across all natural leaves. On

the contrary, their natural surfaces micro- and nanostructures

are observed to be dissimilar when compared in Table 2. Guo

and Liu27 obtained similar ndings when evaluating these leaves

using X-ray photoelectron spectroscopy (XPS) against FTIR

measurements.

It can be seen from Figure 2 that all ngerprints of leaves and

membranes are nearly identical. The broad band ranging from

Although the variation of the demixing rate for dierent

polymer concentrations cannot be accurately determined,

observations of SEM images have proven that an increased

polymer content increases the thickness of the dense top layer

(Figure 1df). This then decreases the porosity of the

membrane and the interconnectivity of the pores.19 For

biological epicuticular wax, the construction of various crystals

geometry in shape (i.e., massive crusts, granules, plates,

platelets, laments, rods, and tubules with hollow center) is

strongly dependent on the crystal habits.3 Recrystallization of

isolated wax from organic solutions shows that the wax

morphologies originate from a self-assembly process. It is a

general process of structuring in biological system, in which

atoms, molecules, particles, or other building units interact and

self-organize to form well-dened structure.24 Although only

several plants are sampled and studied in this investigation, the

vastly available literature on biomimetics enables our results to

be easily compared to other plant samples.

3.2. Characterization. 3.2.1. Wettability: From Natural

Models to Synthetic Membranes. Images of the three natural

models (i.e., Lotus, Taro, and Cherry laurel leaf) and a

synthetic membrane (M1) taken at macro to micro scales are

shown in Table 2. The replication of the hydrophobic

characteristic similar to those of a natural plant leaf was

performed using a combination of coating and curing

procedures. Results show that PDMS facilitates replication of

complex topographic patterns, besides exhibiting a at-surface

water contact angle of 115 2. This signies nearly 50

increment in comparison to the reference PPSU membranes

contact angle, which was also observed by Tserapi et al. and

Cortese et al.25,26 The higher 161 and 159 2 water contact

angles for lotus and taro leaf, respectively, are mainly

contributed by the existence of the combined micro- and

nanostructure at their surfaces (Table 2), as was also observed

by related researchers.2,2730 This then minimizes the total

surface contact area for other materials as well.27 However,

these properties are not found in cherry laurel and the synthetic

PDMS/PPSU membrane, as can be deduced from the SEM

images in Table 2. This is in agreement with the ndings by

Wosten et al.31 They discovered that the contact angle of cherry

laurel is between 65 and 81, which is lower as compared to

the synthetic PDMS/PPSU membrane. They have also

Figure 2. The surface functional group analysis of the hydrophobic

wax-like materials by means of using FTIR.

3200 to 3600 cm1 is attributed to OH groups aected by

hydrogen bonding. The strong peak at 1653 cm1 is due to

CO stretching from the carboxylate group, while bands 2852

and 2922 are assigned to CH stretching vibration of CH,

CH2, and CH3 groups. Comparison between the leaves and

membranes indicates the absence of three signicant peaks in

the synthetic membranes spectra: 1653, 2852, and 2922 cm1.

1513

dx.doi.org/10.1021/la3050253 | Langmuir 2013, 29, 15101516

Langmuir

Article

However, the relation between surface functional groups and

hydrophobicity in this study is yet to be fully comprehended.

This is because in Figure 2, the leaf of cherry laurel indicates a

trend similar to that of the other two superhydrophobic leaves.

Nevertheless, the contact angle analysis indicates that the

hydrophobicity of cherry laurel is much less than that of the

PDMS/PPSU membrane. Thus, it is concluded that the FTIR

analysis may enable the study of supercial functionality but is

unable to distinguish up to the level of molecular speciation.

3.3. PV Using Biologically Inspired Membrane.

3.3.1. Permeation of Aroma Compounds. It was found that

among the seven volatile compounds, only ethyl acetate

permeated signicantly. While other compounds were still

detected on the permeate side, quantitative analyses using HSGC indicated that their permeation was either signicantly

lower or did not take place at all, as can be seen from Table 3.

Figure 3. Variation of PV ux for dierent feed concentrations and

feed temperatures for the M1 membrane.

Table 3. Eect of Temperature on Permeating Components

in PV Using MR-1 and 1 ppm HAc in Feed Solutiona

avg sep factor MR-1 in 1 ppm HAc

temp ( C)

25

35

45

4.7

6.1

4.3

0

0

0

0.3

0

1.16

0

0

0

0

0

0

2.13

0

0

0

0

0

1 = ethyl acetate, 2 = 3-methylbutyraldehyde, 3 = 2,3-pentanedione, 4

= hexanal, 5 = 1-penten-3-ol, 6 = 1-octen-3-ol, 7 = benzaldehyde.

Thus, our further discussions will focus on the permeation of

ethyl acetate because hexanal, 1-penten-3-ol, and 1-octen-3-ol

investigated in this work are insoluble. This property may be

advantageous to the permeating components, because a loose

hydrogen bond between solvent and solute facilitates surface

boundary contact between the feed mixture and the membrane.

The hydrophobic surface of the synthesized membrane repels

water molecules, but may be attracted to other organic

materials by chemical interaction at the boundary layer.

Moreover, when the organic compounds are totally insoluble

in water, the likelihood of chemical transport onto the

hydrophobic surface of the membrane is reduced. This

increases the possibility that the water-insoluble aroma

compounds remain on top of the liquid layer in the feed

tank. Another reason that restricts the component permeation

through the membrane is due to the high boiling point of the

solutes. Increasing the feed temperature from 25 to 45 C gives

no signicant eect on the solubility, although, in general, a

better permeation rate is to be expected.

3.3.2. Eect of Operating Conditions on Pervaporation

Performance. Permeation through the synthesized membranes

was then studied using PV, by analyzing the total ux as a

function of feed temperature for dierent feed concentrations,

as presented in Figure 3. No signicant permeation of ethyl

acetate can be observed when using thicker PDMS layers for

M2 and M3. Thus, only the permeation behavior through M1

membrane matrix is discussed here. As can be seen, the total

ux increases with increase of feed temperature and

concentration. For all examined temperatures, the highest

total ux was achieved at 45 C in 10 ppm solution, while the

lowest was obtained at 25 C using 1 ppm feed concentration.

The behavior of the bioinspired synthetic PDMS/PPSU

membranes showed selectivity to only one particular

compound, that is, ethyl acetate. In Figures 4 and 5, the eect

Figure 4. Permeance of ethyl acetate as a function of feed

concentration obtained in PV using M1 for dierent temperatures.

Figure 5. Enrichment factor of ethyl acetate for dierent temperatures

and feed concentrations.

of feed concentration and temperature for the permeance of

ethyl acetate in multicomponent system is presented. From

Figure 4, it is deduced that the permeance of ethyl acetate

decreases with concentration and temperature, and reaches a

constant plateau value when concentrations are higher than 5

ppm. Meanwhile, in Figure 5, it can be seen that the

enrichment factor decreases with an increasing feed concentration. This is contributed by the presence of other organic

compounds, which aects membrane selectivity due to the

interactions between dierent aroma compounds.32 To further

investigate the permeance behavior of the compounds, pure

water and binary mixture containing water and ethyl acetate

were also investigated. The permeation of pure water through

1514

dx.doi.org/10.1021/la3050253 | Langmuir 2013, 29, 15101516

Langmuir

Article

the PDMS/PPSU membrane was determined using eq 2. For

pure water, x = y = 1, and thus eq 2 reduces to J = P/l Pperm.

Hence, pure water permeances were determined from the slope

of the plot between uxes against reciprocal permeate pressure

(driving force), 2.72 mol m2 h1 bar1. The uxes of water in a

single and binary mixture are illustrated in Figure 6. It is shown

Figure 7. Eect of temperature on ethyl acetate permeance for

dierent feed concentrations.

a decreasing permeability with the increase in temperature.

Because EP/l has been determined and the enthalpy of

vaporization of ethyl acetate is known, EJ can easily be

calculated: EJ = EP/l +Hv.21 Hence, EJ = 27.13 kJ/mol.

Alternatively, EJ can be evaluated from the plot of ln J versus 1/

T.

Figure 6. Permeation ux of water in binary mixtures waterethyl

acetate at dierent operating conditions.

4. CONCLUSION

A plant cuticle is a membrane that covers primarily aboveground plants such as leaves, owers, stems, and fruits. The

superimposed waxes onto the cuticle are called epicuticular

waxes. This natural membrane is very ecient as a transport

barrier. Thus, a biologically inspired membrane was engineered,

synthesized, and investigated for application in the recovery of

aroma compounds using pervaporation. The synthesized

hydrophobic PDMS/PPSU was characterized and compared

against three selected natural leaves, and it was observed that

the synthesized membrane was comparable to cherry laurel leaf.

Evaluating PDMS-coated PPSU membrane against the uncoated membrane indicated a 50 contact angle improvement,

besides resembling the complex topography patterns of the

biological leaves. As was proven in previous investigations,

surface structure is not an obligatory condition to enable

hydrophobicity. Instead, the wax-like material that covers the

surface has enabled this feature. Among the seven aroma

compounds used, only ethyl acetate is able to permeate through

the synthesized hydrophobic membrane matrix in pervaporation due to its high hydrophobic property. This will then

improve the selective permeation of less hydrophobic

compounds through the interaction with dierent aroma

species, consequently enabling the developed membranes to

be applicable to a wider variety of chemicals.

that when more than one component tries to cross the barrier,

the resistance of penetration increases, resulting in lower

permeation. It is hypothesized that besides permeation of single

component, there exists the possibility of couple molecule

(water and ethyl acetate) permeation, which could be the

reason for delay in penetration through the membrane matrix

as can be seen in Figure 6.

The decrease of water ux in the permeate side of the

membrane when the feed concentration is 1 ppm of ethyl

acetate is expected due to the higher solubility of ethyl acetate

in the solution. The hydrogen bond between both water and

ethyl acetate has made the couple molecule more hydrophilic,

which easily repels by the hydrophobic membrane. As the

concentration of ethyl acetate increases in the feed stream, the

solubility of the solute decreases, resulting in only water

molecule permeating across the barrier.

Considering the importance of feed temperature in PV, its

eect on the biologically inspired membrane was studied.

Burggraaf33 has related both of the activated microscopic

models based on the conguration and surface diusion with

temperature dependence in the classical adsorptiondiusion

model as shown in eq 5:

EJ = Hs + E D + H vap

(5)

where Hvap is the heat of vaporization of the permeant (ethyl

acetate) through the membrane (32.33 kJ/mol). The term

(Hs + ED) is the activation energy of permeance, EP/l (kJ/

mol), and when the permeate pressure is suciently low; thus

eq 5 can be written as follows:

EJ = EP / l + H vap

AUTHOR INFORMATION

Corresponding Author

*E-mail: nora.jullok@cit.kuleuven.be.

Notes

The authors declare no competing nancial interest.

(6)

ACKNOWLEDGMENTS

Financial support from the Malaysian Ministry of Higher

Education (MOHE) is gratefully acknowledged.

The ethyl acetate permeance dependence on temperature is

presented in the logarithmic plot versus the reciprocal

temperature (1/T) shown in Figure 7. The activation energy,

EP/l, for ethyl acetate in this particular application was 5.2 kJ/

mol. Positive activation energy indicates that the permeation

ux increases with temperature increase. On the contrary, the

activation energy obtained in Figure 7 is negative, thus implying

REFERENCES

(1) Bar-Cohen, Y. Biomimetics-using nature to inspire human

innovation. Bioinspiration Biomimetics 2006, 1, P1.

1515

dx.doi.org/10.1021/la3050253 | Langmuir 2013, 29, 15101516

Langmuir

Article

(2) Bhushan, B.; Jung, Y. C. Natural and biomimetic artificial surfaces

for superhydrophobicity, self-cleaning, low adhesion, and drag

reduction. Prog. Mater. Sci 2011, 56, 1108.

(3) Koch, K.; Ensikat, H. J. The hydrophobic coatings of plant

surfaces: epicuticular wax crystals and their morphologies, crystallinity

and molecular self-assembly. Micron 2008, 39, 759772.

(4) Jetter, R.; Schaffer, S.; Riederer, M. Leaf cuticular waxes are

arranged in chemically and mechanically distinct layers: evidence from

Prunus laurocerasus L. Plant, Cell Environ. 2001, 23, 619628.

(5) Perkins, M. C.; Roberts, C. J.; Briggs, D.; Davies, M. C.;

Friedmann, A.; Hart, C. A.; Bell, G. A. Surface morphology and

chemistry of Prunus laurocerasus L. leaves: a study using X-ray

photoelectron spectroscopy, time-of-flight secondary-ion mass spectrometry, atomic-force microscopy and scanning-electron microscopy.

Planta 2005, 221, 123134.

(6) Carver, T. L. W.; Thomas, B. J. Normal germling development by

Erysiphe graminis on cereal leaves freed of epicuticular wax. Plant

Pathol. 2007, 39, 367375.

(7) Carver, T. L. W.; Thomas, B. J.; Ingerson-Morris, S. M.;

Roderick, H. W. The role of the abaxial leaf surface waxes of Lolium

spp. in resistance to Erysiphe graminis. Plant Pathol. 2007, 39, 573

583.

(8) Burghardt, M.; Riederer, M. Cuticular transpiration. Annu. Plant

Rev.-Biol. Plant Cuticle 2006, 292.

(9) Riederer, M.; Schreiber, L. Protecting against water loss: analysis

of the barrier properties of plant cuticles. J. Exp. Bot. 2001, 52, 2023

2032.

(10) Riederer, M.; Muller, C. Annual Plant Reviews-Biol. Plant Cuticle;

Wiley-Blackwell: New York, 2006.

(11) Li, L.; Xiao, Z.; Tan, S.; Pu, L.; Zhang, Z. Composite PDMS

membrane with high flux for the separation of organics from water by

pervaporation. J. Membr. Sci. 2004, 243, 177187.

(12) Mohammadi, T.; Aroujalian, A.; Bakhshi, A. Pervaporation of

dilute alcoholic mixtures using PDMS membrane. Chem. Eng. Sci.

2005, 60, 18751880.

(13) Dobrak, A.; Figoli, A.; Chovau, S.; Galiano, F.; Simone, S.;

Vankelecom, I. F. J.; Drioli, E.; Van der Bruggen, B. Performance of

PDMS membranes in pervaporation: Effect of silicalite fillers and

comparison with SBS membranes. J. Colloid Interface Sci 2010, 346,

254264.

(14) Park, H. B.; Kim, C. K.; Lee, Y. M. Gas separation properties of

polysiloxane/polyether mixed soft segment urethane urea membranes.

J. Membr. Sci. 2002, 204, 257269.

(15) Darvishmanesh, S.; Jansen, J. C.; Tasselli, F.; Tocci, E.; Luis, P.;

Degreve, J.; Drioli, E.; Van der Bruggen, B. Novel polyphenylsulfone

membrane for potential use in solvent nanofiltration. J. Membr. Sci.

2011, 379, 6068.

(16) Dastgir, M. G.; Peeva, L. G.; Livingston, A. G. The performance

of composite supported polymeric liquid membranes in the Membrane

Aromatic Recovery System (MARS). Chem. Eng. Sci. 2005, 60, 7034

7044.

(17) Weng, T. H.; Tseng, H. H.; Wey, M. Y. Preparation and

characterization of PPSU/PBNPI blend membrane for hydrogen

separation. Int. J. Hydrogen Energy 2008, 33, 41784182.

(18) Karlsson, L. E.; Jannasch, P. Polysulfone ionomers for protonconducting fuel cell membranes: 2. Sulfophenylated polysulfones and

polyphenylsulfones. Electrochim. Acta 2005, 50, 19391946.

(19) Jullok, N.; Darvishmanesh, S.; Luis, P.; Van der Bruggen, B. The

potential of pervaporation for separation of acetic acid and water

mixtures using polyphenylsulfone membranes. Chem. Eng. J. 2011,

175, 306315.

(20) Baker, R. W.; Wijmans, J. G.; Huang, Y. Permeability,

permeance and selectivity: A preferred way of reporting pervaporation

performance data. J. Membr. Sci. 2010, 348, 346352.

(21) Feng, X.; Huang, R. Y. M. Estimation of activation energy for

permeation in pervaporation processes. J. Membr. Sci. 1996, 118, 127

131.

(22) Van de Witte, P.; Dijkstra, P. J.; Van den Berg, J. W. A.; Feijen, J.

Phase separation processes in polymer solutions in relation to

membrane formation. J. Membr. Sci. 1996, 117, 131.

(23) Reuvers, A. J.; Van den Berg, J. W. A.; Smolders, C. A.

Formation of membranes by means of immersion precipitation:: Part

I. A model to describe mass transfer during immersion precipitation. J.

Membr. Sci. 1987, 34, 4565.

(24) Benyus, J. M. Biomimicry: Innovation Inspired by Nature; William

Morrow and Co. Inc.: New York, 1997.

(25) Cortese, B.; DAmone, S.; Manca, M.; Viola, I.; Cingolani, R.;

Gigli, G. Superhydrophobicity due to the hierarchical scale roughness

of PDMS surfaces. Langmuir 2008, 24, 27122718.

(26) Tserepi, A. D.; Vlachopoulou, M. E.; Gogolides, E. Nanotexturing of poly (dimethylsiloxane) in plasmas for creating robust

super-hydrophobic surfaces. Nanotechnology 2006, 17, 3977.

(27) Guo, Z.; Liu, W. Biomimic from the superhydrophobic plant

leaves in nature: Binary structure and unitary structure. Plant Sci. 2007,

172, 11031112.

(28) Caponigro, M. A.; Eriksen, C. H. Surface film locomotion by the

water strider, Gerris remigis Say. Am. Midl. Nat. 1976, 268278.

(29) Cassie, A. B. D.; Baxter, S. Wettability of porous surfaces. Trans.

Faraday Soc. 1944, 40, 546551.

(30) Bhushan, B. Biomimetics: lessons from nature - an overview.

Philos. Trans. R. Soc., A 2009, 367, 1445.

(31) Wosten, H. A. B.; Ruardy, T. G.; van der Mei, H. C.; Busscher,

H. J.; Wessels, J. G. H. Interfacial self-assembly of a Schizophyllum

commune hydrophobin into an insoluble amphipathic protein

membrane depends on surface hydrophobicity. Colloids Surf., B:

Biointerfaces 1995, 5, 189195.

(32) Martinez, R.; Sanz, M. T.; Beltran, S. Concentration by

pervaporation of representative brown crab volatile compounds from

dilute model solutions. J. Food Eng. 2011, 105, 98104.

(33) Burggraaf, A. J. Single gas permeation of thin zeolite (MFI)

membranes: theory and analysis of experimental observations. J.

Membr. Sci. 1999, 155, 4565.

1516

dx.doi.org/10.1021/la3050253 | Langmuir 2013, 29, 15101516

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Synthesis of Mordenite Type ZeoliteДокумент7 страницSynthesis of Mordenite Type ZeoliteRodrigoОценок пока нет

- Five Things That Are Evidence of Chemical Reactions: PrecipitateДокумент2 страницыFive Things That Are Evidence of Chemical Reactions: Precipitateমেঘলা আকাশОценок пока нет

- Davco k10 Polyurethane PlusДокумент2 страницыDavco k10 Polyurethane PlusSUCHARITОценок пока нет

- Caleng3 - Problem Set - Q2Документ5 страницCaleng3 - Problem Set - Q2Rheina VelasquezОценок пока нет

- Dualization of Mandi Bahauddin Sarai Alamgir Road Via Rasool Village (Length 42 KM) Particle Size Distribution CurveДокумент10 страницDualization of Mandi Bahauddin Sarai Alamgir Road Via Rasool Village (Length 42 KM) Particle Size Distribution CurveObaid Ur RehmanОценок пока нет

- 16.3 - Precipitation and The Solubility Product - Chemistry LibreTextsДокумент14 страниц16.3 - Precipitation and The Solubility Product - Chemistry LibreTextsThereОценок пока нет

- Science Oct 2018 Paper 1 QP PDFДокумент20 страницScience Oct 2018 Paper 1 QP PDFJeffrey Piggott100% (1)

- 1.4841 - AISI 314 - UNS S31000 S31400 - JIS SUH310 - Data SheetДокумент1 страница1.4841 - AISI 314 - UNS S31000 S31400 - JIS SUH310 - Data SheetShariq KhanОценок пока нет

- EXP1 Batch ReactorДокумент20 страницEXP1 Batch ReactorDeepak AgarwalОценок пока нет

- 10.3 Using Materials QPДокумент37 страниц10.3 Using Materials QPRОценок пока нет

- 3340 and 3345 Bench Ion MetersДокумент5 страниц3340 and 3345 Bench Ion MetersAmir MohammedОценок пока нет

- Seeds To LSD, Comprehensive Tek & RamblingsДокумент56 страницSeeds To LSD, Comprehensive Tek & Ramblingsjavasolo100% (2)

- DAY Date Physics Chemistry Biology: NEET Pattern TEST NO. 1Документ1 страницаDAY Date Physics Chemistry Biology: NEET Pattern TEST NO. 1Arman GoyalОценок пока нет

- Materials Cheat Sheet - WIP PDFДокумент1 страницаMaterials Cheat Sheet - WIP PDFesaОценок пока нет

- On The Mechanism of High Temperature Corrosion: December 2018Документ22 страницыOn The Mechanism of High Temperature Corrosion: December 2018A&R FilesОценок пока нет

- 2018-Li-Effect of Vacuum Thermal Cycling On The Compression and Shear Performance of Composite Sandwich Structures Containing Pyramidal Truss CoresДокумент12 страниц2018-Li-Effect of Vacuum Thermal Cycling On The Compression and Shear Performance of Composite Sandwich Structures Containing Pyramidal Truss CoresroxanaОценок пока нет

- Practice 3 SHELДокумент9 страницPractice 3 SHELHusnul HotimaahОценок пока нет

- Basf en FormulationspfДокумент8 страницBasf en Formulationspfajitbadboy2Оценок пока нет

- Test Bank For Drugs Behaviour and Society 3rd Canadian Edition Carl L Hart Charles J Ksir Andrea Hebb Robert Gilbert 2Документ36 страницTest Bank For Drugs Behaviour and Society 3rd Canadian Edition Carl L Hart Charles J Ksir Andrea Hebb Robert Gilbert 2shammerabolisher.qrc0100% (49)

- Stuchre - Onaos: 4C Covaleat Bonds Ae - Directional WheaxasДокумент3 страницыStuchre - Onaos: 4C Covaleat Bonds Ae - Directional WheaxasDeveshОценок пока нет

- Distillation - Part 5 - 2Документ13 страницDistillation - Part 5 - 2SyafiyatulMunawarahОценок пока нет

- PHP RFZ KBVДокумент11 страницPHP RFZ KBVpranavmmistry210% (1)

- Biological Tools TechniquesДокумент10 страницBiological Tools Techniquesayushi75086Оценок пока нет

- TDS - LD 2023 CC PDFДокумент1 страницаTDS - LD 2023 CC PDFYasir SiddiquiОценок пока нет

- Importance/Uses of PH: in Our Daily LivesДокумент5 страницImportance/Uses of PH: in Our Daily LivesBhanavi HagargiОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0086848 A1Документ14 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0086848 A1梅汉Оценок пока нет

- DESIGN of Sodium Carbonate PRODUCTION PLANT Comprehensive Design Project PDFДокумент149 страницDESIGN of Sodium Carbonate PRODUCTION PLANT Comprehensive Design Project PDFMayank Visalpara80% (5)

- Paper 6 Notes ChemistryДокумент3 страницыPaper 6 Notes ChemistryWuttoxki100% (1)

- Conversion FactorsДокумент2 страницыConversion FactorsKathleen May BarrilОценок пока нет

- Ocma-505 AstmДокумент2 страницыOcma-505 AstmHasmin CarpioОценок пока нет