Академический Документы

Профессиональный Документы

Культура Документы

Safety tips for rigging gangways and accommodation ladders

Загружено:

sbcheahИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Safety tips for rigging gangways and accommodation ladders

Загружено:

sbcheahАвторское право:

Доступные форматы

Loss Prevention Bulletin

Gangways and Accommodation Ladders

For many people the gangway or accommodation ladder is

while warping astern placed undue stress on the top platform

the first point of contact with a ship. Initial impressions are

hinge pins which worked loose and caused the gangway to

important, and a properly rigged ladder may be the first

collapse. Similarly, a number of disembarking personnel were

indication to a visitor that they are boarding a well run vessel.

injured when an aluminium gangway they were using broke in

However, someone obliged to climb a ladder which is

unsteady, slippery or unsafe may have formed an unfavourable

opinion of the ship and its crew by the time they have reached

the top.

half. The weakness was traced to a cracked structural

member which had deteriorated unnoticed over a period

of time.

In another case insufficient monitoring caused the inner rail of

an accommodation ladder to become wedged against the

davit arm when the tide fell. While attempting to free and lower

Gangway and Accommodation Ladder

Incidents

standing on the upper platform, managed to pull the rail free.

Gangways and accommodation ladders may be hazardous if

However, the sudden release of the rail caused him to stagger

badly rigged, improperly tended or inadequately maintained. In

backwards and he fell over the platform guard rail into the river.

the inner rail on its collapsible stanchions a crewmember,

spite of the acknowledged dangers, accidents associated with

Despite an extensive search his body was never recovered. It

such shortcomings continue to arise.

was found that the guard rail ropes on the upper platform were

In one incident three seamen sustained injuries, one seriously,

only 65cm high rather than the recommended 1 metre.

after falling to the quay from an accommodation ladder which

A further recent example concerned the death of a seaman

they were breaking out. In another, failure to raise the gangway

when the hoist winch gearbox failed while he was rigging the

Inadequate guard rail ropes over which a seaman fell to

his death (Courtesy MAIB)

accommodation ladder. The failure of the gearbox caused the

assessment or job safety assessment should also be carried

lower telescopic section of the ladder to descend

out beforehand in case additional measures to reduce the risk

uncontrollably. When the ladder reached the end of its travel

are necessary before commencing the operation. Suitable

the bolts holding the rollers sheared and the lower section fell

protective equipment should be worn as appropriate including

into the water. At the time of the failure the seaman was

personal floatation devices fitted with self activating lights,

standing on the lower section rigging stanchions and fell

whistles and reflective material, and safety harnesses of the

overboard. He was not wearing a fall prevention device or a

arrestor type rather than fall restraints. Fall arrestors should

lifejacket. It was subsequently found that the gearbox had

always be attached to suitable securing points fixed to the

been incorrectly re-assembled following maintenance by the

ships structure.

ships crew.

Surveyors carrying out condition surveys for the Club often

Moreover it is not uncommon

report

for the Managers to be

accommodation ladder was rigged incorrectly. Safety nets are

notified of injuries sustained

often the subject of such observations and are frequently

by crew, stevedores, port

found to be secured to each side of the ladder along its entire

where

vessel's

gangway

or

officials, contractors or other

length. This results in the net hanging uselessly below the

visitors while embarking or

steps instead of leading away to the side of the ship to catch

disembarking.

anyone unfortunate enough to fall off.

Steps,

whether they are part of a

ship's access arrangements

or a flight of stairs ashore,

The damaged telescopic

accommodation ladder from which

a seaman fell to his death when the

hoist winch failed (Courtesy MAIB)

occasions

may increase the chances of

Rope guard rails must be tight if they are to be effective, and

all stanchions must be fitted in place and properly secured.

Steps, handrails and platforms should be free of oil, grease

slips and falls occurring.

and ice. When landed on the quay, care should also be taken

Given that gangways and

to ensure that the lifting bridle and/or davit arm is kept well

accommodation ladders are

above head height or moved clear as necessary.

also susceptible to movement by external factors such as

As far as practicable the approaches to the ladder both on

cargo operations, tidal conditions, swell and other gangway

deck and on the quay should be free of hazards to allow safe

users, the risks may be magnified.

access and egress to and from the vessel. Close attention

should also be paid to any significant difference in height

Rigging

between the ends of the ladder and the quay or deck. This

may mean placing and securing a portable step or steps in

Gangways and accommodation ladders are heavy and

such locations to minimise the risk of slips and falls. Warning

cumbersome pieces of equipment. Operating instructions

notices should be posted in such cases.

should be posted in the vicinity of the boarding arrangements

and it is essential that the personnel required to break out and

When gangways are placed on top of bulwarks, a suitable

rig ladders or operate lifting gear are sufficiently experienced,

bulwark ladder should be used between the deck and the

bearing in mind the possible consequences of a mistake.

gangway. It should be adequately secured and all gaps

Anyone unfamiliar with such tasks should be closely

between the top of the bulwark ladder and the gangway

supervised by a responsible person until considered

should be fenced off to a height of at least one metre.

competent.

Gangways and accommodation ladders should be adequately

If inexperienced crewmembers are required to assist with the

illuminated at night, particularly at each end. If there are no

rigging of a gangway or accommodation ladder, a risk

permanent fittings, portable lighting should be rigged.

Loss Prevention Bulletin

A lifebuoy with a self-activating light plus a separate buoyant

necessary to provide alternative arrangements if the means of

lifeline with a quoit or similar device attached should be

access is likely to become excessively steep. National

stationed at the point of access ready for immediate use. Many

legislation on this issue may vary, but in the absence of firm

vessels also place a small box containing a fire plan, stowage

rules it may be prudent to observe UK regulations; a gangway

plan, dangerous goods list, stability details, crew list and other

should not be used if its angle of inclination is more than 30

relevant information at the head of the ladder ready for use in

above or below the horizontal, similarly for an accommodation

an emergency.

ladder if the angle is more than 55 below the horizontal,

unless designed and constructed for use at angles greater

than these.

Positioning

Where possible, boarding arrangements should be positioned

away from working areas and places where cargo may pass

Tending

overhead. If there appears to be no safe option using the

A crewmember should be assigned to monitor the gangway

ship's own equipment, it may be possible to hire a shore

or accommodation ladder as regular adjustment may be

gangway if such facilities are available. It should be

required due to the movement caused by tidal conditions and

remembered that tending a shore gangway and ensuring it is

variations in draft and trim.

rigged safely remains the responsibility of the vessel.

Regular monitoring is essential as changed circumstances

Gangways should never be secured to a ship's guard rails

may lead to a vessel's access arrangements rapidly becoming

unless they have been designed for that purpose. If positioned

difficult to negotiate.

through an open section of bulwark or railings, any remaining

gaps should be roped off to a height of at least one metre.

The deck watch should also look out for potential dangers

ashore such as bollards, tracks and cranes bearing in mind

Consideration should also be given to the angle of inclination,

that most ladders are constructed of aluminium alloy and are

making sure that design limits are not exceeded. It may be

easily damaged.

Important points to be considered during the rigging

process:

1. Rope guardrails tight and free of damage and/or

degradation

2. Stanchions free of distortion and all in place

3. Safety net positioned between ladder and ship, free of

damage and/or degradation

4. Hoisting arrangements clear of head height

5. Steps free of oil, grease and ice

6. Bottom platform level (where fitted)

7. Lighting arrangements positioned effectively

8. Base clear of obstructions

9. Lifebuoy fitted with a light and a lifeline with a quoit

available at the point of access

Loss Prevention Bulletin

If the position of the ladder is such that cargo residues

maintained according to a planned schedule. The condition

accumulate on a ladder and its approaches during a port stay,

of hoist wires is to be closely monitored for broken wires,

then the residues should be cleaned away regularly to prevent

corrosion or distortion, with particular attention paid to areas

a slip/trip hazard.

passing through sheaves. Damaged wires should be

To assist those responsible for tending gangways and

accommodation ladders, it may be worthwhile noting the

times of high and low water on the sailing board each day.

replaced in line with the companys wire discard criteria prior

to their condition becoming unacceptable. In any event hoist

wire replacement should never exceed 5 years. Hoist wires

should be provided with a suitable test certificate prior to

fitment and it is recommended that the date the hoist wires

Maintenance

It is a SOLAS requirement that inspection and maintenance of

accommodation ladders and gangways be conducted

periodically. Monthly inspection and maintenance should be

were last renewed is stencilled in the vicinity of the ladder for

easy reference.

Hoist wires should be periodically treated with a suitable wire

rope dressing over their entire length.

included in the planned maintenance system and should

Arrangements should also be made to examine the

always be carried out by a competent person in accordance

underside of gangways and accommodation ladders at

with manufacturers' instructions.

regular intervals. It is often difficult to gain access to these

In addition to planned maintenance inspections, further checks

areas in the course of normal activities and it may be

should be made each time the ladder is rigged, looking out for

necessary to turn the ladder over periodically to perform a

signs of damage, distortion, cracks and corrosion.

detailed inspection.

Periodic inspections of accommodation ladders and

gangways should incorporate the following:

The structure of the ladder should be closely examined for

cracks, distortion, damage and corrosion, and repaired as

necessary.

Winch bed plates and supporting structures for sheaves and

turntables should be inspected for cracks, distortion,

damage and corrosion, and repaired as necessary.

Control levers/buttons and limit switches should be tested

to ensure they are working correctly.

If an aluminium ladder has fittings made of mild steel, these

Operating instructions should be conspicuous, markings on

areas should be examined closely. Accelerated corrosion

the accommodation ladder or gangway as required by the

may occur if the two dissimilar metals come into contact,

flag state (such as the maximum safe loading by persons

and deterioration of the separation material could lead to a

and by total weight) should be legible, and control levers or

severely weakened structure.

buttons should be clearly marked.

Bent stanchions should be replaced or repaired, and guard

All inspections, maintenance work and repairs should be

ropes inspected for wear and renewed where necessary.

recorded in the planned maintenance system in order to

Safety nets should be inspected for damage, actinic

provide an accurate detailed history for each appliance.

degradation and for the impregnation of grease, paint or

chemicals which may affect their strength.

Moving parts such as sheaves, tracks, turntables, bearings

and rollers should be free to turn, and greased as

appropriate.

Lifting equipment should be inspected, tested and

Checklists

Checklists may be used as an additional safeguard when

rigging gangways and accommodation ladders. Members

may wish to adapt the attached example to suit their own

requirements.

West of England Insurance Services (Luxembourg) S.A., Tower Bridge Court, 226 Tower Bridge Road, London, SE1 2UP

Loss Prevention Dept: T: +(44) (0)20 7716 6106 F: +(44) (0)20 7716 6061 E: loss.prevention@westpandi.com W: www.westpandi.com

Loss Prevention Bulletin

Gangways and Accommodation Ladders Checklist

Vessel

Date

Port

No.

Checkpoint

Preparatory Work:

1.

Assemble a sufficient number of experienced personnel

2.

Arrange supervision of less experienced personnel

3.

Discuss work plan and allocate tasks

4.

Conduct a risk assessment if deemed necessary and close out all action points

5.

Ensure personal protective equipment including suitable personal floatation devices and fall

arrestors are worn as necessary

6.

Check that boarding arrangements will be clear of working areas

7.

Check for obstructions likely to impede lowering/positioning

8.

Place lifebuoy with light and buoyant line with quoit close by

Rigging:

9.

Test and position lighting arrangements

10.

Check that ladder is sufficiently stable

11.

Check that the angle of inclination is satisfactory

12.

Check safety net for wear and defects

13.

Fit safety net correctly to span gap between the outboard side of the ladder and the vessel

14.

Inspect rope guardrails for wear and ensure ropes are pulled tight

15.

Examine stanchions and fixed guardrails for damage and secure in position

16.

Ensure bottom platform is level (accommodation ladders, where fitted) and suitably fenced

17.

Check boarding arrangements are free of oil, grease and ice

18.

Ensure that lifting equipment/bridle does not cause an obstruction

19.

Position and secure additional steps if required

20.

Post notices warning of additional steps as appropriate

21.

Ensure bulwark ladders, where used, are properly secured

22.

Rope off any gaps in the bulwark or railings

23.

Verify that safe access exists at shore side end of ladder

24.

Verify that safe access exists at shipboard end of ladder

25.

Examine ladder closely for signs of distortion, cracks or corrosion

26.

Examine hoisting wires and equipment for wear and damage

27.

Report and record all defects found and equipment replaced

28.

Post sailing board

Yes/No

Loss Prevention Bulletin

No.

Checkpoint

Yes/No

Tending:

29.

Ensure gangway watch is maintained throughout

30.

Check regularly whether repositioning is required

31.

Check regularly whether safety net/rope guardrails require adjustment

32.

Watch out for potential obstructions ashore

33.

Keep the access arrangements and approaches clear of ice, oil, grease and cargo residue

34.

Carry out regular checks to ensure that safe access is maintained

West of England Insurance Services (Luxembourg) S.A., Tower Bridge Court, 226 Tower Bridge Road, London, SE1 2UP

Loss Prevention Dept: T: +(44) (0)20 7716 6106 F: +(44) (0)20 7716 6061 E: loss.prevention@westpandi.com W: www.westpandi.com

Вам также может понравиться

- Working Aloft & OversideДокумент6 страницWorking Aloft & OversideMitanshu Chadha100% (2)

- 2012-04 ST Gangway SafetyДокумент3 страницы2012-04 ST Gangway SafetykhavihongОценок пока нет

- 22 Important PointsДокумент13 страниц22 Important PointsharrdyОценок пока нет

- Guide Line N Check List For Cargo ShipДокумент47 страницGuide Line N Check List For Cargo ShipGansh100% (1)

- Panamax Cargo Hold Cleaning Manual Rev00Документ36 страницPanamax Cargo Hold Cleaning Manual Rev00Cenk ÇobanОценок пока нет

- Week 2 - Securing Cargoes & Deck CargoДокумент56 страницWeek 2 - Securing Cargoes & Deck CargoShaira Mae Paguntalan100% (1)

- Code 17 DeficienciesДокумент18 страницCode 17 DeficienciescapmanirajОценок пока нет

- Code of Safe Working Practices: Objectives & ContentsДокумент8 страницCode of Safe Working Practices: Objectives & Contentssidadams2Оценок пока нет

- Pilot Ladder ChecklistДокумент1 страницаPilot Ladder ChecklistguoterryОценок пока нет

- Register of Materials Handling Equipment-AMSA357Документ10 страницRegister of Materials Handling Equipment-AMSA357SudheerRawatОценок пока нет

- Industry Guidance On Pilot Boarding Arrangement - July 2012Документ5 страницIndustry Guidance On Pilot Boarding Arrangement - July 2012anil.rai100% (1)

- Oral 2Документ23 страницыOral 2MamunОценок пока нет

- Japanese Pilot Association Pilot Ladders - v3Документ72 страницыJapanese Pilot Association Pilot Ladders - v3Manoj VarrierОценок пока нет

- Automatic Release Hook Parts ReplacementДокумент1 страницаAutomatic Release Hook Parts ReplacementRyan Ferguson100% (1)

- GL Checklist For Maintenance of Safety Equipment Tcm4-590999Документ21 страницаGL Checklist For Maintenance of Safety Equipment Tcm4-590999Eyoma EtimОценок пока нет

- Section (1) : 1. With Respect To Loading Timber Cargo in Question A) Explain Under What Circumstances, Vessel Is Able To Load To Lumber Load LinesДокумент6 страницSection (1) : 1. With Respect To Loading Timber Cargo in Question A) Explain Under What Circumstances, Vessel Is Able To Load To Lumber Load Linescanigetaccess100% (1)

- DNV Safety Equipment GuideДокумент14 страницDNV Safety Equipment GuideParamjyot Singh Sabharwal100% (2)

- Hatch cover checklistДокумент2 страницыHatch cover checklistDAVYDEBOCKОценок пока нет

- Eu MRV and Imo Dcs Requirements BV Day Algeria 2018-04-25Документ28 страницEu MRV and Imo Dcs Requirements BV Day Algeria 2018-04-25Hocine TouatiОценок пока нет

- MONITOR CARGO DURING VOYAGEДокумент29 страницMONITOR CARGO DURING VOYAGEYap JoshuaОценок пока нет

- 2 Reefer Cargo ManifestДокумент3 страницы2 Reefer Cargo Manifestjimmy_shroffОценок пока нет

- Questions For All RanksДокумент5 страницQuestions For All RanksRobert M. MaluyaОценок пока нет

- Anchoring Poster For BridgeДокумент1 страницаAnchoring Poster For BridgeSachin SikkaОценок пока нет

- Preparing for DepartureДокумент26 страницPreparing for DepartureAN IYERОценок пока нет

- A Master's Guide To BerthingДокумент28 страницA Master's Guide To BerthingMaciej Reichel100% (1)

- NP 133CДокумент2 страницыNP 133Cjohn mark manuel magalonaОценок пока нет

- Chain RegisterДокумент20 страницChain RegisterShanAlanОценок пока нет

- Watchkeeping Responsibilities in PortДокумент33 страницыWatchkeeping Responsibilities in PortVesa MihaiОценок пока нет

- MAIB - Collision Due To Anchor DragДокумент16 страницMAIB - Collision Due To Anchor DragBinh Pham100% (1)

- TGM 2.6.6 Cargo Care During VoyageДокумент4 страницыTGM 2.6.6 Cargo Care During VoyageBoris PetrovicОценок пока нет

- Anchoring Large Vessels PDFДокумент24 страницыAnchoring Large Vessels PDFwebwebwebwebОценок пока нет

- Free-Fall Lifeboat Safety: Purpose Incident Analysis - AquarosaДокумент2 страницыFree-Fall Lifeboat Safety: Purpose Incident Analysis - AquarosavdevivОценок пока нет

- AMSA399 - Pilot LaddersДокумент3 страницыAMSA399 - Pilot LaddersPJGОценок пока нет

- Good Maintenance On Board Ships e 2015Документ83 страницыGood Maintenance On Board Ships e 2015Yuhyi SeОценок пока нет

- Good Practice: Galley Fire HazardsДокумент1 страницаGood Practice: Galley Fire Hazardsเปีย วันชัย สวนทองОценок пока нет

- GOMO APPENDIX 10 - B BULK CARGO TRANSFER CHECKLISTSДокумент6 страницGOMO APPENDIX 10 - B BULK CARGO TRANSFER CHECKLISTSasdasd0% (1)

- Iacs Ship Structure Access ManualДокумент18 страницIacs Ship Structure Access ManualKordalhs Kyriakos100% (1)

- 1627466460ADVANCED SHIPBOARD MANAGEMENT BY CAPT. MUKESH JIVRAJ SOALNKI-minДокумент519 страниц1627466460ADVANCED SHIPBOARD MANAGEMENT BY CAPT. MUKESH JIVRAJ SOALNKI-minMrithyunjayanRathnam100% (2)

- Port State Detentions Quick ReferenceДокумент36 страницPort State Detentions Quick Referencestamatis100% (2)

- Seam 1 Assessment (Catch Up) - UnansweredДокумент11 страницSeam 1 Assessment (Catch Up) - UnansweredJohn Paul FebreroОценок пока нет

- Cargo Handling & Stability - I: Captain Nazim ErsenДокумент52 страницыCargo Handling & Stability - I: Captain Nazim ErsenberОценок пока нет

- 01 Taking A Pilot AboardДокумент7 страниц01 Taking A Pilot AboardEnder SemsedinОценок пока нет

- Anchor Loss in Heavy Weather: Learn from IncidentsДокумент4 страницыAnchor Loss in Heavy Weather: Learn from IncidentsJivanJyotiRout100% (1)

- Survey Guidelines under HSSC 2015Документ176 страницSurvey Guidelines under HSSC 2015Deepesh MerchantОценок пока нет

- SOLAS Pilot LadderДокумент8 страницSOLAS Pilot LadderManoj VarrierОценок пока нет

- Pilot Ladder SafetyДокумент59 страницPilot Ladder SafetyYamani100% (1)

- Rule 8: Action To Avoid A CollisionДокумент48 страницRule 8: Action To Avoid A Collisionbloodyspark77100% (2)

- Chain RegisterДокумент2 страницыChain RegisterAseem SinghОценок пока нет

- HRUДокумент2 страницыHRUANANT VIJAY100% (1)

- Stowage and Lashing of ContainersДокумент54 страницыStowage and Lashing of Containersalfonxxl100% (1)

- Mooring & Wire RopesДокумент14 страницMooring & Wire RopesAlexОценок пока нет

- Annual Survey Checklist For Bulk Carrier: Condition To Be Reported Using Number Code As FollowsДокумент11 страницAnnual Survey Checklist For Bulk Carrier: Condition To Be Reported Using Number Code As FollowsIlker KoksoyОценок пока нет

- Mandatory Emergency Towing Systems in Ships Other Than Tankers of Not Less Than 20,000 DWTДокумент6 страницMandatory Emergency Towing Systems in Ships Other Than Tankers of Not Less Than 20,000 DWTnawanОценок пока нет

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7От EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7Оценок пока нет

- West of England - Loss Prevention Bulletin - Gangways and Accomodation Ladders PDFДокумент6 страницWest of England - Loss Prevention Bulletin - Gangways and Accomodation Ladders PDFDave Moreno100% (1)

- MSF Safety Flash 13 09Документ2 страницыMSF Safety Flash 13 09Eric BergerОценок пока нет

- Ra 08 Safe Mooring PracticeДокумент3 страницыRa 08 Safe Mooring PracticeNelum PereraОценок пока нет

- HSE and SOP ON EMBARKATIONДокумент5 страницHSE and SOP ON EMBARKATIONNajmirzan IsraОценок пока нет

- CATZOCДокумент52 страницыCATZOCsbcheah100% (1)

- ISM Code 2015Документ18 страницISM Code 2015Gaurav HarjaiОценок пока нет

- Final Transportation ManagerДокумент8 страницFinal Transportation ManagersbcheahОценок пока нет

- FLEET ZONES GUIDEДокумент18 страницFLEET ZONES GUIDEsbcheahОценок пока нет

- What A Marine Surveyor Needs To Know About Working in Enclosed SpacesДокумент54 страницыWhat A Marine Surveyor Needs To Know About Working in Enclosed Spacesacere18Оценок пока нет

- Muster List Sigloo NorseДокумент2 страницыMuster List Sigloo Norsesbcheah100% (10)

- Chevron EverythingYouNeedToKnowAboutFuels v3 1a DESKTOPДокумент32 страницыChevron EverythingYouNeedToKnowAboutFuels v3 1a DESKTOPNamal FernandoОценок пока нет

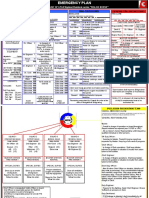

- 005 - Chapter 4 - Appendix 2 - Emergency PlanДокумент1 страница005 - Chapter 4 - Appendix 2 - Emergency Plansbcheah100% (1)

- ABB Turbocharger Tips For The OperatorДокумент44 страницыABB Turbocharger Tips For The Operatorsevero97100% (4)

- DNV Competence ManagementДокумент22 страницыDNV Competence Managementbill baileyОценок пока нет

- Mooring Winch Brake Holding CapacityДокумент2 страницыMooring Winch Brake Holding CapacitysbcheahОценок пока нет

- Ycnsunom 3. Hull FoulingДокумент22 страницыYcnsunom 3. Hull Foulingswapneel_kulkarniОценок пока нет

- Risk Assessment For Installation of Drainage PipesДокумент17 страницRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- Osh 29 CFR 1910 Subpart DДокумент39 страницOsh 29 CFR 1910 Subpart DAnonymous I8nZsDqlmhОценок пока нет

- How To Replace A Shingle - DIY Roof RepairДокумент6 страницHow To Replace A Shingle - DIY Roof RepairPR.comОценок пока нет

- Safe access to vessels MSD41503Документ27 страницSafe access to vessels MSD41503sukhjit78Оценок пока нет

- Jsa For Work at HeightДокумент8 страницJsa For Work at HeightMuhammad Umar Gondal50% (2)

- ISO 5488 Accomm LaddersДокумент8 страницISO 5488 Accomm LaddersCinthia Lidia Hidrogo Paulino0% (1)

- SAYFA Working at Heights ManualДокумент20 страницSAYFA Working at Heights ManualMiodrag LjumovicОценок пока нет

- AHA WorksheetДокумент6 страницAHA WorksheetRev DezviОценок пока нет

- Risk Assessment For Harmonic Measurement Study ProcedureДокумент13 страницRisk Assessment For Harmonic Measurement Study ProcedureAnandu AshokanОценок пока нет

- Tales of Daring Dan 00 He Ntial AДокумент202 страницыTales of Daring Dan 00 He Ntial A351647172Оценок пока нет

- College Physics A Strategic Approach 3rd Edition Knight Test BankДокумент23 страницыCollege Physics A Strategic Approach 3rd Edition Knight Test Bankpaullanb7nch100% (30)

- 003 Hirac Ladder SafetyДокумент2 страницы003 Hirac Ladder Safetyeunice.pacerstradingsОценок пока нет

- Ladder Safety ChecklistДокумент3 страницыLadder Safety ChecklistzulfactОценок пока нет

- Plastering Risk AssessmentДокумент22 страницыPlastering Risk AssessmentAhmed IbrahimОценок пока нет

- Safety TalksДокумент85 страницSafety TalksMahmoud AbdallahОценок пока нет

- Safety tips for rigging gangways and accommodation laddersДокумент6 страницSafety tips for rigging gangways and accommodation ladderssbcheahОценок пока нет

- L&T Toolbox Meeting on Safe Ladder UseДокумент1 страницаL&T Toolbox Meeting on Safe Ladder UseProsun SarkarОценок пока нет

- Cabloc Vertical Fall Arrest PDFДокумент10 страницCabloc Vertical Fall Arrest PDFTunaru GabrielОценок пока нет

- Ladder Risk AssessmentДокумент3 страницыLadder Risk Assessmentvasanth pugazhendhiОценок пока нет

- Second Condition of EquilibriumДокумент7 страницSecond Condition of EquilibriumJescil Ann OriolОценок пока нет

- Drew Ladder Safety Program Policy SOP 0412Документ6 страницDrew Ladder Safety Program Policy SOP 0412MechanicalОценок пока нет

- Supervisors - HSE ChecklistДокумент2 страницыSupervisors - HSE Checklistchikkam50% (4)

- Project ProposalДокумент3 страницыProject ProposalTharindu ChathurangaОценок пока нет

- 1910.23-OSHA Ladders StandardsДокумент10 страниц1910.23-OSHA Ladders Standardsr afriantoОценок пока нет

- Risk Assessment of Trees MaintenanceДокумент9 страницRisk Assessment of Trees Maintenanceطارق رضوان100% (1)

- 4 Feb 10NAVAL SHIPS' TECHNICAL MANUAL 600Документ44 страницы4 Feb 10NAVAL SHIPS' TECHNICAL MANUAL 600Francisco Javier Cordero Esquivel100% (1)

- Taking You One Step Higher with Penguin LaddersДокумент28 страницTaking You One Step Higher with Penguin LaddersAmanush KoolОценок пока нет

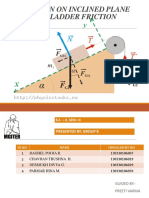

- FRICTION ON INCLINED PLANES AND LADDERSДокумент15 страницFRICTION ON INCLINED PLANES AND LADDERSdivyannshОценок пока нет

- Working at Height Technical GuideДокумент70 страницWorking at Height Technical GuideMa GabbyОценок пока нет

- Ladders: Revision / Approval HistoryДокумент10 страницLadders: Revision / Approval HistoryibrahimОценок пока нет