Академический Документы

Профессиональный Документы

Культура Документы

D352004107-MKT-001 Rev 02 Drilling Solutions Mission

Загружено:

Ashok SureshАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

D352004107-MKT-001 Rev 02 Drilling Solutions Mission

Загружено:

Ashok SureshАвторское право:

Доступные форматы

Drilling Solutions

Mission Products

Mission

Our Mission group offers

technical expertise for

pumping systems, fluid end

expendables, pressure control

systems, flowline equipment,

wellheads and continuous

technology development of

fluid management systems.

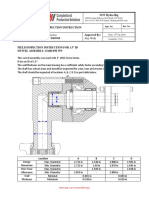

Drilling Solutions Mission Products

Centrifugal Pumps

The NOV centrifugal pump line has proven to be the best centrifugal

design for handling abrasive mud. This pump line offers a broad

selection of innovative features for a variety of routine, demanding,

abrasive, and corrosive applications. These pumps are designed for a

wide range of flow rates, from a few gallons per minute to thousands

of gallons per minute. Unitization services and options compliment

the centrifugal pump line.

Centrifugal Pump Offerings

Magnum

2500 Supreme

Sandmaster

Magnum Xp

Magnum Vortex

Shear pumps

Close coupled centrifugal pumps

1180 Type S

1780 Type W

Versatile drive and mounting options

Centrifugal pumps are available in a

variety of engineered options:

Horizontal Electric

Vertical Electric

Close Coupled Electric

Horizontal Diesel

Overhead Belt

Side Belt

Hydraulic Driven Pumping Units

Magnum

Magnum Belt-Driven

Magnum Direct Connect

2500 Supreme

Centrifugal Pumps

Fluid End Expendables

Custom Dies and Inserts

Fluid End Modules

Blak-Jak Equipment

Drilling Chokes

Gate Valves

Manifolds

Reset Relief Valves

Shear Relief Valve

Float Valves

Solids Control Equipment

Custom Design and Unitization

Reciprocating Pumps

Page

1

24

5

5

67

89

10 11

12

13 14

14

15

15 16

16 17

18 19

Table of Contents

Vertical Close Coupled Magnum

mission@nov.com

nov.com/mission

Drilling Solutions Mission Products

Fluid End Expendables

Mission manufactures field-proven fluid end expendables for all pump

manufactures. All fluid end expendables are manufactured from high

quality materials to provide extended run times and longer service life.

Crosshead Extension Rods (Pony

Rods)

Piston Rods

Blak-JAK HydrA-LIGN Rod System

Self-Aligning

OEM

Piston Rod Clamps

Pullers/Tools

Bushing X-tractor

Liner Bushing Puller (P Series

Pumps)

Liner Pullers

Piston Rod Nut Wrenches

Seat Pullers

Wear Plate Pullers

Seats

Gland Bushings and Junk Rings

Supreme Valves and Seats

White Lightning Roughneck Bonded

Valve

Roughneck Bonded Drilling Valves

Modules

Mission L Style Module-5,000 and

7,500 psi

Monoblock

OEM Style

Packing

Rod (Duplex)

Pony Rod

Roughneck Bonded Valve and Seat

Liners

Ceramic

Chrome Iron Sleeved

Hardened Steel

Valves

Bonded

Crossarm Style

Full Open

Roughneck and Roughneck HP

Gaskets

Cylinder Head

High Temperature Polyurethane

Liner

OEM

Polyurethane

Valve Cover

Wear Plate

Valve Inserts

Springs

Bushing X-tractor

Self-Aligning Rod with Dual Cooling

Tubes

Ceramic Liner

Supreme Liner

Bushing

X-tractor

Self-Aligning

Rod with Dual

Cooling Tubes

Ceramic liners offer longer run

times, lower operating costs

and reduced risk exposure when

compared to operating with

chrome iron liners. The ceramic

sleeve material is manufactured

from alumina oxide, known for

its wear resistance, and has

proven run times in all types of

operating conditions. The outer

hull material for large bore liners

is manufactured from alloy steel

to increase yield strength and

aid in fatigue resistance. Ceramic

liners are corrosion resistant

and have a smoother surface

finish for reduced friction and

heat. Combining these features,

the extensive history of NOV in

ceramics and proprietary pump

technology, results in a liner

unmatched by any other in the

industry. NOV ceramic liners

are field proven as the longest

running liner (up to 16,000 hrs.)

ever manufactured.

The Supreme liner is

manufactured using only

the highest-grade materials.

The outer section, or shell, is

manufactured from high strength

carbon alloy steel. The shell is

heat-treated to provide optimum

mechanical properties providing

the end user with longer liner

and piston life. The inner section

of the liner, or the liner sleeve, is

manufactured from a proprietary

high chrome iron alloy that has

excellent abrasion, erosion, and

corrosion resistance.

The current method for removing

the liner bushing on a 9P100,

10P130, 12P160 or 14P220 can

take three mechanics up to 8

hours to remove one bushing.

The Bushing X-tractor uses a

hydraulically actuated cylinder

to remove the liner bushing

which provides a consistent

straight pull resulting in bushing

removal in minutes instead of

hours. This significantly reduces

maintenance downtime, requires

fewer mechanics and provides a

much safer work environment.

The self-aligning rod resolves

misalignment issues between

the crosshead and fluid end

of the mud pump. In addition,

it reduces piston side loading

for increased piston run times.

The self-aligning rod increases

liner life on all types of liners

and reduces downtime due to

less frequent piston and liner

replacement. The dual cooling

tubes on the self-aligning rod

provide more uniform coolant

delivery, increasing piston run

times.

NOV also manufactures Zirconia

sleeved liners to accommodate

particular customers requests.

Pistons

Blue Lightning

Flexlip

Green Duo

Supreme

Slip Seal Bullitt

White Lightning

The Roughneck bonded drilling valve design is the model for extreme

pressure drilling. It improves maintenance conditions in valveover-valve fluid ends and the uniform loading of the fluid end taper

increases fluid end life. The Roughneck has a heat treated forged

alloy steel valve body and valve seat for extended service life, ideal

for higher horsepower pumps and pressures to 7,500 psi. Roughneck

bonded valves are also available in White Lightning which is good to

230 F.

Supreme Liner

Liner, Cylinder and Valve Cover

Gaskets

Rod Clamp Assembly

Ceramic Liner

mission@nov.com

nov.com/mission

Drilling Solutions Mission Products

Custom Dies and Inserts

Fluid End Expendables

NOV dies and inserts are accurately machined to tolerances using state of

the art CNC machinery. All dies and inserts are then heat treated to specific

standards to provide the best resistance to wear even in the harshest

environments. Consistent quality and proper fit are guaranteed by extensive

testing and gauging programs utilized by NOV. Various tooth patterns are

available for specific applications.

Most extensive range of dies and inserts in the marketplace today

Consistent quality, proper fit, and improved product life by design

Shaped steel, precision tooling and fixtures, and CNC equipment

Several stocking distributors with large inventory for short delivery times

Valuable experience gained in many decades of die and insert specialization

Blue Lightning Piston

Slip Seal Bullitt Piston

Green Duo Piston

White Lightning Bonded Piston

White Lightning Blue Lightning

Bonded Piston

Piston

Slip Seal Bullitt Green Duo

Piston

Piston

The White Lightning bonded

piston is manufactured from a

highly engineered elastomeric

compound that provides high

resistance to water, oil, and

synthetic based drilling fluids.

The compound provides superior

resistance to tear, abrasion,

and extrusion and is capable of

operating in fluid temperatures

up to 230F (110C).

Built to deliver an economical

solution for harsh drilling

environments, the Slip Seal

Bullitt piston is a multidurometer, solid bonded

urethane piston. The design

of the piston promises ease of

assembly when loading into

the liner due to the smooth

engagement of the piston into

the liner bore. It offers increased

resistance to synthetic and

oil based drilling fluids and is

capable of operating in fluid

temperatures of up to 225F

(107C).

Designed for operating in all

drilling environments, the Blue

Lightning piston is a super

premium bonded polyurethane

piston. It is manufactured from

an engineered elastomeric

compound that delivers excellent

resistance to tear, abrasion and

extrusion while maintaining high

mechanical properties. The Blue

Lightning piston is capable of

operating in fluid temperatures

up to 200F (93C).

Piston Applications

Excellent

Good

Very Good

Poor/Not Recommended

Features

Blue

Lightning

Bonded

White

Lightning

Green Duo

Slip Seal

Bullitt

Features

Abrasion Resistance

Use in Water Based Mud >#11

Tear Resistance

Use in Water Based Mud <#11

Resistance Oil

Use in Clear Water

Chemical Resistance

Use in Salt Water

Resistance to Synthetic Oil

Use in Low Solids

Temperature Resistance

Use in Moderate Solids

Extrusion Resistance

Use in High Solids

Use in Oil Base Muds

Linear Wear Characteristics

Use in Synthetic Base Muds

Use in Ceramic Liners

Use in Water Based Mud >#10

Maximum Temperature

(Flow Line) (F)

Use in Water Based Mud <#10

Blue

Lightning

200

The Green Duo piston is a

bonded dual durometer piston

that is highly resistant to

abrasion and tear. The bonded

construction resists extrusion

under pressure and restricts

movement to reduce the buildup of heat. Green Duo pistons

are recommended for systems

with oil or synthetic based mud.

It is also recommended for

water based muds when weights

are 11 lb/gal or over. As in all

urethane pistons, the backflush

requirement is recommended at

14 gal/min or greater for

each piston.

Bonded

White

Lightning

230

Diamond Tooth Tong Die

Reducing Large

Pyramid Tooth Tong Die

Die Cavins Type C

Reducing Medium

Standard Small

Fluid End Modules

NOV Products manufactures fluid end modules and jewelry to exacting

standards to ensure product reliability and performance. Mission

produces fluid ends for all legacy NOV mud pump brands including

Continental Emsco, Ideco, National, Oilwell, and Skytop Brewster as well

as all other popular pump models.

Mission L 7500 Module

Green Duo

180

Slip Seal

Bullitt

225

Designed as an upgrade solution for existing mud pumps, the NOV L 7500

modules are equipped with 5,000 psi fluid ends. They can also be specified

as original equipment for certain new NOV mud pumps and as original

equipment on new pumps from other manufacturers. These modules create

added value by increasing the operating range of existing mud pumps and by

reducing maintenance and pump downtime. Added features can include the

Blak-JAK liner retention system, Torque Pro valve cover retention system,

Blak-JAK HydrA-LIGN rod system, NOV ceramic liners, and Roughneck valves

and seats.

The Mission L 7500 modules are available for specific National, Oilwell,

Continental Emsco and Ideco brand pumps as well as other manufacturers

popular mud pump models.

14P220 7500 psi Mission L

mission@nov.com

nov.com/mission

Drilling Solutions Mission Products

Blak-JAK Equipment

Blak-JAK equipment is safer, faster and eliminates the use of hammers and creates value through shorter change-out times when compared to

OEM equipment.

Blak-JAK HydrA-LIGN Rod System

Blak-JAK

HydrA-LIGN

Rod System

Hammerless Valve Cover Retention

System Installed

1. Valve Cap Lug Adapter

2. Stop Locator

Blak-JAK Liner

Retention

System

Blak-JAK Torque Blak-JAK Torque

Pro Hammerless Pro Lite

Valve Cover

Improving safety by eliminating

the need for hammers, the BlakRetention

JAK Torque Pro Lite utilizes a

hydraulic wrench to tighten and

System

loosen the valve cap retainer. It

Blak-JAK Liner Retention System

mounted in a pump

Only 1 person required for liner changeout

33% lighter than OEM

Blak-JAK Torque Pro Wrench

Original 5000 psi Blak-JAK Washpipe

Cartridge System

Blak-JAK 7500 Washpipe Cartridge

with Blak-JAK Pressure Indicator

Light Mounted

Pressure Indicator Light

A spanner bar is utilized to tighten the nuts, eliminating the use of

hammers.

Reduced risk exposure for rig floor personnel

Compatibility to virtually all conventional top drives

Field proven reliability at pressures up to 7500 psi

Quick change cartridge system

25% lighter than competing designs for ease of maneuverability

Cartridge assembly and disassembly is simple and quick

Utilizes standard packing and washpipe with optional high temperature

resistant packing available

Available for 5000 psi and now 7500 psi working pressure

* Patent Pending

uses hydraulic over mechanical

retention and no hydraulics stay

on the pump while the pump

is in operation. This system is

designed for OEM valve over

valve one piece fluid ends as well

as L shaped fluid ends that do

not utilize a threaded ring for the

valve cover. No modification to

the fluid end is required.

The Blak-JAK Pressure Indicator light ensures optimum life of

washpipe packing, while at the same time providing a 12-36 hour

warning before packing failure. Packing rings in the lower rotating

housing of a washpipe cartridge fail sequentially. Once the third

packing ring begins to leak and the fourth packing ring energizes, the

light will begin to strobe; this indicates that the washpipe packing

needs to be replaced at the soonest opportunity. The early warning

provided by the Blak-JAK Pressure Indicator light can consistently

prevent mud leakage and unnecessary downtime. The Blak-JAK

Pressure Indicator light adds value through the following:

* Lewco is a trademark of Joy Global

Longview Operations LLC.

* Hong Hua is a trademark of Honghua

Group Ltd.

* Bomco is a trademark of Baoji Oilfield

Machinery Co., Ltd.

* Gardner Denver is a trademark of

Gardner Denver, Inc.

The NOV Mission Blak-JAK

Torque Pro valve cover retention

system utilizes a hydraulic

wrench to tighten and loosen

the valve cap retainer and then

requires only a quarter turn to

remove the retainer. This quick

and easy valve access allows

for faster hammers. This system

works with OEM valve covers as

well as Mission L style plugs. No

modification to the fluid end is

required.

Designed for speed and efficiency, the Blak-JAK Washpipe Cartridge

System is a self-contained unit designed to be repacked on the

rig floor, not at the swivel. Once the assembly has been repacked,

the single cartridge can be installed quickly in the swivel just by

tightening the nuts to the gooseneck.

Blak-JAK Pressure Indicator* Light

Providing a simple, compact

design with easy installation,

the Blak-JAK liner retention

system reduces weight for easier

operation. There is only one

Hydra-CEL (hydraulic, tension

device) to maintain rather than

individual hydraulic assemblies.

The redesigned Lok-CEL

(tensioned, mechanical device)

body and locking nut assemblies

are designed in conjunction

with NOV fluid end technology.

These mechanical designs are

simple, rugged, and effective.

Blak-JAK equipment is available

for specific National, Oilwell,

Continental Emsco, Lewco*,

Hong Hua*, Bomco*, *Gardner

Denver and other manufacturer

pumps.

Blak-JAK Washpipe Cartridge

System

The Blak-JAK HydrA-Lign rod

assembly is designed to reduce

operational risk exposure and

improve risk environments

during change-outs of high

use fluid expendable parts.

Additional value to operators

and contractors is realized

through design features that

allow self-aligning capabilities

between the pump liner and

piston. Run times of expendables

will be positively affected and

pump downtime reduced. The

Blak-JAK HydrA-Lign rod can be

used on all popular makes and

models.

mission@nov.com

nov.com/mission

Drilling Solutions Mission Products

Drilling Chokes

MPX-40D Drilling Choke

HXE-G3 Worm Gear and HXE-G3 Piston Choke

HXE-Auto-Choke

T-3 E-S Drilling Choke

Mission Electric Drilling Choke

MPX-40D Drilling

Chokes

T3 HXE-G3 Drilling Chokes

HXE Auto

Chokes

T3 E-S Drilling

Chokes

Mission Electric

Drilling Chokes

The MPX-40D drilling choke is an adjustable drilling choke available

with interchangeable linear orifice sizes and tungsten carbide flow

control components. Its pressure balanced plug reduces operating

force and stem loads. Its non-threaded seat requires fewer parts,

less downtime and it offers ease of maintenance. The bolted bonnet

design increases safety and uses a metal bonnet seal. The MPX-40D

drilling choke is a direct bolt-in replacement for current CSO drilling

chokes.

replaceable nose, reversible gate and seat. Standard choices of positioning;

Pneumatic, Digital Position Sensor or Digital Position Sensor with 4-20mA

output.

The Model HXE Auto-Choke and Control

System combines the field-proven reliability

and wear-resistance of the Model HXE choke

with a continuous duty-cycle Siemens

electric servo motor, yielding extremely

precise pressure control and quick response

times. The choke itself is run by a remote

console that allows manual or automated

control of the choke. In automatic mode,

the choke will rapidly adjust trim positioning

to maintain the set-point pressure that is

input at the remote console. In addition to

maintaining pressure within a more precise

range than hydraulically actuated chokes are

able to maintain, the electric servo motor

allows the choke to function reliably in very

cold conditions, and without the cost of

running and maintaining hydraulic lines.

The E-S Hydraulic Drilling choke is ideal for

situations requiring precise control of flow

rates. The rotary actuator control allows

operation in high-pressure environments.

The NOV Mission line of Shaffer drilling

choke systems provide fast, accurate

well control through one or two chokes

operating remotely from the rig floor. Fluids

can be circulated from the well bore while

holding any desired back pressure rating

of the choke. The system includes one or

two electrically operated chokes, pressure

transmitters for drill pipe and annulus

pressures, and a floor-mounted control

panel.

Pressure rating 5K

Orifice size 3" max but can be converted in the

field to 2" or 1.5" orifice

API 4-1/16" inlet and outlet

Actuator Electric servo, Class I, Div. 1, with

internal velocity and position feedback

High quality and performance

Eliminates the additional cost of a hydraulic

system

Low maintenance - no hoses, reservoirs or

potential safety issues with leaks paths

Manual override capability at the manifold

Electronically operated - one connection

Higher resolution and precision choke

feedback

Valve/actuator diagnostics available

Dual-tapered choke plug

Erosion possibilities minimized

Additional feedback available to rigs

Positive visual valve position indication

Data acquisition system available if required

Full automation and diagnostic capabilities

Flanges are attached with 100% penetration

welds and bored out

All welds are X-ray quality

All flow fittings are manufactured to H2S

specifications

Products maintained and serviceable

worldwide

The outlet spool is a unique Wear Sub design. It can be built to give up to

18 inches of downstream wear protection with a standard of 12 inches. Many

chokes of this nature cannot compete.

The body is manufactured with external bonnet nut threads allowing bonnet

removal without disconnecting hydraulic lines from choke.

Both the Gate and Seat are reversible giving each piece double the usage

thus reducing even more cost.

The Gate and Seat are designed to direct high velocity wear away from the

positive sealing surface, this feature extends the life of the choke trim.

Non-threaded seat

API-6A/16C PR2 Qualified

Material Class EE-NL

Temperature Class L/X

While the 3" Max design will give you full range trim accepting trim sizes 1",

1 ", 2 and 3" orifice trim.

Large body reservoir, minimal erosion

API-6A annex F PR2 qualified

Material Class EE-NL

Temperature Class P/X

(-20F/350F) (-29C/180C)

End Connection Sizes 3-1/8", 3-1/16" and 4-1/16"

Pressure Ratings 5K, 10K and 15K

API-16C flow test qualified

ANSI class V shut-off capability

Manual or automated designs

Internal plug and cage design for increased well control

Forged integral flange bodies

Compatible with Swaco Hydraulic Drilling Choke

Provides positive seal

Tungsten carbide wear sleeves extend service life

Orifice plate design provides greater control of

flow rates

2" Max body design with reduced mass lowers cost of trim and will accept

1", 1 ", and 2" orifice trim.

Two body designs available:

HXE-G3 designs in any inlet/outlet configurations are available in either

worm gear or double acting piston operated designs. Both standard with

mission@nov.com

nov.com/mission

Drilling Solutions Mission Products

Gate Valves

E-TYPE Gate Valve

2300 SFC Gate Valve

MVD-7500 Disc Type Mud Valve

MVD-7500 Disc Type Mud Valve

T3 HPT Gate Valves

ANSON E-Type Gate Valves

Designed for the most demanding applications, NOVs T3 brand

model HPT gate valve meets the industrys toughest standards,

including API 6AV1 (Slurry), API 6FC (Fire Test) and DNV Type Approval.

It is available in sizes ranging from 2" 5,000 psi to 7" 15,000 psi, with

20,000 psi option. Special bore sizes available on request.

Anson brand E-TYPE through-conduit gate valves have been

developed to satisfy the need for a high quality, high specification

valve which is reliable and reasonably priced. The E-TYPE gate valve

makes full use of modern materials and manufacturing techniques.

The valve is robust, easy to maintain, and conforms to international

design requirements and quality assurance programs.

Shaffer 2300 SFC

Gate Valves

ANSON Mud

Gate Valves

MVD-7500 Disc Type

Mud Valves

The Shaffer 2300 SFC initiated from legacy

Shaffer and T3 technologies combining the

NOV Shaffer Model 2300 SurSeal gate valve

with the Robbins and Myers T3 FC gate

valve line. The Shaffer Model 2300 SFC will

replace these two product offerings with one.

Mission is able to offer a superior gate valve

by combing our extensive experience of gate

valve manufacturing processes, testing, and

reliable service history.

Anson mud valves are solid gate, rising stem,

gate valves with resilient seals. They are

purpose-made for mud, cement, fracturing,

and water service. They are easy to operate

and simple to maintain. Two ranges are

available:

Specifications

MV50: The valve is suitable for a maximum

working pressure of 5,000 psi

MVD-7500: The valve is suitable for a maximum

working pressure of 7,500 psi

Temperature Rating

-20F (-29C) to 250F (121C) (standard)

-50F (-46C) to 250F (121C) (optional)

Qualification Testing

Hydrostatic cyclic testing (high and low

pressure), gas testing (high and low pressure),

mud pump pulsation and flow testing (high and

low pressure)

The Shaffer HB subsea gate valves are through-conduit gate valves

designed for subsea BOP stacks and systems. The hydraulic operated API

6A gate valve actuators are double acting with spring assist fail open or

close and are designed for use with hydraulic failsafe systems.

Options

Position feedback

Position lock

316 stainless steel/CRA 625 corrosion resistant

API ring grooves, hub sealing areas

Enhanced corrosion protection options (CRA

625bonnet and seat seal areas)

Hydraulic or electric actuation

Butt weld, hub or flanged end connections

Forged steel body and bonnet

Bidirectional Sealing

Low operating torque

Shear pin protected internal works

API 6A PSL 2, 3 or 3G

PR1 rated

Supplied with full material certification

API 6A material classes: DD and EE

Manual Operated (Non-rising stem)

Hydraulic Operated (Double acting with

MOR)

Available bore sizes: 2, 3, 4

Pressure Ratings: 5K, 10K and 15K

Shaffer HB Subsea Gate Valves

Pressure

Up to 7,500 psi maximum allowable working

pressure

API 6A material classes: AA to HH

Available bore sizes: 1-13/16" to 9"

Pressure Ratings: 3K up to 20K

Temperature Class: L up to X

API 6AV1 Class 2 Slurry Tested

Forged steel body and bonnet

Bidirectional Sealing

API 6A PSL 2, 3 or 3G

PR2 rated

Supplied with full

material certification

Shaffer 2300 SFC through-conduit gate valves

are robust, easy to maintain and conform

to international design requirements and

quality assurance programs. The valve can be

monogrammed, conforming in all aspects to

API 6A.

Design

API 6D, API 6A (where each is applicable)

Specifications

The E-TYPE gate valve is a monogrammable API 6A valve available

with hydraulic actuation. Valves can be supplied with spring return

fail-safe, open (FSO) or closed (FSC), or double acting cylinders (DA).

Both types offer a compact design, are fully weather sealed and

available with extras such as position indicators, hydraulic power

packs and control systems.

Forged steel body and bonnet

Bidirectional Sealing

Low operating torque

API 6A PSL 2, 3 or 3G

PR2 rated

Supplied with full material certification

API 6A material classes: DD and EE

Good for methane, methanol, paraffin solvents,

completion fluids, acids containing 13.5% HCL,

Heavy BRINE and Salt Water

All seals meet NORSOK M-710 Rev.2 compliance

HPT Gate Valve

Supplied with full material certification

Available bore sizes: 3-1/16" and 4-1/16"

Pressure Ratings: 10K and 15K

Material Class: DD-360 and DD-NL

Temperature Class: P up to X

(-20F up to 350F) (-29C up to 180C)

10

Floating seats

Downstream sealing

Bidirectional Sealing

Metal-to-metal body and seat,

seat-to-gate, bonnet to body

Valve Body Styles:

Dual, Angle and Single

Third Party Approvals

ABS, LRS, DNV, BV

HB Subsea Gate Valve

11

mission@nov.com

nov.com/mission

Drilling Solutions Mission Products

Manifolds

Reset Relief Valves

NOV manifold systems are designed and manufactured to customer

specifications using only the highest quality materials and standards.

Valve options include Anson/ T3/Shaffer API 6A gate valves, Anson mud

valves, Anson/T3 check valves, and Anson plug valves. These, coupled

with Anson manifold fittings, flanges, hubs, hammer unions, API blocks,

and NOV welding capabilities allow NOV to control the design quality and

scheduling of the most complex manifold projects.

Titan Class reset relief valves encompass the best stand-alone,

mechanically operated reset relief valves on the market today.

The Titan Class includes:

Standpipe Manifolds

Anson plug valves

Anson forged crosses

Anson hammer unions

Anson forged tees

Anson forged long

radius elbows

Individually pressure tested fittings and valves

Pressure tested assembly

Full material traceability

Design codes include

API.6A, ASME VIII (Div.1 and 2)

ASME B.31.

Choke and Kill Manifold

6" NB 7,500 psi

Standpipe Manifold

Choke and Kill Manifolds

Anson/T3/Shaffer gate valvesmanual and hydraulic

Anson/T3/Shaffer positive and adjustable chokes

T3/Shaffer Hydraulic chokes

API studded crosses, tees, adaptors, flanges and spools

NOV blinds, crossovers and fittings

NOV choke control systems

Individually pressure tested valves

Pressure and function tested prior to dispatch

Standpipe Manifolds

NOV standpipe manifolds are designed and manufactured to

customer requirements utilizing the Anson/T3 range of mud valves

and forged manifold fittings. The incorporation of standard Anson/

T3 products enables NOV to control quality and scheduling to ensure

prompt delivery and competitive prices. Welded, flanged, hubbed

or hammer union construction is available. Pressures up to 7,500

psi using standard Anson/T3 mud valves can be accommodated.

NOV standpipe manifolds are designed and supplied fully certified in

accordance with the recognized oilfield equipment standards.

Anson/T3 mud valves

Anson forged manifold fittings

Anson/T3/Shaffer chokes

Anson original quality unions

Anson hammer union forged

tees and elbows

12

Titan Class C Relief Valve

Titan BX Automatic Reset Relief Valve

Titan BX Automatic Reset Relief

Valve System

The Titan BX reset relief valve is the only air-operated, fully automatic

reset relief valve on the market that fails open. When pump pressure

exceeds set pressure, the Titan BX reset relief valve automatically opens

through an electronic system. After a time delay pre-selected by the

operator, the valve will automatically close using instrument air pressure,

eliminating the need for manual reset. In the event that the rig loses

power, air, or mud pressure, the valve will automatically open.

The unit is ISO 9001:2008, ABS and DNV type approved and can be

CE/PED certified.

The Titan BX automatic reset relief valve system consists of 1- 6

valves, one pilot valve box per valve, one mud cup transducer per

valve, and one control panel for the entire system.

Titan RX Reset Relief Valve

Anson/T3/Shaffer choke and kill manifolds are designed and

manufactured to customer requirements by a highly qualified

multidiscipline team. Choke and kill manifolds are manufactured

from Anson/ T3/Shaffer standard off the shelf products which enable

NOV to exercise control over quality and scheduling to ensure prompt

delivery and competitive prices. Complete control systems can be

supplied with pressure requirements of up to 20,000 psi. Anson/T3/

Shaffer choke manifolds are designed and supplied fully certified in

accordance with the recognized oilfield equipment standards.

Titan Class B Relief Valve

Full material traceability

Individually pressure tested valves and

fittings

Hydrostatically pressure tested

assembly

Titan B, C, CH & RX Reset Relief

Valves

The Titan manual reset relief valves automatically snap to a full open

position when the set pressure is reached. In addition, this relief valve

comes equipped with a position release button that indicates, at a

glance, whether the valve is open or closed.

Gas Gathering Manifolds

Mud Tank Manifolds

Underbalanced Drilling Manifolds

Managed Pressure Drilling Manifolds

Cement Manifolds

Anson high pressure cement manifolds are designed and manufactured

to customer requirements. The Anson product line offers the widest range

of hammer union ended equipment available from any one manufacturer.

Purpose forged tees, crosses, Ys, laterals, plug valves, crossovers;

the list is endless. This allows NOV to supply very competitively priced

cement manifolds in a wide variety of sizes and configurations. Manifolds

with pressure ratings up to 20,000 psi are available. Anson cement

manifolds are designed and supplied fully certified in accordance with the

recognized oilfield equipment standards.

Choke and Kill Manifolds

Diverter Manifolds

Truck Mounted Manifolds

Ground Pipe Manifolds

Containerized Manifolds

Titan Class 3-inch B

Titan Class C and CH

Titan RX

Titan BX

NOV designs and builds the following types of manifolds:

Cement Manifolds

NOV manifolds are designed and supplied fully certified in accordance

with the recognized oilfield equipment standards.

3" Fig. 1502 10,000 psi

Cement Manifold

Titan BX Mud Cup Transducer

Titan B: Pressure Ratings from 400 psi to 5000 psi

Titan C: Pressure Ratings from 400 psi to 5000 psi

Titan CH: Pressure Rating 2500 psi to 6200 psi

Titan RX: Pressure Rating 2000 psi to 8000 psi

Titan BX Control Panel

13

mission@nov.com

nov.com/mission

Drilling Solutions Mission Products

Float Valves

Air Titan Reset Relief Valves

The Air Titan Reset Relief Valve offers a pneumatically actuated cylinder that allows for remote

control and resetting, which reduces personnel contact with high pressure equipment and

improves safety. The Air Titan rapidly actuates to a full open position when the set pressure is

reached, thereby protecting the mud pump from harmful pressure spikes.

The set pressure is set and changed using the inline pressure regulator on the pneumatic actuator.

Set pressures range from 2,000 - 8,000 psi.

Features

Flapper Type Float Valve

Mud Gun

A complete line of float valves

and repair kits are manufactured

to accommodate a wide range of

drilling situations and operating

conditions. These drill pipe float

valves provide added blowout

protection at the bottom of the

drill string to prevent flowback

when joints are added and keep

cuttings out of the drill pipe

to prevent bit plugging while

making connections.

MODEL G - Flapper - Full Flow

The Model G flapper style

valve features an investment

cast flapper. Its quick opening

provides unrestricted full

flow through the valve. This

model is designed for highly

abrasive drilling fluids. (Parts

are interchangeable with *Baker

style equipment.)

Mud Guns

The following products are

available in standard service and

Hi-Temp/NACE assemblies:

Valve opens completely in less than on second when set pressure is reached

Minimum downtime for repairs

Optimum seal life (field proven)

Actuator assembly, top-loaded piston (seals can be removed while body is in line)

Hydraulically balanced and cushioned piston

Control Panel allows for remote resetting

and changes in the set pressure

Easy adjustment of set pressure

Accuracy within 5% of set pressure

Rugged inconel 718 body insert

Eliminates mechanical calibration

Plunger Type Float Valve

Shear Relief Valves

Shear relief valves are economical, easy to use and require minimal maintenance. They

are available in 2" or 3" threaded connections and are capable of relieving pressure at

settings from 400 psi up to 5,000 psi. Mission shear relief valves are interchangeable

with other Demco* style shear relief valves.

MODEL F - Plunger Type

The Model F plunger type

valve offers positive and instant

shut-off. During normal drilling

operations, the Model F offers

economy and durability. The

piston type stops flowback when

making connections and keeps

cuttings out of the drill string.

(Parts are interchangeable with

*Baker style equipment.)

MODEL GA - Flapper - Full

Flow with Carbide Orifice

The Model GA is identical to

the G, except for the addition

of a carbide orifice in the flapper.

It allows differential pressure

readings at the surface. (Parts

are interchangeable with *Baker

style equipment.)

This premium quality mud gun

is considered to be one of the

longest lasting on the market

today. With a nozzle insert lined

with engineered elastomer,

the mud gun will not wear as

easily as common steel inserts.

Worrying less about the wear on

mud guns means worrying less

about the wear on mud pumps.

Mud guns are an inexpensive

solution to a potentially expensive

problem. Other features include a

collapsible handle, a 360 rotating

swivel body, and the ability to be

customized to any length, flanged

or threaded.

Mud Hopper

Mud hoppers

4", 6"

Properly engineered hoppers

ensure the highest discharge

pressures, solid addition

rates, and shear rates. NOV

manufactures 4" and 6" hoppers

with standard flow rates from

130 GPM to 830 GPM as well

as the TurboShear, primarily

used for shearing hard to mix

additives.

* Baker is a trademark of Forum Energy

Technologies. National Oilwell Varco,

L.P. is not affiliated with Forum Energy

Technologies or its affiliates and Forum

Energy Technologies does not endorse

any of the National Oilwell Varco, L.P. float

valves.

Air Titan Reset Relief Valve

Solids Control Equipment

* Demco is a trademark of Cameron International Corporation. National Oilwell Varco, L.P. is not affiliated with

Cameron International Corporation or its affiliates and Cameron International Corporation does not endorse any of the

Mission shear relief valves.

Shear Relief Valve

14

15

mission@nov.com

nov.com/mission

Drilling Solutions Mission Products

Custom Design and

Unitization

TurboShear System

Fire Suppression Systems

Potable Water Pressure Set

TurboShear System

NOV offers custom and standard fluid transfer systems. Offering

versatility and a wide range of capabilities, NOV designs, tests, and

certifies complex systems and packages. To complement products

manufactured, 50 and 60 HZ explosion proof electric motors and

motor controls are in stock. As one of the largest explosion proof

motor distributors globally, NOV creates value for customers.

Whether needs are simple or complex, standard or custom, NOV

can respond to customer design and critical delivery requirements.

Cooling Packages

Brake/Winch Cooling Systems

Brine Filtration Systems

Close Coupled Pumps

Customized Unitizations

Diesel Fuel Filtration Systems

Electric, Diesel and Belt Driven Pump Packages

Fire Suppression Systems

Hoppers with Dust Collectors

Mud Guns

Oil Filtration Systems

Potable/Sanitary Water Pressure Sets

TurboShear Systems

Vertical Pumps

Washdown Systems

NOV engineers and custom manufactures quality cooling packages for

the most demanding applications, some of which include drawworks,

top drives, winches, mud pumps, dynamic thrusters, and quarters

cooling. These packages can be equipped with horizontal or vertical

centrifugal pump configurations, numerous size tanks, and a variety

of heat exchangers to meet virtually any footprint requirement. Land

and offshore models are available.

The TurboShear System reduces the cost of mixing polymers and

clays while improving mud properties. Shearing the polymers

eliminates fish eyes and prevents polymer chaining (long strings),

which cannot pass through the shaker screens. The TurboShear

pump is available as a belt-driven or diesel-driven package including

a hopper, mud gun, and transfer line orifice plate. A complete system

with skid, tanks and piping is also available.

Top Drive Cooling Package

Brine Filtration Systems

Diesel Fuel

Filtration

Systems

Brine Filtration

Systems

NOVs Model FF1080 and FF0181

Diesel Fuel Filtration Systems are

each equipped with a prefilter

tank, coalescer, dual gear

pumps and filter gauges. Diesel

Fuel Filtration Systems remove

water and other contaminants

more effectively that centrifuge

systems and standard fuel filters.

Versatile stuffing box

Thick, strong, concentric casing with replaceable casing wear pad

Long-life, no-adjustment mechanical seal available for near zero leakage

Replaceable shaft sleeve prevents shaft wear

Labyrinth seals for maximum bearing protection come standard

Duplex angular contact bearings eliminate shaft end play and increase

bearing and seal life

Full pipe diameter entrance for minimum turbulence and maximum

efficiency

FF1081 Fuel Filtration System with

upgraded Galvanized Base

High Pressure Washdown Systems

High Pressure Washdown Systems

NOV manufactures high pressure washdown systems available

at 10 GPM at 2,200 psi, 22 GPM at 1,200 psi or 14 GPM at 3,000 psi.

Each unit can be customized with optional features to meet various

needs and budgets.

Fuel filtration systems are

available with the prefilter,

coalescer-separator, transfer

pumps and piping all mounted

on a common base (Model

FF1081); or with prefilter and

coalescer-separators piped and

mounted on one base and the

transfer pumps mounted on a

second base (Model FF1080).

Both fuel filtration systems are

equipped with gauges on each

side of the filtration tanks to

indicate when the filters need to

be changed.

Features and Benefits

Quality construction

Corrosion prevention

Personnel safety

Installation of extra hose reels allows one unit to service multiple

locations

The Brine Filtration system

is a self-contained unit that

emphasizes efficient particle

removal and extended filter

life. The unit utilizes a threevessel filter configuration with

a manifold system to meet a

wide variety of flow and filter

requirements. Each particular

system is dependent on the

particle load and the desired

flow rate of the fluid to be

filtered. Filter element longevity

is accomplished by filtering

the larger particles in the initial

stages, which is commonly

50-micron elements. With the

stepped filter arrangement there

is less particle load, thereby

increasing filter life. Increased

efficiency is realized due to the

multi-staged vessel flow path

as compared to conventional

passage through one vessel. In

addition, the vessels are stainless

steel and possess a static seal

between the filter element and

the vessel to eliminate cross

contamination.

16

17

mission@nov.com

nov.com/mission

Drilling Solutions Mission Products

Reciprocating Pumps

JWS-400

550T-7D

JWS-400 Triplex Piston Pump

550T-7D Triplex Piston Pump

D-750LA Triplex Piston Pump

Custom Pump Unitization Services

The JWS-400 5-1/2 x 7 Stroke Triplex Piston Pump is ideal for mobile

rig applications. It is compact in size and including gear reducer

has a dry weight of 15,000 lbs. (6,804 kg). The JWS-400 is capable

of pumping volumes up to 378 gallons per minute and working

pressures up to 5,000 psi.

The 550T-7D has a large operating envelope in a small footprint

design. The 550T-7D 7 x 7 Stroke Triplex Piston Pump with the valve

over valve fluid end is ideal for light weight rig applications. Including

the gear reducer it has a dry weight of 18,500 lbs. (8,392 kg). The 550T7D is capable of pumping volumes up to 612 gallons per minute and

working pressures up to 5,000 psi.

The D-750LA is a compact, lightweight machine capable of delivering

big pump performance.

Unitized skid mounted pumps, packaged with electric motors,

internal combustion engines and other accessories are available

upon request.

18

D-750LA

Custom Pump Unitization

The D-750LA 7 x 6 Stroke Triplex Piston Pump is equipped with an

L shaped fluid end which provides ease of access for changing valves

and seats. The D-750LA has a dry weight of only 11,500 lbs. (5,216 kg),

making it the lightest pump in its performance class. The D-750LA

is capable of pumping volumes up to 506 gallons per minute and

working pressures up to 5,000 psi.

*Other pump models to fit specific applications are available upon request.

19

mission@nov.com

nov.com/mission

National Oilwell Varco has produced this brochure for

general information only, and it is not intended for design

purposes. Although every effort has been made to maintain

the accuracy and reliability of its contents, National Oilwell

Varco in no way assumes responsibility for liability for any

loss, damage or injury resulting from the use of information

and data herein. All applications for the material described

are at the users risk and are the users responsibility.

Corporate Headquarters

7909 Parkwood Circle Drive

Houston, Texas 77036

USA

Rig Systems Headquarters

10000 Richmond Avenue

Houston, Texas 77042

USA

2015 National Oilwell Varco All Rights Reserved

D352004107-MKT-001 Rev. 02

mission@nov.com

nov.com/mission

Вам также может понравиться

- D352004107 MKT 001 PDFДокумент20 страницD352004107 MKT 001 PDFEloy Lardet LafiОценок пока нет

- SB Darron Non-Magnetic Drill Collar CatalogДокумент51 страницаSB Darron Non-Magnetic Drill Collar CatalogSiva GanaОценок пока нет

- Swivel Interface - CD420160Документ1 страницаSwivel Interface - CD420160ralph100% (1)

- HMH KFDJ Diverters r1Документ9 страницHMH KFDJ Diverters r1budygmoodОценок пока нет

- Case Study VR Lubricator ToolДокумент2 страницыCase Study VR Lubricator ToolVictorОценок пока нет

- Deublin Engineering Catalog English NAmerДокумент56 страницDeublin Engineering Catalog English NAmerOilGasManОценок пока нет

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopДокумент34 страницыTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopRiski KurniawanОценок пока нет

- Swivel Joints - Operating & MaintenanceДокумент4 страницыSwivel Joints - Operating & MaintenanceGenard Sabenacio GarciaОценок пока нет

- Wireline Depth CountersДокумент1 страницаWireline Depth CounterssitaОценок пока нет

- 7.6 SingleДокумент226 страниц7.6 Singlewuillian barretoОценок пока нет

- 980 Catwalk Broch 2014 v10 FINALДокумент6 страниц980 Catwalk Broch 2014 v10 FINALtictacalОценок пока нет

- Caja de Cambio John DeereДокумент52 страницыCaja de Cambio John Deerenelson.oyanadel21Оценок пока нет

- Cameron DL Packer Assembly 11in - TC9609 - E-22Документ1 страницаCameron DL Packer Assembly 11in - TC9609 - E-22Marcos ChavarriaОценок пока нет

- Psi Max2000 MudgunsДокумент12 страницPsi Max2000 MudgunsBernardo PadillaОценок пока нет

- ReLineMNS Omega PDFДокумент3 страницыReLineMNS Omega PDFJuan Manuel Rojas AcuñaОценок пока нет

- D392005428-MKT-001 6012 Bop PDFДокумент2 страницыD392005428-MKT-001 6012 Bop PDFMitul PatelОценок пока нет

- Te ValveДокумент30 страницTe Valvecrni roko100% (2)

- SC-90 Conventional Surface Wellhead System PDFДокумент12 страницSC-90 Conventional Surface Wellhead System PDFErcan YilmazОценок пока нет

- k10 GeothermalДокумент1 страницаk10 GeothermalshegateОценок пока нет

- Venturetech XK 90 Power Swivel Spec SheetДокумент1 страницаVenturetech XK 90 Power Swivel Spec Sheetwilliam pinzonОценок пока нет

- Fail Safe or TR RegulatorДокумент2 страницыFail Safe or TR RegulatorYeit HauОценок пока нет

- Skytop Brewster N46Документ3 страницыSkytop Brewster N46dvdv vdvdzvОценок пока нет

- API Spec 16C - Union Connections 20140103Документ2 страницыAPI Spec 16C - Union Connections 20140103Deby PristantoОценок пока нет

- Hi Kal Catalogue New OptДокумент16 страницHi Kal Catalogue New Optask101Оценок пока нет

- Oil States Swab Cups PDFДокумент2 страницыOil States Swab Cups PDFramudo ZОценок пока нет

- Pages From PS 21 NOVДокумент1 страницаPages From PS 21 NOVHanyОценок пока нет

- Operating Manual: Tubing TongДокумент314 страницOperating Manual: Tubing Tongwuillian barreto100% (1)

- Oilfield Union Color Code GuideДокумент5 страницOilfield Union Color Code Guidelalberto96Оценок пока нет

- CamesaEMC Catalog 12-2013 7Документ1 страницаCamesaEMC Catalog 12-2013 7Gerardo LizardoОценок пока нет

- Parker HTR ActuatorДокумент22 страницыParker HTR ActuatorYorkistОценок пока нет

- Downhole Instrumentation Qualification RPДокумент4 страницыDownhole Instrumentation Qualification RPabinadi1230% (1)

- Model D Tech Unit Stripper Packer SpecsДокумент14 страницModel D Tech Unit Stripper Packer SpecsДудла Станіслав100% (1)

- B+V General Catalog 2010Документ32 страницыB+V General Catalog 2010Leonardo Faria Bueno100% (1)

- Hydril Annular BOP1Документ2 страницыHydril Annular BOP1Abde EsselamОценок пока нет

- 350 Direct Pump Setting tool-DPSTДокумент2 страницы350 Direct Pump Setting tool-DPSTAdarsh HegdeОценок пока нет

- Retsco/Demco Mud Guns: Bottom TypeДокумент1 страницаRetsco/Demco Mud Guns: Bottom TypeGregory StewartОценок пока нет

- Packer Cup Testing - 9-5-8 Packer Cup LineДокумент2 страницыPacker Cup Testing - 9-5-8 Packer Cup LineFerney FonsecaОценок пока нет

- BHDecat072013_bu0930Lexar_From080607 10/3/14 12:15 Am Page 12Документ1 страницаBHDecat072013_bu0930Lexar_From080607 10/3/14 12:15 Am Page 12Prime Energy Warehouse-YemenОценок пока нет

- Regulator3 4 DSДокумент4 страницыRegulator3 4 DSargaОценок пока нет

- Wellbore Cleanup Magnets BrochureДокумент12 страницWellbore Cleanup Magnets Brochurefreebookie88100% (1)

- Instructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Документ7 страницInstructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Heri VillaОценок пока нет

- PSC Ergodyne Range 2021Документ45 страницPSC Ergodyne Range 2021Project Sales CorpОценок пока нет

- Sheave Selection GuideДокумент1 страницаSheave Selection GuideFauzanОценок пока нет

- List of API Monogram LicensesДокумент5 страницList of API Monogram LicensesGopi SelvarajОценок пока нет

- General Catalog 2016Документ64 страницыGeneral Catalog 2016Jamal100% (1)

- Mud King Swivel Cartridge GuideДокумент16 страницMud King Swivel Cartridge GuideVishal RamsookОценок пока нет

- Casing Packer Setting Tool (CPST) : WL Equipment Guidelines CPSTДокумент9 страницCasing Packer Setting Tool (CPST) : WL Equipment Guidelines CPSTJose Antonio AcostaОценок пока нет

- CentraDesign - Centralizer Placement SoftwareДокумент2 страницыCentraDesign - Centralizer Placement SoftwarePegasus Vertex, Inc.Оценок пока нет

- Wireline Combi Unit PPДокумент141 страницаWireline Combi Unit PPЕТМОценок пока нет

- Maintain and operate gate valvesДокумент32 страницыMaintain and operate gate valvesNeilton Junior100% (1)

- Om Series Kickover PDFДокумент2 страницыOm Series Kickover PDFSufian R EllabbadОценок пока нет

- Maintenance Schedule For Adapter Flange - 5131086 - 01Документ7 страницMaintenance Schedule For Adapter Flange - 5131086 - 01franko guddiОценок пока нет

- KT13625 FarrBackup CompressionCellManual Rev072011Документ129 страницKT13625 FarrBackup CompressionCellManual Rev072011enuvos engineeringОценок пока нет

- Solidrill Wellhead System Ps PDFДокумент1 страницаSolidrill Wellhead System Ps PDFبلال حسيني100% (1)

- West TucanaДокумент3 страницыWest TucanaSarfaraz PatelОценок пока нет

- Hardfacing Workshop Supplies BrochureДокумент8 страницHardfacing Workshop Supplies BrochureAhmad Reza FarokhiОценок пока нет

- Oil Field Elastomer LeadersДокумент21 страницаOil Field Elastomer Leadersjesus100% (1)

- WWW - Incar.tw-Kelly Spinner ManualДокумент6 страницWWW - Incar.tw-Kelly Spinner ManualSachin KumarОценок пока нет

- b5860 For Slurry ApplicationДокумент6 страницb5860 For Slurry Applicationpeach5Оценок пока нет

- KETO Pumps K-HS Product Brochure - A4 - 0Документ7 страницKETO Pumps K-HS Product Brochure - A4 - 0euan crozierОценок пока нет

- Belzona 5111: Instructions For UseДокумент2 страницыBelzona 5111: Instructions For UsePedro RuizОценок пока нет

- P16MBA3Документ4 страницыP16MBA3Ashok SureshОценок пока нет

- Third Party Inspection ScopeДокумент1 страницаThird Party Inspection ScopeAshok SureshОценок пока нет

- Briggs & Stratton Small Engine Reassembly Visual GuideДокумент40 страницBriggs & Stratton Small Engine Reassembly Visual GuideAshok SureshОценок пока нет

- Technical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarДокумент2 страницыTechnical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarAshok SureshОценок пока нет

- NPS - Unit 102 ScopeДокумент2 страницыNPS - Unit 102 ScopeAshok SureshОценок пока нет

- P16MBA4Документ2 страницыP16MBA4Ashok SureshОценок пока нет

- Demco DM Iom PDFДокумент24 страницыDemco DM Iom PDFAshok SureshОценок пока нет

- BD-28 (B24) IomДокумент39 страницBD-28 (B24) Iomkrishan_raj_1Оценок пока нет

- Drilling Chokes BrochureДокумент12 страницDrilling Chokes BrochureAshok SureshОценок пока нет

- Demco DM Iom PDFДокумент24 страницыDemco DM Iom PDFAshok SureshОценок пока нет

- Kemper Catalog FlowControl Oct2013Документ20 страницKemper Catalog FlowControl Oct2013jesdcp7Оценок пока нет

- Choke Maintnance PDFДокумент42 страницыChoke Maintnance PDFbtrasla9023Оценок пока нет

- ShowdocwДокумент7 страницShowdocwFahad KhanОценок пока нет

- Masts/Derricks/Substructures: Api RP 4GДокумент12 страницMasts/Derricks/Substructures: Api RP 4GegyinspectoryahooОценок пока нет

- Cost Breakup For SGS Second PumpДокумент1 страницаCost Breakup For SGS Second PumpAshok SureshОценок пока нет

- PVCMC 0501 Us PDFДокумент40 страницPVCMC 0501 Us PDFAshok SureshОценок пока нет

- Adapter CouplingДокумент48 страницAdapter CouplingIan_SmythОценок пока нет

- Fastener HandoutДокумент32 страницыFastener HandoutRaifan RaizerОценок пока нет

- Welded Flanged Spool Design CalculationДокумент1 страницаWelded Flanged Spool Design CalculationAshok SureshОценок пока нет

- BD-28 (B24) IomДокумент39 страницBD-28 (B24) Iomkrishan_raj_1Оценок пока нет

- Hercules Production Solutions Catalog PDFДокумент28 страницHercules Production Solutions Catalog PDFPedro Antonio Mejia SuarezОценок пока нет

- 12 Drilling PreventersДокумент82 страницы12 Drilling PreventersDavid Kusuma100% (1)

- Cameron Part Numbering SystemДокумент10 страницCameron Part Numbering SystemAshok SureshОценок пока нет

- 4th 120316074120 Phpapp02Документ27 страниц4th 120316074120 Phpapp02Ahmed ghОценок пока нет

- Pressure Control EquipmentДокумент169 страницPressure Control EquipmentAshok SureshОценок пока нет

- Ailgent Vs Pro - BrochureДокумент6 страницAilgent Vs Pro - BrochureTasha MorrisОценок пока нет

- Vciom 06204 enДокумент19 страницVciom 06204 enAshok SureshОценок пока нет

- Stainless Steel Sheet Metal SpecificationsДокумент2 страницыStainless Steel Sheet Metal SpecificationsAshok SureshОценок пока нет

- pressureProcedTest PDFДокумент7 страницpressureProcedTest PDFfaizal azizОценок пока нет

- Useful List of Responsive Navigation and Menu Patterns - UI Patterns - GibbonДокумент16 страницUseful List of Responsive Navigation and Menu Patterns - UI Patterns - Gibbonevandrix0% (1)

- Special Functions of Signal ProcessingДокумент7 страницSpecial Functions of Signal ProcessingSaddat ShamsuddinОценок пока нет

- F2970.1558734-1 Trampoline CourtДокумент22 страницыF2970.1558734-1 Trampoline CourtKannan LakshmananОценок пока нет

- 4.6.6 Lab View Wired and Wireless Nic InformationДокумент4 страницы4.6.6 Lab View Wired and Wireless Nic InformationThắng NguyễnОценок пока нет

- ADEC Al Maali International Private School 2015 2016Документ18 страницADEC Al Maali International Private School 2015 2016Edarabia.com100% (1)

- TK17 V10 ReadmeДокумент72 страницыTK17 V10 ReadmePaula PérezОценок пока нет

- HB Im70 QRДокумент1 страницаHB Im70 QROsamaОценок пока нет

- Mahabharata Book 9 Shalya ParvaДокумент413 страницMahabharata Book 9 Shalya Parvaavacdis1969Оценок пока нет

- Production of Carotenoids From Rhodotorula Mucilaginosa and Their Applications As Colorant Agent in Sweet CandyДокумент7 страницProduction of Carotenoids From Rhodotorula Mucilaginosa and Their Applications As Colorant Agent in Sweet CandyEspinosa Balderas GenaroОценок пока нет

- Symbolic Calculus Sage ReferenceДокумент25 страницSymbolic Calculus Sage ReferenceLn Amitav BiswasОценок пока нет

- En GBДокумент4 страницыEn GBahmedОценок пока нет

- Villanueva - Taxation and Regulatory ComplianceДокумент8 страницVillanueva - Taxation and Regulatory ComplianceEDRICK ESPARRAGUERRAОценок пока нет

- Renold Transmission Chain Catalogue ENG 0112Документ94 страницыRenold Transmission Chain Catalogue ENG 0112nataliaОценок пока нет

- Future TenseДокумент6 страницFuture TenseMuhammad Ibnu LaksonoОценок пока нет

- Mr. Sanjeev Nanda - Devoted Son and GrandsonДокумент1 страницаMr. Sanjeev Nanda - Devoted Son and GrandsonSanjeev NandaОценок пока нет

- Phlebotomy Blood, Micro-OrganismДокумент4 страницыPhlebotomy Blood, Micro-Organismapi-372107867% (3)

- Grade 9 SyllabusДокумент23 страницыGrade 9 SyllabusClopzОценок пока нет

- Impact of Aadhaar On Different Sectors of SocietyДокумент5 страницImpact of Aadhaar On Different Sectors of SocietyPunyak SatishОценок пока нет

- YavorskyДокумент544 страницыYavorskyFilipe PadilhaОценок пока нет

- ASTM 3950 Testing Methods For Strapping Versie 2007 211007 PDFДокумент7 страницASTM 3950 Testing Methods For Strapping Versie 2007 211007 PDFNestor CzerwackiОценок пока нет

- Socsci 032 Midterm Compilation NotesДокумент12 страницSocsci 032 Midterm Compilation NotesCarla AbalaОценок пока нет

- Holiday Tradition Lesson PlanДокумент2 страницыHoliday Tradition Lesson Planapi-458585393Оценок пока нет

- Corporate Social Responsibility International PerspectivesДокумент14 страницCorporate Social Responsibility International PerspectivesR16094101李宜樺Оценок пока нет

- Record of Appropriations and Obligations: TotalДокумент1 страницаRecord of Appropriations and Obligations: TotaljomarОценок пока нет

- Nutritional Deficiency Disorder Edit OneДокумент23 страницыNutritional Deficiency Disorder Edit One01 HifzaОценок пока нет

- The Biologic Width: - A Concept in Periodontics and Restorative DentistryДокумент8 страницThe Biologic Width: - A Concept in Periodontics and Restorative DentistryDrKrishna DasОценок пока нет

- Total Cost of Ownership in PV Manufacturing - GuideДокумент12 страницTotal Cost of Ownership in PV Manufacturing - GuidebirlainОценок пока нет

- Modern Pharmacy Layout TrendsДокумент9 страницModern Pharmacy Layout TrendsRaheem KhanОценок пока нет

- Deepa CVДокумент3 страницыDeepa CVDeepa M PОценок пока нет

- Trends1 Aio TT2-L2Документ4 страницыTrends1 Aio TT2-L2Bart Simpsons FernándezОценок пока нет