Академический Документы

Профессиональный Документы

Культура Документы

Oos Out of Specification

Загружено:

Shumaila IftikharОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Oos Out of Specification

Загружено:

Shumaila IftikharАвторское право:

Доступные форматы

STANDARD OPERATING PROCEDURE

DEPARTMENT:

QUALITY ASSURANCE DEPARTMENT

TITLE :

HANDLING OUT OF SPECIFICATION

1.0

PURPOSE

To describe procedure for Handling Out Of Specification (OOS).

2.0

SCOPE

This SOP shall be applicable to all OOS test results of Raw and Packaging Materials, In

Process Materials, Finished Products and Stability Samples at PEGASUS, Bhongir.

3.0

RESPONSIBILITIES

3.1

Originating Department shall be responsible for:

3.1.1

Verify the OOS results for accuracy and error.

3.1.2

Report questionable results to QC department.

3.1.3

Initiating the OOS investigation and documentation and reporting to QC

department.

3.1.4

Carrying out re-testing as per OOS investigation flowchart, wherever

applicable after approval of retest by QC department.

3.1.5

Archiving the OOS investigation reports.

Issue Date:-05.07.2014

STANDARD OPERATING PROCEDURE

DEPARTMENT:

QUALITY ASSURANCE DEPARTMENT

Effective Date

01.08.2014

Review Date

31.07.2016

TITLE :

HANDLING OUT OF SPECIFICATION

3.2

SOP No.

PB/SOP/QAD/032/00

Supersedes

NEW

Page No.

2 of 12

Head - Originating Department Shall be responsible for:

3.2.1

Providing training to the personnel of originating department.

3.2.2

Initiating the actions recommended in investigation report.

3.2.3

Monitor and confirm compliance to actions recommended in the

investigation report.

3.2.4

3.3

Head - Quality Assurance shall be responsible for:

3.3.1

4.0

Final disposal of material, if any.

Review and approval of final OOS investigation report.

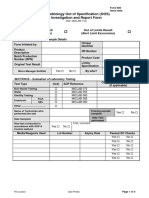

LIST OF ATTACHMENTS

Annexure - 1: Format for OOS Logbook

F/PB/QAD/032/24

Annexure - 2: Department code for OOS

NA

Annexure - 3: Format for record and observation of OOS Results (Phase - I)

F/PB/QAD/032/25

Annexure - 4: Format for Checklist for Investigation of OOS

F/PB/QAD/032/26

Annexure - 5: Flowchart for OOS Investigation (Phase - I)

NA

Annexure - 6: Flowchart for OOS Investigation (Phase - II)

NA

Annexure - 7: Format for Investigation Report for Phase II

Prepared By:

Date:

SWATHI. KOTLA

(Officer QA)

Reviewed By:

Date:

M. RAJAREDDY

(Incharge QC)

F/PB/QAD/032/27

Approved By:

Date:

A. K. BHATTACHARYA

(Manager QA)

Issue Date:-05.07.2014

STANDARD OPERATING PROCEDURE

DEPARTMENT:

QUALITY ASSURANCE DEPARTMENT

Effective Date

01.08.2014

Review Date

31.07.2016

TITLE :

HANDLING OUT OF SPECIFICATION

5.0

SOP No.

PB/SOP/QAD/032/00

Supersedes

NEW

Page No.

3 of 12

PROCEDURE

5.1

Frequency:

Immediately on being aware of OOS results or within 1 or maximum 2 days after

completing analytical test (After being checked, audited and reviewed by immediate

supervisor).

5.2

Introduction:

OOS results obtained in the laboratory fall into three general categories:

5.2.1

Laboratory error

5.2.2

Non-process-related or operator error

5.2.3

Process-related or manufacturing error.

When an individual test result does not meet the specifications, it need not

necessarily indicate that the batch has failed. The cause of the OOS result should be

investigated adequately and thoroughly and in time. The results of such an

investigation should be documented. Corrective and preventive actions must be taken

and should be reviewed during batch release.

Phase - I means the Laboratory OOS investigation and Phase - II means the Full

scale OOS investigation.

Prepared By:

Date:

SWATHI. KOTLA

(Officer QA)

Reviewed By:

Date:

M. RAJAREDDY

(Incharge QC)

Approved By:

Date:

A. K. BHATTACHARYA

(Manager QA)

Issue Date:-05.07.2014

STANDARD OPERATING PROCEDURE

DEPARTMENT:

QUALITY ASSURANCE DEPARTMENT

Effective Date

01.08.2014

Review Date

31.07.2016

TITLE :

HANDLING OUT OF SPECIFICATION

5.3

SOP No.

PB/SOP/QAD/032/00

Supersedes

NEW

Page No.

4 of 12

Action to be taken by Analyst:

5.3.1

When any OOS test result is obtained, log the OOS entry in the OOS log

book as per Annexure - 1.

The numbering system for OOS shall be as follow:

PB / OOS / XXX / YY / NNN

PB

indicates Area code allotted by QAD to Pegasus, Bhongir.

OOS

indicates Out Of Specification.

XXX

indicates initiating Department

{as per SOP on SOP :- PB/SOP/QAD/001/01}.

YY

indicates two digits year code.

NNN

indicates three digits numerical OOS allocated in an incremental

manner starting from 001 from each calendar year.

i.e. PB/OOS/XXX/QCD/13/001

indicates that this is the first OOS raised by the QC department of the

Pegasus, Bhongir.

5.3.2

When instruments have been used, check whether they have been calibrated

and were suitable at the time of use.

5.3.3

Investigate for the miscalculations, weighing error, transcription errors,

incomplete transfer of material, and incorrect settings of instruments

parameters.

5.3.4

Retain all test preparations and check the raw data for any clear mistakes

such as incorrect preparation, dilution, injection or storage, inappropriate

environmental conditions. Also check

Prepared By:

Reviewed By:

Date:

Date:

SWATHI. KOTLA

M. RAJAREDDY

(Officer QA)

(Incharge QC)

if the containers of sample are

Approved By:

Date:

A. K. BHATTACHARYA

(Manager QA)

Issue Date:-05.07.2014

STANDARD OPERATING PROCEDURE

DEPARTMENT:

QUALITY ASSURANCE DEPARTMENT

Effective Date

01.08.2014

Review Date

31.07.2016

TITLE :

HANDLING OUT OF SPECIFICATION

SOP No.

PB/SOP/QAD/032/00

Supersedes

NEW

Page No.

5 of 12

incorrectly closed, improperly sampled and improperly stored and use of

expired working/reference standard microbial culture, air bubble in

spectrophotometer cell or HPLC system or specified conditions not

maintained in dissolution medium.

5.3.5

Check whether any deviations had been noted during the time of Analysis

and whether they were recorded in the worksheets.

5.3.6

Record the observations in the Annexure - 3 and hand over to the

immediate supervisor with all the original data. Do not repeat the testing.

5.3.7

Protocol / Worksheet should be attached to OOS investigation form and new

Protocol / Worksheet is issued by QC department.

5.4

Phase - I (Laboratory OOS Investigation)

Investigation by Quality control or immediate supervisor:

5.4.1

Carry out the assessment of the OOS result as soon as the result is

reported.

5.4.2

Discuss the test method with the analyst to confirm that the analyst had

performed the test procedure correctly.

5.4.3

Examine the test data sheet and accompanying attachments in order to find

out whether the results can be attributed to laboratory error.

5.4.4

Arrange for the re-examination of actual test preparations used by the

analyst and to the extent possible, the glassware used in the original testing.

Prepared By:

Date:

SWATHI. KOTLA

(Officer QA)

Reviewed By:

Date:

M. RAJAREDDY

(Incharge QC)

Approved By:

Date:

A. K. BHATTACHARYA

(Manager QA)

Issue Date:-05.07.2014

STANDARD OPERATING PROCEDURE

DEPARTMENT:

QUALITY ASSURANCE DEPARTMENT

Effective Date

01.08.2014

Review Date

31.07.2016

TITLE :

HANDLING OUT OF SPECIFICATION

5.4.5

SOP No.

PB/SOP/QAD/032/00

Supersedes

NEW

Page No.

6 of 12

Confirm the performance of the instruments and ascertain whether the

instrument was within the period of validity of calibration at the time of use.

5.4.6

Determine that appropriate reference standards, solvents, reagents and other

solutions were used and that they meet quality control requirements.

5.4.7

Evaluate the performance of the testing method to ensure that it is

performing according to the authorized documents (Specification / STP).

5.4.8

Record all the observations of the investigation using checklist for

investigation of OOS as per Annexure - 4. The checklist has to be filled by

other immediate supervisor.

5.4.9

Suspected error must be investigated by QC personnel and if the error found

is genuine then the OOS result must be immediately invalidated and

disregarded after appropriate recording and filing.

5.4.10

Analyst and QC personnel both shall review for completeness of entire

procedure using the available checklist.

5.5

Action to be taken by immediate supervisor / In-Charge QC Situations I:

(Conclusive error retest):

5.5.1

If clear error has occurred, arrange for the retesting of the second aliquot of

the same sample solution or aliquot prepared from the same portion of the

original sample by the same analyst in triplicate.

5.5.2

If all the three results of retesting are within the specification, average it,

and substitute the average result for the initial test result (ensure that the

Prepared By:

Reviewed By:

Approved By:

Date:

Date:

Date:

SWATHI. KOTLA

M. RAJAREDDY

A. K. BHATTACHARYA

(Officer QA)

(Incharge QC)

(Manager QA)

Issue Date:-05.07.2014

STANDARD OPERATING PROCEDURE

DEPARTMENT:

QUALITY ASSURANCE DEPARTMENT

Effective Date

01.08.2014

Review Date

31.07.2016

TITLE :

HANDLING OUT OF SPECIFICATION

SOP No.

PB/SOP/QAD/032/00

Supersedes

NEW

Page No.

7 of 12

averaged results are within the proven and acceptable range) and record it

along with an explanation for the initial analysis failure (Genuine lab error reversible error). Invalidate and disregard the previous results on knowing

the probable cause of error, (Record and file the observations with

signature) Retain all the data together.

Statistical acceptance criteria:

The percentage RSD of 3 replicate determinations should not exceed the established

precision for the test.

If immediate supervisor analyst investigation is inconclusive then Situation II:

(Inconclusive error retest):

5.5.3

If the result of retesting is outside the specification and there is no clear

error, arrange for the prompt retesting in replicates by a 2 nd analyst (with

higher experience of testing) using the additional portion of the original

sample. Involve Quality Assurance/Production to look at quality trend of

other batches for the same test to have an idea whether the results of the

earlier batches are within the proven and established range.

5.5.4

If the results of retesting (3 replicates) by the 2nd analyst are individually

within the specification, substitute average of these results for the initial test

results of the 1st analyst (ensure that the average results are within the

proven and acceptable range) and consider them for any decision on batch

release, after investigating the cause of the failure of initial results, (Genuine

lab error - Reversible error). Invalidate and disregard the previous results on

Prepared By:

Date:

SWATHI. KOTLA

(Officer QA)

Reviewed By:

Date:

M. RAJAREDDY

(Incharge QC)

Approved By:

Date:

A. K. BHATTACHARYA

(Manager QA)

Issue Date:-05.07.2014

STANDARD OPERATING PROCEDURE

DEPARTMENT:

QUALITY ASSURANCE DEPARTMENT

Effective Date

01.08.2014

Review Date

31.07.2016

TITLE :

HANDLING OUT OF SPECIFICATION

SOP No.

PB/SOP/QAD/032/00

Supersedes

NEW

Page No.

8 of 12

ascertaining the cause of error (sample integrity being biased); document the

investigation with the signature.

5.5.5

If the result of retesting (3 replicates) by the 2 nd analyst are outside the

specification, report all the results in the worksheet. It may still be possible

that the sample is biased and has laid to the failing results. Retain all the

data together.

Statistical acceptance criteria:

The percentage RSD of 3 replicate determinations should not exceed the established

precision for the test.

Situation III: (Investigation of sampling procedure and sample integrity

homogeneity and representative portion):

5.5.6

When the initial test and retest on the same sample produces the

OOS

results, determine whether it is possible that the original Sample was nonrepresentative of the whole lot and requires re-sampling.

5.5.7

Before re-sampling activity, it should be conclusively proved that the

original sample was non-representative and also the sampling procedure

should be thoroughly reviewed. Re-sampling is not permitted for uniformity

of content and dissolution testing failure.

5.5.8

Re-sampling is performed under the authority of Head-QA if the

investigation reveals that the integrity of sample is affected; in such

situation a portion of fresh sample from warehouse / manufacturing

Prepared By:

Date:

SWATHI. KOTLA

(Officer QA)

Reviewed By:

Date:

M. RAJAREDDY

(Incharge QC)

Approved By:

Date:

A. K. BHATTACHARYA

(Manager QA)

Issue Date:-05.07.2014

STANDARD OPERATING PROCEDURE

DEPARTMENT:

QUALITY ASSURANCE DEPARTMENT

Effective Date

01.08.2014

Review Date

31.07.2016

TITLE :

HANDLING OUT OF SPECIFICATION

SOP No.

PB/SOP/QAD/032/00

Supersedes

NEW

Page No.

9 of 12

department is subjected to reanalysis by an experienced analyst in

triplicates. If the results (3 replicates) are in conformance to the

specification individually, the batch may be released (ensure that the

average results are within the proven and acceptable range). Investigation

into sampling error is to be documented. Retain all the data on retesting and

re-sampling together.

Situation III is not applicable to content uniformity and dissolution test.

5.5.9

If in a situation where re-sampling does not meet specification it is not

reversible classification. Retesting for OOS stops here which has to go for

full scale investigation into manufacturing or processing through Quality

Assurance.

Statistical acceptance criteria:

The percentage RSD of 3 replicates determination should not exceed the established

precision for the test.

5.5.10 Corrective measures / actions to be taken by QA/QC:

5.5.10.1 Training to the 1st analyst to perform the test, if a laboratory error has

occurred and the same should be documented.

5.5.10.2 If the testing procedure/sampling procedure needs updation, it

should be done promptly with due analytical method validation and

all concerned should be informed.

5.5.11

If the OOS is not sorted at laboratory stage i.e. Phase - I, then Full scale

OOS investigation of production process review is required i.e. Phase - II.

Prepared By:

Date:

SWATHI. KOTLA

(Officer QA)

Reviewed By:

Date:

M. RAJAREDDY

(Incharge QC)

Approved By:

Date:

A. K. BHATTACHARYA

(Manager QA)

Issue Date:-05.07.2014

STANDARD OPERATING PROCEDURE

DEPARTMENT:

QUALITY ASSURANCE DEPARTMENT

Effective Date

01.08.2014

Review Date

31.07.2016

TITLE :

HANDLING OUT OF SPECIFICATION

5.6

SOP No.

PB/SOP/QAD/032/00

Supersedes

NEW

Page No.

10 of 12

Phase II: Full Scale OOS Investigation:

5.6.1

When the initial assessment does not determine that laboratory error caused

the OOS result and testing results appear to be accurate, a full-scale OOS

investigation is required. This investigation may consist of a production

process review and/or additional laboratory work. The objective of such an

investigation should be to identify the root cause of the OOS result and take

appropriate corrective and preventative action. A full-scale investigation

should include a review of production. Such investigations should be given

the highest priority.

5.6.2

Full scale OOS investigation should be carried out when a product does not

meet the approved specification or any unusual observations are made

during the process of storage, handling, manufacturing or testing of the

product and /or initiated by any of the following conditions.

5.6.2.1 OOS investigation (not due to analytical error)

5.6.2.2 Market complaint.

5.6.2.3 Product recall.

5.6.3

Whenever a failure is identified in product or process or system the same

should be immediately brought to the notice of Head QA.

5.6.4

The Quality Assurance department under instruction of Head QA shall

initiate failure investigation.

5.6.5

Investigation should be extended to all the batches/products, which could

have possibly been affected by the failure.

Prepared By:

Date:

SWATHI. KOTLA

(Officer QA)

Reviewed By:

Date:

M. RAJAREDDY

(Incharge QC)

Approved By:

Date:

A. K. BHATTACHARYA

(Manager QA)

Issue Date:-05.07.2014

STANDARD OPERATING PROCEDURE

DEPARTMENT:

QUALITY ASSURANCE DEPARTMENT

Effective Date

01.08.2014

Review Date

31.07.2016

TITLE :

HANDLING OUT OF SPECIFICATION

5.6.6

SOP No.

PB/SOP/QAD/032/00

Supersedes

NEW

Page No.

11 of 12

Head QA shall hold the release of the batch during investigation of the

subjected batch. Such batch should be quarantine and should not be released

for dispatch, till investigation is complete and a decision is made.

5.6.7

If required, Head QA shall decide the cause of action to be taken after

consultation with Head-CQA to recall those which might have been affected

by the subjected failure.

5.6.8

An investigation report shall be prepared as per given format in Annexure

7

5.6.9

The Flow chart for OOS investigation (Phase - I) given in Annexure - 5

and Flow chart for OOS investigation (Phase - II) given in Annexure - 6

shall be followed in case of an investigation of out of specification / failure.

5.7

Corrective Actions

5.7.1

Based on the outcome of the investigation one or many of the following

appropriate activity should be initiated by QA / Production.

5.7.1.1 Change in the process

5.7.1.2 Instrument servicing

5.7.2

Whenever assignable cause is identified and is attributed to improper

interpretation of method, the concerned analyst should be provided

appropriate training in order to avoid such OOS in the future.

Prepared By:

Date:

SWATHI. KOTLA

(Officer QA)

Reviewed By:

Date:

M. RAJAREDDY

(Incharge QC)

Approved By:

Date:

A. K. BHATTACHARYA

(Manager QA)

Issue Date:-05.07.2014

STANDARD OPERATING PROCEDURE

DEPARTMENT:

QUALITY ASSURANCE DEPARTMENT

Effective Date

01.08.2014

Review Date

31.07.2016

TITLE :

HANDLING OUT OF SPECIFICATION

6.0

Rev. No.

SOP No.

PB/SOP/QAD/032/00

Supersedes

NEW

Page No.

12 of 12

REVISION HISTORY:

Effective Date

Prepared By:

Date:

SWATHI. KOTLA

(Officer QA)

Details of revision and Reason of revision

Reviewed By:

Date:

M. RAJAREDDY

(Incharge QC)

Approved By:

Date:

A. K. BHATTACHARYA

(Manager QA)

Вам также может понравиться

- SOP - QA-007 SOP For Out of Specification (OOS) For Pharmaceutical ResultsДокумент5 страницSOP - QA-007 SOP For Out of Specification (OOS) For Pharmaceutical Resultsد.عمر خليل العباسي100% (2)

- Handling of OOTДокумент18 страницHandling of OOTjameer80100% (2)

- QCG - 001-2 SOP Handling OOS and OOT ResultsДокумент8 страницQCG - 001-2 SOP Handling OOS and OOT ResultsAftab S. Mirza100% (1)

- Sop For Analytical Method Validqation and VerificationДокумент7 страницSop For Analytical Method Validqation and Verificationvasant ugale100% (3)

- Sop 003 For Analysis of Rinse SampleДокумент3 страницыSop 003 For Analysis of Rinse Samplevasant ugale100% (1)

- SOP On Handling of OOT and OOS-impДокумент16 страницSOP On Handling of OOT and OOS-impAkshita100% (1)

- Practical Approaches to Method Validation and Essential Instrument QualificationОт EverandPractical Approaches to Method Validation and Essential Instrument QualificationОценок пока нет

- ICH Quality Guidelines: An Implementation GuideОт EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleОценок пока нет

- 007 Out of SpecificationДокумент12 страниц007 Out of Specificationmarkandey gupta100% (2)

- Out of SpecificationДокумент7 страницOut of SpecificationMichelle Morgan LongstrethОценок пока нет

- Temperature Mapping Protocol: Lincoln Parenteral LTDДокумент7 страницTemperature Mapping Protocol: Lincoln Parenteral LTDRajender SinghОценок пока нет

- QCD-036-01 Good Chromatography PracticesДокумент12 страницQCD-036-01 Good Chromatography Practicesarnab rayОценок пока нет

- 02 LC of Double Cone Blender 02Документ2 страницы02 LC of Double Cone Blender 02Ravi YadavОценок пока нет

- Annual Product Quality Review (APQR) SOP - PharmaBДокумент14 страницAnnual Product Quality Review (APQR) SOP - PharmaBrehmat ali100% (1)

- Stability ReportДокумент9 страницStability ReportShagorShagorОценок пока нет

- Annual Product Quality Review APQR FormatДокумент9 страницAnnual Product Quality Review APQR FormatDr.Sivakumar Selvaraj100% (1)

- Annual Product Review Developing An SOPДокумент26 страницAnnual Product Review Developing An SOPanants2567% (3)

- Out of Specifications IIДокумент39 страницOut of Specifications IIHaekal Ramadhan100% (1)

- Sop For Technology TransferДокумент3 страницыSop For Technology TransferDolly Bijani100% (3)

- 8.3 Operation Qualification Protocol For Dispensing BoothДокумент4 страницы8.3 Operation Qualification Protocol For Dispensing BoothTanveer Ahmed Quadri100% (1)

- Microbiology Out of Specification (OOS) Investigation and Report FormДокумент3 страницыMicrobiology Out of Specification (OOS) Investigation and Report FormIra Nurjannah100% (1)

- Product Quality Review or Annual Product Review-1Документ6 страницProduct Quality Review or Annual Product Review-1nataarajan praveen100% (1)

- Quality Dossier of Asmatab TabletДокумент16 страницQuality Dossier of Asmatab TabletShagorShagor100% (1)

- Temperature Mapping For FG StoreДокумент19 страницTemperature Mapping For FG Storemehrdarou.qaОценок пока нет

- OOS InvestigationДокумент5 страницOOS Investigationmarkandey gupta100% (2)

- Labaid Pharmaceuticals Limited: Standard Operating ProcedureДокумент8 страницLabaid Pharmaceuticals Limited: Standard Operating ProceduremasumОценок пока нет

- Oos-Out of SpecificationДокумент12 страницOos-Out of Specificationasit_m50% (2)

- Protocol Jacketed MFG Tank LV02Документ7 страницProtocol Jacketed MFG Tank LV02pooja aswal100% (3)

- Oos Laboratory Investigation Checklist Phase 1aДокумент2 страницыOos Laboratory Investigation Checklist Phase 1atghons100% (3)

- SOP of Line Clearance of Manufacturing AreaДокумент3 страницыSOP of Line Clearance of Manufacturing Areashekhar khanal0% (1)

- Sop Qa 037 00 OosДокумент19 страницSop Qa 037 00 OosAnand H S100% (3)

- 023-SOP For Conducting Hold Time StudyДокумент3 страницы023-SOP For Conducting Hold Time StudyAshok Lenka100% (2)

- Apqr PDFДокумент10 страницApqr PDFHARESH NIRMALОценок пока нет

- Capsule Process ValidationДокумент28 страницCapsule Process ValidationNavdeep ChaudharyОценок пока нет

- 23-08-19 Investigation Report For OOSДокумент2 страницы23-08-19 Investigation Report For OOSDeepak67% (3)

- Hold Time Studies For FBD BagsДокумент12 страницHold Time Studies For FBD BagsShubam Sharma100% (1)

- Validation Master Plan Example - LongДокумент31 страницаValidation Master Plan Example - LongJayesh kolheОценок пока нет

- Juvia Protocol 50-1000Документ16 страницJuvia Protocol 50-1000ziauddin bukhariОценок пока нет

- Investigation Report No. Title Investigation of Finished ProductДокумент4 страницыInvestigation Report No. Title Investigation of Finished ProductGlobela2 QC100% (1)

- Analytical Report For Ketofast 10 TabletДокумент20 страницAnalytical Report For Ketofast 10 TabletShagorShagorОценок пока нет

- SOP For Analyst ValidationДокумент5 страницSOP For Analyst ValidationGencay Ergin100% (1)

- VMPДокумент15 страницVMPshah241Оценок пока нет

- SOP of Glassware HandlingДокумент1 страницаSOP of Glassware HandlingPrince Moni100% (2)

- 01 LC Vibratory Sifter 01Документ2 страницы01 LC Vibratory Sifter 01Ravi YadavОценок пока нет

- Process Validation Protocol (500 MG Tablet)Документ6 страницProcess Validation Protocol (500 MG Tablet)Mohammed Zubair100% (1)

- Cleaning of Sampling BoothДокумент4 страницыCleaning of Sampling Boothasit_m100% (3)

- IVT - Validation Final ReportДокумент5 страницIVT - Validation Final ReportDoan Chi ThienОценок пока нет

- ASEAN Guideline Process OnДокумент7 страницASEAN Guideline Process OnVipin GuptaОценок пока нет

- SOP For Handling of Out of Specification Results-1Документ54 страницыSOP For Handling of Out of Specification Results-1osamatqm9Оценок пока нет

- Cleaning Validation Report TEMPLATEДокумент9 страницCleaning Validation Report TEMPLATEnatavceОценок пока нет

- Example Annual Product Review Report FormatДокумент8 страницExample Annual Product Review Report Format刘朝阳100% (2)

- SOP For Handling of Out of Specification Results in Microbiological Testing - Pharmaceutical GuidelinesДокумент4 страницыSOP For Handling of Out of Specification Results in Microbiological Testing - Pharmaceutical Guidelinesalnzeer omerОценок пока нет

- Production of Plasma Proteins for Therapeutic UseОт EverandProduction of Plasma Proteins for Therapeutic UseРейтинг: 3 из 5 звезд3/5 (5)

- 2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFДокумент4 страницы2 Process Validation QandA Version 4 (June 2011) - Adopted 18th PPWG Meeting PDFVishal SomaniОценок пока нет

- SOP of Stability Study - 1Документ5 страницSOP of Stability Study - 1YousifОценок пока нет

- Assay by Titration Validation Protocol-ModelДокумент9 страницAssay by Titration Validation Protocol-ModelAnzari Muhammad100% (4)

- Title: Cleaning Validation Report For - ToДокумент41 страницаTitle: Cleaning Validation Report For - TocpkakopeОценок пока нет

- Process Validation Interim / Final Report: (Enter Product Title, Number & Strength) Product CodeДокумент4 страницыProcess Validation Interim / Final Report: (Enter Product Title, Number & Strength) Product CodevanessaОценок пока нет

- VAL-085 Process Validation Guideline SampleДокумент2 страницыVAL-085 Process Validation Guideline SampleVizit31Оценок пока нет

- Concepts of Quality Management in Pharmaceutical IndustryОт EverandConcepts of Quality Management in Pharmaceutical IndustryОценок пока нет

- Esofil 20mg CapsuleДокумент2 страницыEsofil 20mg CapsuleShumaila IftikharОценок пока нет

- Log Book: Conductivity MeterДокумент2 страницыLog Book: Conductivity MeterShumaila IftikharОценок пока нет

- 60 HNL Purified Water 3Документ2 страницы60 HNL Purified Water 3Shumaila IftikharОценок пока нет

- Hvac PQДокумент24 страницыHvac PQShumaila IftikharОценок пока нет

- Tablet Process ValidationДокумент38 страницTablet Process Validationasit_m100% (6)

- Frame: The Service ConceptДокумент31 страницаFrame: The Service ConceptFatmahОценок пока нет

- Standard Operating ProceduresДокумент11 страницStandard Operating ProceduresAlok Kumar100% (2)

- Method Study Is The Systematic Recording and Critical Examination of Ways of Doing Things in Order To Make ImprovementsДокумент4 страницыMethod Study Is The Systematic Recording and Critical Examination of Ways of Doing Things in Order To Make ImprovementsManjesh ThilakОценок пока нет

- Required Documents For ISO 15189 CertificationДокумент13 страницRequired Documents For ISO 15189 CertificationGlobal Manager Group100% (4)

- SOP5Документ7 страницSOP5ASHOK KUMAR LENKAОценок пока нет

- Virtual Content SOPДокумент11 страницVirtual Content SOPAnezwa MpetaОценок пока нет

- Sop of Tablet & CApsuleДокумент2 страницыSop of Tablet & CApsuleZeyad A AbdullahОценок пока нет

- SOPsДокумент26 страницSOPsmnegm2890Оценок пока нет

- Sop Warehouse DistributionsДокумент19 страницSop Warehouse DistributionsAriel CarreroОценок пока нет

- How To Write A Standard Operating Procedure: Formatting Your SOPДокумент6 страницHow To Write A Standard Operating Procedure: Formatting Your SOPNaveed UllahОценок пока нет

- Nafdac Requirement For DrinksДокумент2 страницыNafdac Requirement For DrinksAlphonsus Chukwuemeka SundayОценок пока нет

- SOP-016-Testing of LPG ResidueДокумент9 страницSOP-016-Testing of LPG ResidueAmnaKamranОценок пока нет

- SOP For Quality ImprovementДокумент70 страницSOP For Quality ImprovementMintu Sarker TonmoyОценок пока нет

- SOP ON SOP Procedure For Standard Operating Procedure (SOP)Документ12 страницSOP ON SOP Procedure For Standard Operating Procedure (SOP)Abou Tebba Sam100% (1)

- WordPress Installation SOPДокумент17 страницWordPress Installation SOPSheikh Zain100% (1)

- QA005-04 Vendor Qualification-IM & PMKДокумент9 страницQA005-04 Vendor Qualification-IM & PMKSagar ChavanОценок пока нет

- Standard Operating Procedures in Pharmaceutical Quality SystemsДокумент3 страницыStandard Operating Procedures in Pharmaceutical Quality SystemsYousifОценок пока нет

- A Guide To The GAP Certification Process: Preparing For The USDA GAP (Good Agricultural Practices) AuditДокумент5 страницA Guide To The GAP Certification Process: Preparing For The USDA GAP (Good Agricultural Practices) Auditpwilkers36Оценок пока нет

- SOP-MER-02 Control of Customer Property SOP-MER-02Документ3 страницыSOP-MER-02 Control of Customer Property SOP-MER-02ABDULОценок пока нет

- School Building Maintenance ProcedureДокумент3 страницыSchool Building Maintenance ProcedureSalma ElsirОценок пока нет

- Standard Operating Procedure of Fluidized Bed DryerДокумент4 страницыStandard Operating Procedure of Fluidized Bed DryerSolomonОценок пока нет

- Sanitation Standard Operating Procedures LoxДокумент15 страницSanitation Standard Operating Procedures LoxSherry Salazar100% (1)

- SOP Suggestion SchemeДокумент5 страницSOP Suggestion SchemegautamxlОценок пока нет

- Standard Operating Procedures "Sops": Pharmacist University of The Punjab-PakistanДокумент16 страницStandard Operating Procedures "Sops": Pharmacist University of The Punjab-PakistanMuhammad Bilal Tahir100% (1)

- Handbook of Pharmaceutical Generic Development Vol 03 Part 1 PDFДокумент304 страницыHandbook of Pharmaceutical Generic Development Vol 03 Part 1 PDFradhakrishnabv100% (5)

- Skip Testing in Pharmaceutical Industry-Where To ApplyДокумент7 страницSkip Testing in Pharmaceutical Industry-Where To ApplyMubarak PatelОценок пока нет

- Unit2 - Producing Pharmaceutical BiopharmaceuticalДокумент27 страницUnit2 - Producing Pharmaceutical BiopharmaceuticalBrigitte ReyesОценок пока нет

- BMR PraperationДокумент9 страницBMR PraperationwondwossengОценок пока нет

- SOP TemplateДокумент2 страницыSOP TemplateJojo MalikОценок пока нет

- Validation ChecklistДокумент2 страницыValidation Checklistjamil voraОценок пока нет