Академический Документы

Профессиональный Документы

Культура Документы

MS For Hydro Test Mod

Загружено:

rijОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MS For Hydro Test Mod

Загружено:

rijАвторское право:

Доступные форматы

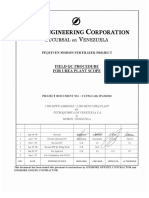

Revision 03

SEG-ISF-Project

MS FOR xxcxbzn

TYPE

Date

Page

Doc. No: SA-JER-TF802-SEGC500044

PRC

05-Mar2016

1/7

TABLE OF CONTENTS

1.0 SCOPE.........................................................................................................................................2

2.0 REFERENCE DOCUMENTS.......................................................................................................2

3.0 DEFINITIONS...............................................................................................................................3

4.0 RESPONSIBILITIES:...................................................................................................................4

5.0 METHODOLOGY.........................................................................................................................5

6.0 QUALITY CONTROL AND QUALITY ASSURANCE.................................................................6

7.0 MACHINERY AND RESOURCES...............................................................................................6

8.0 SAFETY EQUIPMENTS...............................................................................................................7

9.0 HEALTH, SAFETY AND RISK ASSESSMENT...........................................................................7

10.0 Job Safety Analysis or Risk Assessment..............................................................................9

1.0 SCOPE

This procedure covers Hydrostatic Pressure Testing, Punch listing and Test Package compilation for

Underground Fire Water and Cooling Water system within SEG's scope of Works.

2.0 REFERENCE DOCUMENTS

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

JEREF-023 Power Transformer LCC

JERES-A-112 Rev 3 Meteorological and Seismic Design Data

JERES-H-001 Rev 5 Coating Selection & Application Requirements

JERES-P-104 Rev 3 Wiring Methods and Materials

JERES-P-121 Rev 2 Transformers and Reactors

JERES-P-200 Rev 2 Document Management and Final Documentation Requirements

JERES-P-100 Rev 4 Basic Power System Design Criteria

JERES-P-113 Rev 2 Motors and Generators

1

Revision 03

SEG-ISF-Project

MS FOR xxcxbzn

TYPE

Date

Page

Doc. No: SA-JER-TF802-SEGC500044

PRC

05-Mar2016

2/7

2.9 JERES-P-114 Rev 4 Power System and Equipment Protection

2.10JERES-P-119 Rev 3 Onshore Substations

2.11JERES-P-127 Rev 1 Electrical Control Systems

2.12JERMS-P-4531 Rev 2 Power Transformers

2.13JERMS-P-4533 Rev 1 Three-Phase Dry-Type Power Transformers

2.14JERMS-P-5502 Rev 3 Electrical Cables

2.15JERMS-P-6513 Rev 2 Protective Devices

2.16JERSD-P-0008 Low Voltage Switchgear Transformer Incomer

2.17JERSD-P-0015 Rev 1 High Voltage Controlgear Motor Outer with Circuit Breaker

2.18JERSD-P-0017 Rev 3 High Voltage Switchgear Incomer

2.19JERSD-P-0019 High Voltage Switchgear HV HV Transformer

2.20JERSD-P-0025 4.16kV Diesel switchgear Transformer outgoer

2.21JERSD-P-0030 LV LV transformer outgoer

2.22JERITP-P-140200 Pad-mounted transformer

2.23JERITP-P-140300 Dry-Type Power transformer

2.24JERITP-P-140400 Pad-mounted transformer

2.25JERITP-P-140500 Power transformer

2.26JERITP-P-160300 HV MCC

2.27Project Quality Plan

2.28Safety and Medical plan

2.29Schedule D & Sec. 11-14 of JER Contraction Safety Manual

2.30Project Specifications & Standards

2.31All the transformer related IFC drawing

CODES AND STANDARDS

The following, but not limited to, codes and standards shall govern the design, ratings, manufacturing and testing

and installation of the power transformer.

IEC 60034

Rotating electrical machinery

IEC 60044-1

IEC 60044-2

Instrument Transformers : Part 1-Current Transformers

Instrument Transformers : Part 2-Voltage Transformers

IEC 60073 Coding principles for indicators and actuators

IEC 60076

Power Transformers

IEC 60076-1

IEC 60076-3

General

Insulation levels, dielectric tests and external clearances in air

IEC 60076-11 Dry-type transformers

IEC 60137

Bushings for alternating voltages above 1000V

IEC 60214

IEC 60296

On-load tap changers

Mineral Insulating oils for transformers & switchgear

IEC 60445

Basic and safety principles for man-machine interface, marking and identification

identification of equipment terminals and of terminations of certain designated

conductors, including general rules for alphanumeric system

IEC 60446

Basic and safety principles for man-machine interface, marking and identification

Identification of conductors by colours and numerals

IEC 60529

Degrees of protection provided by enclosures (IP Code)

IEC 60664

Insulation co-ordination for equipment within low-voltage systems

IEC 60755

General requirements for residual-current operated protective devices

2

IEC 60947

Revision 03

SEG-ISF-Project

MS FOR xxcxbzn

TYPE

Date

Page

Doc. No: SA-JER-TF802-SEGC500044

PRC

05-Mar2016

3/7

Low-voltage switchgear and controlgear

3.0 DEFINITIONS

All the definitions mentioned in the JER Documents have priority over other standards and any deviation of

these standards shall be brought to attention of the COMPANY. It means to the company representative for

resolution.

All terms used in the development of this procedure are defined below:

COMPANY

Saudi Aramco Total Refining and Petrochemical Company

CONTRACTOR

Sinopec Engineering Group Saudi Ltd

4.0 RESPONSIBILITIES:

4.1The project manager shall ensure that all operations related to transformer installation work have been risk

assessed and necessary control measures have been implemented to carry out the task in a safely

manner.

4.1 The construction or site manager shall manage and control overall responsibility for site, QA/QC and

provide management commitment to the site quality plan.

4.2 The QA/QC manager shall ensure that all works is in compliance with project procedures and ITP

requirements. Also to ensure the project quality management systems documentation is prepared for the

project. Reviewing test plans if necessary to ensure adequate assurance is provided for implementation of

activities affecting quality. Ensure all documentations reported are audited to ensure compliance with

SATORP requirements. He is responsible for developing and maintaining the authorized QC signatories

list.

4.3 Contractors construction engineer shall review and confirm that all transformer installation sequence of

work being implemented are as per the activities stated in the method statement and in compliance with

the (SATORP) codes, standards and project specification.

4.4 Contactors supervisor shall supervise all Installation activities as required by the project drawings and

specifications. He shall prepare all the necessary permits in advance and get it approved from the

companys designated representative for the execution.

4.5 Contractors site supervisor shall conduct regular toolbox meetings and explain the requirements of PPE

and other special needs to create a safe working environment. He is responsible for achieving the target

and the project milestones.

4.6 Contractors QA/QC Inspector shall closely monitor and assure all installation activities are carried out as

per (SATORP) QA/QC requirements and conduct frequent inspections and maintain all records as

required by project QA/QC Program.

4.7 Contractors Safety inspector shall closely monitor and assure that all works are carried out in highly safe

manner. Gearing the workers with full strength of safety protective equipment, preparation of safety

barricading and dust control screening wherever applicable in safe manner, safe workability of equipment

to be used and fulfilling any other additional safety needs as required during work executions. He shall

also check and ensure that only qualified personals are carrying out the equipment and machinery related

works.

4.8 Contractor shall appoint their own safety manager and he shall conduct safety routine inspection around

the site in weekly basis. He shall prepare and submit a report to the company any accidents occurrence.

Revision 03

SEG-ISF-Project

MS FOR xxcxbzn

TYPE

Date

Page

Doc. No: SA-JER-TF802-SEGC500044

PRC

05-Mar2016

4/7

5.0 METHODOLOGY

5.1 GENERAL

Ensure that all relevant site condition and working practices are observed.

Check and ensure Cold and Hot Work permits are obtained.

Ensure that the materials are in accordance with the project specifications.

Verify and prepare all tools and equipment required for safe execution of work is available.

5.2 SEQUENCE OF WORK

Review and finalized the installation documents on listed below together with the clients representative.

Power transformers construction details drawing, transformer power and control cables schedule layout/termination drawings, Material Requisition Form, Material Receiving and Inspection Report, Material

Receiving, Storage and Issue Checklist, Installation Work Permit, JSA , Risk Assessment and Lifting /

Transport Permit.

Transformers foundation base final inspection.

Foundation base installation, orientation, wheel mounting rail or mounting rail, elevation, center, alignment,

squareness and plumpness shall comply with construction approved drawing. This drawing shall show

recommended clearances for safe operation and future maintenance of the transformer installation.

Prior to Lifting, Work permit to be produced for Lifting & Road Closure. Ensure that all relevant site condition

03

and safety work practices are observed prior to work execution. Barricade range of work area to assure

safety work environment with safety barricade tape and warning signs.

Prior to transformers mobilization and upon equipment receipt, inspection shall be done to verify if the

transformers technical specification from the nameplate details complies with the equipments PR,

manufacturers equipment MSDS and Vendors Declaration of Conformity documents.

Mobilization of materials, equipments and machineries to the designated area by using manpower, trolley and

forklift.

The crane (refer to attached mobile crane data sheet for reference) shall be parked at the parking area and

the outriggers shall be fully extended to secure firm parking.

After Crane has been parked Barricades & Safety signals to be placed for road closure & lifting in progress

board to be provided

Lifting team including rigger, signalman and lifting supervisor shall implement and execute the lifting and

03

installation operation with the guidance of the construction engineer for the final setting down positioning of

the transformer. For each lifting, the boom length shall be extended within safety range in order to lift the

Transformer secure and safely.

Transformer will be pulled out from Truck by using crane using lifting Chains and swung to its foundation

plinth.

The transformer should be mobilized and installed in an upright position, swung to its foundation plinth and

03

then be slowly lowered down for positioning. Stopper will be used to fix its position.

For the remaining assembly body parts will be done by transformer vendor.

Proper identification and labeling shall be implemented from the transformers switchgear panel/ OLTC control

panel/local control panels NAMEPLATE, electrical and instrument control relays, contactors, devices,

sensors, power/control cables and motors.

Clear all the barricading tape and close-up once work completion to resume normal traffic flow.

To do housekeeping after works to ensure work place has been always remain tidy and safe.

4

Revision 03

SEG-ISF-Project

MS FOR xxcxbzn

TYPE

Date

Page

Doc. No: SA-JER-TF802-SEGC500044

PRC

05-Mar2016

5/7

6.0 QUALITY CONTROL AND QUALITY ASSURANCE

The quality of the works shall be in line with the SATORP standards. Required tests shall be performed on each

stage of concrete works and the report shall be prepared and submitted to the company representative for prior

approval.

6.1

INSPECTION AND TESTING PROCEDURE

Transformer installation, inspection and testing shall be carried out in accordance with approved for

construction drawings, specifications and details, JERES-P-104 Wiring Methods and Material Selection, Field

Installation and Testing of Electrical Equipment IEC Standard.

Field Installation and Testing of Electrical Equipment as per SATORP Code, and Project Specification.

The required inspection shall be carried out based on, ITP for Transformer Installation.

Inspection results shall be recorded and documented.

7.0 MACHINERY AND RESOURCES

Basic Electrical Hand Tools

Measuring tape

Walkie Talkie

Lifting gears / shackles (certified)

Ladders

03

Mobile Hydraulic Crane

Scaffolding

QA/QC Inspector

Construction(Electrical and Mechanical) Engineer

HSE Officer

Lifting Supervisor with complete Lifting Crew.

8.0 SAFETY EQUIPMENTS

Safety shoes

Safety helmet

Safety glass

Safety harness (for working at height more than 2 meters)

Approved body wear/uniform

Hand gloves

9.0 HEALTH, SAFETY AND RISK ASSESSMENT

The health and safety shall perform a splendid role in all construction activities to ensure that all the works are

carried out in a safe manner and creating a healthy environment. The individuals especially in related with health

and safety and complying with the SATORP safety standards shall perform the duties. Appropriate work permit

5

Revision 03

SEG-ISF-Project

MS FOR xxcxbzn

TYPE

Date

Page

Doc. No: SA-JER-TF802-SEGC500044

PRC

05-Mar2016

6/7

shall be applied in accordance to the requirements of Schedule D and Section II-14 of the JER Construction

Safety Manual.

9.1 A safety officer or a safety coordinator shall be present at site full time during the execution of works and

also to clarify the safety related issues.

9.2 Daily toolbox meetings shall be conducted as mandatory requirements to describe and discuss the safety

related issues.

9.3 The works shall be risk assessed and proper guidance should be managed before implementation of

every individual activities.

9.4 Following safety requirements shall be fulfilled.

9.4.1 Safety barricade shall be provided wherever necessary.

9.4.2 The Lifting Supervisor shall examine the equipments, lifting gears, tag lines, surrounding and its

environment to ensure the operation can be safely executed.

9.4.3 Throughout the operation, the lifting team shall ensure their presence. Lifting Supervisor and the

Signalman shall be within the visible distance of the crane operator throughout the whole operation.

9.4.4 Necessary safety signboards shall be provided at work places as required by safety Standards.

9.4.5 All workers shall be provided with job specific Personal Protective Equipment.

9.4.6 Safety flickering lights shall be provided for vehicles working on long-time hours especially on night

hours.

9.4.7 The approving authority shall inspect all equipment checklists for machineries related to the activities

prior before commencing the works.

9.4.8 Working equipment shall be equipped with amber lights, horns, safety guards, etc. as required and

mentioned in safety manuals.

9.4.9 Any incident at site shall be immediately reported to company and recorded.

9.4.10 Weekly safety statistics reports and safety performance reports etc. shall be repaired and recorded.

9.4.11 Daily safety task assignment shall be prepared.

9.4.12 Man shelters shall be provided to protect the workers from adverse climatic condition, i.e. sand storm,

high temperature.

9.4.13 Potable water source shall be provided for adequate numbers for workers.

9.4.14 Work place to be tidied before leaving as to ensure safely work environment always has been remain.

Revision 03

SEG-ISF-Project

MS FOR xxcxbzn

TYPE

Date

Page

Doc. No: SA-JER-TF802-SEGC500044

PRC

05-Mar2016

7/7

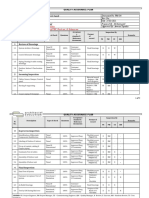

10.0 Job Safety Analysis or Risk Assessment.

No

Work

Activity

Hazard

Possible

accident/

Health

Person

at Risk

Lifting,

Strike by

Serious injury or

Transport

and lowering

swinging boom.

death.

to

transformers

base

foundation.

Pin down or

Serious injury or

striken by lifted

load.

death.

Power or Dry

Transformer

s

Installation

Knifecuts during

power

and

control

and

Serious injury.

Existing risk

Additional Risk

control(if any)

Control

Lifting watchman

or

supervisor proper

safety watch.

Safety work

Lifting watchman

or

supervisor proper

safety watch.

Safety work

Proper wearing of

PPE and use of

Safety work

practice.

practice for crane

liftworks.

practice for crane

liftworks.

cable installs.

tools.

Accidental bruise

and muscle

dislocation.

Serious injury.

Proper wearing of

PPE and use of

tools.

Safety work

practice.

Serious injury or

may cause

Blind ness.

Proper wearing of

appropriate

safety glass.

Safety work

practice.

Serious injury

Proper wearing of

PPE and use of

tools.

Safety work

practice.

Accidental eye

injury.

Accidental burn

from exothermal

weld.

Вам также может понравиться

- Method Statement For Static EquipmentДокумент10 страницMethod Statement For Static EquipmentYurizal firmansyahОценок пока нет

- Construction Method Statement: Fabrication & Erection of Piping SystemДокумент24 страницыConstruction Method Statement: Fabrication & Erection of Piping SystemHarun Akkaya100% (2)

- Installation Procedure For Pressure VesselДокумент8 страницInstallation Procedure For Pressure VesselSamuel Babu100% (1)

- Itp - Rev eДокумент36 страницItp - Rev ezaki_saddarОценок пока нет

- MIP17-MS-2012 Method Statement For Fabrication and Installation of PipingДокумент23 страницыMIP17-MS-2012 Method Statement For Fabrication and Installation of PipingAmeerHamzaWarraichОценок пока нет

- ITP - 003 - Rotating Equipment - IFRДокумент3 страницыITP - 003 - Rotating Equipment - IFRMari Belajar100% (1)

- Taping and Chilled Water Pipe InstallationДокумент13 страницTaping and Chilled Water Pipe InstallationProject enghvacОценок пока нет

- WMS JOB Procedure FOR PIPING WORKДокумент9 страницWMS JOB Procedure FOR PIPING WORKsatyamech1_395565923Оценок пока нет

- Vessel Final BoxДокумент14 страницVessel Final Boxmanoj thakkarОценок пока нет

- 22.MS For HydrotestДокумент9 страниц22.MS For HydrotestASHWANIОценок пока нет

- Fabrication Erection and Installation Procedure For PipingДокумент60 страницFabrication Erection and Installation Procedure For Pipinghasan_676489616Оценок пока нет

- Itp PipingДокумент15 страницItp PipingEkhy Transmisi100% (1)

- Ms Ag 002 Rev 0 - Method Statement For Above Ground PipingДокумент16 страницMs Ag 002 Rev 0 - Method Statement For Above Ground Pipingsugumar50% (4)

- MS For Fabrication & Erection of PipingДокумент24 страницыMS For Fabrication & Erection of PipingravikumarОценок пока нет

- Steam BoilerДокумент3 страницыSteam BoilerMohammad AzlanОценок пока нет

- Method Statement For Insulation WorksДокумент16 страницMethod Statement For Insulation WorksAhmed Farman AlqaysiОценок пока нет

- 02 MechanicalДокумент44 страницы02 Mechanicalmusaismail8863Оценок пока нет

- Method of Statement For Bus Duct InstallationДокумент11 страницMethod of Statement For Bus Duct InstallationMohd MuksinОценок пока нет

- Procedure For Fab, Erec & Testing of Undergroud PipingДокумент12 страницProcedure For Fab, Erec & Testing of Undergroud Pipingvpsimbu86Оценок пока нет

- MOS For InstrumentationДокумент6 страницMOS For Instrumentationrenjithv_4100% (1)

- Re-Welding, Expansion & HT ProcedureДокумент6 страницRe-Welding, Expansion & HT Proceduresuria qaqcОценок пока нет

- Quality Plan and Checklist (HVAC) - Sandvik G BlockДокумент3 страницыQuality Plan and Checklist (HVAC) - Sandvik G BlockParasОценок пока нет

- Contractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationДокумент5 страницContractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationSergey KichenkoОценок пока нет

- Method Statement For Underground Piping & Puddles InstallationДокумент27 страницMethod Statement For Underground Piping & Puddles InstallationAhmed ImranОценок пока нет

- Hydrotest Procedure For PipingДокумент4 страницыHydrotest Procedure For Pipingsuria qaqcОценок пока нет

- Work Procedure Pipe SupportДокумент10 страницWork Procedure Pipe Supportmc chesterОценок пока нет

- Specification FOR Piping Fabrication and InstallationДокумент27 страницSpecification FOR Piping Fabrication and Installationgc_panchaОценок пока нет

- Piping Above Ground Installation Work ProcedureДокумент38 страницPiping Above Ground Installation Work Proceduremanoj thakkar100% (1)

- Hydrotest Check List PDFДокумент1 страницаHydrotest Check List PDFSaut Maruli Tua Samosir100% (1)

- R057-Ac-It-001 (C) - Inspection and Test Plan For Instrument Air Compressor PackageДокумент10 страницR057-Ac-It-001 (C) - Inspection and Test Plan For Instrument Air Compressor Packagedharwin100% (1)

- MS For Tank Installation - R1Документ6 страницMS For Tank Installation - R1alvinchuan100% (1)

- Tie in MosДокумент2 страницыTie in MosAAISATОценок пока нет

- Method Statement For Ug Piping 6423dp420!00!00200 00 - Rev03Документ20 страницMethod Statement For Ug Piping 6423dp420!00!00200 00 - Rev03mister pogi100% (2)

- Gse Ms Ug 001 Rev 0 - Method Statement For Underground PipingДокумент7 страницGse Ms Ug 001 Rev 0 - Method Statement For Underground PipingsugumarОценок пока нет

- Method Statement For Refrigerant Piping Installation and Pressure TestingДокумент4 страницыMethod Statement For Refrigerant Piping Installation and Pressure TestingRyan WongОценок пока нет

- Tank Erection Procedure: Note: This Is The Sample Document For The Related Job OnlyДокумент5 страницTank Erection Procedure: Note: This Is The Sample Document For The Related Job Onlygeorge israelОценок пока нет

- Method Statement For Piping FabricationДокумент107 страницMethod Statement For Piping FabricationTrương Đông HưngОценок пока нет

- QA&QC - Installation of Field InstrumentationДокумент4 страницыQA&QC - Installation of Field InstrumentationMuhammadZahirKhan100% (1)

- BN-S-UC001B Checklist For The Mechanical Completion, Incl. Pre-Commissioning ActivitiesДокумент13 страницBN-S-UC001B Checklist For The Mechanical Completion, Incl. Pre-Commissioning ActivitiesGiftObionochieОценок пока нет

- QCP 10 Hydrotest and Flushing ProcedureДокумент15 страницQCP 10 Hydrotest and Flushing Procedureคุณพ่อน้อง บิ๊กบอสОценок пока нет

- Inspection Test Plan (Itp) at Shop: Remark No DescriptionДокумент2 страницыInspection Test Plan (Itp) at Shop: Remark No Descriptionanang_pri100% (1)

- Toaz - Info Method Statement For Hydrostatic Testing PRДокумент15 страницToaz - Info Method Statement For Hydrostatic Testing PRPresanna RajasekaranОценок пока нет

- Installation, Testing & Flushing of Firefighting Piping System MSTДокумент10 страницInstallation, Testing & Flushing of Firefighting Piping System MSTMohamedОценок пока нет

- QA - QC Plan For PEP 13-03-2017Документ16 страницQA - QC Plan For PEP 13-03-2017osersОценок пока нет

- Method Statement For Replacing Ball ValveДокумент3 страницыMethod Statement For Replacing Ball Valveamg007100% (3)

- Metallic Piping Fabrication and Installation Method Statement & Job Safety AnalysisДокумент34 страницыMetallic Piping Fabrication and Installation Method Statement & Job Safety AnalysisMohamed100% (1)

- CCFM U 00 TP430 010 R5 Field QC ProcedureДокумент258 страницCCFM U 00 TP430 010 R5 Field QC ProcedureCARLOS OLIVEROSОценок пока нет

- Iqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Документ17 страницIqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Ali MajeedОценок пока нет

- Itp Forabove Grade and Embedded Conduits Rev. 0Документ6 страницItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- Execution Procedure For Pipe Connection Tie in and Hot TapzДокумент7 страницExecution Procedure For Pipe Connection Tie in and Hot TapzyuwantoniОценок пока нет

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFДокумент36 страницDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823Оценок пока нет

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Документ7 страницINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- Pipe Laying HDPEДокумент6 страницPipe Laying HDPEFun TonОценок пока нет

- Method Statement For SS & CS - Uaq Independent Water Project - 150 MigdДокумент14 страницMethod Statement For SS & CS - Uaq Independent Water Project - 150 MigdMdubdtОценок пока нет

- Method Statement LV Distribution Boards InstallationДокумент9 страницMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- Method Statement LV Distribution Boards Installation PDF FreeДокумент9 страницMethod Statement LV Distribution Boards Installation PDF Freetristan guarinoОценок пока нет

- PP13 00 y QNQ Gam 043 0 PDFДокумент22 страницыPP13 00 y QNQ Gam 043 0 PDFRıdvan UyarОценок пока нет

- Telephone System SpecificationДокумент63 страницыTelephone System SpecificationRonaldo RomeroОценок пока нет

- PP13 00 y QNQ Gam 044 0 PDFДокумент20 страницPP13 00 y QNQ Gam 044 0 PDFRıdvan UyarОценок пока нет

- LBS-RC-EO001-MS-MEP-ELE-0015 Method Statement For Testing and Commissioning of Emergency Lighting SystemДокумент9 страницLBS-RC-EO001-MS-MEP-ELE-0015 Method Statement For Testing and Commissioning of Emergency Lighting SystemfidgetyОценок пока нет

- Received With Thanks ' 1,015.00 Through Payment Gateway Over The Internet FromДокумент1 страницаReceived With Thanks ' 1,015.00 Through Payment Gateway Over The Internet FromIbrahim KhanОценок пока нет

- Engine PartsДокумент19 страницEngine PartsIbrahim KhanОценок пока нет

- (Seamless and Welded Pipe For Low Temp Service) (Seamless C Steel Pipe For High Temp Service)Документ1 страница(Seamless and Welded Pipe For Low Temp Service) (Seamless C Steel Pipe For High Temp Service)Ibrahim KhanОценок пока нет

- In This Section You Will Be Introduced To Some Useful Piping CommandsДокумент98 страницIn This Section You Will Be Introduced To Some Useful Piping CommandsIbrahim KhanОценок пока нет

- Devappa E&I QCДокумент4 страницыDevappa E&I QCIbrahim KhanОценок пока нет