Академический Документы

Профессиональный Документы

Культура Документы

Seawater RO Units Containerised

Загружено:

hermit44535Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Seawater RO Units Containerised

Загружено:

hermit44535Авторское право:

Доступные форматы

Containerized Reverse Osmosis Systems

CRO

10ft, 20ft and 40ft containers

SERIES

Pure Aquas containerized reverse osmosis systems are self contained, turnkey units that can function

on-the-go or as a permanent water treatment plant, able to start producing high-quality water in less

than a day after arrival on-site. Pure Aquas containerized reverse osmosis systems are made to order,

meaning that your containerized system will be specifically engineered to meet your water treatment

requirements. Each containerized reverse osmosis system is engineered with high-quality components

to handle all types of harsh conditions.

66,000 GPD brackish water

containerized reverse osmosis system

Pure Aqua supplies a full line of standard and fully

customizable water treatment systems, all of which are

engineered using advanced 3D computer modeling and

process design software.

Standard Features

S 20ft or 40ft standard shipping container

S Centralized external connections

S Interconnecting piping and wiring

S Overhead lighting

S 110V/1ph and 460V/3ph/60Hz power

S Pretreatment mounting and plumbing

S Centralized control panels

S Operation and maintenance manual

S Full 3D/2D CAD drawings

Brackish water reverse osmosis system

Integrated clean-in-place skid (CIP)

For more information, please

refer to our RO data sheets

Available Options

S 10ft non seaworthy container for small systems

S Air conditioning/heater unit

S Membrane clean-in-place skid (CIP)

S 380-415V/3ph/50Hz or 220V/60Hz power supply

S Chemical dosing systems

S Media and iron prefiltration systems

S Ozonation and UV sterilization systems

S Diamond plate flooring

S Insulation for temperature control

Pre-filtration with interconnecting piping, wiring and backwash pump

Pure Aqua, Inc.

Containerized Reverse Osmosis Systems

CRO

10ft, 20ft and 40ft containers

SERIES

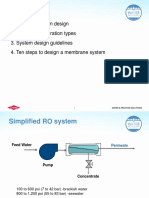

Membrane Schematic Diagram

The spiral membrane is constructed from one or more

Perforated Central Tube

membrane envelopes wound around a perforated central

tube. The permeate passes through the membrane into

the envelope and spirals inward to the central tube

eate

Perm

for collection. The layers of the membrane

te

envelope are detailed in the diagram to the

entra

Conc

Permeate Collection Mat.

Membrane

right.

Brine Seal

Feed

on

Soluti

Feed Channel

Spacer

Membrane

Feed Channel Spacer

Operation Specifications

Outer Wrap

S Max. feed water temperature: 42C

S Feed water TDS: up to 45,000 ppm

S Feed water pressure: 20 to 60 psi

S Turbidity must be removed

S Operating pressure: 150 to 1,000 psi

S Hardness over 1 GPG requires antiscalant dosing

S Hydrogen Sulfide must be removed

S pH tolerance range: 3-11

Sea water containerized reverse osmosis system

Weights and Dimensions

Non Insulated Container

Insulated Container

Container

Specification

10ft

20ft

40ft

20ft

40ft

External length (in)

120

240

480

240

480

External width (in)

96

96

96

96

96

External height (in)

102

102

114

102

114

Internal length (in)

111

233

474

229

470

Internal width (in)

92

92

92

88

88

Internal height (in)

93

95

104

91

100

Tare weight (lbs)

3,200

4,800

7,300

6,500

9,400

Max shipping weight (lbs)

22,400

40,000

45,000

40,000

45,000

Access

1 double-door

Pure Aqua also supplies: Multimedia Pretreatment, Activated Carbon Pretreatment, Water Conditioning,

Chemical Dosing Systems, Ultraviolet (UV) Sterilizers and Ozonation Systems.

CRO.june 2014

Вам также может понравиться

- GVT-ODIS-SWRO For PBMC PDFДокумент35 страницGVT-ODIS-SWRO For PBMC PDFSwati BhattacharyyaОценок пока нет

- Hague WaterMax Owners ManualДокумент36 страницHague WaterMax Owners ManualGreg ReynekeОценок пока нет

- L 18UF 215 Manual R1Документ33 страницыL 18UF 215 Manual R1Martin Bangueses100% (1)

- Prensentation Slides For Industry BriefingДокумент40 страницPrensentation Slides For Industry BriefingkunalkhubaniОценок пока нет

- STP BioshaftДокумент54 страницыSTP BioshaftImran KhanОценок пока нет

- DOW Filmtec Brackish Water RO Membranes Product SpecificationsДокумент1 страницаDOW Filmtec Brackish Water RO Membranes Product SpecificationsArnel V. EsllerОценок пока нет

- Uaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileДокумент20 страницUaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileABHIJITH M SОценок пока нет

- ProcessIndustriesandDrives - Introduction - Slide - SetДокумент26 страницProcessIndustriesandDrives - Introduction - Slide - Setmfonseca31Оценок пока нет

- North Sea 150m3 Basic (Containerized) : Owner's ManualДокумент239 страницNorth Sea 150m3 Basic (Containerized) : Owner's ManualirdawanОценок пока нет

- Water Softening IndustryДокумент4 страницыWater Softening IndustryArslanAliОценок пока нет

- Installation Guideline 1 Pretreatment Engineering Guide: Edition: 12A-2017 Part No.: F40002688Документ145 страницInstallation Guideline 1 Pretreatment Engineering Guide: Edition: 12A-2017 Part No.: F40002688Aleksei PodkopaevОценок пока нет

- محاضرات امدادات المياه - الكورس الاولДокумент146 страницمحاضرات امدادات المياه - الكورس الاولمحمد حيدر هاشم زبون100% (1)

- Discharge Calculator - Flowrates, Jet Properties and Outfall DesignДокумент35 страницDischarge Calculator - Flowrates, Jet Properties and Outfall DesignjnmanivannanmechОценок пока нет

- Voutchkov (2010) CoinsiderationdForSelectionOfSeawaterFiltrationPretrementSystem Desalination (261 354-364Документ12 страницVoutchkov (2010) CoinsiderationdForSelectionOfSeawaterFiltrationPretrementSystem Desalination (261 354-364Shamma DamaniОценок пока нет

- Rode Sign BasicsДокумент43 страницыRode Sign BasicsAshish GulrandheОценок пока нет

- WDR 20160919 Water Desalination ReporTДокумент4 страницыWDR 20160919 Water Desalination ReporTPhilip Jay-ar DimailigОценок пока нет

- Operating A Water Treatment Plant Is Complex and Requires Knowledge of MachineryДокумент12 страницOperating A Water Treatment Plant Is Complex and Requires Knowledge of MachineryJoshua OmolewaОценок пока нет

- Uf Toray PresentationДокумент54 страницыUf Toray PresentationPrateek VermaОценок пока нет

- 04 - STP Boq - 1080 (3x360) KLD STP MBBR - Sec-35Документ12 страниц04 - STP Boq - 1080 (3x360) KLD STP MBBR - Sec-35kunal singhОценок пока нет

- Hyflux Standard Membrane Systems Brochure - Ver5.1 - ENДокумент40 страницHyflux Standard Membrane Systems Brochure - Ver5.1 - ENIGNyomanAnomWijayaОценок пока нет

- RunxinДокумент149 страницRunxinMAUROОценок пока нет

- Pumpts PDFДокумент273 страницыPumpts PDFRomel LeoОценок пока нет

- Technical Specifications TR-3.0 E IngeДокумент10 страницTechnical Specifications TR-3.0 E Ingegowri shankarОценок пока нет

- Rock Catchment Dam With Self-Closing WatertapДокумент90 страницRock Catchment Dam With Self-Closing WatertapGreen Action Sustainable Technology GroupОценок пока нет

- 18-06 27 Presentation VTS Roediger Version 02 enДокумент33 страницы18-06 27 Presentation VTS Roediger Version 02 enmunjaОценок пока нет

- Teknofanghi Monoscrew Pump - CatalougeДокумент4 страницыTeknofanghi Monoscrew Pump - CatalougeKarim ShamashergyОценок пока нет

- Nordic WaterДокумент12 страницNordic WaterCarlos PeixotoОценок пока нет

- Pepsi ReportДокумент43 страницыPepsi ReportShoaib ShahidОценок пока нет

- Thermal Model Consolidated v.30 (1) .0Документ222 страницыThermal Model Consolidated v.30 (1) .0Uzair Ahmad SiddiquiОценок пока нет

- Siemens Water TechnologiesДокумент33 страницыSiemens Water TechnologiesmaheshvbendreОценок пока нет

- Reverse Osmosis Design GuidelinesДокумент2 страницыReverse Osmosis Design Guidelineswacsii ccasullaОценок пока нет

- Boiler Water Treatment: Deposit ControlДокумент5 страницBoiler Water Treatment: Deposit ControlKrishna RayuduОценок пока нет

- Dimension Ing 2000 Me CДокумент24 страницыDimension Ing 2000 Me COsoba Ismail AbiodunОценок пока нет

- WAVE Technical Manual 45 D01378 enДокумент226 страницWAVE Technical Manual 45 D01378 enSamoel AnjosОценок пока нет

- FiltriДокумент255 страницFiltriLavinia CalinОценок пока нет

- Filtration SystemДокумент11 страницFiltration Systemwaleed.murad@gmail.comОценок пока нет

- Desalination Unit 10.84 Midg P&I Diagram: 20-DW - PFB-00002-SID 7Документ1 страницаDesalination Unit 10.84 Midg P&I Diagram: 20-DW - PFB-00002-SID 7Shaik SameeruddinОценок пока нет

- 2010chapter 1WaterTechnologyДокумент96 страниц2010chapter 1WaterTechnologydeep34Оценок пока нет

- 2002 A Solar Desalination Plant For Domestic Water Needs in Arid Areas of South AlgeriaДокумент5 страниц2002 A Solar Desalination Plant For Domestic Water Needs in Arid Areas of South AlgeriaRahul TripathiОценок пока нет

- Degasifier SpecificationsДокумент1 страницаDegasifier SpecificationsMuhammad Hamza NaveedОценок пока нет

- Metito - TSE RO Presentation KM DC WorkshopДокумент24 страницыMetito - TSE RO Presentation KM DC WorkshopMohamed TahounОценок пока нет

- Water Desalination MatrixДокумент37 страницWater Desalination MatrixShehreyar KhanОценок пока нет

- BN44 00428bДокумент73 страницыBN44 00428bClaudio Hector Arrosa100% (1)

- Watertech Mar 04Документ4 страницыWatertech Mar 04Junnaid NissarОценок пока нет

- Air Reverse OsmosisДокумент12 страницAir Reverse Osmosisirdawan100% (2)

- Vulnerable Water Resources in Jordan: Hot SpotsДокумент51 страницаVulnerable Water Resources in Jordan: Hot SpotsHind Al ShdaifatОценок пока нет

- ZLD ProcessДокумент36 страницZLD ProcessLim Chee Siang100% (1)

- OÊÊ Ê OÊÊ Ê Oêê Ê OÊÊ ÊДокумент18 страницOÊÊ Ê OÊÊ Ê Oêê Ê OÊÊ ÊRudi Sutanto TanОценок пока нет

- Review of LVPP Power Plant and Auxiliary System Water Quality AnalysisДокумент16 страницReview of LVPP Power Plant and Auxiliary System Water Quality AnalysisJayanath Nuwan SameeraОценок пока нет

- Argentina Membrane Filtration JCD PDFДокумент42 страницыArgentina Membrane Filtration JCD PDFjpsingh75Оценок пока нет

- Exp 3Документ15 страницExp 3mjunaidОценок пока нет

- Case Study: A Modular, Scalable & Highly-Efficient Seawater Desalination SolutionДокумент4 страницыCase Study: A Modular, Scalable & Highly-Efficient Seawater Desalination Solutionwahyu raharjoОценок пока нет

- Multi Stage Flash Desalination Plant With Brine-Feed Mixing and CoolingДокумент8 страницMulti Stage Flash Desalination Plant With Brine-Feed Mixing and CoolingMuhammadEhtishamSiddiquiОценок пока нет

- Intake Pipe & Scraper LauncherДокумент14 страницIntake Pipe & Scraper Launcherraymond gtpanОценок пока нет

- Performance of Reinforced Thermosetting Resin Pipe Systems in Desalination Applications: A Long-Term Solution To Corrosion - The Arabian Gulf ExampleДокумент6 страницPerformance of Reinforced Thermosetting Resin Pipe Systems in Desalination Applications: A Long-Term Solution To Corrosion - The Arabian Gulf ExamplejatecconsultОценок пока нет

- Water Desalination & Wastewater Treatment For Vietnam 18.2Документ5 страницWater Desalination & Wastewater Treatment For Vietnam 18.2Luan NguyenОценок пока нет

- 50industrial Sea Water Reverse Osmosis System SwiДокумент2 страницы50industrial Sea Water Reverse Osmosis System SwiMohamedAlami100% (1)

- Es WQ PWR4024Документ2 страницыEs WQ PWR4024WattsОценок пока нет

- Es WQ PWR4022Документ2 страницыEs WQ PWR4022WattsОценок пока нет

- Es WQ PWR4011Документ2 страницыEs WQ PWR4011WattsОценок пока нет

- Forward Plan of Key Decisions: Civic Centre, Darwall Street, Walsall, WS1 1TP 9 August 2007Документ10 страницForward Plan of Key Decisions: Civic Centre, Darwall Street, Walsall, WS1 1TP 9 August 2007hermit44535Оценок пока нет

- 06 - Walsall Partnership Programmes and ResourcesДокумент5 страниц06 - Walsall Partnership Programmes and Resourceshermit44535Оценок пока нет

- 14 - Financial Plan 2013 - 14 To 2017 - 18 - Appendices 1 and 2Документ87 страниц14 - Financial Plan 2013 - 14 To 2017 - 18 - Appendices 1 and 2hermit44535Оценок пока нет

- 5 - 333 Bus RouteДокумент3 страницы5 - 333 Bus Routehermit44535Оценок пока нет

- 14 - Financial Plan 2013 - 14 To 2017 - 18 - Appendices 1 and 2Документ87 страниц14 - Financial Plan 2013 - 14 To 2017 - 18 - Appendices 1 and 2hermit44535Оценок пока нет

- Quarterly Financial MonitoringДокумент8 страницQuarterly Financial Monitoringhermit44535Оценок пока нет

- TC A 301 Section A Layout1Документ1 страницаTC A 301 Section A Layout1hermit44535Оценок пока нет

- TC A 101 Ground Floor Plan A 101Документ1 страницаTC A 101 Ground Floor Plan A 101hermit44535Оценок пока нет

- TC A 102 First Floor Plan A 102Документ1 страницаTC A 102 First Floor Plan A 102hermit44535Оценок пока нет

- TC A 201 Elevation 1 Layout1Документ1 страницаTC A 201 Elevation 1 Layout1hermit44535Оценок пока нет

- TC A 103 Roof Plan Layout1Документ1 страницаTC A 103 Roof Plan Layout1hermit44535Оценок пока нет

- Refrig System RepairДокумент32 страницыRefrig System Repairhermit44535Оценок пока нет

- TC A 202 Elevation 2 Layout1Документ1 страницаTC A 202 Elevation 2 Layout1hermit44535Оценок пока нет

- TC-A-203 Elevation 3 and 4-A-203 PDFДокумент1 страницаTC-A-203 Elevation 3 and 4-A-203 PDFhermit44535Оценок пока нет

- R600a CompressorsДокумент140 страницR600a Compressorshermit44535100% (1)

- 100 MW CCPP - 6FA - Peace - Costing and LayoutsДокумент90 страниц100 MW CCPP - 6FA - Peace - Costing and Layoutskrajeev28Оценок пока нет

- TC A 302 Section B A 302Документ1 страницаTC A 302 Section B A 302hermit44535Оценок пока нет

- Pipeline Booster Pump BrochureДокумент16 страницPipeline Booster Pump Brochurehermit44535Оценок пока нет

- Performance Analysis of A Hermetic Reciprocating CompressorДокумент10 страницPerformance Analysis of A Hermetic Reciprocating Compressorhermit44535Оценок пока нет

- Rev2 132kV OHL Bab To Asab Plan and Profile Tower 1 To 13Документ6 страницRev2 132kV OHL Bab To Asab Plan and Profile Tower 1 To 13hermit44535Оценок пока нет

- SECOP R600a CompressorsДокумент8 страницSECOP R600a Compressorshermit44535Оценок пока нет

- Seawater RO Units To 100 m3 Per HДокумент2 страницыSeawater RO Units To 100 m3 Per Hhermit44535Оценок пока нет

- Refrig R600a Practical GuidelineДокумент16 страницRefrig R600a Practical Guidelinehermit44535Оценок пока нет

- 33 - 99 - 07 - 0602 - C - 132kV Line Routing BabДокумент1 страница33 - 99 - 07 - 0602 - C - 132kV Line Routing Babhermit44535Оценок пока нет

- R600a Catalogue SK53CY (Mine)Документ4 страницыR600a Catalogue SK53CY (Mine)hermit44535100% (4)

- Isobutane TwoДокумент2 155 страницIsobutane Twohermit44535Оценок пока нет

- Refrig System ServiceДокумент8 страницRefrig System Servicehermit44535Оценок пока нет

- MWB A 102 Roof Plan A 102Документ1 страницаMWB A 102 Roof Plan A 102hermit44535Оценок пока нет

- MWB A 301 Sections A 102Документ1 страницаMWB A 301 Sections A 102hermit44535Оценок пока нет

- MWB A 201 Elevations A 201Документ1 страницаMWB A 201 Elevations A 201hermit44535Оценок пока нет

- Sanitary HospitalsДокумент71 страницаSanitary Hospitalsdemullu reddiОценок пока нет

- Of Cac03: Inhibition Scaling in Reverse Osmosis System by Zinc IonДокумент6 страницOf Cac03: Inhibition Scaling in Reverse Osmosis System by Zinc IondonsombreroОценок пока нет

- c9cp05026d PDFДокумент7 страницc9cp05026d PDFshubhamОценок пока нет

- BKG WaterДокумент40 страницBKG WaterCHRISTIANCHIROQUEОценок пока нет

- Watts RO System Manual PDFДокумент28 страницWatts RO System Manual PDFTNОценок пока нет

- Reverse OsmosisДокумент2 страницыReverse Osmosistcd_usaОценок пока нет

- Lista Detalhada de Equipamentos ETAДокумент3 страницыLista Detalhada de Equipamentos ETADimitri DiogoОценок пока нет

- Bajaj Processpack Limited Juice Packaging Machines & Juice Packaging EquipmentsДокумент20 страницBajaj Processpack Limited Juice Packaging Machines & Juice Packaging EquipmentsBajaj Process PackОценок пока нет

- Water Treatment ManualДокумент72 страницыWater Treatment Manualminhankyaw92% (25)

- Awareness About The RO Water PurifierДокумент7 страницAwareness About The RO Water PurifiervikaskamaljnuОценок пока нет

- Nitrate and NitriteДокумент8 страницNitrate and Nitritesyafiqabang75% (4)

- Reverse Osmosis Chemical BrochureДокумент4 страницыReverse Osmosis Chemical BrochuredavidnpsОценок пока нет

- Water Purifier TypesДокумент28 страницWater Purifier TypesRISHABH MUDGALОценок пока нет

- Fulflo Multicartucho GeneralДокумент24 страницыFulflo Multicartucho GeneralZoranОценок пока нет

- Vertex PWC 2000Документ1 страницаVertex PWC 2000Anonymous G4EVMV5rW7Оценок пока нет

- GE - Technologies For Industrial Water ReuseДокумент130 страницGE - Technologies For Industrial Water ReusesujatarjadhavОценок пока нет

- Solar Water Distillation SystemДокумент95 страницSolar Water Distillation SystemermankurОценок пока нет

- User Manual 50 LPH Ro Skid: Ion Exchange (India) LTDДокумент8 страницUser Manual 50 LPH Ro Skid: Ion Exchange (India) LTDAnand SachanОценок пока нет

- Aquacell CatalogueДокумент15 страницAquacell CatalogueVo Ngoc HoangОценок пока нет

- CH 4 Separation TechniquesДокумент16 страницCH 4 Separation TechniquestanhuikuanОценок пока нет

- CHM031 Module 3 ReviewerДокумент21 страницаCHM031 Module 3 ReviewerrainОценок пока нет

- Reverse Osmosis System Quotation For RO System 20m /H Recovery Rate 73%Документ6 страницReverse Osmosis System Quotation For RO System 20m /H Recovery Rate 73%tata_77Оценок пока нет

- Bonderlube 745 enДокумент6 страницBonderlube 745 eniwedificationОценок пока нет

- Reverse Osmosis System FaridДокумент30 страницReverse Osmosis System FaridAchFaridWadjdiОценок пока нет

- PURELAB Classic Spec Sheet LITR38748-05Документ2 страницыPURELAB Classic Spec Sheet LITR38748-05Cecilio SantosОценок пока нет

- Water Resilience For CitiesДокумент32 страницыWater Resilience For CitiesAnstret 22Оценок пока нет

- Membrane Test UnitДокумент14 страницMembrane Test UnitAzzian AriffinОценок пока нет

- LCM Catalouge PDFДокумент20 страницLCM Catalouge PDFRSD Water SolutionОценок пока нет

- A Trusted Manufacture Of: Water and Waste Water Treatment PlantДокумент4 страницыA Trusted Manufacture Of: Water and Waste Water Treatment PlantHiren VaghasiyaОценок пока нет