Академический Документы

Профессиональный Документы

Культура Документы

Versatile heavy duty SplitHanger for timber beams

Загружено:

jlolhnpИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Versatile heavy duty SplitHanger for timber beams

Загружено:

jlolhnpАвторское право:

Доступные форматы

E N GI NE E RED

B UILD ING

PR OD UC TS

SplitHanger

Sp

l i t

Ha

n g e r

SUITABLE FOR VARIOUS

WIDTHS OF TIMBER BEAM

APPLICATION:

SplitHangers are versatile hangers that provide a heavy

duty connection for various solid timber beam widths

to supporting beams. They provide a fast and easy fixing

method for various width of timber beam to supporting

beam, waling plate to stud and where clearance is

required at corner beam connection.

SPECIFICATIONS:

ADVANTAGES

No requirement to determine

hangers width to suit beam

thickness.

Steel Grade

G300

Thickness

(Total Coated)

Quick installation with screws.

Proprietary MSA screws can

drive through sheet metal

without need to pre-drill.

Galvanized

Coating

Improved performance over

nailed hanger alternatives.

Screws

1.55mm

Z275

MSA1430 MiTek No.14 x 30mm

anti-split self-drilling

HD galvanized screws

Versatile heavy duty hanger

Product Code

This Engineered Building Product complies with the

National Construction Code Series and Australian Standards.

SPH140

SPH180

SPH220

Sp

l i t

Ha

- SPH140

n g e r

FIXING POSITION

SPH140 with

3 MiTek screws to each face

SPH140 with

6 MiTek screws to each face

Locating

nail holes

for optional

positioning

SIDE

FRONT

135mm

FRONT

Drive MiTek screws into

round holes only.

SIDE

Drive MiTek screws into

round and square holes.

70mm

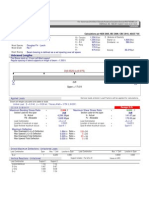

SplitHanger SPH140 LOAD DATA

Number of screws fixed

to each face

Load Case

DL Only

k1 = 0.57

DL + Floor LL

k1 = 0.69

DL + Roof LL

k1 = 0.77

DL + WL

k1 = 1.14

Supporting

Beam

Supported

Beam

Limit State Design Capacity for a pair of SPH140 (kN) in standard configuration

Timber Joint Group

J2

J3

J4

J5

J6

JD2

JD3

JD4

JD5

JD6

9.9

7.0

5.0

3.7

2.3

12.5

9.9

7.0

5.0

3.7

17.4

12.4

8.8

6.4

4.1

23.3

18.3

13.1

9.3

6.8

11.9

8.5

6.1

4.4

2.8

15.2

11.9

8.5

6.1

4.4

21.0

15.0

10.6

7.8

5.0

28.2

22.2

15.9

11.3

8.2

13.3

9.5

6.8

4.9

3.2

15.3

13.3

9.5

6.8

4.9

23.4

16.8

11.9

8.7

5.6

29.6

24.8

17.7

12.6

9.2

15.3

14.1

10.0

7.3

4.7

15.3

15.3

14.1

10.0

7.3

29.6

24.8

17.6

12.8

8.2

29.6

29.6

26.2

18.6

13.6

NOTES:

1. The design capacities in this table apply to a pair of

SplitHangers fitted on both sides of the supported beam

in the standard configuration.

2. When a pair of SplitHangers is stacked on one side,

use 65% of the standard capacity.

Category

Adjustment factor

1.00

0.94

0.88

Values in this table incorporate the Category 1 capacity factor ()

for houses. For other categories, multiply the design capacities by the

following factors. Refer to AS1720.1 for a full definition of each category.

3. When a single SplitHanger is fitted on one side only,

use 33% of the standard capacity.

Design capacities have been obtained from laboratory testing and

procedures given in AS1720.1.

3

Sp

l i t

Ha

- SPH180

n g e r

FIXING POSITION

SPH180 with

4 MiTek screws to each face

SPH180 with

8 MiTek screws to each face

175mm

Locating

nail holes

for optional

positioning

SIDE

FRONT

FRONT

Drive MiTek screws into

round holes only.

SIDE

Drive MiTek screws into

round and square holes.

70mm

SplitHanger SPH180 LOAD DATA

Number of screws fixed

to each face

Load Case

DL Only

k1 = 0.57

DL + Floor LL

k1 = 0.69

DL + Roof LL

k1 = 0.77

DL + WL

k1 = 1.14

Supporting

Beam

Supported

Beam

Limit State Design Capacity for a pair of SPH180 (kN) in standard configuration

Timber Joint Group

J2

J3

J4

J5

J6

JD2

JD3

JD4

JD5

JD6

13.1

9.4

6.7

4.9

3.1

16.7

13.1

9.4

6.7

4.9

22.1

15.8

11.2

8.2

5.2

30.7

24.2

17.3

12.3

8.9

15.9

11.4

8.1

5.9

3.8

20.2

15.9

11.4

8.1

5.9

26.7

19.1

13.6

9.9

6.4

37.2

29.3

20.9

14.8

10.8

17.8

12.7

9.0

6.6

4.4

20.4

17.8

12.7

9.0

6.6

29.8

21.3

15.1

11.0

7.1

37.8

32.7

23.3

16.6

12.1

20.4

18.8

13.3

9.7

6.2

20.4

20.4

18.8

13.3

9.7

37.8

31.6

22.4

16.3

10.5

37.8

37.8

34.6

24.5

17.9

NOTES:

1. The design capacities in this table apply to a pair of

SplitHangers fitted on both sides of the supported beam

in the standard configuration.

2. When a pair of SplitHangers is stacked on one side,

use 65% of the standard capacity.

Category

Adjustment factor

1.00

0.94

0.88

Values in this table incorporate the Category 1 capacity factor ()

for houses. For other categories, multiply the design capacities by the

following factors. Refer to AS1720.1 for a full definition of each category.

3. When a single SplitHanger is fitted on one side only,

use 33% of the standard capacity.

Design capacities have been obtained from laboratory testing and

procedures given in AS1720.1.

4

Sp

l i t

Ha

- SPH220

n g e r

FIXING POSITION

SPH220 with

5 MiTek screws to each face

SPH220 with

10 MiTek screws to each face

215mm

Locating

nail holes

for optional

positioning

SIDE

FRONT

FRONT

Drive MiTek screws into

round holes only.

SIDE

Drive MiTek screws into

round and square holes.

70mm

SplitHanger SPH220 LOAD DATA

Number of screws fixed

to each face

Load Case

DL Only

k1 = 0.57

DL + Floor LL

k1 = 0.69

DL + Roof LL

k1 = 0.77

DL + WL

k1 = 1.14

Supporting

Beam

Supported

Beam

Limit State Design Capacity for a pair of SPH220 (kN) in standard configuration

Timber Joint Group

J2

J3

J4

J5

J6

JD2

JD3

JD4

JD5

JD6

14.9

10.6

7.5

5.5

3.5

19.6

15.4

11.0

7.8

5.7

10

10

26.3

18.8

13.3

9.7

6.2

37.5

29.6

21.1

15.0

10.9

17.9

12.8

9.1

6.6

4.3

23.4

18.7

13.4

9.5

6.9

10

10

31.8

22.7

16.1

11.8

7.6

45.4

35.8

25.6

18.1

13.2

20.0

14.3

10.1

7.4

4.7

25.5

20.9

14.9

10.6

7.7

10

10

35.5

25.4

18.0

13.1

8.4

46.0

40.0

28.6

20.3

14.8

25.5

21.1

15.0

10.9

7.0

25.5

25.5

22.1

15.7

11.4

10

10

46.0

37.6

26.7

19.4

12.5

46.0

46.0

42.3

30.0

21.9

NOTES:

1. The design capacities in this table apply to a pair of

SplitHangers fitted on both sides of the supported beam

in the standard configuration.

2. When a pair of SplitHangers is stacked on one side,

use 65% of the standard capacity.

Category

Adjustment factor

1.00

0.94

0.88

Values in this table incorporate the Category 1 capacity factor ()

for houses. For other categories, multiply the design capacities by the

following factors. Refer to AS1720.1 for a full definition of each category.

3. When a single SplitHanger is fitted on one side only,

use 33% of the standard capacity.

Design capacities have been obtained from laboratory testing and

procedures given in AS1720.1.

5

Sp

l i t

Ha

- In

n g e r

1. Use only MiTek MSA1430 screws (longer MSA1465 screws

are optional).

s ta l l at i o n

2. Drive selected number of MiTek screws into supporting

and supported beam as indicated in the tables for each

SplitHanger size to obtain the required design capacities.

Always fit MiTek screws into round holes before using

square ones.

Standard Configuration

SplitHanger

pair on both sides

Stacked Configuration

32mm min.

edge distance

SplitHanger pair

stacked on one side

Single Configuration

32mm min. gap

between screws

SplitHanger single

on one side only

Stud

Waling plate

32mm min.

edge distance

SPH 07/15

For more information about MiTeks Engineered Building Products or any other MiTek products or your nearest

licensed MiTek fabricator, please call your local state office or visit: mitek.com.au

HOME OF GANG-NAIL BUILDING SYSTEMS

VIC (03) 8795 8888

NSW (02) 8525 8000

QLD (07) 3861 2100

SA (08) 8234 1326

WA (08) 9412 3534

New Zealand (09) 274 7109

Вам также может понравиться

- Lumberlok: Timber Connectors Characteristic Loadings DataДокумент12 страницLumberlok: Timber Connectors Characteristic Loadings DataGajanthan Vethanathan0% (1)

- Trusses How They WorkДокумент7 страницTrusses How They Workprabhu81Оценок пока нет

- LumberLok Fixing ManualДокумент124 страницыLumberLok Fixing Manualjcvalencia100% (1)

- Physical - Mechanical Properties PDFДокумент131 страницаPhysical - Mechanical Properties PDFCharbel Saad SaadОценок пока нет

- Design For Fire Safety PDFДокумент64 страницыDesign For Fire Safety PDFCharbel Saad SaadОценок пока нет

- Written ReportДокумент5 страницWritten ReportJerick RoseОценок пока нет

- Wood beam design summaryДокумент1 страницаWood beam design summaryNoel GuadesОценок пока нет

- Structural Wood Products and Systems PDFДокумент105 страницStructural Wood Products and Systems PDFCharbel Saad SaadОценок пока нет

- Efficient 3D Modeling of Complex Steel StructuresДокумент87 страницEfficient 3D Modeling of Complex Steel Structuresacin_mОценок пока нет

- Design of CLT Structures PDFДокумент49 страницDesign of CLT Structures PDFCharbel Saad SaadОценок пока нет

- Linear Structures Workflow Guide PDFДокумент52 страницыLinear Structures Workflow Guide PDFJОценок пока нет

- 204835structural Steel Shop Drawings Services - How To Make A Winning Selection?Документ2 страницы204835structural Steel Shop Drawings Services - How To Make A Winning Selection?z1dqslm149Оценок пока нет

- Roof/Truss Con ManualДокумент24 страницыRoof/Truss Con ManualDaniel DincaОценок пока нет

- Advance Design - Starting GuideДокумент40 страницAdvance Design - Starting GuideNabil AssamОценок пока нет

- Process PlantДокумент133 страницыProcess PlantVijayabaraniОценок пока нет

- Outline PDFДокумент4 страницыOutline PDFGreg LoncaricОценок пока нет

- Mitek ManualДокумент124 страницыMitek ManualTuroyОценок пока нет

- Design and Application GuidelinesДокумент391 страницаDesign and Application GuidelinesonspsnonsОценок пока нет

- Enercalc 6.0 PDFДокумент642 страницыEnercalc 6.0 PDFamirkhanlouОценок пока нет

- WisDOT Civil 3D beginner training overviewДокумент929 страницWisDOT Civil 3D beginner training overviewRavi ShenkerОценок пока нет

- TT - Revit Structure - Working With Slab PDFДокумент21 страницаTT - Revit Structure - Working With Slab PDFAshutosh AnandОценок пока нет

- D&C Post-Tensioning Projects - Design For PDFДокумент13 страницD&C Post-Tensioning Projects - Design For PDFzfanОценок пока нет

- Mastermesh Perforated MetalДокумент8 страницMastermesh Perforated MetalnovadistributorsОценок пока нет

- SECTION 05 12 00 Structural Steel FramingДокумент6 страницSECTION 05 12 00 Structural Steel FramingmiteshsuneriyaОценок пока нет

- Advance Steel 2017 Implementation GuideДокумент155 страницAdvance Steel 2017 Implementation GuideSoufian BelfadilОценок пока нет

- AISI S913-13 - SДокумент18 страницAISI S913-13 - SEdison BecerraОценок пока нет

- Everett Civil CAD Standards - 2018 - 201806220925365186Документ82 страницыEverett Civil CAD Standards - 2018 - 201806220925365186Reynaldo CastilloОценок пока нет

- Preliminary design Rules of thumb for reinforced concrete structuresДокумент6 страницPreliminary design Rules of thumb for reinforced concrete structuresOyens EstoyeОценок пока нет

- CISC Handbook of Steel Construction Update 2017Документ6 страницCISC Handbook of Steel Construction Update 2017hetpinОценок пока нет

- Drawings PDFДокумент726 страницDrawings PDFPetros IosifidisОценок пока нет

- Mitek 12kN Pile FixingДокумент2 страницыMitek 12kN Pile FixingTuroyОценок пока нет

- Garages Stubbie InstallДокумент16 страницGarages Stubbie InstallMattОценок пока нет

- Safe Load TablesДокумент12 страницSafe Load TablesdeviationzОценок пока нет

- Fundamentals of Piping System PDFДокумент24 страницыFundamentals of Piping System PDFravi00098Оценок пока нет

- PEB 2D Vs 3D ModelДокумент5 страницPEB 2D Vs 3D ModelGautam PaulОценок пока нет

- Structural Engineer SkillsДокумент2 страницыStructural Engineer SkillsReceb AgaОценок пока нет

- Professional Practices CodeДокумент19 страницProfessional Practices CodeHamza IkhlaqОценок пока нет

- Girder TrussДокумент0 страницGirder Truss74747474Оценок пока нет

- Invatare Revit StructureДокумент450 страницInvatare Revit StructuremargitorsiОценок пока нет

- CADS RC3D - Release Notes PDFДокумент6 страницCADS RC3D - Release Notes PDFengrrozayОценок пока нет

- SteelWise - Connection Design Options in The Real WorldДокумент4 страницыSteelWise - Connection Design Options in The Real Worldjavier121212Оценок пока нет

- Guidance On Structural Connections For SAEДокумент7 страницGuidance On Structural Connections For SAEGaruda GarudaОценок пока нет

- Post Installed RebarДокумент38 страницPost Installed RebarSingDollarОценок пока нет

- Revit Structure Worksets 101Документ17 страницRevit Structure Worksets 101nneka101Оценок пока нет

- Welding and bolting requirements for structural steelДокумент10 страницWelding and bolting requirements for structural steelIndra SidikОценок пока нет

- Properties of The Objects - Inp File - Tekla User AssistanceДокумент4 страницыProperties of The Objects - Inp File - Tekla User AssistanceThắng PhạmОценок пока нет

- Inertia Base FrameДокумент2 страницыInertia Base FrameLasandu WanniarachchiОценок пока нет

- Standard Hooks Card-ASTM PDFДокумент2 страницыStandard Hooks Card-ASTM PDFRhio CruzОценок пока нет

- Cistron Detailing Manual: DraftДокумент15 страницCistron Detailing Manual: DraftRamume188Оценок пока нет

- 2000 IBC Handbook Seismic Wind PDFДокумент9 страниц2000 IBC Handbook Seismic Wind PDFAnonymous xC6bM4x6U6Оценок пока нет

- Scaffold Basic PartsДокумент57 страницScaffold Basic PartsSn Carbonel100% (1)

- Post-Installed Rebar.: in Compliance With AS 3600-2009Документ38 страницPost-Installed Rebar.: in Compliance With AS 3600-2009caner_kurtoglu-1Оценок пока нет

- IDEA-Connection-Theoretical-Manual EN Ver 8 2Документ65 страницIDEA-Connection-Theoretical-Manual EN Ver 8 2Massimo LatourОценок пока нет

- Advance Steel Class Presentation FAB197439L Up and Running With Advance Steel Deepak MainiДокумент71 страницаAdvance Steel Class Presentation FAB197439L Up and Running With Advance Steel Deepak MainiFongho Eric Sinclair100% (1)

- Week 2 - Design of Key Wood Elements PDFДокумент131 страницаWeek 2 - Design of Key Wood Elements PDFKennyОценок пока нет

- Advance Steel - AutoCAD Structural Detailing Comparison MatrixДокумент2 страницыAdvance Steel - AutoCAD Structural Detailing Comparison Matrixdev_1989Оценок пока нет

- Split HangerДокумент6 страницSplit HangerkjdaraОценок пока нет

- Pryda Steel Connectors Guide - June 2010Документ20 страницPryda Steel Connectors Guide - June 2010Pawel MilewskiОценок пока нет

- Grid-Lign Fl4011 1209 WebДокумент2 страницыGrid-Lign Fl4011 1209 WebRenzo Jo LaurentОценок пока нет

- Registration of Engineers Stakeholder Consultation PaperДокумент26 страницRegistration of Engineers Stakeholder Consultation PaperjlolhnpОценок пока нет

- Registration of Engineers Stakeholder Consultation PaperДокумент26 страницRegistration of Engineers Stakeholder Consultation PaperjlolhnpОценок пока нет

- Revisiting A 90-Year-Old Debate - The Advantages of The Mean DeviationДокумент10 страницRevisiting A 90-Year-Old Debate - The Advantages of The Mean DeviationAreem AbbasiОценок пока нет

- Joints in Poured Walls - tcm45-342541Документ3 страницыJoints in Poured Walls - tcm45-342541Youssef RomanosОценок пока нет

- Salary and Remuneration Survey 2017Документ12 страницSalary and Remuneration Survey 2017jlolhnpОценок пока нет

- SAL ReportДокумент130 страницSAL ReportjlolhnpОценок пока нет

- Concrete Construction Article PDF - Repairing Curled SlabsДокумент5 страницConcrete Construction Article PDF - Repairing Curled SlabsjlolhnpОценок пока нет

- Revisiting A 90-Year-Old Debate - The Advantages of The Mean DeviationДокумент10 страницRevisiting A 90-Year-Old Debate - The Advantages of The Mean DeviationAreem AbbasiОценок пока нет

- Color Bond Metallic Data SheetДокумент3 страницыColor Bond Metallic Data SheetjlolhnpОценок пока нет

- Product CatalogДокумент66 страницProduct CatalogEnkhmend-Od UlziibatОценок пока нет

- Starting Your Business Checklist PDFДокумент86 страницStarting Your Business Checklist PDFengr_dkОценок пока нет

- Kelly Salary Survey 2017Документ39 страницKelly Salary Survey 2017jlolhnpОценок пока нет

- Masonry Design GuideДокумент62 страницыMasonry Design GuideFernando Lopez100% (10)

- Slab Design by Wood Armer MethodДокумент2 страницыSlab Design by Wood Armer MethodUmesh Patil75% (4)

- Bi-Fold-instructions-v1 Final Aug 2012Документ1 страницаBi-Fold-instructions-v1 Final Aug 2012jlolhnpОценок пока нет

- Ramset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringДокумент10 страницRamset Specifiers Anchoring Resource Book ANZ - TruBolt Mechanical AnchoringjlolhnpОценок пока нет

- Hyspan Span Guide 28pp Oct12 PDFДокумент28 страницHyspan Span Guide 28pp Oct12 PDF_Asylum_Оценок пока нет

- 07 TransverseShearДокумент34 страницы07 TransverseShearEssy BasoenondoОценок пока нет

- Orrcon Steel Purlins GirtsДокумент3 страницыOrrcon Steel Purlins GirtsLandon MitchellОценок пока нет

- 484 Welding Guidelines For Design EngineersДокумент4 страницы484 Welding Guidelines For Design EngineersPham Song Hong100% (1)

- Ramset Specifiers Anchoring Resource Book ANZ Chemical Anchoring Anchor StudsДокумент59 страницRamset Specifiers Anchoring Resource Book ANZ Chemical Anchoring Anchor StudsjlolhnpОценок пока нет

- Seismic RC Design Guide SRIAДокумент76 страницSeismic RC Design Guide SRIAjlolhnp100% (1)

- Triple L GripДокумент4 страницыTriple L GripjlolhnpОценок пока нет

- Steel Reinforcement SRIAДокумент2 страницыSteel Reinforcement SRIAjlolhnpОценок пока нет

- Purlin and Girts Design TablesДокумент32 страницыPurlin and Girts Design TablesTimothy BarnesОценок пока нет

- Mechanical Anchoring TruBoltДокумент3 страницыMechanical Anchoring TruBoltjlolhnpОценок пока нет

- Chemset 101 Plus MSDSДокумент12 страницChemset 101 Plus MSDSjlolhnpОценок пока нет

- STAAD - Difference Between Surface Element, PlateДокумент4 страницыSTAAD - Difference Between Surface Element, PlatejlolhnpОценок пока нет

- R.46 X2 CLASS METALLIZED POLYPROPYLENE FILM CAPACITOR TECHNICAL DATAДокумент2 страницыR.46 X2 CLASS METALLIZED POLYPROPYLENE FILM CAPACITOR TECHNICAL DATAวรพงษ์ กอชัชวาลОценок пока нет

- RT809F TutorialLlogic Board Gamma Chip BUF16821Документ7 страницRT809F TutorialLlogic Board Gamma Chip BUF16821Sk WongОценок пока нет

- CEL Single Section Digital Axle Counter Installation GuideДокумент13 страницCEL Single Section Digital Axle Counter Installation Guidesuraj srivastavОценок пока нет

- 3406 Engine TroubleshootingДокумент3 страницы3406 Engine TroubleshootingB E BalaramenterpriseОценок пока нет

- D0000083Документ16 страницD0000083tinduongОценок пока нет

- 2004 Infiniti G35 Coupe Quick Reference SpecsДокумент17 страниц2004 Infiniti G35 Coupe Quick Reference Specsnikkon1100% (2)

- 2007 V70 V70R XC70 XC90 Wiring DiagramДокумент337 страниц2007 V70 V70R XC70 XC90 Wiring DiagramRoger SegoОценок пока нет

- Classification and Processes of ComputersДокумент5 страницClassification and Processes of Computerspolaris1543Оценок пока нет

- Panasonic TX32A400 Service ManualДокумент27 страницPanasonic TX32A400 Service ManualJan Kowalski100% (1)

- Premium Maintenance Plan Brochure v202210Документ2 страницыPremium Maintenance Plan Brochure v202210vashen.moodleyОценок пока нет

- SUB-EN-Mini Split-Inverter-50-60Hz-4MYW2312A9Документ2 страницыSUB-EN-Mini Split-Inverter-50-60Hz-4MYW2312A9JordyLópezBenavidesОценок пока нет

- Lock-O-Ring FlangeДокумент6 страницLock-O-Ring FlangeAm EОценок пока нет

- Basic Computer TermsДокумент4 страницыBasic Computer TermsDharma LingamОценок пока нет

- Gujarat Technological University: 1 of 3 W.E.F. AY 2018-19Документ3 страницыGujarat Technological University: 1 of 3 W.E.F. AY 2018-19gecg ICОценок пока нет

- Illustrated Assembly Manual k4306 PDFДокумент16 страницIllustrated Assembly Manual k4306 PDFcicero220358Оценок пока нет

- VLSI BasicsДокумент3 страницыVLSI BasicsAlok YadavОценок пока нет

- GA-H61M-S2PV Motherboard DiagramДокумент33 страницыGA-H61M-S2PV Motherboard DiagramDouble HelixОценок пока нет

- Dura Products Product-Catalogue PDFДокумент306 страницDura Products Product-Catalogue PDFMahmoud MorsiОценок пока нет

- Arctic Cat 2001 ATVs All Models Service Manual PDFДокумент430 страницArctic Cat 2001 ATVs All Models Service Manual PDFWheelz Mitchell100% (1)

- Transformadores PDFДокумент1 страницаTransformadores PDFAlex RamirezОценок пока нет

- MC024-120 and 122 - Data SheetДокумент2 страницыMC024-120 and 122 - Data SheetRomain CAFFOОценок пока нет

- Controls: Valve Actuation &Документ4 страницыControls: Valve Actuation &Tg TarroОценок пока нет

- brz15d4 Installation InstructionsДокумент8 страницbrz15d4 Installation InstructionsPaul BowerОценок пока нет

- Lift ReportДокумент16 страницLift ReportAisha Abdullahi MuhammadОценок пока нет

- Motor StepperДокумент4 страницыMotor Stepperfavour ukpai100% (1)

- IM-250 SP User GuideДокумент27 страницIM-250 SP User GuideLuis Antonio Hernandez CastroОценок пока нет

- Troubleshooting Guide: Inteligen, Intelisys, Intelimains Modular ControllerДокумент44 страницыTroubleshooting Guide: Inteligen, Intelisys, Intelimains Modular ControllerTamОценок пока нет

- Imac Intel 21.5" Emc 2308 Led Driver Board Replacement: Escrito Por: Andrew BookholtДокумент7 страницImac Intel 21.5" Emc 2308 Led Driver Board Replacement: Escrito Por: Andrew BookholtReinaldo Ortega100% (1)

- Sample Paper Class 3 Unicus Cyber Olympiad (2020-21Документ4 страницыSample Paper Class 3 Unicus Cyber Olympiad (2020-21Shashi Bhushan Singh GMPe 2020 B4Оценок пока нет

- Instruction Manual - Series 200 Remote Meter Panels 500 PPD (10 KG/H) Maximum CapacityДокумент14 страницInstruction Manual - Series 200 Remote Meter Panels 500 PPD (10 KG/H) Maximum CapacityJorge RiverosОценок пока нет