Академический Документы

Профессиональный Документы

Культура Документы

How To Succeed in Medical Machining - 47

Загружено:

Pham LongОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

How To Succeed in Medical Machining - 47

Загружено:

Pham LongАвторское право:

Доступные форматы

medical manufacturing

A supply chain primer

Multitasking machine executing complex

five-axis machining operation.

How to Succeed in

Medical Machining

Iulian Trifan

FANUC America

here is still demand today for medical devices gener-

providing competitive pricing for surgical instruments, spinal/

ated by aging baby boomers and their desire to

trauma implants and orthopedic devices. So, reliability and

enjoy a sustainable quality of life for a longer period

highly efficient machining processes for high-performance

of time. That being said, reality is that the medical device

machining are paramount to achieving the lowest total cost

manufacturing industry has seen significant layoffs over

of ownership and thereby success in machining these medi-

the last few years due to cost pressure, increased regula-

cal devices. Other process improvements to consider are

tory and public scrutiny, costly recalls and the demands of

integrated manufacturing technologies, intelligent robotic

globalization. Cost-cutting initiatives in the healthcare sector

machine-tending automation and a pre-engineered integrated

have put significant pressure on prices. Original Equipment

automation solution.

Manufacturers (OEMs) are moving more of their compo-

High-Performance Machining

nent manufacturing out to contract manufacturing suppli-

In order to achieve maximum machine tool performance,

ers while focusing their time and resources on enhancing

you have to find the optimum balance between speed (mate-

innovation and bringing new products faster to market.

rial removal rate), accuracy and surface finish based on the

This opens up opportunities for contract manufactur-

individual machine tool characteristics. Additionally, quite

ing companies to become a bigger partner to the OEMs by

often the size and features of parts that are machined on

medical manufacturing

the same piece of equipment present significant differences

based on highly customized production orders. So, it is necessary to optimize the process based on individual machine

tool characteristics as well as size and features of the part

family to be machined. Todays innovative CNCs feature an

Finding ways to reduce costs

when machining intricate

shapes and exotic materials

is not an easy task.

extensive suite of advanced path and acceleration optimization functions with on-screen guidance to select the set of

parameter values best suited for the machining conditions to

reduce cycle time with enhanced part accuracy and surface

finish. Powerful integrated and advanced 3D servo and machine optimization tools aligned with expert services can finetune machine performance for a specific part or part family,

even for the most complex medical machining applications.

Finding ways to reduce costs when machining intricate

shapes and exotic materials is not an easy task. The most effective way to achieve this goal is by using advanced features

in the CNC that allow reaching the final shape and surface

finish during the machining process and eliminate or at least

reduce the need for postprocessing secondary operations

such as grinding, deburring and polishing.

Only the most innovative CNCs and drive systems

execute the programmed path at a nanometer resolution for

the maximum precision and smoothest contoured surface

finish. Advanced control systems are designed to simplify

complex, high-performance five-axis machining applications by using advanced CNC functions that are essential

to achieving the high quality standards that medical device

manufacturing demands:

AI Contour Control function looks ahead (up to 1000 blocks)

in the part program to eliminate the acc/dec and servo delays

that limit feed rates when cutting short line segments or

contours and effectively eliminates path errors in corners and

small radii.

Jerk Control function can be used to effectively suppress

vibration and machine shock in part program sections in

which acceleration changes abruptly, such as where the cutting path changes from straight line to curve, thus reducing

associated machining errors.

Smart Overlap function helps reduce cycle time by allowing

overlapping of cutting feed rates and rapid traverse program

blocks within a programmable permitted toolpath deviation

range which can be easily confirmed using the CNC automatic calculation screen.

Nano Smoothing with spline interpolation recreates the shape

in the 3D CAD model from line segment approximations. The

five-axis CAD/CAM/CNC process chain is simplified by creating part programs that describe part geometry in workpiece

coordinate systems. This in turn simplifies the CAM and

postprocessor as well as allows for machine, tooling and

setup data to be provided at the machine, similar to typical

three-axis workflow.

High-Speed Smooth TCP function provides Tool Center

Point Control (TCP) to allow part geometry programming

independent of the machine kinematics and ensures that the

tool tip follows the programmed toolpath precisely and at the

programmed feed rate. To help maintain the accuracy of the

five-axis machining center, an automatic cycle for measurement and compensation of inclined angular error of rotary

axis is now available in todays most modern CNCs, making

3D rotary error compensation easier and faster.

Integrated Manufacturing Technologies

An additional process improvement worth investigating to

significantly reduce cycle time and produce more accurate

medical parts is multiaxis machining operations in a single

setup. Machine designs for five- and six-sided machining

operations have blurred the line between milling and turning.

In recent years there has been a flurry of activities around integrating multiple manufacturing technologies such as traditional

metalcutting (milling, turning, grinding) with laser machining

and additive manufacturing into a single machine tool platform.

Advanced and versatile CNCs provide high-performance,

multiaxis, multipath nano technology in a flexible and scalable

CNC platform. This is ideal for high-speed, highly accurate

complex medical part manufacturing by seamlessly combining

milling, turning, laser machining and cladding in a single part

program. This in turn reduces the number of machines and

operators required to manufacture the final medical part which

decreases cycle times and reduces costs.

Intelligent Robotic Machine Tending Automation

Robots can increase machine production by up to 20%

over traditional methods while allowing for greater flexibility

to accommodate for small batch production. However, quite

often when we talk about automation in a machining department, the first thing that comes to mind is a generic robot

loading and unloading parts into a machine tool. But todays

intelligent robots in conjunction with highly sophisticated

CNCs can do so much more. Servo doors can be incorporated

on the machine to allow high-speed synchronization with the

CNC to allow faster part load/unload. Intelligent vision systems

medical manufacturing

can be used for part confir-

ity. Simplified machin-

mation or 2D barcodes can

ing system architecture

be read for part identifi-

reduces start-up time and

cation to ensure that the

system engineering costs

correct part program is

for machine tool builders to

executed on the machine

integrate CNCs and robots

tool. Both 2D and 3D vision

with a cell controller. Pro-

systems can be used for

cess and machine condition

picking randomly placed

data is easily transferred

parts from a bin, flexible

to enterprise IT systems

feeding device, trays/pal-

enabling better decision

lets, or a moving con-

making and cost reduction.

veyor to take advantage

EtherNet/IP is an example

of noncutting cycle time,

of a network that can be

minimize expensive fixtures

utilized to connect the cell

controller to CNCs, robots

and allow for untended

operation. These systems

can be used to identify

FANUC/Rockwell Automation integrated machining cell

architecture with EtherNet/IP.

and other devices. An

integrated solution is ideal

for an automated machin-

and track parts as they are

fed into the machine tool and unloaded for the next operation,

ing cell comprised of one or several CNCs cutting parts, and

and this information can be provided for SPC data collection.

robots handling part load/unload, coolant and chip removal

Additionally, while the machines are cutting, the robot can be

systems, deburring and washing machines, part marking

utilized for other processes such as material removal, gaging,

and identification, inspection stations, and more. Common

inspections, part cleaning, and assembly.

connectivity to EtherNet/IP simplifies system engineering and

A standard interface between a robot and any machine

tool significantly reduces the integration time and cost.

maintenance significantly.

Lowest Total Cost of Ownership

Robots and multiple CNCs can be easily connected over Eth-

The first and most critical step to succeed in machining

ernet, I/O Link, and FL Net using the Machine Tool and Robot

the highest quality medical parts at the lowest total cost of

Connection functions. Robot operation and monitoring can

ownership is with a CNC system that is reliable, efficient and

be performed through one of the integrated or custom CNC

innovative. Specifically, a CNC system that has nanometer

screens in an automated cell without entering the safety zone

resolution throughout the system achieves superior precision

of the robot. Conversely, screens on the robot teach pendant

and surface finish quality. Advanced innovative CNC technol-

can be used for complete CNC and robot system operation

ogies assure the fastest cycle times without sacrificing quality,

when the CNC control panel is located inside the robot. This

lowering the cost per part and increasing machining capacity

allows for a more efficient use of floor space as one opera-

to avoid the need to add equipment or increase overhead.

tor can run multiple machines/cells while reducing part setup

Select CNCs that have the features necessary to support the

time and increasing flexibility.

most efficient CAD/CAM/machine workflows for five-axis and

Pre-Engineered Integrated Automation Solution

complex medical machining applications. To support even

In todays complex regulatory and highly competitive

more advanced process automation, CNCs need to support

medical market environment, it is critical to have a coordinat-

Ethernet connectivity to manufacturing and business net-

ed manufacturing system and the supporting infrastructure to

works for process monitoring and validation, and robots for

keep the workflow organized, efficient and documented. To

cellular automation. Additionally, look for a CNC system with

address the market challenges, a pre-engineered integrated

the highest Mean Time Between Failure (MTBF) in the industry

automated solution for medical device manufacturing is

coupled with lifetime maintenance which will ensure the

available. This integrates CNCs and robots to cell control-

lowest total cost of ownership. In the end, a CNC manufac-

lers to provide cost efficiencies, better part quality, usable

turer that supports their CNC for its entire production life will

manufacturing intelligence and overall increased productiv-

increase ROI for medical device manufacturing companies.

ENGINEERING

MARCH 2015

Copyright Notice: 2015 Copyright by SME. All rights retained. User may not save

any text or graphical items to hard drives or duplicate this article in whole

or in part in any medium This USAGE with permission from Manufacturing

Engineering, the official publication of SME. www.sme.org.

Вам также может понравиться

- Renishaw Ballbar LaserДокумент21 страницаRenishaw Ballbar LaserPham LongОценок пока нет

- Mitsubishi Manual Fx5-40ssc AdvancedДокумент598 страницMitsubishi Manual Fx5-40ssc AdvancedPham LongОценок пока нет

- Yuasa International: Full 4 Axis vs. Programmable Indexer?Документ4 страницыYuasa International: Full 4 Axis vs. Programmable Indexer?Pham LongОценок пока нет

- H PulseДокумент18 страницH PulsePham LongОценок пока нет

- CNC Advanced ConceptsДокумент100 страницCNC Advanced ConceptsPham LongОценок пока нет

- NSK CAT E1102m B234-243Документ5 страницNSK CAT E1102m B234-243LeandroОценок пока нет

- NSK CAT E1102m B234-243Документ5 страницNSK CAT E1102m B234-243LeandroОценок пока нет

- H PulseДокумент18 страницH PulsePham LongОценок пока нет

- NSK CAT E1102m B234-243Документ5 страницNSK CAT E1102m B234-243LeandroОценок пока нет

- TM A1000sw 063Документ36 страницTM A1000sw 063Pham LongОценок пока нет

- Handle PulseДокумент17 страницHandle PulsePham LongОценок пока нет

- Micro Smart ManualДокумент455 страницMicro Smart ManualDaniel HilariОценок пока нет

- Delta Ispsoft M en 20130118Документ617 страницDelta Ispsoft M en 20130118Daniel Iurck VosgerauОценок пока нет

- G Code List OkumaДокумент10 страницG Code List OkumaPham Long50% (2)

- NextMove Input and Output CircuitДокумент2 страницыNextMove Input and Output CircuitPham LongОценок пока нет

- SU-matic Instruction ManualДокумент12 страницSU-matic Instruction ManualPham LongОценок пока нет

- GT User Manual Revision 1.10Документ66 страницGT User Manual Revision 1.10Pham LongОценок пока нет

- Radioactive PrincipleДокумент17 страницRadioactive PrincipleHenry LingОценок пока нет

- Tny267pn PDFДокумент24 страницыTny267pn PDFPham LongОценок пока нет

- NX 10 For Engineering Design PDFДокумент207 страницNX 10 For Engineering Design PDFAnonymous EVAzqFeburОценок пока нет

- UE-42-09-fiber Optic Catalog Med PDFДокумент40 страницUE-42-09-fiber Optic Catalog Med PDFPham LongОценок пока нет

- Parallel Port Interfacing Inpout32 DLL Source Code and TheoryДокумент2 страницыParallel Port Interfacing Inpout32 DLL Source Code and TheoryPham LongОценок пока нет

- Manual For USB To 9 Pin RS 232 Serial Adaptor PDFДокумент20 страницManual For USB To 9 Pin RS 232 Serial Adaptor PDFPham LongОценок пока нет

- Analog Drive Configuration and Setup NotesДокумент3 страницыAnalog Drive Configuration and Setup NotesPham LongОценок пока нет

- A F700 PID ControlДокумент8 страницA F700 PID ControlPham LongОценок пока нет

- CH 17 SCR IGBTДокумент14 страницCH 17 SCR IGBTPham LongОценок пока нет

- Rs 232 For Ka CounterДокумент4 страницыRs 232 For Ka CounterPham LongОценок пока нет

- 7mbp75ra060 PDFДокумент8 страниц7mbp75ra060 PDFPham LongОценок пока нет

- 6sn1145 1aa01 0aa2 ManualДокумент485 страниц6sn1145 1aa01 0aa2 ManualjohnysonycumОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Strategic ManagementДокумент33 страницыStrategic Managementwahyu munawanОценок пока нет

- Waste in Paper ProductionДокумент10 страницWaste in Paper Productiongo2_sumitОценок пока нет

- Reverse LogisticsДокумент28 страницReverse LogisticsJc LC0% (1)

- CAT Ground Engaging ToolsДокумент35 страницCAT Ground Engaging ToolsJimmy Nuñez VarasОценок пока нет

- Epocem PrimerДокумент2 страницыEpocem PrimerAnonymous v1blzDsEWAОценок пока нет

- The Birth of SwatchДокумент4 страницыThe Birth of SwatchanujdeshmukhОценок пока нет

- Grungeboard Surfaces: by Sue BleiweissДокумент2 страницыGrungeboard Surfaces: by Sue BleiweissLogan MckeeОценок пока нет

- BS 4346 - 3Документ13 страницBS 4346 - 3Ronnie1478Оценок пока нет

- Compressive Strength of Concret by Fly AshДокумент16 страницCompressive Strength of Concret by Fly AsheranjanishuklaОценок пока нет

- Hoist Yale 360Документ10 страницHoist Yale 360Vitor OlivettiОценок пока нет

- 2015 Foster HVAC Selection GuideДокумент2 страницы2015 Foster HVAC Selection Guidesiva_nagesh_2Оценок пока нет

- Case example: Inventory control system automates trading company operationsДокумент2 страницыCase example: Inventory control system automates trading company operationslekhanh_y2kОценок пока нет

- What Is Stainless Steel EN PDFДокумент0 страницWhat Is Stainless Steel EN PDFsssf-dobojОценок пока нет

- Carbon Dioxide Enhanced Oil Recovery Injection Operations TechnologiesДокумент8 страницCarbon Dioxide Enhanced Oil Recovery Injection Operations TechnologiesSaeid RajabiОценок пока нет

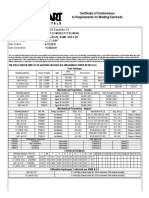

- Certificado de Cumplimiento Alambre 0.062Документ2 страницыCertificado de Cumplimiento Alambre 0.062gizaloОценок пока нет

- 2.2.3.1 Buildex® Screw Fasteners: 2.2.3.1.1 Fastener Assembly and DesignationДокумент11 страниц2.2.3.1 Buildex® Screw Fasteners: 2.2.3.1.1 Fastener Assembly and DesignationJoseph BookerОценок пока нет

- Types of Extrusion and Extrusion Equipment: NPTEL - Mechanical Engineering - FormingДокумент8 страницTypes of Extrusion and Extrusion Equipment: NPTEL - Mechanical Engineering - FormingtechopelessОценок пока нет

- Quality Risk Management PharmДокумент9 страницQuality Risk Management Pharmagarciah15891Оценок пока нет

- Early international trade routes using camels and donkeysДокумент6 страницEarly international trade routes using camels and donkeysGian Paul JavierОценок пока нет

- A Presentation On Inventory ManagementДокумент24 страницыA Presentation On Inventory ManagementHari RittiОценок пока нет

- Seminar On " ": Pre Engineered BuildingsДокумент27 страницSeminar On " ": Pre Engineered BuildingsPrasad NbОценок пока нет

- PEST Analysis Ceramics Industry in PakistanДокумент2 страницыPEST Analysis Ceramics Industry in PakistanabubakarОценок пока нет

- 5S & Visual Factory - SampleДокумент9 страниц5S & Visual Factory - SamplecomyahoothanhОценок пока нет

- Automotive Materials Course OverviewДокумент6 страницAutomotive Materials Course OverviewKonathala SwamiОценок пока нет

- CastingДокумент10 страницCastingAkshay GargОценок пока нет

- ASTM Grades PDFДокумент0 страницASTM Grades PDFRaj KamalОценок пока нет

- Operations Management: Facility LayoutДокумент54 страницыOperations Management: Facility LayoutSunnyОценок пока нет

- LIGHT WEIGHT CONCRETE MIXДокумент14 страницLIGHT WEIGHT CONCRETE MIXkaran9027100% (1)

- Pickling and Passivating of Stainless SteelДокумент4 страницыPickling and Passivating of Stainless SteelSds Mani SОценок пока нет

- AbrasivesДокумент49 страницAbrasivesfockewulОценок пока нет