Академический Документы

Профессиональный Документы

Культура Документы

Dsi Report

Загружено:

MariusАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Dsi Report

Загружено:

MariusАвторское право:

Доступные форматы

DEPARTMENT OF WATER AFFAIRS

DW 149E

FORM FOR THE DAM SAFETY EVALUATION AND INSPECTION REPORT OF A SMALL

DAM

Name of dam:

Stormwater Dam 1____________________________________

Departmental file reference for dam: 12/2/X201-92______________________________________

Name of Approved Professional Person:

Marius Kolesky_________________________________

Name of Owner: Assmang Chrome____________

________________________________

Address of Owner: P.O. Box 152, Machadodorp 1170____________________________

Email: jonathanc@assmangchrome.co.za_______________________ Tel: 013 256 5137___

Notes: (i)

(ii)

(iii)

(iv)

(v)

Sections 1 to 8 should be completed prior to the dam safety inspection. Delete any

sections not applicable to the particular dam and insert extra lines where needed.

Survey instruments (at least a level and tape) should be taken along to survey the

relative heights of the non overspill crest, spillway crest, and embankment slopes.

Additional information may be included in annexures.

For a detailed checklist of the requirements for the dam safety evaluation of a Category

1, 2 or 3 dam, refer to Regulation 34 to 36 in the new dam safety regulations in

Government Notice No R. 139 of 24 February 2012.

Please also make the report available in electronic format.

SECTION 1: AVAILABLE INFORMATION

List all plans and reports that are available on the dam and which have been studied for the dam safety

inspection. Please enclose copies of plans with typical details. If no such plans exist, sketches must be

made. A copy of a 1:50 000 map showing the location must also be supplied. Photographs taken

during the inspection should also be enclosed and referred to in the report.

The 2010 Inspection Report refers to some drawings which were not available for this

evaluation but this is not considered a problem, with the Dam being rather straight forward.

SECTION 2: DESCRIPTION OF THE DAM

Wall type: Earth fill____________________

Wall height (maximum): 8 m_____________

Storage capacity: 99 670__m__________ Completion date: 2004________________

Crest length: 415 m__________

Contractor: Unknown______

__

____

Crest width: 3m______________________

Designer: Kwezi V3 Engineers______

Betterment works done after completion: None_____________________________________

Problems which occurred previously: Sedimentation of dam below the northern inlet canals, also

resulting in damage to the plastic liner at that point. This occurred before the 2010 inspection.

SECTION 3: GEOLOGY OF DAM SITE

General details (Rock types, quality, weathering, joint spacing, joint openings, joint filling, shear

zones)

Deeply weathered fine-grained shale and mudstone overlain by clayey silty sand with abundant fine to

coarse shale gravel.

Geological conditions and actual or potential problems such as sliding resistance, settlement,

seepage, erodability.

Left flank: Geological conditions as described above. No problems foreseen.

Right flank: As on left flank.

River section: Not applicable, off-channel

Spillway channel: No spillway at the moment. It will however be proposed that a spillway be

provided on right bank, just below the feeder canal from the west. This area is well grassed and

suitable for the purpose

Are the slopes around the dam basin stable? Yes

SECTION 4: DESCRIPTION OF DAM WALL MATERIAL

Dam was constructed through a cut and fill operation, with the material as described above being used

for embankment fill.

SECTION 5: CHECKING OF REGISTRATION INFORMATION

A computer printout of the registration information of the dam is available from the Dam Safety

Office. Please check whether all information is correct and complete. If there are any changes, please

indicate them on the computer printout and send it back with the report. Information corrected?

Yes, or No?

No

SECTION 6: EVALUATION OF THE HAZARD POTENTIAL

Any downstream development since the last dam safety inspection report? No____

Estimate of potential loss of life: 0

Estimate of potential economic loss: R 10 million_

Hazard potential rating as classified: Significant

Do you agree with the classification? Yes

If not, please apply for reclassification on the DW692E form.

SECTION 7: FLOOD ESTIMATES

Catchment area (km2): 0,6

Mean Annual Precipitation (mm): 800

Methods used for flood estimates: Rational Method. The catchment area is too small to use TR137

with any confidence at all

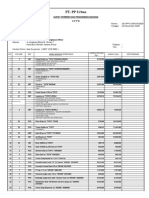

Flood estimates

1:20 (m3/s):

1:50 (m3/s):

1:100 (m3/s):

1:200 (m3/s):

6___

9__

12__

16__

Regional maximum flood (m3/s):

26__

Probable maximum flood (m3/s):

50__

Recommended design flood (m3/s): 12__

Safety evaluation flood (m3/s):

16 (1:200 year event) __

Motivation for choice of recommended design flood and safety evaluation flood (which guidelines

were used): SANCOLD Report No 4: Safety in Relation to Floods.

SECTION 8: EVALUATION OF SPILLWAY CAPACITY

Spillway type: No Spillway.

Spillway length: Not Applicable_ Critical spillway width: Not Applicable

Non overspill level: 1613,25

Full Supply Level or spillway level (m): 1612, 45(proposed)

Height of lowest point on non-overflow crest above spillway (m): 0,8

Spillway capacity with no freeboard (m3/s): Not Applicable

Will the incoming flood be significantly reduced by flood absorption? Yes.

Available freeboard during recommended design flood (m): Not Applicable

Will the dam fail if the non-overflow crest is overtopped? Yes, although the outside slope is quite

flat and well grassed, which may retard erosion. However, one of the pylons carrying the overhead

Eskom line, is positioned inside the downstream slope of the embankment, causing steeper slopes

around it. This may be a weak point, should overtopping occur. See photos 1 and 2.

What erosion could be expected during the recommended design flood? If a spillway is not

provided, the downstream slope may erode, particularly around the above pylon. Failure of the

embankment is possible.

And during the safety evaluation flood? Again, if no spillway is provided, erosion is certain and

failure quite likely.

Final evaluation of spillway capacity: The dams need to be provided with a spillway. A suitable

position is probably on the western side, just below the concrete canal that delivers dirty water from

that side to the dam.

SECTION 9: INSPECTION OF THE DAM

Date: 29 April 2016

Water level in dam: 2,5 m below crest

Did it rain recently? No

Describe: Not Applicable

Persons present at inspection: Jonathan Chunda, Willie Coetzee from AssMang Chrome, Marius

Kolesky(APP) and Mfundo Dlamini from the IUCMA.

EARTH WALLS

CREST OF EARTH WALLS

Crest width (m): 3

Has the crest width changed since construction? No____________

Is the crest still level or has settlement occurred? Impressively level, a line of levels was running

along the crest and it was shown to the very level, as indicated in the attached Appendix 2: Crest Long

Section. See photos 3,4 and 5

Are there signs of erosion? No_____________

Describe: -______________________________

Are there signs of cracks? No______________

Describe) -__

Is maintenance necessary on the crest? No

Are there signs of holes (ants, rats, Meercats, moles, crabs, etc.?) No__ Describe: -____________

UPSTREAM FACE OF EARTH WALLS

Slope (vertical: horizontal): 1:2,5

Slope protection measures (if any): Plastic lining.

Are there signs of erosion? _No________________

Describe: -________________________

Are there signs of cracks? No________________

Describe: The plastic lining has

developed tears and punctures over the years, generally having been repaired as is evidenced by the

number of repairs but also unrepaired tears/punctures. See photos number 6,7,8 and 9. Photo 9 shows a

very recent repair, but there are of course some others that should have been done at the same time.

Clearly the large tear at the sediment deposition is a special case and needs special attention. It is also

possible that some of the repairs may have separated over time and is recommended that all repairs

above water be inspected to ensure they are still competent. ________________________

Are there signs of settlement? No_____________

Describe: -_______________________

DOWNSTREAM FACE OF EARTH WALLS

Slope (vertical: horizontal): 1:4 to 1:5.

______________________________

Slope protection measures (if any): Well grassed.

Are there signs of erosion? No_________________

Describe: -_______________________

Are there signs of cracks? No__________________

Describe: -________________________

Are there signs of settlement? No__________________ Describe: -________________________

Are there signs of bulging/sliding? No__________________________________________________

Are there wet patches? No____________________

Describe: -_________________________

Are there signs of seepage/leaks? No____________

Describe: -________________________

Amount of leakage? N/A_____________________________________________________________

Is the leaking water clear or turbid? N/A_______________________________________________

Are there signs of holes (ants, rats, meercats, moles, crabs, etc.)? No____

Describe: -______

VEGETATION ON EARTH WALLS

Are there any trees or shrubs on the wall? No.

If so describe type, size, number and position: N/A

DRAINAGE SYSTEM IN EARTH WALL

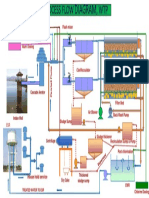

Has a toe drain or internal drainage systems been provided? There is a drainage system below the

plastic lining which also serves as leak detection. Any leakage water is piped to a sump below the dam.

See photo 10.

Describe: Leakage water that reaches the sump is pumped back into the dam as it is polluted water.

_____________________________________________________________________

Amount of leakage (m3/s)? It is not possible to measure the leakage water inside the sump, but one

can clearly hear the dripping. It is suggested that the possibility of this leakage flow being measured,

should be investigated. If possible, the flow should be monitored to be aware of sudden variations.

_______________________________________________________

Is the water from the drains clear or turbid? The water appears clear.

DOWNSTREAM TOE AND FLANKS OF ANY DAM

Describe wet patches (position, size): None

Seepage/leaks (position, flow rate): None

Is the leakage water turbid /clear? None _______________________________________________

Are there trees within 5 meter of the dam wall? No____________________________________

Describe: -____________________________________

FLOOD OUTLETS (OF ANY DAM) / RETURN CHANNELS / TRAINING WALLS

Condition of structures in spillway channel (sills, retaining walls etc.) The dam does not have a

spillway and it is recommended that one be provided on the upper western side. The spillway can be

cut through the embankment just below the concrete canal discharge position. The plastic lining can be

extended through the spillway, up to where spillage is released down the well grassed slope.

Is the stability of the dam wall threatened by the spillway channel? N/A_______

Is there loose material in the spillway channel? N/A _______

Describe: -_______

Is there any erosion in the spillway channel? N/A ________

Describe: See above

Is there any erosion in the river? N/A ___________________

dam, a long distance from the nearest river.

Describe: This is an off-channel

Are the spillway length and freeboard still as shown on the drawings? N/A

STILLING BASINS / APRON

When was the stilling basin last emptied and inspected for scouring? N/A

Observations and Evaluation.

OUTLET WORKS (OF ANY DAM)

Number of outlet pipes: 2_______ Diameter: 200 mm_________

Type: Steel_________

Condition of outlet pipe foundation: The areas in the vicinity of the two pipes are completely dry, it

does not appear as if the outlet pipes are in any distress at all.

Is the control upstream or downstream? Downstream only_

Is there provision for an upstream emergency valve? No_

Are the valves used regularly? Yes

Are the valves in working condition?

Yes

Are there leaks alongside the outlet pipe? No

Any erosion downstream of the outlet works

No

Rust protection? Still in reasonable condition. _

Other observations: The 2 outlet pipes abstract from different levels inside the dam. The one shown

on photo 10 is at lowest level and can empty the dam. The other pipe takes off at a higher level and

serves the treatment works below the dam, not in use anymore. See photo 11

SECTION 10: EVALUATION OF STABILITY OF DAMWALL

The embankment appears perfectly stable.

SECTION 11: EVALUATION OF DRAINAGE SYSTEM

The leak detection system works well and appears to be able to deal with any leakage through the

plastic lining. An effort must be made however to monitor leakage rate, in order to note any

deviations.

SECTION 12: EVALUATION OF THE QUALITY OF OPERATION AND MAINTENANCE

Have the operating personnel been interviewed? Yes. The Assmang Chrome Plant has cut down

drastically on its operations. Water requirements from the dam has therefore reduced and the operation

thereof is affected. This needs to be recognised and allowed for in the Operations and Maintenance

Manual.

_________________________

Have there been any floods since the last dam safety inspection report? Yes

Were the Operation and Maintenance Manual / Emergency Preparedness Plan available; is it

used and up to date? It is available in 2 separate documents. There is one Operation, Maintenance

and Inspection Manual for the 2 dams, while dam failure and flooding are addressed as part of the

companys comprehensive Emergency Response Plan. These documents appear reasonably acceptable,

but they have probably not been approved by the Dam Safety Office. A major shortcoming of the

Operations Manual is the fact that it does not guide the operation in order to adhere to the requirements

of General Notice 704 of 4 June 1999, that stipulates that the dam should be operated at a level that

would prevent spillage during the 1:50 year flood event. A water balance that determines how excess

water is to be dealt with, must be carried out. Particularly now that the plant operations have been

reduced, less water is abstracted and therefore the means by which water level is maintained below the

critical 1:50 year available capacity, that must be spelled out. It is suggested that the Operation and

Maintenance Manual with Emergency Preparedness Plan, be updated (possibly combined) to allow for

the changed Operational Situation, now and into the future. There is a talk that Smelter Operations

may cease completely.

What routine inspection reports, monitoring records or maintenance records was available for

evaluation? There were no records available. __

Is everybody ready to implement the Emergency Plan? Probably not, as smelter operations are at

skeleton staff level.

SECTION 13: POLLUTIONCONTROL DAMS

How is ground water and surface water quality monitored around the dam? Groundwater

monitoring is not taking place.

How many times did the dam spill during the last five years? No spillage occurred.

Will the dam be able to hold a 1:50 year flood without spilling? Yes, if operated at the right level,

which it is not at the moment. There does however not appear to be a coherent plan in place to achieve

this.

Evaluation of the effectiveness of the dam to prevent pollution of ground and surface water

Under normal conditions there does not appear to be a problem, both ground and surface water. Under

extreme flooding, spillage is likely and surface water will be polluted. It is therefore necessary to

relook at the water balance and come up with proposals as to how this should be dealt with. This then

needs to be incorporated into the Operations and Maintenance Manual.

SECTION 14: OTHER FINDINGS

The deposition of sediment below the eastern stormwater canal brought down from the reworked ore

residue, has cause significance damage to the plastic lining at this point. See photo 6. It is likely that

this is still the same stuff, just added to by subsequent storms since the 2010 inspection. To remove this

sediment, means that a large area of plastic lining will have to be sacrificed, to be reinstated

afterwards. This work is now urgently required.

It is however quite clear that runoff from the discard ore dump now being reworked, will continue to

bring down excessive volumes of sediment. See photos 12 and 13. Once the ore has been remined and

the dumps rehabilitated, the situation will improve. It is also clear that the silt trap below this middle

canal is way too small for the sediment being carried down. Alternatively, some protection work must

be carried out at the ore dump to prevent excessive erosion there.

Looking at the silt trap for the eastern canal (Photo 14) it is clear that it is not being cleaned often

enough. It is too full, resulting in high velocity through it, causing only the coarser material to settle

and all fines to be washed into the dam. The visible silt deposition looks very coarse. It is

recommended that these silt traps be cleared more often, preferably a few times after rain in the rainy

season.

SECTION 15: LIST OF APPENDICES

Item

Appendix

Site plan / Locality plan

Recent Surveys as required by Regulation 35 (5)

Selected Design / Completion Drawings

Photos

Spillway discharge curve / table / formula

Area capacity curves / tables

Inflow / Outflow Hydrographs

Instrumentation graphs

Google Earth Dam Layout

Position and Direction of Photos

N Comments

Crest long section

X

X

X

X

SECTION 16: RECOMMENDATIONS OF PREVIOUS DAM SAFETY EVALUATION BY AN

APP

Date of previous evaluation _2010/08/31_____________ Name of APP __Mr G.P Steyn_______

List of previous recommendations and status of implementation.

No. Recommendations

Compile rules to ensure dam water level maintained at

3m or more below crest level.

1

Status

Not Done

Repair tears in HDPE Liner

Done

Repair Rodent Burrows

Done

Remove debris at northern canal inlet

Not Done

Repair/replace gratings covering silt traps in canals

Done

Compile Operation and Maintenance Manual

Done

SECTION 17: RECOMMENDATIONS OF THIS DAM SAFETY EVALUATION

Recommendations for maintenance, regular routine inspections, monitoring, further

investigations, rehabilitation must be included.

No. Recommendations

Perform water balance for current and future scenarios in order to determine dam operational

rules for compliance with the Regulation of Notice 704 of 4 June 1999.The possibility of

1

incorporating the River Dam across the valley in such operating rules, can be considered.

Include the operating rules determined above in the Operation and Maintenance Plan and

submit that with the existing Emergence Response Plan, to the Dam Safety Office for

2

approval.

3

Proceed to construct a spillway for the dam based on the results of the Operational Rules

determined above.

4

Repair all tears and punctures in the dam lines at the same time also inspecting and repairing

as necessary, the existing liner repairs.

5

Remove the sediment deposit below the northern stormwater canal. Afterwards repair/replace

the dam liner over the affected area.

6

Investigate means whereby the sediment ingress into the dam from the northern stormwater

canal can be reduced.

7

The silt traps should be cleaned of sediment more regularly.

8

Investigate means whereby the leakage rake into the drainage system can be measured and

monitored.

___________________________________________________

SIGNATURE (APPROVED PROFESSIONAL PERSON):

______________________

DATE:

Вам также может понравиться

- May 2016 MinutesДокумент7 страницMay 2016 MinutesMariusОценок пока нет

- FrontPage AnnexureAДокумент1 страницаFrontPage AnnexureAMariusОценок пока нет

- Stormwater Dam Photographs Taken During Dam Safety Inspection Date: 29/04/2016Документ7 страницStormwater Dam Photographs Taken During Dam Safety Inspection Date: 29/04/2016MariusОценок пока нет

- Dsi ReportДокумент9 страницDsi ReportMariusОценок пока нет

- Dsi ReportДокумент9 страницDsi ReportMariusОценок пока нет

- Chapter 3 Porous MediaДокумент9 страницChapter 3 Porous MediaMariusОценок пока нет

- Standard RainbowliteДокумент2 страницыStandard RainbowliteMariusОценок пока нет

- Adding A Folder of A Hatch and SymbolsДокумент1 страницаAdding A Folder of A Hatch and SymbolsMariusОценок пока нет

- BTech Timetable Civil Sem1 2016Документ1 страницаBTech Timetable Civil Sem1 2016MariusОценок пока нет

- 1072 MDS MediBonus Benefit Guide 2016 Members March2016Документ32 страницы1072 MDS MediBonus Benefit Guide 2016 Members March2016MariusОценок пока нет

- Explorer LicenseДокумент23 страницыExplorer LicensepingbackОценок пока нет

- Submission Requirement HYD401TДокумент19 страницSubmission Requirement HYD401TMariusОценок пока нет

- Hge 301b-Individual ProjectДокумент1 страницаHge 301b-Individual ProjectMariusОценок пока нет

- Dewatering TechnologiesДокумент31 страницаDewatering TechnologiesChokri ChakiirОценок пока нет

- ACET108 LevellingДокумент4 страницыACET108 LevellingKomputershengalОценок пока нет

- Uni StrutДокумент142 страницыUni StrutlimresОценок пока нет

- Submission Requirement HYD401TДокумент19 страницSubmission Requirement HYD401TMariusОценок пока нет

- ACET108 LevellingДокумент4 страницыACET108 LevellingKomputershengalОценок пока нет

- Hydrology Iv (Hyd401T) - Adapted For Use: Assessment of Individual Contributions To Group ProjectДокумент1 страницаHydrology Iv (Hyd401T) - Adapted For Use: Assessment of Individual Contributions To Group ProjectMariusОценок пока нет

- Stability of Floating BodiesДокумент2 страницыStability of Floating BodiesMarc Dared CagaoanОценок пока нет

- Annexure C Department of LabourДокумент3 страницыAnnexure C Department of LabourMariusОценок пока нет

- OriginalДокумент5 страницOriginalTirupathi RaoОценок пока нет

- BTech Timetable Civil Sem1 2016Документ1 страницаBTech Timetable Civil Sem1 2016MariusОценок пока нет

- Photos of Site Notices June 2013Документ5 страницPhotos of Site Notices June 2013MariusОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Deep Well Submersible Pump - HydraulicsДокумент1 страницаDeep Well Submersible Pump - HydraulicsImran AzizОценок пока нет

- Grey WaterДокумент3 страницыGrey WaternkhiangteОценок пока нет

- National Plumbing Code of The Philippines: Basic PrinciplesДокумент10 страницNational Plumbing Code of The Philippines: Basic PrinciplescorbitecoОценок пока нет

- Assignment 1Документ3 страницыAssignment 1Victor Megong JakiОценок пока нет

- DR Change in Direction Fittings PDFДокумент1 страницаDR Change in Direction Fittings PDFbilal almelegyОценок пока нет

- Apco Check Valve Guide 769 PDFДокумент12 страницApco Check Valve Guide 769 PDFhalder_kalyan9216Оценок пока нет

- List Barang (Material)Документ128 страницList Barang (Material)AdzrA RОценок пока нет

- Hose Fittings Catalogue PDFДокумент20 страницHose Fittings Catalogue PDFSuresh HaldipurОценок пока нет

- Pump Head Calculations Using Darcy-Weisbach FormulaДокумент6 страницPump Head Calculations Using Darcy-Weisbach FormulaHind ZarifОценок пока нет

- BG Q2 MajorHazardsAwareness TeamSheet 6Документ4 страницыBG Q2 MajorHazardsAwareness TeamSheet 6Said SalemОценок пока нет

- Cover+High and DryДокумент12 страницCover+High and DryAlbuquerque JournalОценок пока нет

- Steel Pipe VesselДокумент258 страницSteel Pipe VesselmaubochОценок пока нет

- CLASS 251031: DEP 31.38.01.12-Gen Class 251031, Rev. L Page 1 of 13Документ13 страницCLASS 251031: DEP 31.38.01.12-Gen Class 251031, Rev. L Page 1 of 13SaguesoОценок пока нет

- IV EQR2016 PDFДокумент36 страницIV EQR2016 PDFAnis Najihah100% (1)

- Scour Protection Downstream From Gated Low Head DamsДокумент8 страницScour Protection Downstream From Gated Low Head DamsdjajadjajaОценок пока нет

- Line No. Iso. Sht. Rev. Date Drawing No. Code No. S.O No Client Project SHTДокумент5 страницLine No. Iso. Sht. Rev. Date Drawing No. Code No. S.O No Client Project SHTAgus Umar FaruqОценок пока нет

- Hydro-Test Procedure For HDPE PipelineДокумент14 страницHydro-Test Procedure For HDPE PipelineAhmedОценок пока нет

- Beginners Guide To Septic SystemsДокумент4 страницыBeginners Guide To Septic SystemsBob CОценок пока нет

- Design of Water-Control SystemДокумент13 страницDesign of Water-Control SystemKyle Francis L. ProndaОценок пока нет

- AquaCulture Application Process and Product ChartДокумент1 страницаAquaCulture Application Process and Product ChartBhavya MewadaОценок пока нет

- 22 - Sanitary Toto & GroheДокумент2 страницы22 - Sanitary Toto & GroheYon Galang FebriawanОценок пока нет

- 3 - Spring Water TappingДокумент39 страниц3 - Spring Water Tappingمهندس ابينОценок пока нет

- 1198 01 90 T01 ESP 002 REV C Anexo - 1 - Piping ClassДокумент71 страница1198 01 90 T01 ESP 002 REV C Anexo - 1 - Piping ClassCarlos Perez100% (1)

- CERA Combined Catalogue October 2018Документ103 страницыCERA Combined Catalogue October 2018gautam duttaОценок пока нет

- WTP Process DiagramДокумент1 страницаWTP Process DiagramKumar AbhishekОценок пока нет

- Water ResourcesДокумент28 страницWater ResourcesNarendra Vaidya0% (1)

- Commissioning of LP Dosing System of BoilerДокумент11 страницCommissioning of LP Dosing System of Boilerdeepakkesri26Оценок пока нет

- Cross Drainage Works - 29052016Документ30 страницCross Drainage Works - 29052016Md Raihan Ali100% (1)

- FD-230-A Specification SheetДокумент1 страницаFD-230-A Specification SheetWattsОценок пока нет

- Plano Hidraulico EXCAVADORA 345DДокумент2 страницыPlano Hidraulico EXCAVADORA 345DJaime Basquez Pacco100% (2)