Академический Документы

Профессиональный Документы

Культура Документы

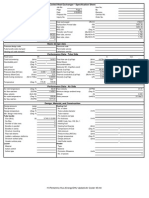

Design Item Design Class Class 1 Class 2 Class 3

Загружено:

Sixto Gerardo Oña AnaguanoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design Item Design Class Class 1 Class 2 Class 3

Загружено:

Sixto Gerardo Oña AnaguanoАвторское право:

Доступные форматы

Design Class Detail

Utilities Heat Transfer Fluids (HTF)

Systems

PROJECT

Date

Capacity

Design

Item

Design Class

Class 1

Class 2

Class 3

Design Heating

Duty

Total design duty + heat

loss of 0.3%

Total design duty + 10%

margin for process

variations +heat loss of

0.5%

Total design duty + 20%

margin for process

variations +heat loss of

2%

Process temperature

approach to HTF

temperature

A. Shell and Tube

HE

15 C (30 F)

10 C (20 F)

10 C (20 F)

Process temperature

approach to HTF

temperature

B. Plate Heat

Exchanger

(Limited to supply

temperature < or =

175 C (345 F))

8 C (15 F)

5 C (10 F)

3 C (5 F)

Design flow,

hydraulics

Design operating flow +

0% hydraulic margin

Design operating flow +

10% hydraulic margin

Design flow + 15%

hydraulic margin

Trim cooler duty

Maximum of

Maximum of

Maximum of

For design with

fired heater

a. Minimum fired heater

duty

b. Minimum trim

cooling duty required

not to exceed MABT

+ 0% margin

a. Minimum fired heater

duty

b. Minimum trim cooling

duty required not to exceed

MABT

+ 10% margin

a. Minimum fired heater

duty

b. Minimum trim cooling

duty required not to

exceed MABT

+ 20% margin

For design with

WHRU

a. Installed w/

bypass

5% of the design duty as

leakage

10% of the design duty as

leakage

20% of the design duty as

leakage

b. installed w/o

bypass

Maximum of the trim

cooling duties for all the

operating cases at the

premised conditions to

maintain supply

temperature temp not

exceeding MABT.

(Heat source process/gas

turbine trip in

emergency)

WHRU heat duty with

60% gas turbine load for

the WHRU in turbine

exhaust with no process

user on line (Emergency

gas turbine load turn down

in the design)

100% WHRU duty at the

premised conditions with

no process users on line.

DEP 00.00.07.94-Gen. September 2011

WHRU heat duty at the

premised conditions

(WHRU in process) less the

Page 1 of

Design Class Detail

Utilities Heat Transfer Fluids (HTF)

Systems

PROJECT

Date

minimum always on line

consumer duty

Expansion vessel

capacity

The expansion volume

of the HTF system

between minimum to

Maximum operating

temperature = volume

between Low to High

level (about 30% of the

vessel volume)

+

0% additional vessel

volume

Storage tank and

spare HTF

inventory

Circulation pumps

sparing

N+1

3x50% pumps

DEP 00.00.07.94-Gen. September 2011

Maximum of

a. The expansion volume of

the HTF system between

minimum to Maximum

operating temperature =

volume between Low to

High level (about 30% of

the vessel volume)

+

20% additional vessel

volume to cater for

operational variations and

stability

Maximum of

a. The expansion volume

of the HTF system

between minimum to

Maximum operating

temperature = volume

between Low to High

level (about 30% of the

vessel volume)

+

30% additional vessel

volume to cater for

operational variations and

stability

Inventory of a single train.

Inventory of a single train

+ 10% margin

N+1

(2x100% pumps)

N+2 pumps

Page 2 of

Design Class Detail

Utilities Heat Transfer Fluids (HTF)

Systems

PROJECT

Date

Operability & Maintainability

Design

Item

Design Class

Class 1

Types of liquid

based Heat transfer

fluid

A.

Supply temperature

of about 120 C

(250 F)

Class 2

Hot water system

Class 3

Refinery process

rundown such as VGO,

Hydrocrcked gasoil,

HCCCO (Heavy Cat

Cracked Cycle oil), LGO

Mineral oils of HTF

quality

( such as Thermia A,

Thermia B)

Hot water system

B.

Maximum supply

temperature ~200

C (390 F)

Refinery process

rundown such as VGO,

Hydrocrcked gasoil,

HCCCO (Heavy Cat

Cracked Cycle oil), LGO

Mineral oils of HTF

quality

( such as Thermia A,

Thermia B)

C.

Supply temperature

> 200 C and < 300

C (> 390 F and <

570 F)

Mineral oils of HTF quality

Thermia A up to 250 C

(480 F)

Thermia B up to 320 C

(605 F)

Synthetic Aromatics

( such as Dowtherm G up

to 370C, Dowtherm A up to

385C, Santotherm VP-1 up

to 385C etc)

D.

Supply temperature

> 300 C and < 400

C

(> 570 F and < 750

F

Supply temperature = 5

C (10 F) below the

manufacturer specified

MABT of the HTF

Expansion vessel

design

Single leg (cold) design

Silicone based synthetic

HTF (such as Syltherm 800

up to 400 C (750 F))

Supply temperature = 10 C

(18 F) below the

manufacturer specified

MABT of the HTF

DEP 00.00.07.94-Gen. September 2011

Double leg (hot, flow

through) design.

Synthetic Aromatics

(such as Dowtherm Q up

to 330 C (625 F),

Dowtherm HT up to 345

C (650 F), Therminlol

66 up to 345 C (650 F),

Dowtherm RP up to 350

C (660 F), Dowtherm G

up to 370 C (700 F),

Dowtherm A up to 385 C

(725 F), Santotherm VP1 up to 385C (725 F),

etc.)

Silicone based synthetic

HTF

( such as Syltherm 800

up to 400 C (750 F))

Supply temperature = 20

C (35 F) below the

manufacturer specified

MABT of the HTF

Not considered.

Page 3 of

Design Class Detail

Utilities Heat Transfer Fluids (HTF)

Systems

PROJECT

Date

Energy Efficiency

Design

Item

Heat duty source

Design Class

Class 1

Class 2

No waste heat recovery

100% duty from furnace

At least 50% of heat duty is

sourced from waste heat

recovery or gas turbine

exhaust if available.

DEP 00.00.07.94-Gen. September 2011

Class 3

100% of the heat is

sourced from waste heat

recovery or gas turbine

exhaust if available.

Page 4 of

Вам также может понравиться

- Essential design parameters and components of fired heatersДокумент38 страницEssential design parameters and components of fired heatersSong Hoe100% (2)

- Design Item Design Class Class 1 Class 2 Class 3Документ4 страницыDesign Item Design Class Class 1 Class 2 Class 3Ignatios StaboulisОценок пока нет

- Basic Refinery Equipment - Heat Exchanger (E003/1)Документ27 страницBasic Refinery Equipment - Heat Exchanger (E003/1)ebsmsart100% (1)

- TEWI AnalysisДокумент63 страницыTEWI Analysismirali74Оценок пока нет

- Bitzer - 4GE-30-40P X 2comp - (1'C) - r407c - 070917 PDFДокумент7 страницBitzer - 4GE-30-40P X 2comp - (1'C) - r407c - 070917 PDFAgus CahyonoОценок пока нет

- Recuperator de Caldura Eco V DX Coil - PliantДокумент58 страницRecuperator de Caldura Eco V DX Coil - PliantDana LoreОценок пока нет

- Hen 4TC2Документ195 страницHen 4TC2jaywan91Оценок пока нет

- METAL COIL SIZINGДокумент2 страницыMETAL COIL SIZINGagrocel_bhv5591Оценок пока нет

- Technical Data Manual: Vitocell 300-H EHA SeriesДокумент16 страницTechnical Data Manual: Vitocell 300-H EHA SeriesLaith MahmoudОценок пока нет

- Obtencion de AcetonaДокумент7 страницObtencion de AcetonaLiz Laureano RodriguezОценок пока нет

- VU 40 Bi-drum Boiler SpecificationДокумент27 страницVU 40 Bi-drum Boiler SpecificationNatarajan AОценок пока нет

- 115 AllДокумент8 страниц115 Alljob_openings4094Оценок пока нет

- Armstrong Plate and FramesДокумент6 страницArmstrong Plate and FramesbenОценок пока нет

- Engine Room Ventilation - Calculation PDFДокумент2 страницыEngine Room Ventilation - Calculation PDFSarawut Jae100% (1)

- MINIMIZING ATMOSPHERIC EMISSIONS IN HYDROCARBON PROCESSING WITH HIGH-EFFICIENCY HEAT EXCHANGERSДокумент17 страницMINIMIZING ATMOSPHERIC EMISSIONS IN HYDROCARBON PROCESSING WITH HIGH-EFFICIENCY HEAT EXCHANGERSJaishree ChauhanОценок пока нет

- Process Design ConditionsДокумент8 страницProcess Design ConditionsGerald RahanraОценок пока нет

- 6JE-25; R507A; t0 -35; tc 45Документ4 страницы6JE-25; R507A; t0 -35; tc 45FERNANDO RECALDEОценок пока нет

- 20V4000L32 - 93800050099 - en - GB - MZ80 - 2Документ2 страницы20V4000L32 - 93800050099 - en - GB - MZ80 - 2hadi0% (2)

- Air-to-Water Heat Pump (50Hz, R410A) 5BPM0-01C (Replace:5BPM0-01B)Документ73 страницыAir-to-Water Heat Pump (50Hz, R410A) 5BPM0-01C (Replace:5BPM0-01B)CallGRОценок пока нет

- High-temperature heat pumps for industrial processesДокумент6 страницHigh-temperature heat pumps for industrial processesMark ChongОценок пока нет

- LNG RegasificationДокумент16 страницLNG RegasificationCal100% (1)

- Product - Info C 3 UCF B High Temperature Laboratory Furnace HTF ENДокумент4 страницыProduct - Info C 3 UCF B High Temperature Laboratory Furnace HTF ENCarlos Alberto Salazar DuqueОценок пока нет

- Techstuff 3.09Документ130 страницTechstuff 3.09Víctor Rojas100% (1)

- Polyscience-Model 4100 Liquid-to-Liquid Cooler-2019-12-31Документ4 страницыPolyscience-Model 4100 Liquid-to-Liquid Cooler-2019-12-31putut d. utomoОценок пока нет

- Fral FD520TCR Spec SheetДокумент1 страницаFral FD520TCR Spec SheetmoisturecarevidsОценок пока нет

- Principals of Condensing Boiler System Design PDFДокумент8 страницPrincipals of Condensing Boiler System Design PDFilikefreeОценок пока нет

- Ca SMC HRWДокумент35 страницCa SMC HRWErdinc SenmanОценок пока нет

- Project Survey: Selected CompressorsДокумент6 страницProject Survey: Selected CompressorsMr. RfОценок пока нет

- Heat Exchanger Design OptimizationДокумент26 страницHeat Exchanger Design OptimizationEhsan MoemeniОценок пока нет

- LG EcoV DX PDFДокумент62 страницыLG EcoV DX PDFAnonymous THUA6AsJ100% (1)

- Heavy-Duty Gas Turbine Maintenance ConsiderationsДокумент40 страницHeavy-Duty Gas Turbine Maintenance ConsiderationsAli Eng100% (1)

- ALFA LAVAL Compact Heat Exchangers in HVAC SystemsДокумент27 страницALFA LAVAL Compact Heat Exchangers in HVAC SystemsvickersОценок пока нет

- Air Cooler 45 Case1 PDFДокумент2 страницыAir Cooler 45 Case1 PDFHeny MarthaОценок пока нет

- 2 Power PresДокумент12 страниц2 Power PresYonel SambranoОценок пока нет

- Carrier Air Con 38QRR ManualДокумент30 страницCarrier Air Con 38QRR ManualYorkistОценок пока нет

- Plate Heat ExchangersДокумент7 страницPlate Heat ExchangersBaneMarkovicОценок пока нет

- Hot Oil Package Unit Design SpecificationДокумент5 страницHot Oil Package Unit Design SpecificationSuchart TarasapОценок пока нет

- 10d Troubleshooting Crude HeatersДокумент15 страниц10d Troubleshooting Crude HeatersTissa1969Оценок пока нет

- HR E577rДокумент6 страницHR E577rAnton RenaldoОценок пока нет

- Preliminary Heat Exchanger Sizing: These Calculations Are Provided For Educational Use Only - USE AT YOUR OWN RISKДокумент4 страницыPreliminary Heat Exchanger Sizing: These Calculations Are Provided For Educational Use Only - USE AT YOUR OWN RISKRajdeepsinhОценок пока нет

- Problem of Heat Exchanger DesignДокумент15 страницProblem of Heat Exchanger DesignSumit KaushikОценок пока нет

- HOVAL BrochureДокумент28 страницHOVAL Brochurenisuss100% (1)

- Re BoilersДокумент42 страницыRe BoilersShashi MashalОценок пока нет

- Industrial Boiler Presentation PDFДокумент45 страницIndustrial Boiler Presentation PDFMiguel OrihuelaОценок пока нет

- GTG MaintenanceДокумент40 страницGTG MaintenanceKalyankumar Kumar100% (1)

- BITZER Output data summaryДокумент10 страницBITZER Output data summarySaša ColićОценок пока нет

- Process Industries - Lecture Material 1Документ49 страницProcess Industries - Lecture Material 1Barnabas YohannesОценок пока нет

- Heat-Pipes Heat-Pipe Heat SinksДокумент14 страницHeat-Pipes Heat-Pipe Heat SinksNesreen AreefОценок пока нет

- A. Bitzer 4FES-3Y-40SДокумент6 страницA. Bitzer 4FES-3Y-40SĐiện IceОценок пока нет

- Double Pipe by Sannan & HarisДокумент72 страницыDouble Pipe by Sannan & HarisQuân Nguyễn ĐìnhОценок пока нет

- Fise Tehnice Unitati Exterioare Multi V IVДокумент3 страницыFise Tehnice Unitati Exterioare Multi V IVlucicazaineaОценок пока нет

- Installation and Servicing Instructions: Alpha CD24C/32CДокумент40 страницInstallation and Servicing Instructions: Alpha CD24C/32CTrudie TravisОценок пока нет

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОт EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОценок пока нет

- Power Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryОт EverandPower Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryОценок пока нет

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualОт EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualОценок пока нет

- Heating Equipment World Summary: Market Values & Financials by CountryОт EverandHeating Equipment World Summary: Market Values & Financials by CountryОценок пока нет

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsОт EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsОценок пока нет

- Southern Marine Engineering Desk Reference: Second Edition Volume IОт EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IОценок пока нет

- Transparency in Central BanksДокумент7 страницTransparency in Central BanksSixto Gerardo Oña AnaguanoОценок пока нет

- UK Interest Rates During The Financial CrashДокумент5 страницUK Interest Rates During The Financial CrashSixto Gerardo Oña AnaguanoОценок пока нет

- Transparency in Central BanksДокумент7 страницTransparency in Central BanksSixto Gerardo Oña AnaguanoОценок пока нет

- Along:: GO AWAY - Irse, Marcharse THROW AWAY - Tirar (En La Basura)Документ3 страницыAlong:: GO AWAY - Irse, Marcharse THROW AWAY - Tirar (En La Basura)Sixto Gerardo Oña AnaguanoОценок пока нет

- (0153) 4664-MSP-008 Fired HeatersДокумент16 страниц(0153) 4664-MSP-008 Fired HeatersSixto Gerardo Oña Anaguano100% (1)

- Banking Sector Fragility CausesДокумент7 страницBanking Sector Fragility CausesSixto Gerardo Oña AnaguanoОценок пока нет

- Role of Swiss Banks in Tax EvasionДокумент4 страницыRole of Swiss Banks in Tax EvasionSixto Gerardo Oña AnaguanoОценок пока нет

- Along:: GO AWAY - Irse, Marcharse THROW AWAY - Tirar (En La Basura)Документ3 страницыAlong:: GO AWAY - Irse, Marcharse THROW AWAY - Tirar (En La Basura)Sixto Gerardo Oña AnaguanoОценок пока нет

- Analysis For Tesla's Expansion Into Russia: Essay Writing Service Samples of Our Professional Work HereДокумент11 страницAnalysis For Tesla's Expansion Into Russia: Essay Writing Service Samples of Our Professional Work HereSixto Gerardo Oña AnaguanoОценок пока нет

- My Trip To SantiagoДокумент1 страницаMy Trip To SantiagoSixto Gerardo Oña AnaguanoОценок пока нет

- (0159) 010102Документ10 страниц(0159) 010102Sixto Gerardo Oña AnaguanoОценок пока нет

- Scope: An Asterisk (Документ9 страницScope: An Asterisk (Sixto Gerardo Oña AnaguanoОценок пока нет

- Design Item Design Class Class 1 Class 2 Class 3: Once Through Cooling Water System Design Cooling DutyДокумент3 страницыDesign Item Design Class Class 1 Class 2 Class 3: Once Through Cooling Water System Design Cooling DutySixto Gerardo Oña AnaguanoОценок пока нет

- Steam, Boiler Feed Water, and Condensate Systems Design Class DetailДокумент8 страницSteam, Boiler Feed Water, and Condensate Systems Design Class DetailSixto Gerardo Oña AnaguanoОценок пока нет

- (0152) 4664-MSP-001 - API610 Centrifugal PumpsДокумент6 страниц(0152) 4664-MSP-001 - API610 Centrifugal PumpsSixto Gerardo Oña AnaguanoОценок пока нет

- API 510 Final Model Exam-Open Book Page 1 of 6Документ6 страницAPI 510 Final Model Exam-Open Book Page 1 of 6jay2kay5793Оценок пока нет

- (0018) 2.3 - SteelWaterPipe - Aug2011Документ14 страниц(0018) 2.3 - SteelWaterPipe - Aug2011Sixto Gerardo Oña AnaguanoОценок пока нет

- (0111) 00000796Документ5 страниц(0111) 00000796Sixto Gerardo Oña AnaguanoОценок пока нет

- Api 653 Preparatory Course Answer Key: Final Exam - Closed BookДокумент1 страницаApi 653 Preparatory Course Answer Key: Final Exam - Closed BookSixto Gerardo Oña AnaguanoОценок пока нет

- Fuel System Design ClassesДокумент5 страницFuel System Design ClassesSixto Gerardo Oña AnaguanoОценок пока нет

- 00000787Документ35 страниц00000787aminОценок пока нет

- (0110) 00000795Документ4 страницы(0110) 00000795Sixto Gerardo Oña AnaguanoОценок пока нет

- (0105) 00000785Документ6 страниц(0105) 00000785Sixto Gerardo Oña AnaguanoОценок пока нет

- Api 653 Preparatory Course Answer Key: Final Exam - Closed BookДокумент1 страницаApi 653 Preparatory Course Answer Key: Final Exam - Closed BookSixto Gerardo Oña AnaguanoОценок пока нет

- EAR99 ECCN Design Classes for Heat ExchangersДокумент7 страницEAR99 ECCN Design Classes for Heat ExchangersSixto Gerardo Oña AnaguanoОценок пока нет

- (0098) 220kV GIS InstallationДокумент8 страниц(0098) 220kV GIS InstallationSixto Gerardo Oña AnaguanoОценок пока нет

- Api 653 Preparatory Course Answer Key: Final Exam - Open BookДокумент1 страницаApi 653 Preparatory Course Answer Key: Final Exam - Open BookSixto Gerardo Oña AnaguanoОценок пока нет

- Scope: Plant Buildings For Operation and Storage IP 4-3-1Документ8 страницScope: Plant Buildings For Operation and Storage IP 4-3-1Sixto Gerardo Oña AnaguanoОценок пока нет

- Pipe Supports IP 4-2-2: ScopeДокумент3 страницыPipe Supports IP 4-2-2: ScopeSixto Gerardo Oña AnaguanoОценок пока нет

- Matter in Our Surroundings Topic-1: Matter-Solid, Liquid and Gas Characteristics of Solid, Liduid and GasДокумент107 страницMatter in Our Surroundings Topic-1: Matter-Solid, Liquid and Gas Characteristics of Solid, Liduid and GasLatha GowdaОценок пока нет

- 2014 IPhO Solution To Theory Problem 1Документ4 страницы2014 IPhO Solution To Theory Problem 1Souseiseki ChromeОценок пока нет

- Transfer of Thermal Energy WorksheetДокумент2 страницыTransfer of Thermal Energy WorksheetCHRISTOPHER SCALEОценок пока нет

- Thermodynamic ProcessДокумент18 страницThermodynamic ProcessAmar DixitОценок пока нет

- Heat Power Engineering NotesДокумент10 страницHeat Power Engineering NotesDimple Pawan Saini100% (1)

- GR 8 Teaching Guide in ScienceДокумент66 страницGR 8 Teaching Guide in ScienceDecy Raye75% (8)

- Finite Element Analysis of Welded JointsДокумент5 страницFinite Element Analysis of Welded JointsjangdiniОценок пока нет

- Fire Load Calculation Formula ExplainedДокумент25 страницFire Load Calculation Formula ExplainedAnonymous M4BGwOkIpОценок пока нет

- Heat Transfer Coefficients of Shell and Coiled Tube Heat ExchangersДокумент5 страницHeat Transfer Coefficients of Shell and Coiled Tube Heat ExchangersShalehAhmad100% (1)

- Drying of Loose and Particulate PDFДокумент1 страницаDrying of Loose and Particulate PDFImags GamiОценок пока нет

- Access and Utilization of The Dippr Physical Property Database in Ch. E. EducationДокумент12 страницAccess and Utilization of The Dippr Physical Property Database in Ch. E. Educationingbarragan87Оценок пока нет

- Carbom NanotubesДокумент404 страницыCarbom Nanotubesjose carlosОценок пока нет

- JAMB Physics Past Questions EduNgr Sample1 1Документ33 страницыJAMB Physics Past Questions EduNgr Sample1 1FlowealthОценок пока нет

- Heat Capacity of LiquidДокумент15 страницHeat Capacity of LiquidsevenayuraОценок пока нет

- Calculation The Loads For Water Cooling SystemДокумент15 страницCalculation The Loads For Water Cooling SystemmassomieОценок пока нет

- Law of Conservation of Energy: ActivityДокумент3 страницыLaw of Conservation of Energy: ActivityZac McGillОценок пока нет

- A Review of Ventilation and Cooling Technologies in Agricultural Greenhouse ApplicationДокумент15 страницA Review of Ventilation and Cooling Technologies in Agricultural Greenhouse ApplicationMassi MateenОценок пока нет

- Fundamentals of Machining: Qualitative ProblemsДокумент14 страницFundamentals of Machining: Qualitative ProblemsVinod ThakurОценок пока нет

- Experimental Study of The Latest Design of The Powerful Air-Cooled Turbogenerator StatorДокумент8 страницExperimental Study of The Latest Design of The Powerful Air-Cooled Turbogenerator StatorR0B0T2013Оценок пока нет

- Basic Thermo 3Документ65 страницBasic Thermo 3Matthew SmithОценок пока нет

- Grade 9 Thermal Energy TransferДокумент2 страницыGrade 9 Thermal Energy TransferR4iDОценок пока нет

- Jee M AДокумент70 страницJee M AMallikarjuna SarmaОценок пока нет

- Met302 AДокумент4 страницыMet302 AVenkitaraj K PОценок пока нет

- Barometric desalination system designДокумент32 страницыBarometric desalination system designNurrohman NurrohmanОценок пока нет

- Heat Transfer Oil Properties GuideДокумент5 страницHeat Transfer Oil Properties GuideMalek MahmoudОценок пока нет

- Lecture Slides - MIN - 106 - Second LawДокумент100 страницLecture Slides - MIN - 106 - Second LawISHAAN JAIN 22114039Оценок пока нет

- Australian Standard: Rotating Electrical Machines - General Requirements Part 106: Methods of Cooling (IC Code)Документ22 страницыAustralian Standard: Rotating Electrical Machines - General Requirements Part 106: Methods of Cooling (IC Code)Mark Aspinall - Good Price CambodiaОценок пока нет

- Six Steps To Successful Repair of GT ComponentsДокумент13 страницSix Steps To Successful Repair of GT ComponentsThanapaet RittirutОценок пока нет

- Chemical Thermodynamics & Energetics-1Документ22 страницыChemical Thermodynamics & Energetics-1hgurmaita4321Оценок пока нет