Академический Документы

Профессиональный Документы

Культура Документы

Cost Optimization of Post-Tensioned I-Girder

Загружено:

PUENTES2407Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cost Optimization of Post-Tensioned I-Girder

Загружено:

PUENTES2407Авторское право:

Доступные форматы

International Journal of Students Research in Technology & Management

Vol 2 (01), Jan Feb 2014, ISSN 2321-2543, pg 14-18

COST OPTIMIZATION OF POST-TENSIONED I- GIRDER

Devashree U. Sawant, N.G.Gore, P.J.Salunke, V.G.Sayagavi

devashreesawant81289@gmail.com

Abstract

Nowadays Post-tensioned simply supported pre-stressed concrete (PC) I-girder bridges are widely used

bridge system for short to medium span (20m to40m) highway bridges due to its moderate self-weight,

structural efficiency, ease of fabrication, low maintenance etc. In order to compete with steel bridge

systems, the design of PC I-girder Bridge system must lead to the most economical use of materials.

In this present study, cost optimization approach of a post-tensioned PC I-girder is presented. The

objective is to minimize the total cost in the design process of the bridge system considering the cost of

materials. For a particular girder span and bridge width, the design variables considered for the cost

minimization of the bridge system, are top flange width, girder depth, bottom flange thickness, number of

cables (i. e. X1, X2, X3,X4 resp.) Design constraints for the optimization are considered according to

AASHTO (American Association of State Highway and Transportation Officials) Standard Specifications

and IS: 1343-1980. The optimization problem is characterized by having a combination of continuous,

discrete and integer sets of design variables. For An optimization purpose Matlab Software with SUMT

(Sequential Unconstrained Minimization Technique) is used that is capable of locating directly with high

probability the minimum design variables.

1. INTRODUCTION

In conventional structure design process, the design method proposes a certain solution that is validated by

mathematical analysis in order to verify that the problem requirements or specifications are satisfied. If such

requirements are not satisfied, then a new solution is proposed by the designer based on his intuition

experience .The process undergoes many manual iterations before the design can be finalized making it a slow

and very costly process. There is no formal attempt to reach the best design in the strict mathematical sense of

minimizing cost. The process of design is relied exclusively on the designers experience, intuition and

creativity resulting in high cost in terms of times and human efforts.

An alternative to the conventional design method is optimum design. An optimum design normally implies the

most economic structure without harming the functional purposes of the structure. An optimization technique

transforms the conventional design process of trial and error into a formal and systematic procedure.

Pre-stressed concrete (PC) I-girder bridge systems are ideal as short to medium span (20 to 40 m) highway

bridges because of their moderate self-weight, structural efficiency, ease of fabrication, fast construction, low

initial cost, long life expectancy, low maintenance, simple deck removal, and replacement. Large and important

projects containing I-girder bridge structures have the potential for substantial cost reduction through application

of optimum design methodology and thus, will be of great value to practicing engineers.

Rana et al. (2010) presented Cost optimization approach of a post-tensioned PC I-girder bridge system. A global

optimization algorithm named EVOP (Evolutionary Operation) was used. The comparison was made between

optimum design and a real life project named Teesta Bridge. This comparison leads up to 35% saving. Ahsan et

al. (2012) presented an optimization approach to the design of simply supported, post-tensioned, pre-stressed

concrete I-girder bridges. Sami et al(1996) presented a systematic procedure for selecting the most economic

girder type and spacing for a given span. They conclude that it is more economical to space the girders at their

maximum spacing. Macrae et al(1984) presented a computer approach to the optimal design of structural

concrete beams. An optimal design program called OSCON was used for this purpose. The main objective of

this study was Minimizing the amount of reinforcement for a given concrete-section, evaluating the effect of

steel cost ratios on optimal solutions, Optimizing the section shape of partially pre-stressed concrete beams,

Analysis of given designs with respect to all relevant criteria.

2. PROBLEM FORMULATION

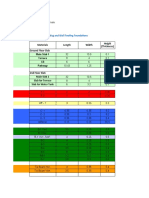

A. Design variables

For a particular girder span and bridge width, a large number of parameters control the design of the bridge such

as girder spacing, cross sectional dimensions of girder, deck slab thickness, number of strands per tendon,

number of tendons, deck slab reinforcement, configuration of tendons, anchorage system, pre-stress losses,

concrete strength etc. the design variables consider in this study are tabulated in Table 1. A typical cross-section

of the PC I-girder is illustrated in Fig. 1 to highlight several of the design variables reflect in this study.

Figure 1: Girder composite section with design variables

1www.giapjournals.com/ijsrtm/

International Journal of Students Research in Technology & Management

Vol 2 (01), Jan Feb 2014, ISSN 2321-2543, pg 14-18

Pre-stress is considered to be applied in two stages, a percentage of total pre-stress at initial stage to carry only

the girder self-weight and stress produced during lifting and transportation and full pre-stress during casting of

deck slab.

Table1. Design variables with constraints

Sr No.

Design Variables

Constraints

Top flange width (X1)

300 X1 S

Girder depth (X2)

1000 X2 3500

Bottom flange thickness (X3)

a X3 600

Number of cables (X4)

1 X4 20

a= clear cover + duct diameter, S= Girder spacing

B. Objective function

The objective function in the present optimization problem is the cost of PSC slab bridge deck whose main

components are cost of concrete, and pre stressing steel. It is assumed that cost of steel, launching and casting

formwork etc. are directly proportional to volume of concrete, hence all these cost are included in the rate of

concrete. It is also assumed that cost of anchor, sheathing etc. are directly proportional to volume of prestressing steel, hence all these cost are included in the rate of pre-stressing steel.

Objective function can be expressed as:

TOTALcost = Qconc*Ccost+Qsteel*Scost

Rate of objective function can be expressed as,

Qconc = Quantity of concrete in m3

Qsteel = Quantity of steel in Kg

Ccost = Cost of concrete/ m3

Scost = Cost of steel/ Kg

C. Constraints

These are specified limitation (upper or lower limit) on design variables which are derived from geometric

requirements (superstructure depth, clearances etc.), minimum practical dimension for construction, code

restriction etc. The constraint is defined as

XL X XU (1)

Where

X = Design variable.

XL = Lower limit of the design variable.

XU = Upper limit of the design variable.

The constraints imposed in the design of pre-stressed concrete flexural member are generally the following:

1. Stresses developed at top n bottom fibres of the critical section at the stage of transfer of pre-stressed and

under service loads. These conditions yield four inequalities expressed as:

.(2)

... (3)

... (4)

.. (5)

2. Code requirements for the limit state of collapse to ensure desirable load factors against flexural failure which

can be written as:

.. (6)

D. Deflection constraint at the limit state of serviceability which takes the form,

(7)

Where,

and are the actual and permissible deflection, which is usually a small fraction of the span.

E. Limitation on the minimum ratios of reinforcement in the section is expressed in the form,

2www.giapjournals.com/ijsrtm/

International Journal of Students Research in Technology & Management

Vol 2 (01), Jan Feb 2014, ISSN 2321-2543, pg 14-18

Where, is the ratio of reinforcement provided,

is the minimum ratio required to prevent failure by fracture of steel in tension, and is the maximum permissible

ratio to ensure failure of the section by yielding of steel. The constraint equations used for this study are

tabulated in Table 2.

Table 2 Constraint equation

Check for minimum section modulus

G1=(Zb2/Zb1)-1

Pre-stressing force

G2=((p/Psf)-1)

Permissible tendon zone at support section

G3=((es/J)-1)

Permissible tendon zone at support section

G4=((es/K)-1)

Stresses at transfer stage at top

G5=((Ftt/Sgtr)-1)

Stresses at transfer stage at bottom

G6=(Sgbt/Fct)-1

Stresses at working load stage at top

G7= (Sgtw/Fcw)-1

Stresses at working stage at bottom

G8=(Ftw/Sgbw)-1

Check for ultimate flexural strength

G9= (Mu1/Mu2)-1

Check for shear stress

G10=((Tv/Tc)-1)

3. OPTIMIZATION METHOD

Mathematical

Stochastic

Programming

Programming

Techniques

Techniques

Mathematical Programming Techniques

1. Calculus Method

2. Calculus Of Variations

3. Nonlinear Programming

4. Geometric Programming

5. Quadratic Programming

6. Linear Programming

7. Dynamic Programming

8. Integer Programming

9. Stochastic Programming

10. Separable Programming

11. Multi Objective Programming

12. Cpm & Pert

13. Game Theory

Stochastic Programming Techniques

1. Stastical Decision Theory

2. Markov Processes

3. Queing Theory

4. Renewal Theory

3www.giapjournals.com/ijsrtm/

Statistical Methods

International Journal of Students Research in Technology & Management

Vol 2 (01), Jan Feb 2014, ISSN 2321-2543, pg 14-18

5. Simulation Methods

6. Reliability Theory

Statistical Method

1. Regression Analysis

2. Cluster Analysis

3. Design of Experiments

4. Discriminate Analysis

The optimum cost design of I-Girder formulated in is nonlinear programming problem (NLPP) in which the

objective function as well as constraint equation is nonlinear function of design variables. The various methods

available for the solution of NLPP are compared in brief and the advantages and limitation of the chosen method

is discussed. The various subroutines used in the program are also discussed.

Methods for the Solution of the NLPP

1. Method of Feasible Directions

2.

Sequential Unconstrained Minimization Technique (SUMT)

3.

Sequential Linear Programming (SLP)

4.

Dynamic Programming

A. The sequential unconstrained minimization technique (SUMT)

In SUMT the constraint minimization problem is converted into unconstraint one by introducing penalty

function. In the present work is of the form, f(x, r) is the penalty function f(x) is the objective function r is the

non-negative penalty parameter, and m is the total number of constraints. The penalty function (x, r) is

minimized as an unconstrained function of x and r, for a fixed value of r. The value of r is reduced sequent

rained and the sequence of minima obtained converges to the constrained minimum of problems as r 0.

A. Computer program

The present optimization problem is solved by the interior penalty function method. The method is used for

solving successive unconstrained minimization problems coupled with cubic interpolation methods of on

dimensional search. The program developed by S. S. Rao for SUMT is used for the solution of the problem. The

program is written in Matlab language.

4. CONCLUSIONS

The objective of this study is to investigate the appropriate optimization method to the minimum cost of a PSC I

Girder. In view of achieving this objective it is decided to develop a computer code in MATLAB. After

validating this computer code by comparing the results with analytical results, it is planned to carry out the

economical and safe design.

1. It is possible to formulate and obtain solution for the minimum cost design for PSC I-Girder.

2. It is possible to obtain the global minimum for the optimization problem by starting from different starting

points with the interior penalty function method.

3. Significant savings in cost over the normal design can be achieved by the optimization. However the actual

percentage of the saving obtained for optimum design for PSC I-Girder depend upon the span of slab and

grade of material.

4. Maximum cost saving of 14.25% for conventional design is achieved in PSC I-Girder 30m span of M50

grade concrete. Maximum cost saving of 9.81% for conventional design is achieved in PSC I-Girder 30m

span of M60 grade concrete.

5. The cost of PSC I-Girder decreases with the increase in the girder depth.

6. The cost of girder is directly proportional to grade of concrete.

ACKNOWLEDGEMENT

I take this opportunity to thank staff members of Civil Engineering Department, Mahatma Gandhi Missions

College of Engineering and Technology, Kamothe, library staff for their assistance useful views and tips. A word

of thanks is also reserved for all my batch mates for their selfless help, support and entertaining company.

REFERENCES

4www.giapjournals.com/ijsrtm/

International Journal of Students Research in Technology & Management

Vol 2 (01), Jan Feb 2014, ISSN 2321-2543, pg 14-18

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

M. Z. Colin, and A. J. Mac Rae (1984) Optimization Of Structural Concrete Beams Journal Of Structural

Engineering, American Society of Civil Engineering, Pp.1573-1588.

James Tyvand, A. M. and Arthur T. Blachly (1986) Foamed Plastic Absorbs Staged Post-Tensioning Deflections

Journal Of Constructions Engineering, American Society of Civil Engineering, Pp.582-587.

Hany Abdalla and John B. Kennedy (1995) Design Of Pre-stressed Concrete Beams With Openings Journal Of

Structural Engineering, American Society of Civil Engineering, Pp.894-898.

Sami M. Fereig (1996) Economic Preliminary Design Of Bridges With Pre-stressed I-Girders Journal Of Bridge

Engineering, American Society of Civil Engineering.

Nabil F. Grace and Brian Ross (1996) Dynamic Characteristics of Post-tensioned Girders with Web Openings

Journal Of Structural Engineering, American Society of Civil Engineering, Pp.643-650.

Charles G. Schilling. (1996) Yield-Interaction Relationships For Curved I-Girders Journal Of Bridge Engineering,

American Society of Civil Engineering, Pp. 26-33.

Z. Lounis, M. S. Mirza, M. Z. Cohn, and Fellow, (1997) Segmental And Conventional Precast Pre-stressed Concrete IBridge Girders Journal Of Bridge Engineering, American Society of Civil Engineering, Pp.73-84

Bradley N. Robsonl and Issam E. Harik (1998) Pullback Testing Of Seismically Isolated P/C I-Girder Bridge Journal

Of Structural Engineering, American Society of Civil Engineering, Pp.643-650.

Jeffrey A. Laman (1999) Load Distribution and Impact Factors For I-Girder Bridges Journal Of Bridge Engineering,

vol 2.

Paul J. Barr, Marc O. Eberhard, and John F. Stanton (2001) Live-Load Distributions Factors In Pre-stressed Concrete

Girder Bridges Journal Of Bridge Engineering, American Society of Civil Engineering, Pp.298-306.

N. Robson, I. E. Harik, and V. Gupta (2001) Effectiveness Of Seismic Isolation Of Highly Skewed P/C I-Girder

Bridge Journal Of Bridge Engineering, American Society of Civil Engineering, Pp.211-214.

D. Linzell1, D. Hall, and D. White. (2004) Historical Perspective on Horizontally Curved I Girder Bridge Design in

the United States Journal Of Bridge Engineering, American Society of Civil Engineering,

Peter Kocsis, and P.E., (2004) Evaluation of AASHTO Live Load and Line Load Distribution Factors for I-Girder

Bridge Decks, Practice Periodical On Structural Design And Construction American Society of Civil Engineering,

Pp.211-215.

Joseph Yura, Todd Helwig, Reagan Herman, and Chong Zhou, A.M. (2008) Global Lateral Buckling of I-Shaped

Girder Systems Journal Of Structural Engineering, American Society of Civil Engineering, Pp.1487-1494.

Benjamin A. Graybeal (2008) Flexural Behavior of an Ultrahigh-Performance Concrete I-Girder, Journal Of Bridge

Engineering, American Society of Civil Engineering,vol.13.

Benjamin Z. Dymond, Carin L. Roberts-Wollmann, and Thomas E. Cousins (2010) Shear Strength of a Lightweight

Self-Consolidating Concrete Bridge Girder Journal Of Bridge Engineering, American Society of Civil Engineering,

Pp.615-618

S. Rana & R.Ahsan (2010) Design of pre-stressed concrete I-girder bridge superstructure using optimization

algorithm Journal Of Bridge Engineering.

David A. Petty, Paul J. Barr, G. Parry Osborn, Marvin W. Halling, and Travis R. Brackus (2011) Carbon Fiber Shear

Retrofit of Forty-Two-Year-Old AASHTO I-Shaped Girders Journal Of Composites For Construction, American

Society of Civil Engineering, Pp.773-781.

Raquib Ahsan, Shohel Rana, and Sayeed Nurul Ghani (2012) Cost Optimum Design of Posttensioned I-Girder Bridge

Using Global Optimization Algorithm Journal of Structural Engineering, American Society of Civil Engineering,

Pp.273-284.

Se-Jin Jeon, Myoung-Sung Choi, and Young-Jin Kim (2012) Graphical Assessment for Span Ranges of PSC Girder

Bridges Journal Of Bridge Engineering, American Society of Civil Engineering, Pp.343-352.

N. Krishna Raju (2007) pre-stressed concrete Tata mcgraw hill publication Pp. 613-653.

5www.giapjournals.com/ijsrtm/

Вам также может понравиться

- Optimal Design of Axially Loaded RC ColumnsДокумент4 страницыOptimal Design of Axially Loaded RC ColumnsBONFRING100% (1)

- Flat Slab GuideДокумент3 страницыFlat Slab GuideAMAN FREDYОценок пока нет

- 0192 Design Optimization of Eot Crane BridgeДокумент9 страниц0192 Design Optimization of Eot Crane BridgeJignesh Tala100% (1)

- I-Girder Bridge SuperstructureДокумент13 страницI-Girder Bridge SuperstructureAlvaro Garnica Trujillo100% (2)

- Brij KishorДокумент102 страницыBrij KishorShahbaz KhanОценок пока нет

- ChapДокумент49 страницChapAhmed AlrashidОценок пока нет

- Design Optimization of Industrial Portal Frame With Overhead CranesДокумент6 страницDesign Optimization of Industrial Portal Frame With Overhead CranesedurahalimОценок пока нет

- IJREATV1I2029Документ5 страницIJREATV1I2029amit_saxena_10Оценок пока нет

- Design Optimization of EOT Crane GirderДокумент5 страницDesign Optimization of EOT Crane Girdermech_abhiОценок пока нет

- 2018 1 X Y Mohammad PDFДокумент20 страниц2018 1 X Y Mohammad PDFmilan_popovic_2Оценок пока нет

- Local and Global Stability Analysis of A Large Free Span Steel Roof StructureДокумент11 страницLocal and Global Stability Analysis of A Large Free Span Steel Roof StructureJeancarlos Darwin ChiОценок пока нет

- Article 1Документ12 страницArticle 1herdianОценок пока нет

- VivaДокумент76 страницVivaRam NepaliОценок пока нет

- A Computational Model To AutomДокумент14 страницA Computational Model To AutomRenzo Chávez HurtadoОценок пока нет

- Reinforced Concrete Buildings: Behavior and DesignОт EverandReinforced Concrete Buildings: Behavior and DesignРейтинг: 5 из 5 звезд5/5 (1)

- Local and Global Stability Analysis of AДокумент11 страницLocal and Global Stability Analysis of AДиана КихаялОценок пока нет

- RakMek 43 1 2010 4 PDFДокумент18 страницRakMek 43 1 2010 4 PDFayoube mecaОценок пока нет

- Optimum Design of Reinforced Concrete Rectangular Beams Using Simulated AnnealingДокумент10 страницOptimum Design of Reinforced Concrete Rectangular Beams Using Simulated AnnealingAndripgaОценок пока нет

- 2000 ERU DESIGN OF CONTINUOUS PRISMATIC PRESTRESSED CONCRETE SPINE BEAMS WITH VARIABLE PRESTRESSING FORCES RanasingheWMDNJayasingheMTRДокумент20 страниц2000 ERU DESIGN OF CONTINUOUS PRISMATIC PRESTRESSED CONCRETE SPINE BEAMS WITH VARIABLE PRESTRESSING FORCES RanasingheWMDNJayasingheMTRVarun VermaОценок пока нет

- Advanced Design and Optimization of Steel Portal Frames: January 2010Документ18 страницAdvanced Design and Optimization of Steel Portal Frames: January 2010مازن ال بدريОценок пока нет

- Optimal Design of Through-Truss Steel Bridges: C. Maraveas, A. Papagiannakis, K. Miamis & K. TasiouliДокумент12 страницOptimal Design of Through-Truss Steel Bridges: C. Maraveas, A. Papagiannakis, K. Miamis & K. TasiouliAafan ShahidОценок пока нет

- 6 Portal FramesДокумент7 страниц6 Portal FramesGeoffrey ArmstrongОценок пока нет

- Design Optimization of EOT Crane Bridge: January 2008Документ10 страницDesign Optimization of EOT Crane Bridge: January 2008Suraj MondalОценок пока нет

- Preliminary Design of Precast, Segmental Box-Girder Bridges Using OptimizationДокумент9 страницPreliminary Design of Precast, Segmental Box-Girder Bridges Using OptimizationTan Duy LeОценок пока нет

- Finite Element AnalysisДокумент5 страницFinite Element AnalysisRonald De Guzman100% (1)

- Advanced Design and Optimization of Steel Portal Frames: Key WordsДокумент17 страницAdvanced Design and Optimization of Steel Portal Frames: Key WordsMahmoud Moustafa ElnegihiОценок пока нет

- Effect of Bridges' Width On Optimum Design of Steel Bridges: Firas Ismael Salman, Abdul Muttalib Issa SaidДокумент7 страницEffect of Bridges' Width On Optimum Design of Steel Bridges: Firas Ismael Salman, Abdul Muttalib Issa SaidyhszaОценок пока нет

- Design Comprasion of Encased Composite Column Under Bi Axial Loading As Per Eurocode-4 and Aisc - LRFD CodeДокумент12 страницDesign Comprasion of Encased Composite Column Under Bi Axial Loading As Per Eurocode-4 and Aisc - LRFD CodeRonakShahОценок пока нет

- Optimization of Prestressed Concrete GirДокумент6 страницOptimization of Prestressed Concrete GirPanji Ginaya TaufikОценок пока нет

- ACI 358 Railway LaodingДокумент35 страницACI 358 Railway LaodingTommy YapОценок пока нет

- ACI 358.1R-92 - Analysys and Design of Reinforced Concrete Guideway StructuresДокумент35 страницACI 358.1R-92 - Analysys and Design of Reinforced Concrete Guideway StructuresJocker_Boy100% (2)

- Efficient Assumption of Design Variables For Stress Ribbon FootbridgesДокумент11 страницEfficient Assumption of Design Variables For Stress Ribbon FootbridgesJORGE BARRERAОценок пока нет

- Markandeya Raju 2021 IOP Conf. Ser. Mater. Sci. Eng. 1025 012005Документ22 страницыMarkandeya Raju 2021 IOP Conf. Ser. Mater. Sci. Eng. 1025 012005Killian WismanОценок пока нет

- Project Information:: ACECOMS GEAR: RC Column Section Design Version: 3.0 (Rev. 1)Документ3 страницыProject Information:: ACECOMS GEAR: RC Column Section Design Version: 3.0 (Rev. 1)Maria Rose Giltendez - BartianaОценок пока нет

- Strength Design Optimization of Structural Steel Members According To Eurocode3Документ20 страницStrength Design Optimization of Structural Steel Members According To Eurocode3Malik AtikОценок пока нет

- Design of Concrete StructuresДокумент11 страницDesign of Concrete StructuressayyadsajidaliОценок пока нет

- Transfer PlateДокумент10 страницTransfer PlateAlex FerrariОценок пока нет

- Shearing Resistance of Steel Fiber Reinforced Self Consolidating Concrete Beams Without StirrupsДокумент8 страницShearing Resistance of Steel Fiber Reinforced Self Consolidating Concrete Beams Without StirrupsSheik MohamedОценок пока нет

- Multi-Objective Optimization of Reinforced Concrete Frames Using Nsga-Ii AlgorithmДокумент8 страницMulti-Objective Optimization of Reinforced Concrete Frames Using Nsga-Ii AlgorithmAusbel Joab Cuyo TtitoОценок пока нет

- Overall Cost Optimization of Prestressed Concrete Bridge Using Genetic AlgorithmДокумент8 страницOverall Cost Optimization of Prestressed Concrete Bridge Using Genetic AlgorithmParth TrivediОценок пока нет

- Trade OffsДокумент6 страницTrade OffsLerie Lou R. PenarroyoОценок пока нет

- Ijtsrd25231 PDFДокумент14 страницIjtsrd25231 PDFanon_776112819Оценок пока нет

- Applications of Matlab in Optimization of BridgeДокумент6 страницApplications of Matlab in Optimization of BridgeInternational Journal of Research in Engineering and TechnologyОценок пока нет

- Optimization of Singly Reinforced RC Beams: ScienceДокумент9 страницOptimization of Singly Reinforced RC Beams: ScienceKillian WismanОценок пока нет

- Irjet V2i985Документ8 страницIrjet V2i985sheikОценок пока нет

- Wood Research Economical Design of Timber-Concrete Composite BeamsДокумент14 страницWood Research Economical Design of Timber-Concrete Composite BeamsFrankie KOWAОценок пока нет

- Advanced Design and Optimization of Steel Portal Frames: January 2010Документ18 страницAdvanced Design and Optimization of Steel Portal Frames: January 2010basel abduОценок пока нет

- Chapter 1 and Chapter 2Документ12 страницChapter 1 and Chapter 2Tan Mei QianОценок пока нет

- UNIT Dfty57Документ8 страницUNIT Dfty57JPDGLОценок пока нет

- Finite Element Analysis PDFДокумент5 страницFinite Element Analysis PDFchetan c patilОценок пока нет

- Optimization of Steel ChimneyДокумент4 страницыOptimization of Steel ChimneyIJRASETPublicationsОценок пока нет

- Discrete Optimum Design of Cable-Stayed BridgesДокумент9 страницDiscrete Optimum Design of Cable-Stayed BridgesspoorthissОценок пока нет

- Cost Optimisation of The Design of Reinf PDFДокумент14 страницCost Optimisation of The Design of Reinf PDFHoo Yen HowОценок пока нет

- Analysis of Precast Building SystemДокумент7 страницAnalysis of Precast Building Systemshashank adigaОценок пока нет

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОт EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОценок пока нет

- Sustainable Steel Buildings: A Practical Guide for Structures and EnvelopesОт EverandSustainable Steel Buildings: A Practical Guide for Structures and EnvelopesBernhard HaukeОценок пока нет

- Nitoflor ET Slurry3Документ4 страницыNitoflor ET Slurry3PUENTES2407Оценок пока нет

- Polyvinylidene Fluoride-Based Coatings Technology PDFДокумент8 страницPolyvinylidene Fluoride-Based Coatings Technology PDFPUENTES2407Оценок пока нет

- Aluminum and Aluminum-Alloy Sheet and Plate (Metric) : Standard Specification ForДокумент26 страницAluminum and Aluminum-Alloy Sheet and Plate (Metric) : Standard Specification ForPUENTES2407Оценок пока нет

- BUSES and BUMPSДокумент49 страницBUSES and BUMPSPUENTES2407Оценок пока нет

- TCRP RPT 19-Buses PDFДокумент37 страницTCRP RPT 19-Buses PDFPUENTES2407Оценок пока нет

- Screws - HILTIДокумент95 страницScrews - HILTIPUENTES2407Оценок пока нет

- Phase 1: Beam Stresses Considering Post Tensioned Strands and Self-WeightДокумент92 страницыPhase 1: Beam Stresses Considering Post Tensioned Strands and Self-WeightPUENTES2407Оценок пока нет

- Dawn of Solar PV CookingДокумент5 страницDawn of Solar PV CookingAbhinav AgrawalОценок пока нет

- Lafarge Interior Building Solutions BrochureДокумент24 страницыLafarge Interior Building Solutions BrochuretwinpixtwinpixОценок пока нет

- World's Standard Model G6A!: Low Signal RelayДокумент9 страницWorld's Standard Model G6A!: Low Signal RelayEgiОценок пока нет

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Документ31 страницаHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcОценок пока нет

- Lesson 1 Chapter 9 ErosiondepositionДокумент1 страницаLesson 1 Chapter 9 Erosiondepositionapi-249320969Оценок пока нет

- Reviews: The Global Epidemiology of HypertensionДокумент15 страницReviews: The Global Epidemiology of Hypertensionrifa iОценок пока нет

- Rekomendasi AnimeДокумент11 страницRekomendasi Animeosvaldo manurungОценок пока нет

- BC-6000 Installation Guide V7.0 enДокумент111 страницBC-6000 Installation Guide V7.0 enmentule88Оценок пока нет

- Lecture Planner - Inorganic Chemistry (Legend) - Yakeen NEET 2.0 2024Документ1 страницаLecture Planner - Inorganic Chemistry (Legend) - Yakeen NEET 2.0 2024Dipendra KumarОценок пока нет

- Elements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesДокумент8 страницElements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesSadman Shaid SaadОценок пока нет

- Ad149 Manual RДокумент69 страницAd149 Manual RCharityОценок пока нет

- Module 1 Notes The White Bird Reading The Image Painting Analysis PDFДокумент4 страницыModule 1 Notes The White Bird Reading The Image Painting Analysis PDFMelbely Rose Apigo BaduaОценок пока нет

- Effects of Climate ChangeДокумент3 страницыEffects of Climate Changejiofjij100% (1)

- Learning Activity Sheets Introduction To World Religions and Belief SystemДокумент56 страницLearning Activity Sheets Introduction To World Religions and Belief SystemAngelica Caranzo LatosaОценок пока нет

- Inverse of One-To-One FunctionДокумент4 страницыInverse of One-To-One FunctionKathFaye EdaОценок пока нет

- 08 Activity 1 (10) (LM)Документ2 страницы08 Activity 1 (10) (LM)Jhanine Mae Oriola FortintoОценок пока нет

- Column, Slab, Footing and Wall Footing Foundations: Class A MixingДокумент47 страницColumn, Slab, Footing and Wall Footing Foundations: Class A MixingGioharry Nul PanambulanОценок пока нет

- Cambridge IGCSE Paper 2Документ4 страницыCambridge IGCSE Paper 2irajooo epik zizterОценок пока нет

- Eldritch HighДокумент39 страницEldritch Highteam_moОценок пока нет

- Niir Integrated Organic Farming Handbook PDFДокумент13 страницNiir Integrated Organic Farming Handbook PDFNatalieОценок пока нет

- Cathodic Protection Catalog - New 8Документ1 страницаCathodic Protection Catalog - New 8dhineshОценок пока нет

- Course Syllabus: Course Code Course Title ECTS CreditsДокумент3 страницыCourse Syllabus: Course Code Course Title ECTS CreditsHanaa HamadallahОценок пока нет

- 12/1/2014 Powder MetallurgyДокумент29 страниц12/1/2014 Powder Metallurgysofyan sam0% (2)

- FRP Handrail Fittings CatalogДокумент6 страницFRP Handrail Fittings CatalogAl Adel MorenoОценок пока нет

- Food Taste Panel Evaluation Form 2Документ17 страницFood Taste Panel Evaluation Form 2Akshat JainОценок пока нет

- S TR GEN ID (Component Marking) (Rev 3 2009) - AN Marked UpДокумент6 страницS TR GEN ID (Component Marking) (Rev 3 2009) - AN Marked UpsnclgsraoОценок пока нет

- GROSS Mystery of UFOs A PreludeДокумент309 страницGROSS Mystery of UFOs A PreludeTommaso MonteleoneОценок пока нет

- Chapter 7 - Muscular SystemДокумент29 страницChapter 7 - Muscular SystemlОценок пока нет

- Drilling & GroutingДокумент18 страницDrilling & GroutingSantosh Laxman PatilОценок пока нет

- Plastics and Polymer EngineeringДокумент4 страницыPlastics and Polymer Engineeringsuranjana26Оценок пока нет