Академический Документы

Профессиональный Документы

Культура Документы

Thread Identification Chart PDF

Загружено:

refaeОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Thread Identification Chart PDF

Загружено:

refaeАвторское право:

Доступные форматы

THINK!

- MARYLAND METRICS - The One-Stop Source For Metric And British Sized Fasteners, Wrenches,

Cutting, & Measuring Tools, Metal Shapes, Oil Seals, O-Rings, Mechanical Power Transmission Equipment,

Bearings, Hydraulic And Pneumatic Fittings & Tubing, Workholding Components, Plumbing Fittings, & Some

Electrical & Electronic Components. Click to go to Maryland Metrics home page

MARYLAND METRICS

Technical Data Chart

MARYLAND METRICS THREAD IDENTIFICATION CHART

Note: Use your back button to return back to this menu.

INTRODUCTION

SOME HELPFUL NOTES ABOUT THREADS

THREAD MEASUREMENT PROCEDURES

SECTION A -- FOR MAJOR DIAMETERS FROM 0.3 mm TO 7.7 mm

SECTION A (continuation) -- FOR MAJOR DIAMETERS FROM 7.8 mm TO 64 mm

SECTION B -- PITCH CONVERSION TABLE

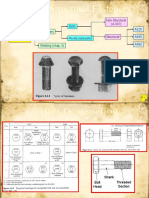

CHART I -- HOW THE 3 MOST POPULAR THREADS ARE IDENTIFIED and CHART II -- DESIGNATION

EXAMPLES

OF VARIOUS THREADS and TABLE III -- DIAGRAMS IV THRU VII -- THREAD ANGLES

DIAGRAM VIII -- THREAD ANGLE 47.5 DEG. vs 60 DEG.

DIAGRAMS II and III -- RULER & MICROMETER PIX

CHART IV -- TAP DRILL FORMULA FOR METRIC THREADS

CHART VIII -- HOW TO CALCULATE THE MAJOR DIAMETER OF THE METRIC MALE THREAD WHEN ONLY

THE

FEMALE THREAD IS KNOWN.

INTRODUCTION

TO IDENTIFY AN UNKNOWN THREAD, CERTAIN TOOLS AND DATA ARE NECESSARY. INCLUDED IN THESE

CHARTS ARE A HELPFUL COMPILATION OF THE DATA NEEDED FOR THE IDENTIFICATION OF MOST

EXTERNAL (MALE) THREADS FROM THE THREE MOST POPULAR THREAD SYSTEMS IN THE WORLD, METRIC

STANDARDS, U.S.A.(INCH) STANDARDS, AND THE BRITISH (INCH) STANDARDS. ALSO THIS CHART WILL

OUTLINE THE USEFUL TOOLS AND PROCEDURES IN ATTEMPTING TO IDENTIFY AN UNKNOWN THREAD.

THESE ARE THE THREE BASIC STEPS TO IDENTIFY A THREAD:

1. MEASURE THE MAJOR DIAMETER OF THE MALE THREAD. {THE MAJOR DIAMETER IS THE OUTSIDE

DIAMETER (OD) OF THE MALE THREAD}. IF YOU ARE TRYING TO IDENTIFY AN INTERNAL (FEMALE) THREAD

THESE DATA CHARTS WILL NOT CONTAIN SUFFICIENT INFORMATION. FOR ADDITIONAL INFORMATION ON

MEASURING INTERNAL (FEMALE) THREADS; SEE THE INSTRUCTIONS IN CHART VIII.

2. DETERMINE THE NUMBER OF THREADS PER INCH {OR THE NUMBER OF THREADS PER CENTIMETER

(cm)}. SEE SECTION (B) FOR CONVERSIONS FROM PITCH TO THREADS PER INCH, AND/OR THREADS PER

CENTIMETER. AN IDEAL WAY TO ACCOMPLISH THIS MEASUREMENT IS WITH PITCH GAGES OR WITH

THREAD GAGES (Note: PITCH GAGES ARE QUITE INEXPENSIVE). HOWEVER, USING A RULE AND TAKING A

CAREFUL COUNT OF THREADS IS NORMALLY ACCEPTABLE.

3. COMPARE YOUR MEASUREMENTS WITH THE DATA CHARTS IN SECTION (A).

CHART I

CHART II

NOTE: CLASS OF FIT - SUCH AS THE U.S.A. '2A/2B' OR THE METRIC '6G/6h'

ARE BEYOND THE SCOPE OF THE DATA INCLUDED IN THESE CHARTS.

TABLE III

THREAD ANGLE DIAGRAMS

SOME HELPFUL NOTES ABOUT THREADS;

1. THE METRIC THREAD DESIGNATION USES PITCH IN PLACE OF THE MORE FAMILIAR U.S.A. METHOD OF

THREADS PER INCH. PITCH IS THE DISTANCE IN mm FROM ANY ONE POINT ON A THREAD TO A

CORRESPONDING POINT ON THE NEXT THREAD, WHEN MEASURED PARALLEL TO ITS AXIS.

2. METRIC COARSE THREAD DOES NOT NEED TO HAVE PITCH SPECIFIED. THE ABSENCE OF THE PITCH

SPECIFICATION INDICATES THAT THE THREAD WILL BE FROM THE COARSE THREAD SERIES.

3. THE NOMINAL DIAMETER OF METRIC PIPE THREADS, BOTH TAPERED AND PARALLEL IS THE SAME AS

THE MAJOR DIAMETER (OD) OF THE THREAD. HOWEVER, THE U.S.A., BRITISH AND JAPANESE NOMINAL

PIPE THREAD DIAMETERS CORRESPOND TO THE APPROXIMATE INSIDE DIAMETER (ID) OF THE PIPE OR

TUBE. IN SECTION (A), ALL THE THREADS ARE LISTED IN ASCENDING MAJOR DIAMETER SIZE ORDER. THIS

PLACES THE U.S.A., BRITISH AND JAPANESE PIPE THREADS AMONG THREAD DIAMETERS WHICH ARE

LARGER THAN THEIR NOMINAL SIZE.

4. MOST METRIC COUNTRIES IN EUROPE AND ASIA USE THE BRITISH BASED INCH SYSTEM (ISO) FOR

MEASURING NON-HYDRAULIC/PNEUMATIC PIPE AND TUBING THREADS. SOME EXAMPLES OF THESE

THREAD DESIGNATIONS FOLLOW:

THREADS EQUIVALENT TO BSPP/BSPF (BRITISH STANDARD PIPE - PARALLEL) ARE DESIGNATED IN

GERMANY AS: G 1/4; IN FRANCE: G 1/4 cyl; IN JAPAN: PF 1/4; IN BRITAIN: R 1/4 Tr.

THREADS EQUIVALENT TO BSPT (BRITISH STANDARD PIPE - TAPERED) ARE DESIGNATED IN GERMANY AS:

R 1/4 keg; IN FRANCE: G 1/4 co; IN JAPAN: PT 1/4; IN BRITAIN: R 1/4.

THE REFERENCE STANDARDS FOR ISO R228 PARALLEL PIPE THREAD ARE DESIGNATED AS: GERMANY DIN 259; BRITAIN - BS 2779; JAPAN - JIS B 0202

THE REFERENCE STANDARDS FOR ISO R7 TAPERED PIPE THREAD ARE DESIGNATED AS: GERMANY - DIN

2999; BRITAIN - BS 21; JAPAN - JIS B 0203

5. IN THE BRITISH SYSTEM THERE IS NO NEED TO INDICATE THE NUMBER OF THREADS PER INCH. EACH OF

THE BRITISH THREAD SERIES HAVE ONLY ONE NUMBER OF THREADS PER INCH ALLOCATED WITHIN ITS

SERIES AND NOMINAL DIAMETER.

6. THE U.S.A. MINIATURE THREAD SERIES (UNM) IS INTERCHANGEABLE WITH THE CORRESPONDING SIZES

OF ISO METRIC THREADS WHERE THE NOMINAL DIAMETERS ARE EQUAL.

7. A FEW ADDITIONAL HINTS TO THREAD SYSTEM IDENTIFICATION ARE AS FOLLOWS: GENERALLY, BOLT

HEADS WITH NUMERICAL MARKINGS SUCH AS 8.8, 9.8, 10.9, 12.9, WILL PROBABLY BE METRIC; AND BOLT

HEADS WITH LINE/SLASH MARKINGS WILL PROBABLY BE FROM THE U.S.A. GRADE MARKING SYSTEM.

MEASUREMENT PROCEDURES:

1. BY USING A MICROMETER OR CALIPER; DETERMINE THE MAJOR DIAMETER (ACTUAL OUTSIDE

DIAMETER) OF THE MALE SCREW THREAD. THE MAJOR DIAMETER MAY BE MEASURED IN DECIMAL INCHES

OR MILLIMETERS. NOTE THAT THE MAJOR DIAMETER VALUE IS SLIGHTLY UNDERSIZED FOR FEMALE

THREAD CLEARANCE, BUT THE MAJOR DIAMETER IS NEVER GREATER THAN THE NOMINAL SIZE OF THE

MALE THREAD. (SEE DIAGRAM III).

2. BY USING A RULE OR CALIPER, DETERMINE THE NUMBER OF THREADS PER INCH. (SEE DIAGRAM II). OR

IF AVAILABLE, A MORE ACCURATE METHOD IS TO USE A PITCH GAGE OR A THREAD GAGE.

NOTE: TO PROPERLY IDENTIFY A THREAD, YOU MUST HAVE BOTH A DIAMETER MEASUREMENT AND A

PITCH VALUE, OR THREAD PER INCH VALUE.

3. GO TO THE APPROPRIATE SIZE RANGE OF SECTION (A). CHECK THE BASIC MAJOR DIAMETER

COLUMNS; LOCATE THE CLOSEST MEASUREMENT IN EITHER THE APPROPRIATE MILLIMETER (mm) OR

DECIMAL INCH COLUMN FOR THE NOMINAL DIAMETER THAT YOU HAVE MEASURED IN STEP ONE. MOVE

ACROSS THE ROW UNTIL YOU HAVE FOUND A MATCH FOR THE THREADS PER INCH OR PITCH

MEASUREMENT FROM STEP TWO.

4. IF THERE IS ONLY ONE THREAD IN THIS ROW WITH YOUR PITCH OR THREAD PER INCH VALUE, THEN THE

THREAD IS NOW IDENTIFIED. HOWEVER, IF THERE IS MORE THAN ONE THREAD IN THIS ROW, YOU WILL

HAVE TO DETERMINE THE ANGLE OF THE THREAD FOR A FINAL IDENTIFICATION (SEE DIAGRAM VIII BELOW

PLUS DIAGRAMS IV THROUGH VII FOR THREAD ANGLES). FOR EXAMPLE, A METRIC SCREW PITCH GAGE

WILL READILY SHOW THE DIFFERENCE IN THREAD ANGLES BETWEEN 'BA' (47 1/2 DEGREE) THREADS AND

METRIC (60 DEGREE) THREADS.

(CHART IV): TAP DRILL FORMULA FOR METRIC 60 DEG. THREADS;

NOMINAL O.D. OF THREAD (MAJOR DIAMETER) - PITCH = TAP DRILL SIZE.

(Note: This formula will yield approximately 68% - 77% of thread.)

Example: TO FIND THE TAP DRILL SIZE FOR AN M10 x 1.5 THREAD.

10 (O.D.) - 1.5 (PITCH) = 8.5 mm (TAP DRILL SIZE).

(CHART VIII): HOW TO CALCULATE THE APPROXIMATE NOMINAL MAJOR DIAMETER (O.D.) OF THE METRIC

MALE (EXTERNAL) THREAD WHEN ONLY THE FEMALE (INTERNAL) METRIC THREAD IS AVAILABLE FOR

MEASUREMENT.

1. MEASURE VERY CAREFULLY THE PITCH (P) USING A THREAD PITCH GAGE, OR ANY OTHER TYPE OF

MEASURING TOOL WHICH WILL GIVE AN ACCURATE READING FOR PITCH.

2. MULTIPLY THE FACTOR VALUE: (F)=1.0825 BY THE PITCH (P) WHICH YIELDS RESULT (R). F x P = R.

Example: 1.0825 (F) X 1.75 (P) = 1.8944 (R)

3. MEASURE VERY CAREFULLY THE (I.D.) INSIDE DIAMETER (MINOR DIAMETER) OF THE FEMALE METRIC

THREAD USING AN INTERNAL MICROMETER, INTERNAL CALIPER, OR GAGE PIN.

4. ADD THE MEASURED VALUE FOR THE INSIDE DIAMETER (I.D.) TO THE RESULT (R) WHICH WILL YIELD THE

NOMINAL MAJOR DIAMETER (O.D.) OF THE FEMALE THREAD. I.D. + R = O.D. Example: ASSUME MEASURED

VALUE 10.1036 (I.D.) + 1.8944 (R) = 12 (O.D. OR APPROXIMATE NOMINAL MAJOR DIAMETER).

SECTION (B)

PITCH CONVERSION TABLE

APPROXIMATE

APPROXIMATE

THREADS per INCH PITCH mm THREADS per cm

338 1/2

0.075

133.33

317 1/2

0.08

125.00

282 1/4

0.09

111.11

254

0.1

100.00

203 1/4

0.125

80.00

169 1/4

0.15

66.67

145 1/4

0.175

57.14

127

0.2

50.00

101 1/2

0.25

40.00

84 3/4

0.3

33.33

72 1/2

0.35

28.57

63 1/2

0.4

25.00

56 1/2

0.45

22.22

50 3/4

0.5

20.00

42 1/4

0.6

16.67

36 1/4

0.7

14.29

33 3/4

0.75

13.33

31 3/4

0.8

12.50

28 1/4

0.9

11.11

25 1/2

10.00

20 1/4

1.25

8.00

17

1.5

6.67

14 1/2

1.75

5.71

12 3/4

5.00

10 1/4

2.5

4.00

8 1/2

3.33

7 1/4

3.5

2.86

6 1/4

2.50

5 3/4

4.5

2.22

2.00

4 1/2

5.5

1.82

4 1/4

1.67

NOTES: [ P=PITCH ] [ 1cm=10mm ] [10/P=Threads/cm ] [25.4/P=Threads/inch ]

CHART III -- DEFINITIONS OF SECTION (A) COLUMN HEADINGS

METRIC

AMERICAN

BRITISH

M - COARSE AND FINE

UNC - UNIFIED NATIONAL COARSE

BA - BRITISH ASSOCIATION

MF - FINE; alternative prefix

UNF - UNIFIED NATIONAL FINE

BSW- BRITISH STANDARD WHITWORTH

M TAPER-METRIC PIPE TAPERED UNEF- UNIFIED NATIONAL EXTRA FINE

BSF- BRITISH STANDARD FINE

STANDARD REFERENCES

UNM - UNIFIED MINIATURE

BSPF-BRITISH STANDARD PIPE - PARALLEL

I - ISO STD. FIRST CHOICE

NPT - NATIONAL PIPE TAPERED

BSPP-BRITISH STANDARD PIPE - PARALLEL

II -ISO STD. SECOND CHOICE

NPS - NATIONAL PIPE STRAIGHT

BSPT-BRITISH STANDARD PIPE - TAPERED

III-ISO STD. THIRD CHOICE

PF-JAPANESE CALLOUT FOR BSPF/BSPP

D - DIN, GERMAN STANDARD

8UN - 8 PITCH (all sizes= 8 T.P.I.)

PT-JAPANESE CALLOUT FOR BSPT

MARYLAND METRICS -- THREAD IDENTIFICATION CHART: SECTION (A)

(Also see the IMPORTANT notes at the bottom of this table.)

BASIC MAJOR

DIAMETER

NOMINAL

DIAMETER:

METRIC

NOMINAL

DIAMETER:

AMERICAN

STD.

METRIC -- PITCH in mm

REF.

AMERICAN -- PITCH

in THREADS per

UNIFIED

Inch

MINI-ATURE

Inch

mm

mm

COARSE

FINE

0.0098

0.25

0.07

0.0114

0.29

0.08

0.0118

0.30

0.3

0.075

0.0118

0.30

0.3

0.08

0.0130

0.33

0.09

0.0138

0.35

0.35

II

0.09

0.0146

0.37

0.098

0.0157

0.40

0.4

ID

0.1

0.0165

0.42

0.0177

0.45

0.45

II

0.0189

0.48

0.0197

0.50

0.5

0.0209

0.53

0.0213

0.54

0.0217

0.55

0.55

0.0236

0.60

0.6

ID

0.0244

0.62

0.0276

0.70

0.7

0.0311

0.79

0.0315

0.80

0.0340

0.86

0.0354

0.90

UNC UNF

BRITISH

ASSOCIATION

NOMINAL

DIAM-ETER

BRITISH -- PITCH in

THREADS per Inch

UNEF

UNM

BA No.

BRITISH

BA

BSW BSF BSPT

25

363

24

317

0.30 mm

318

0.30

23

282

0.35 mm

282

0.35

22

254

0.40 mm

254

0.40

0.11

21

230.91

0.1

0.45 mm

254

0.45

0.12

20

211.67

ID

0.125

0.50 mm

203

0.50

160

0.14

19

181.43

II

0.125

0.55 mm

203

0.55

0.15

0.60 mm

169

0.60

0.15

18

169.33

II D

0.175

0.70 mm

145

0.70

17

149.41

0.19

16

133.68

0.8

ID

0.2

0.80 mm

127

0.80

120

0.9

II D

0.225

0.90 mm

113

0.90

15

120.95

0.0394

ID

0.25

0.2

1.00 mm

102

1.00

14

110.44

0.0433

1.1

1.1

II

0.25

0.2

1.10 mm

102

1.10

0.0470

1.19

90

0.0472

1.2

1.2

ID

0.25

0.2

1.20 mm

102

1.20

13

101.6

0.0512

1.3

0.28

12

90.71

0.0551

1.4

1.4

II D

0.3

0.2

1.40 mm

85

1.40

0.0591

1.5

1.5

0.31

11

81.93

0.0600 1.524

#0

80

0.0625

1.59

1/16

60

0.0629

1.6

1.6

0.35

0.2

0.0669

1.7

1.7

0.35

0.2,0.25

10

72.57

0.0709

1.8

1.8

II

0.35

0.2,(0.4)

0.0730 1.854

#1

64

72

0.0748

1.9

0.39

65.13

0.0781

1.98

5/64

56

0.0787

ID

0.4

0.25,0.3

0.0860 2.184

#2

56

64

0.0866

2.2

2.2

II

0.45

0.25

59.07

0.0906

2.3

2.3

0.4

0.25,0.35

0.0937

2.38

3/32

48

0.0984

2.5

2.5

0.45

0.35

52.92

#3

48

56

0.45

0.25,0.35

0.0990 2.515

0.1024

2.6

2.6

0.1094

2.78

7/64

48

0.1102

2.8

0.53

47.93

0.1120 2.845

#4

40

48

0.1181

ID

0.5

0.35,(0.6)

0.1250 3.175

#5

40

44

1/8

40

0.1260

3.2

0.59

43.05

0.1380

3.5

3.5

II D

0.6

0.35,0.5

#6

32

40

0.1417

3.6

0.66

38.49

0.1563 3.969

5/32

32

0.1575

ID

0.7

0.5,(0.75)

0.1614

4.1

0.73

34.8

#8

32

36

0.1640 4.166

0.1772

4.5

4.5

II

0.75

0.5

0.1850

4.7

0.81

31.36

0.1875 4.762

3/16

24

32

0.1900 4.826

#10

24

32

0.1969

ID

0.8

0.5,0.75,(0.9)

0.2087

5.3

0.9

28.22

#12

24

28

32

0.2160 5.486

0.2165

5.5

III

0.9

0.5

0.2188 5.556

5.5

7/32

24

28

0.2362

ID

0.5,0.75

25.4

0.2480

6.3

6.3

GM

1/8

28(H)

0.2500

6.35

1/4

20

28

32

1/4

20

26

0.2756

III D

0.5,0.75

0.2812 7.144

9/32

20

26

0.3041 7.723

1/16

28

MARYLAND METRICS -- THREAD IDENTIFICATION CHART: SECTION (A)

Continuation: (Also see the IMPORTANT notes at the bottom of this table.)

BASIC

MAJOR

DIAMETER

Inch

mm

0.3108 7.894

NOMINAL

STD.

DIAMETER

REF.

METRIC

NOMINAL

DIAMETER

AMERICAN

METRIC -- PITCH in mm

mm

COARSE

FINE

SPECIAL

USE

NOTES*

AMERICAN -- PITCH in

THREADS per Inch

M

TAPER FRACTIONS UNC UNF UNEF NPT 8UN

.

1/16

27

*See table

SD

NOMINAL

DIAMETER

BRITISH

BRITISH -- PITCH in

THREADS per Inch

FRACTIONS BSW BSF BSPF BSPT

BSPP

0.3125

7.94

5/16

18

24

32

24(C-J)

24(SAE-F)

5/16

18

22

0.3150

8.00

ID

1.25

0.5,0.75,1

0.3543

9.00

III D

1.25

0.75,1

0.3750

9.53

3/8

16

24

32

24(SAE C-J)

3/8

16

20

0.3830

9.73

1/8

28

28

0.3937 10.00

10

ID

1.5

0.75,1,1.25

0.4044 10.271

1/8

27

0.4331 11.00

11

III D

1.5

0.75,1,1.25

0.4375 11.11

7/16

14

20

28

24(C)

20(SAE J-F)

7/16

14

18

0.4724 12.00

12

ID

1.75

1,1.25,1.5

1.5

0.5000 12.70

1/2

13

20

28

24(C)

20(SAE J-F)

1/2

12

16

0.5180 13.16

1/4

19

19

0.5343 13.571

18

0.5512 14.00

14

II D

1,1.25,1.5

0.5625 14.29

9/16

12

18

24

24(C)

18(SAE-J)

9/16

12

16

0.5906 15.00

15

III D

1,1.5

5/8

11

14

0.6250 15.88

5/8

11

18

24

24(C)

18(SAE-F)

0.6299 16.00

16

ID

1,1.5

1.5

0.6560 16.662

3/8

19

19

0.6693 17.00

17

III D

1,1.5

0.6714 17.054

3/8

18

0.6875 17.46

11/16

24

20(C)

18(SAE-F)

11/16

11

14

0.7087 18.00

18

II D

2.5

1,1.5,2

1.5

0.7500 19.05

3/4

10

16

20

16(SAE-J-F)

3/4

10

12

0.7874 20.00

20

ID

2.5

1,1.5,2

1.5

0.8125 20.64

13/16

20

18(C)

13/16

10

12

0.8250 20.955

1/2

14

14

0.8356 21.222

1/2

14

0.8661 22.00

22

II D

2.5

1,1.5,2

1.5

0.8750 22.23

7/8

14

20

14(SAE-F-J)

7/8

11

0.9020 22.911

5/8

14

14

0.9375 23.81

15/16

20

20(C-J)

16(SAE)

15/16

0.9449 24.00

24

ID

1,1.5,2

0.9843 25.00

25

III D

1,1.5,2

1.0000 25.40

12

20

18(C) 14(NF)

10

1.0236 26.00

26

III D

1.5

1.5

1.0410 26.441

3/4

14

14

1.0460 26.568

3/4

14

1.0625 26.99

1 1/16

18

14(F)

12(SAE-J)

1.0630 27.00

27

II D

1,1.5,2

1.1024 28.00

28

III D

1,1.5,2

1.1250 28.58

1 1/8

12

18

18(C)

1 1/8

1.1811 30.00

30

ID

3.5

1,1.5,2,3

1.1875 30.16

1 3/16

18

12(SAE-J)

1.1890 30.20

7/8

14

14

1.2500 31.75

1 1/4

12

18

12(SAE)

1 1/4

1.2598 32.00

32

III D

1.5,2

1.2992 33.00

33

II D

3.5

1.5,2,3

1.3328 33.228

11

1/2

1.3090 33.249

11

11

1.3125 33.34

1 5/16

18

12(SAE-J)

1.3750 34.93

1 3/8

12

18

1 3/8

1.3780 35.00

35

III D

1.5

SEE TABLE

1.4173 36.00

36

ID

1.5,2,3

SD

1.4375 36.51

1 7/16

18

FOR

1.4920 37.897

SPECIAL

1 1/8

11

1.4961 38.00

38

III D

1.5

USE

1.5000 38.10

1 1/2

12

18

DEFINITIONS

1 1/2

1.5354 39.00

39

II D

1.5,2,3

1.5625 39.69

1 9/16

18

1.5748 40.00

40

III D

1.5,2,3

1.6250 41.28

1 5/8

18

12(SAE-J)

1 5/8

1.6500 41.91

1 1/4

11

11

1.6535 41.99

42

ID

4.5

1.5,2,3,4

1.6600 42.16

1 1/4

11

1/2

1.6875 42.86

1 11/16

18

1.7450 44.32

1 3/8

11

1.7500 44.45

16

1 3/4

16

1 3/4

1.7717 45.00

45

II D

4.5

1.5,2,3,4

1.8750 47.63

1 7/8

12(SAE-J)

1 7/8

4 1/2

1.8820 47.802

1 1/2

11

11

1.8898 48.00

48

ID

1.5,2,3,4

1.8919 48.054

1 1/2

11

1/2

1.9685 50.00

50

III D

1.5,2,3

2.0000 50.80

4

1/2

16

4 1/2

2.0472 52.00

52

II D

1.5,2,3,4

2.1654 55.00

55

III D

1.5,2,3,4

2.2047 56.00

56

ID

5.5

1.5,2,3,4

.

.

2.2500 57.15

2 1/4

4

1/2

2 1/4

2.2835 58.00

58

III D

1.5,2,3,4

2.3470 59.613

11

11

2.3622 60.00

60

II D

5.5

1.5,2,3,4

2.3658 60.094

11

1/2

2.4409 62.00

62

III D

1.5,2,3,4

2.5000 63.50

2 1/2

12(SAE-J)

2 1/2

2.5197 64.00

64

ID

1.5,2,3,4

2.4803 63.00

63

1.5

2.9528 75.00

75

1.5

3.1496 80.00

80

3.3465 85.00

85

3.5433 90.00

90

3.937 100.00

100

2, 3

4.3307 110.00

110

Metric Electrical thread

1. The British thread system is fractionally based, but all thread vee angles are different than the American fractionally or decimally based threads.

Most thread per inch values are different than in the American System.

2. Taper pipe thread major diameters are measured at the guage point.

3. (H)= BSPT copper pipe thread.

4. Dimensions within ( ) in the M FINE column are obsolete French or Japanese threads.

5. Dimensions within ( ) in the BSW column are obsolete British coarse threads.

6. The 6.3 mm dimension; marked GM is an obsolete General Motors thread.

TABLE (SD) -- SPECIAL USE THREAD DEFINITIONS

C=

Compression fittings

J=

JIC 37 degree Flare fittings

F=

JIC 45 degree Flare fittings

SAE =

SAE straight thread

NF =

National Fine thread

E=

Electrical thread

WARNING: We are not responsible for any technical errors

or typographical errors in this publication.

Corrections and/or suggestions to improve this data chart are welcome.

[ Please send them to: techinfo@mdmetric.com ]

MARYLAND METRICS

P.O.Box 261 Owings Mills, MD 21117

Phones: (410) 358-3130 (800) 638-1830

Faxes: (410) 358-3142 (800) USA-9-FAX [800-872-9329]

For a free; condensed, printed version of the

MARYLAND METRICS THREAD IDENTIFICATION CHART;

send a stamped self addressed envelope to:

T.I.C.

POB 261

Owings Mills, MD 21117 U.S.A.

THINK!- MARYLAND METRICS - The One-Stop Source For Metric And British Sized Fasteners, Wrenches,

Cutting, & Measuring Tools, Metal Shapes, Oil Seals, O-Rings, Mechanical Power Transmission Equipment,

Bearings, Hydraulic And Pneumatic Fittings & Tubing, Workholding Components, Plumbing Fittings, & Some

Electrical & Electronic Components. Click to go to Maryland Metrics home page

Phones: (800) 638-1830 or (410) 358-3130 are available Monday-Friday 8:30 AM to 5:30 PM Eastern time.

Faxes: (800) 872-9329 or (410) 358-3142 & E-mail are available anytime.

Warehouse & showroom hours are Monday-Friday 10 AM to 5:30 PM.

[ To: Maryland Metrics home page ] [ To: Maryland Metrics Product Guide ] [ e-mail to Maryland Metrics ]

Please note that all Trademarks and Tradenames are the property of their respective owners.

copyright 1996, 2002, 2006, 2007, 2011 maryland metrics -- all rights reserved -- ver gg15fCD tict.htm

Вам также может понравиться

- RP623 03-2013 HResДокумент2 страницыRP623 03-2013 HResvangoetheОценок пока нет

- Manitowoc 4600 S4 Lubrication Guide PDFДокумент40 страницManitowoc 4600 S4 Lubrication Guide PDFnamduong368100% (1)

- Torque Data ChartДокумент2 страницыTorque Data CharttnchsgОценок пока нет

- Thread TablesДокумент22 страницыThread TablesMuthukumar VeerappanОценок пока нет

- Is 5749 - 1970 Specification For Ramshorn HooksДокумент17 страницIs 5749 - 1970 Specification For Ramshorn HookskalpanaadhiОценок пока нет

- Thread Standard BSPДокумент7 страницThread Standard BSPĐạt TrầnОценок пока нет

- Shackle Din 82101Документ1 страницаShackle Din 82101viahulОценок пока нет

- National Pipe Thread Chart OPT P PDFДокумент1 страницаNational Pipe Thread Chart OPT P PDFRoselio MayoОценок пока нет

- Hiab Sea Crane Brochure PDFДокумент8 страницHiab Sea Crane Brochure PDFAndree YudiОценок пока нет

- Cov Fast Stainless Steel Cat - 3rd Ed - Jun 09Документ116 страницCov Fast Stainless Steel Cat - 3rd Ed - Jun 09jaffliangОценок пока нет

- Hydraulic Fitting Thread Chart - Hydraulics DirectДокумент17 страницHydraulic Fitting Thread Chart - Hydraulics DirectprashantОценок пока нет

- Gin PoleДокумент51 страницаGin PoleKeith CuberoОценок пока нет

- Inch Series Dowel Pins: Mechanical PropertiesДокумент2 страницыInch Series Dowel Pins: Mechanical PropertieswilliaqОценок пока нет

- SOUTHLAND PIPE, Steel Pipe General Data Size Chart, Steel Pipe Sales, NationwideДокумент3 страницыSOUTHLAND PIPE, Steel Pipe General Data Size Chart, Steel Pipe Sales, Nationwidea769Оценок пока нет

- Preconisation Kerui2Документ12 страницPreconisation Kerui2zinouОценок пока нет

- Neral Notes On Engineering Hardware - FastenersДокумент45 страницNeral Notes On Engineering Hardware - Fastenersbrotaccristian100% (1)

- ER2 Owners ManualДокумент164 страницыER2 Owners ManualKito Canada100% (5)

- Determining Clearance and Interference Fits for CouplingsДокумент4 страницыDetermining Clearance and Interference Fits for Couplingsvilaschinke123Оценок пока нет

- BARNES Associated Spring Raymond 2010Документ260 страницBARNES Associated Spring Raymond 2010Francois LaroucheОценок пока нет

- Safety Catalog SOFAMEL 2011Документ80 страницSafety Catalog SOFAMEL 2011antegeia2222100% (3)

- Through Conduit Gate Valves Slab & ExpandingДокумент7 страницThrough Conduit Gate Valves Slab & ExpandingRockny310Оценок пока нет

- A9 002 Crane Support TruckДокумент2 страницыA9 002 Crane Support TruckalanparraОценок пока нет

- Groove GaugingДокумент3 страницыGroove GauginghshobeyriОценок пока нет

- Aot GG (350 Ton) Bottleneck ElevatorДокумент1 страницаAot GG (350 Ton) Bottleneck ElevatorCarlig Radu MihaiОценок пока нет

- Manual of Mud GunДокумент13 страницManual of Mud GunQC RegianОценок пока нет

- 5-0001 Wire Line Guide BJДокумент1 страница5-0001 Wire Line Guide BJJacekОценок пока нет

- Chapter 6 - Johnson Blocks - MetricДокумент46 страницChapter 6 - Johnson Blocks - MetricJc ElectroHidraulicos Sac0% (1)

- Thread Identification and Drill Chart: MetricДокумент1 страницаThread Identification and Drill Chart: MetricMOHANОценок пока нет

- Power Tong PartsДокумент16 страницPower Tong PartsSorinОценок пока нет

- Fleet Angle SignificanceДокумент13 страницFleet Angle SignificanceAshish Kumar JhaОценок пока нет

- HoistДокумент4 страницыHoistAnonymous 1qAH6CKCОценок пока нет

- Owner'S Manual For End Carriage: ECN11-2562-A40996A0000-KEДокумент10 страницOwner'S Manual For End Carriage: ECN11-2562-A40996A0000-KEmanafОценок пока нет

- 8008 ControlSwitches EK00 III enДокумент8 страниц8008 ControlSwitches EK00 III enLaurence Malanum100% (1)

- Flange Gasket SimulationДокумент23 страницыFlange Gasket Simulationapi-469023149Оценок пока нет

- Fluid Lines FittingsДокумент61 страницаFluid Lines FittingsVy ThoaiОценок пока нет

- Doutec ProductsДокумент13 страницDoutec Productshemispheretorqueweld100% (1)

- Metric BoltsДокумент52 страницыMetric BoltsDGW100% (1)

- Wheel Calculation IDEA Analyzes Wheel Material OptionsДокумент35 страницWheel Calculation IDEA Analyzes Wheel Material Optionsbambang satryojatiОценок пока нет

- Enerpac P-392 Service InstructionsДокумент8 страницEnerpac P-392 Service InstructionsSergio ReyesОценок пока нет

- Pad Eyes PDFДокумент1 страницаPad Eyes PDFPierluigiBusettoОценок пока нет

- Vibro InfigatorДокумент2 страницыVibro InfigatorDanielGabrielBaleaОценок пока нет

- Bolt CapacityДокумент2 страницыBolt CapacityMoonzeОценок пока нет

- Bridon Offshore ExplorationДокумент44 страницыBridon Offshore ExplorationAthox QhurienОценок пока нет

- How to Replace Wire Rope in 5 StepsДокумент7 страницHow to Replace Wire Rope in 5 StepsBistok MarbunОценок пока нет

- Sae J1231-2011Документ14 страницSae J1231-2011Ace LeeОценок пока нет

- Chapter02 ThimblesДокумент10 страницChapter02 ThimbleswernerrsaОценок пока нет

- Hydraulic PipingДокумент1 страницаHydraulic Pipingpandunugraha04Оценок пока нет

- Screw ForcesДокумент10 страницScrew ForceskasreedharОценок пока нет

- Calculating Yield & Tensile Strength - Portland BoltДокумент21 страницаCalculating Yield & Tensile Strength - Portland BoltKummareashvarОценок пока нет

- 13 Symbols DrawingsДокумент13 страниц13 Symbols DrawingsAlie AlbantaniОценок пока нет

- Premium Swivel Parts List for Oilfield DrillingДокумент15 страницPremium Swivel Parts List for Oilfield Drillinghebert perezОценок пока нет

- DIN 580 ISO 3266: Lifting Eye BoltsДокумент2 страницыDIN 580 ISO 3266: Lifting Eye BoltsbloggerparthiОценок пока нет

- Inch Socket Head Cap Screws Dimensions and SpecificationsДокумент16 страницInch Socket Head Cap Screws Dimensions and SpecificationsyauctionОценок пока нет

- Wire Ropes - Bridon Rope - BAC - TechnicalДокумент25 страницWire Ropes - Bridon Rope - BAC - TechnicalJose BijoyОценок пока нет

- MCM OIL TOOLS Cameron Style ChokesДокумент2 страницыMCM OIL TOOLS Cameron Style ChokesBodega 300150% (2)

- HeliCoil Insert Specs ImperialДокумент1 страницаHeliCoil Insert Specs ImperialAce Industrial SuppliesОценок пока нет

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965От EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerОценок пока нет

- Thread Identification Chart - Part 1Документ2 страницыThread Identification Chart - Part 1Ivan DuncanОценок пока нет

- Thread Identification ChartДокумент4 страницыThread Identification ChartIvan DuncanОценок пока нет

- Maryland Metrics: Technical Data ChartДокумент10 страницMaryland Metrics: Technical Data ChartchethanОценок пока нет

- The Test of English For Academic Purposes (TEAP) Impact Study: Report 1 - Preliminary Questionnaires To Japanese High School Students and TeachersДокумент47 страницThe Test of English For Academic Purposes (TEAP) Impact Study: Report 1 - Preliminary Questionnaires To Japanese High School Students and TeachersrefaeОценок пока нет

- Questions and Answers Parents English PDFДокумент20 страницQuestions and Answers Parents English PDFrefaeОценок пока нет

- The Test of English For Academic Purposes (TEAP) Impact Study: Report 1 - Preliminary Questionnaires To Japanese High School Students and TeachersДокумент47 страницThe Test of English For Academic Purposes (TEAP) Impact Study: Report 1 - Preliminary Questionnaires To Japanese High School Students and TeachersrefaeОценок пока нет

- SEPT Format English June 2011Документ2 страницыSEPT Format English June 2011M Fahrudin MunaОценок пока нет

- Sample Aptitude Test of MBA Karachi UniversityДокумент8 страницSample Aptitude Test of MBA Karachi Universityzeb593100% (6)

- Ilecsample PDFДокумент51 страницаIlecsample PDFrefaeОценок пока нет

- Reading Comprehension PracticeДокумент14 страницReading Comprehension PracticeVasantha Mallar60% (5)

- Testas: Sample QuestionsДокумент72 страницыTestas: Sample QuestionsrefaeОценок пока нет

- SEPT Format English June 2011Документ2 страницыSEPT Format English June 2011M Fahrudin MunaОценок пока нет

- Bulats Sample Paper - En001Документ32 страницыBulats Sample Paper - En001mome85Оценок пока нет

- Ket Handbook2007Документ54 страницыKet Handbook2007hugoysamy29Оценок пока нет

- EOC English 2 Pretest Session 1 PDFДокумент29 страницEOC English 2 Pretest Session 1 PDFrefaeОценок пока нет

- gr7 Reading PT PDFДокумент19 страницgr7 Reading PT PDFrefae100% (2)

- G9a PDFДокумент14 страницG9a PDFrefaeОценок пока нет

- English Language Exam - A2-B1Документ10 страницEnglish Language Exam - A2-B1dule8350% (2)

- TEA Guide For Students 2016Документ10 страницTEA Guide For Students 2016Crashed FailedОценок пока нет

- EP Rtep Qa PDFДокумент2 страницыEP Rtep Qa PDFrefaeОценок пока нет

- FDA General EnglishДокумент13 страницFDA General EnglishAshwin GowdaОценок пока нет

- ExamEssentials Advanced1 SampleTest 0 PDFДокумент2 страницыExamEssentials Advanced1 SampleTest 0 PDFrefaeОценок пока нет

- English II EOC 2015 Release Test PDFДокумент48 страницEnglish II EOC 2015 Release Test PDFrefae0% (1)

- English Language Exam - A2-B1Документ10 страницEnglish Language Exam - A2-B1dule8350% (2)

- NSW, Australia Driver Knowledge Test Questions CarДокумент94 страницыNSW, Australia Driver Knowledge Test Questions Carmesssi269Оценок пока нет

- Ela PDFДокумент35 страницEla PDFrefaeОценок пока нет

- Ela6 - Released 2009 English PDFДокумент27 страницEla6 - Released 2009 English PDFrefaeОценок пока нет

- CAE TestДокумент16 страницCAE TestLuB.100% (3)

- Cbest Practice Test: California Basic Educational Skills TestДокумент36 страницCbest Practice Test: California Basic Educational Skills Testross DowninОценок пока нет

- LAU English Entrance Exam Preparation GuideДокумент12 страницLAU English Entrance Exam Preparation GuidexiaomiredmiОценок пока нет

- ACTprep2013 2014 PDFДокумент64 страницыACTprep2013 2014 PDFrefae100% (1)

- Level 2 Sample Assessment Materials PDFДокумент31 страницаLevel 2 Sample Assessment Materials PDFrefaeОценок пока нет

- CNC Horizontal Drilling Machine for Steel Fabrication ShopsДокумент8 страницCNC Horizontal Drilling Machine for Steel Fabrication ShopsShashidhar ShashiОценок пока нет

- Cutting Tool Applications: by George Schneider, Jr. CmfgeДокумент9 страницCutting Tool Applications: by George Schneider, Jr. CmfgeburakОценок пока нет

- Threaded Rod: Available Size Model Max Service Load (KN) Property Class Tolerance Class Screw Thread Metric Size D (MM)Документ1 страницаThreaded Rod: Available Size Model Max Service Load (KN) Property Class Tolerance Class Screw Thread Metric Size D (MM)PERVEZ AHMAD KHANОценок пока нет

- Secondary or Machining ProcessДокумент49 страницSecondary or Machining ProcessHar QuinОценок пока нет

- Book Parts E-WE 1204-55 INGДокумент138 страницBook Parts E-WE 1204-55 INGricardo assaf marchetiОценок пока нет

- ThreadingДокумент8 страницThreadingVivek SDОценок пока нет

- Control Panel CAT C15 FFHДокумент3 страницыControl Panel CAT C15 FFHGamal El Deen KamalОценок пока нет

- Pipe Thread Size ChartДокумент3 страницыPipe Thread Size ChartarizweruОценок пока нет

- Bolts - SlidesДокумент133 страницыBolts - SlidesImran BabarОценок пока нет

- Cable Glands Cross ReferenceДокумент8 страницCable Glands Cross ReferenceUrip S. Setyadji100% (1)

- Standard of Depth of Cut for External ThreadingДокумент3 страницыStandard of Depth of Cut for External ThreadingNaren SomaruОценок пока нет

- Tightening Torques PDFДокумент1 страницаTightening Torques PDFlaweenceОценок пока нет

- Phoroptor Parts Manual, 2009Документ23 страницыPhoroptor Parts Manual, 2009gersonbartoloОценок пока нет

- E&s Report Prakash .MДокумент43 страницыE&s Report Prakash .MShrigith SОценок пока нет

- BrokeragesДокумент24 страницыBrokeragesCariza BitongОценок пока нет

- CNC PROGRAM FOR 3/4 BSPT NUTДокумент294 страницыCNC PROGRAM FOR 3/4 BSPT NUTNemikumar Gandhi100% (1)

- Npat 2Документ2 страницыNpat 2aaaОценок пока нет

- ROSCA AMERICANA GROSSA (UNC) – SPECS FOR UNC THREAD SIZESДокумент1 страницаROSCA AMERICANA GROSSA (UNC) – SPECS FOR UNC THREAD SIZESromuloacОценок пока нет

- Manual (PDF) - InventorCAM TURNINGДокумент170 страницManual (PDF) - InventorCAM TURNINGИгорь ПлугатырёвОценок пока нет

- 7 Threading ToolsДокумент28 страниц7 Threading ToolsMehdy HosseiniОценок пока нет

- Catalogo CovalcaДокумент109 страницCatalogo CovalcaCarlo MonsalveОценок пока нет

- Catalogo de Equipos de Medicion de Roscas 2Документ27 страницCatalogo de Equipos de Medicion de Roscas 2HERNANDO CASTILLOОценок пока нет

- BSP Vs NPT Thread - Knowledge - Yuyao Jiayuan Hydraulic Fitting FactoryДокумент5 страницBSP Vs NPT Thread - Knowledge - Yuyao Jiayuan Hydraulic Fitting FactorySalahiddin AbuselmiyaОценок пока нет

- Better Homes & Gardens 8 Cube Organizer ENДокумент26 страницBetter Homes & Gardens 8 Cube Organizer ENTenny SupОценок пока нет

- Asme B18.31.3-2014Документ14 страницAsme B18.31.3-2014vijay pawar100% (1)

- Hardware List: Description Part No. Description Part NoДокумент24 страницыHardware List: Description Part No. Description Part NoRuud Bakker100% (1)

- Tapping Screw Performance Specifications: Greenslade & Company, IncДокумент22 страницыTapping Screw Performance Specifications: Greenslade & Company, Inco_l_0Оценок пока нет

- British Standard PipeДокумент3 страницыBritish Standard PipeskluxОценок пока нет

- Bolts Non-Structural (A-307) A325 A449 A490 Rivets (Obsolete)Документ40 страницBolts Non-Structural (A-307) A325 A449 A490 Rivets (Obsolete)claudio perez prietoОценок пока нет

- UN Thread Chart PDFДокумент3 страницыUN Thread Chart PDFDeepan GovindasamyОценок пока нет