Академический Документы

Профессиональный Документы

Культура Документы

Wankel CC Paper

Загружено:

ravian4390 оценок0% нашли этот документ полезным (0 голосов)

332 просмотров15 страницEngine short block with fewer parts reaches the pinnacle in the simplicity of the rotary combustion engine design concept. The single rotor and two rotor engines cover a power range of 5-50Kw when naturally aspirated, with a weight to power ratio close to I lbs lhp. The new engines are suitable for diverse stationary and mobile applications in which weight, box volume and vibration are strict constraints.

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документEngine short block with fewer parts reaches the pinnacle in the simplicity of the rotary combustion engine design concept. The single rotor and two rotor engines cover a power range of 5-50Kw when naturally aspirated, with a weight to power ratio close to I lbs lhp. The new engines are suitable for diverse stationary and mobile applications in which weight, box volume and vibration are strict constraints.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

332 просмотров15 страницWankel CC Paper

Загружено:

ravian439Engine short block with fewer parts reaches the pinnacle in the simplicity of the rotary combustion engine design concept. The single rotor and two rotor engines cover a power range of 5-50Kw when naturally aspirated, with a weight to power ratio close to I lbs lhp. The new engines are suitable for diverse stationary and mobile applications in which weight, box volume and vibration are strict constraints.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 15

900035

cally reduced the seal trochoid housing wear rate.

Extensive endurance tests performed on current pro-

duction rotary engines indicate the rates of these

ABSTRACT engine components low enough to enable 20,000 hours

of engine operation at moderate load (1)*.

A new family of compact, light weight Wankel

Considerable improvements were made on engine

engines for multi-purpose applications was designed

emissions and fuel consumption to a level where now it is

and is currently under an optimization test. generally accepted that the rotary engine is more fuel

The engine short block with fewer parts reaches efficient than a two stroke piston engine and can match the

the pinnacle in the simplicity of the rotary combustion fuel consumption of small four stroke piston engines

engine design concept. for stationary applications.

New technological solutions have been employed With respect to the rotor cooling, two methods were

in the design of the cooling, ignition and lubrication employed - Oil Cooled Rotor - OCR and Charge Cooled

systems in order to lower the engine maintenance Rotor - CCR. See Figure 1. The best known practical

and operating costs. realization are the Mazda and John Deere oil cooled

The paper describes the primary components and rotor engines. The OCR solution is characterized by high

systems of the engine and much of the design and power density while the CCR solution is associated with

development work that led to the validation of the new simplicity (2). Recently, a new concept in rotor

design. cooling was developed at Wankel R & D GmbH using, as a

The single rotor and two rotor engines cover a starting point, a OCR type engine. The rotor and

power range of 5-50Kw when naturally aspirated, rotor bearing temperatures were controlled by an

with a weight to power ratio close to I lbs lhp. The additional cooling circuit through a hollow eccentric

design concept demonstrated a high potential for shaft. The solution was designated as LCCR - Liquid

turbocharged applications. Unparalleled weight to and Charge Cooled Rotor.

power ratio are estimated for the fully developed

Extremely low thermal loads and high durability were

turbocharged version of both engines. The new

experienced for rotor and rotor bearing.

engines are suitable for diverse stationary and mobile

applications in which weight, box volume and vibra-

COOLING SYSTEM FOR ROTOR

tion are strict constraints.

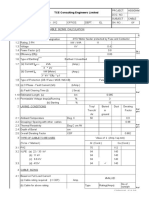

Table 1 suggests a classification of the Wankel type

INTRODUCTION

engines from the point of view of the cooling system

employed for rotor and rotor bearing

The technical "childhood diseases" of the Wankel

The best known concept to date is the oil cooled

type engines were the limited life of the apex seal,

rotor (OCR) which is usually associated with a liquid

overheating of the rotor and rotor bearing, higher

cooling system of engine housings, i.e., rotor housing,

emissions and higher fuel consumption when com-

front housing and rear housing. This was the original

pared with four cycle piston engine of comparable

solution developed by NSU/Wankel, and was successfully

size.

applied in production type engines by Mazda, John

The durability of the apex seal was considered the

Deere, and others (3-7). For these

most critical of all improvement activities. Today,

after better than 20 years of technological effort, it is

no longer a limiting factor in rotary engine

life.Technological progress in materials, heat treat-

ment and surface coating (ceramics) have dramati-

Dankwart Eiermann - Wankel R&D GmbH

Roland Nuber - Wankel R&D GmbH

Michael Soimar Rotec Mfg. & Eng. Corp.

reasons we considered this solution representing the additional liquid cooling circuit hosted by a hollow

current full potential of the Wankel engine and we eccentric shaft. We designated the solution as LCCR -

credited it with 100% rank (see Table 1). For light duty Liquid and Charge Cooled Rotor. While the patented

applications, the charge cooled rotor (CCR) offers cooling circuit is not directly cooling the rotor, t has

significant manufacturing cost reduction and added a remarkable impact on its thermal load by keeping

simplicity by eliminating the oil cooling system. Com- the eccentric shaft and rotor bearing temperature

bined with a liquid cooling system for the engine within close limit.

housing, the CCR system offers only 80% of the The LCCR solution solves a well known drawback of

maximum obtainable power when compared to the OCR the CCR engine, namely, the increased thermal load

system applied to the same basic engine design, imposed on the engine shaft by the blow-by gas

e.g. volumetric displacement, engine rated speed, escaping the side seal system. In both CCR and

port arrangement, etc. LCCR solutions, the charge mixture or intake air is

Poor performance of the CCR type engine is due to drawn in an axial direction throught the rotor, so that

the higher temperature of the rotor, rotor bearing and all gas leakage eluding the side sealing system is

eccentric shaft and to the diminished volumetric mixed with the fresh charge and fed into the suction

efficiency as a result of heat transfer from the above chamber through the chamber intake port. This is

mentioned engine parts to the fresh charge mixture. The equivalent to a built-in ventilation system similar to

engine performance is even lower when the CCR the crankcase ventilation of reciprocating engines.

solution is coupled with an air cooling system for the This "in situ", internal ventilation system unfortu-

engine housings. Some CCR engines are using the nately has an unwanted side effect on shaft areas ad-

fresh charge mixture to cool the eccentric shaft and jacent to the rotor. The blow-by gas escaping the side

rotor bearing. This method is usually employed when sealing system directly hits the shaft surface causing

gasoline (mixed with oil) or natural gas are used as significant thermal loads on the shaft, rotor bearings

fuel. In the first case, the fuel evaporation helps the and rotor gear. The shaft cooling system employed

engine's internal cooling. in the LCCR engines effectively compensates for this

If the power of a basic CCR engine is increased by additional thermal load.

conventional means, such as higher shaft speed or Numerous tests conducted on an early LCCR en-

tuned intake and exhaust systems, the engine dura- gine in its development period revealed the excellent

bility is affected by the higher load. First in line to potential of this solution.

experience functional problems is the rotor bearing, Table 1 is far from being exhaustive. For example,

especially when its lubrication is scarcely in order to the introduction of an intercooler for the charge mix-

control the engine oil consumption. ture in association with the CCR solution opens

another branch of the classification tree. Also, there

A dramatic improvement in the engine thermal

are a few Wankel engines which are using the bleed

distribution was obtained when a charge cooled rotor was

air to cool the rotor and the rotor bearing. This

combined with a liquid cooled rotor bearingthrough an

combination again extends the classification related to with the OCR solution. The CCR solution offers an

the rotor and rotor bearing cooling system. even better cost advantage but its concept is limited

The OCR and intercooler combination improves the to the relatively small engines. To date, only CCR

engine volumetric efficiency and accordingly the power rotary engines up to 650cc have been developed and

penalty of the basic CCR system can be easily produced successfully (9).

compensated for (8). For instance, a 2 rotor racing The total efficiency of the CCR engines can equal

engine with a total displacement of 588cc demon- that of the OCR engines due to the former's lower

strated over 135 hp at 9800 rpm and won the British friction losses as long as the overheating phenomena

Formula 1 championship for motorcycles. On the can be controlled. Overheating is especially

other hand, the intercooler solution increases the worrissom at part load conditions. in this respect, the

engine's overall weight and manufacturing cost. LCCR engine demonstrates a decisive advantage by

Table 2 shows the influence of the rotor cooling exactly controlling its internal temperatures.

design concept on estimated engine performance,

total efficiency potential and production cost. The BASIC RESEARCH

evaluation was limited to the basic design concept

discounting the influence of engine accessories such as In order to assess the thermal load of the rotor, a

intercoolers, etc. single rotor research rig was instrumented with slid-

By eliminating the oil cooling system with an oil ing contact brushes mounted in a slave side housing.

pump, a heat exchanger, an oil sump and especially The rotor was equipped with two corresponding slid-

the oil sealing system, a cost advantage of up to 30% ing rails connected to thermocouples placed dose to

can be achieved for a LCCR engine when compared the rotor flank surface. The instrumentation is shown

in Figure 2.

The rotor temperature variation, Figure 3, clearly about 30% when compared with the CCR solution and

demonstrates the dose dynamic correlation between up to 60% reduction when compared with the UCR

rotor temperature, engine load and intake air tem- sloution.

perature passing through the rotor in a charge cooled To better evaluate the influence of the shaft internal

rotor arrangement Particularly in high load condi- cooling circuit on the rotor assembly thermal load, the

dons, the rotor thermal load can top the thermo- rotor cooling by the fresh charge was interrupted. More

hydrodynamic limits of bearing and lubrication. There- simply stated, only the shaft cooling was employed

fore, in the case of a charge cooled rotary engine, it is as a means to control the rotor assembly

essential to consider a careful layout of an effective temperature. The engine was fed by a direct periph-

bearing lubrication system and a special rotor bearing eral intake port. Even at W.O.T. conditions, 8.5 bar

and shaft design. BMEP at 6000 rpm, the rotor assembly thermal load

did not exceed the critical limits.

When designing the rotor bearing concept, it is

extremely important to keep the surface hardness of

the bearing's inner race under special scrutiny since

the cyclic load burdens the same area every revolu-

tion, while the mirror portion of the outer race moving

with the rotor is loaded only every third rotation.

Therefore, any overheating situation coupled with

poor lubrication will reduce the surface hardness

dramatically in the critical area and finally will destroy

the bearing system. An additional problem to be

taken into account is the increased gas leakage from

the combustion by rotor distortion. In addition to an

effective gas sealing system design, the gas blow-by

effect can be attenuated through efficient internal

ventilation. This is achieved by the rotor charge

cooling system. The thermal loads impact on the

bearing system is further diminished in the LCCR ar-

rangement by the shaft internal cooling system.

The LCCR cooling system arrangement is easy to

follow when considering a longitudinal section of a

twin rotor LCCR engine - Figure 4. The cooling

solution facilitates a careful distribution of the coolant

flow towards the engine's most heated parts. The

water pump is mounted directly on the engine main

shaft opposite the power take-off end - see Figure 4.

The first stage of the water pump rotor controls the

entire circuit for the engine housings. The second

stage of the rotor, comprised of four small blades,

must supply enough coolant to the shaft where the

coolant flows axially through a concentric pipe toward

the critical areas of the hollow shaft and then back to

the water pump inlet

A new manufacturing method has been devel-

In comparative tests the influence of the water

cooled shaft circuit on the rotor and shaft tempera-

tures were evaluated. The engine was tested under

part load and full load conditions in UCR, CCR and

LCCR arrangements - see Table 1. The LCCR

solution demonstrates a rotor thermal load reduction of

oped for the hollow shaft structure - see Figure 5. A rotor engine) and the LCCR 800T, (twin rotor engine)

steel tube is formed in a corresponding pattern by hy- of the family. Figure 7 represents a cross section

draulic pressing (approx 6000 bar) in a cold fashioning of the LCCR engine module. Details of a

process. longitudinal section on the twin rotor engine were

The critical stress areas of this special shaft design shown in Figure 4.

were identified during the development stage using a

sophisticated computer program.

The program input is shaft speed, modulus of

elasticity, shaft wall thickness, engine cycle pressure

diagram and the dynamic load associated with the

rotating parts. The program output display is the

stress distribution in the shaft structure - see Figure 6.

An associated finite element program supplies

decisive information on the critical stress areas and

facilitates the development of an optimized light-

weight shaft with maximum stability.

THE LCCR FAMILY OF WANKEL ENGINES

The LCCR family of engines is based on a modular

concept in which the same carefully proportioned cross

section module is used for the LCCR 400S(single

Capitalizing on the well known advantages of the Figures 9 and 10 depict the LCCR 400S engine

rotary engine's design concept new members of the viewed from the spark plug side and respectively

family can be subsequently created with minimal from intake and exhaust ports. A 200mm ruler helps

additional parts and developmental work. in assessing the engine's

Table 3 presents the main features of the

LCCRengines. Figure 8 summarizes the layout

dimensions of the single and twin rotor engines.

The cooling arrangement has proven high

reliability and facilitates the easy assembly of

the engine housings.

The aluminum rotor housing employs an

electroplated ceramic coating for the apex seals

sliding surface which requires an oscillating

finish grinding process. The aluminum side

housings are coated with wear-resistant materials

in accordance with the engine application,

associated surface load and lubrication

conditions.

The surface ground housings are assembled by

17 tension bolts to keep the axial preload

constant under all mechanical and thermal stress

conditions.

The three housings for a single rotor module

and the five housings for a twin rotor, twin module

engine, are precisely interlocked by dowel

pins.

The rotor shown in Figure 16 from both drive

and antidrive sides, is cast from nodular iron. The

design employs a special thin wall undercut casting

overall proportions. Figures 11 and 12 represent using a ceramic core technique. The driving -

similar views for the LCCR 800T engine. In the case of synchronization gear is integrated in the rotor

the twin rotor engine one single carburetor is mounted body and dimensioned in order to be broached in

to the intermediate housing stippling the fresh charge one step. The gas sealing system uses two piece

alternatively to both combustion chambers. apex seals. Depending on the application, a broad

The engine's main performance, power, torque and composition of materials can be used for apex,

specific fuel consumption, for the gasoline version of corner and side seals.

both engines, are shown in Figure 13. These are baseline The engine uses a total loss lubrication system

figures with no special effort directed to the performance monitored by an oil metering pump which

optimization. delivers small quantities of lubricant to all friction

Figure 14 shows the gear case with all accessory couples. No oil sump or oil filters are necessary

drives, such as metering oil and starter motor gear. The and the engine can operate in any attitude. The

gear case front side is closed by the water pump housing oil consumption is equivalent to that of

with the double stage pump and the water supply port for conventional four cycle piston engines.

the hollow shaft at the rear side. Thermostat valve is Almost five years of development have resulted

located in the gear case beside the pump and controls in a dramatic evolution towards design simplicity.

coolant circuits for both housing and shaft. The side The LCCR 400S engine has only 10 main parts of a

housings, front and rear and the rotor housing, common total of 300 parts including the engine

for both single and twin rotor engines, are shown in fastenings.

Figure 15. Each housing has one coolant supply port, one The number of LCCR engine main components

water outlet and a common axial water return passage, all is significantly low when compared with a piston

sealed by rubber O-ring seals. The water discharge ports engine of a comparable power range. Figure 17

and cross passages are calibrated in order to closely compares an early version of the LCCR 400S engine

control the necessary coolant flow for each housing. The with a four cylinder piston engine of the same

coolant flow pattern is oriented in the circumferential class. The simplicity of the LCCR design concept is

direction in order to minimize coolant leakage, which in still evident when compared with an OCR single

this case are much lower than those associated with an rotor type engine of the same displacement as

axial directed cooling system. shown in Figure 18.

The LCCR 400S and LCCR 800T engines are

currently being optimized on gasoline, natural

gas and heavy fuels.

CONCLUSIONS

A new class of rotary combustion engines has

been designed, developed and is being optimized on

various fuels. The LCCR design concept conserves

the prime advantages of the rotary engine while suc-

cessfully addressing on of its few remaining draw-

backs, the uneven heat rejection thru its rotating parts -

rotor, rotor bearing, rotor gear and the eccentric

shaft and the resulting overheating tendency of the

CCR configuration. Employing a special cooling

system in which the engine hollow shaft plays a central

role, the thermal load of the rotor bearing is closely

controlled. Extensive tests conducted during the

engine development period revealed a high reliability

of the rotor bearing and shaft assemblies.

REFERENCES

1. Steven R King 6. Charles Jones

Durability of Natural Gas Fueled A New source of Lightweight compact

Rotary Engine Multifuel Power for

SAE 870048 Vehicular, Light Aircraft and

Auxiliary Applications -

2. Dr. Kojino Yamaoka, Hiroshi Tado, The John Deere ScoreTM Engines The

Yoshitsugo Hamada American Society of Mech. Engineers

Development of the Rotary Engine with a No. 88-GT-271

Charge Cooled Rotor

MTZ No. 34 (1973) 6 7. Shigeyasu Kamiya and Sada Shirasagi Suzuki

Production Rotary Engine, Model RE-5 for

3. Richard von Basshuysen, Powering

Gottlieb Wilmers Motorcycles

An Update of the Development on the New SAE No. 770190

Audi NSU Rotary

SAE 780418 8. D.W. Garside

Development of the Norton Rotary

4. Wolf-Dieter Bensinger, Motorcycle Engine

Rotationskolben-Verbrennun SAE No. 821068

smotoren

Springer verlag Berlin Heidelberg New 9. Harry M. Ward, Michael Griffith, George

York E. Miller,

ISBN 3-540-05 886-9 Donald K Stephenson

Outboard Marine Corp.'s Production Rotary

5. Kenichi Yamamoto Combustion

Rotary Engine Snowmobile Engine

Published by Sankaido Co., Ltd., SAE 730119

Tokyo, 1981

Вам также может понравиться

- Mazda 4-Rotor Engine Le-MansДокумент10 страницMazda 4-Rotor Engine Le-Mansapi-3810101100% (4)

- Mazda R26B US PDFДокумент11 страницMazda R26B US PDFIrfan Ghani100% (1)

- DENSO - Spark Plug TT CatalogueДокумент255 страницDENSO - Spark Plug TT CatalogueVõ Trí NamОценок пока нет

- Paccar PX 7 Euro 6 Engine 64739 enДокумент4 страницыPaccar PX 7 Euro 6 Engine 64739 enStroe VladОценок пока нет

- Ford - 3543t GCC - Rev4Документ6 страницFord - 3543t GCC - Rev4MakОценок пока нет

- Block de Motor - Especificaciones c15 PDFДокумент19 страницBlock de Motor - Especificaciones c15 PDFFJ OscarОценок пока нет

- "Camless Engine": A Technical Seminar Report OnДокумент29 страниц"Camless Engine": A Technical Seminar Report OnVinayKumarОценок пока нет

- VW SSP PDFДокумент78 страницVW SSP PDFAndres GuamanОценок пока нет

- Detection of Repetitive Forex Chart PatternsДокумент8 страницDetection of Repetitive Forex Chart PatternsDwight ThothОценок пока нет

- The W Engine Concept: Self-Study Program Course Number 821203Документ64 страницыThe W Engine Concept: Self-Study Program Course Number 821203Alwarsamy RamasamyОценок пока нет

- Altitude Performance Comparison of A Wankel enДокумент6 страницAltitude Performance Comparison of A Wankel enrudey18Оценок пока нет

- БЕЛАЗ-75710 BELAZ PDFДокумент2 страницыБЕЛАЗ-75710 BELAZ PDFArturo AllendeОценок пока нет

- Turbo CompoundingДокумент1 страницаTurbo CompoundingPercyLeonОценок пока нет

- Wankel (Rotary) Engines: By: Hoa ChuДокумент8 страницWankel (Rotary) Engines: By: Hoa ChuGabriel MariusОценок пока нет

- GTR R35 FSU-Front SuspensionДокумент21 страницаGTR R35 FSU-Front Suspensiondinodyno100% (1)

- MTU-integrated Bi-Fuel Engine Technology To Reduce Fuel CostsДокумент2 страницыMTU-integrated Bi-Fuel Engine Technology To Reduce Fuel CostsQaiser IqbalОценок пока нет

- Testing The Alco HaulicsДокумент3 страницыTesting The Alco Haulicsstaustell92Оценок пока нет

- BMW Stern Drive Workshop ManualДокумент36 страницBMW Stern Drive Workshop Manualstrumf381Оценок пока нет

- MDiesel Marine2010Документ20 страницMDiesel Marine2010youngfpОценок пока нет

- Luk Clutch Course: Introduction To Clutch Technology For Cars and LcvsДокумент60 страницLuk Clutch Course: Introduction To Clutch Technology For Cars and LcvsKeval KamaniОценок пока нет

- RCE World Rallycross Championship 2014 New PDFДокумент40 страницRCE World Rallycross Championship 2014 New PDFAnita DiazОценок пока нет

- MTU General WhitePaper TurboCharging 2014Документ6 страницMTU General WhitePaper TurboCharging 2014Pankaj KambleОценок пока нет

- Understanding The Mack MP8 - Engine Builder MagazineДокумент5 страницUnderstanding The Mack MP8 - Engine Builder MagazineEslam MansourОценок пока нет

- Navistar 1Документ2 страницыNavistar 1ValBMSОценок пока нет

- Accident Analysis RBMKДокумент70 страницAccident Analysis RBMKcarneoliaОценок пока нет

- Manual Formacion V3300-DI-TДокумент20 страницManual Formacion V3300-DI-TTerah PioОценок пока нет

- S0020028320-Nr 83 1 4 LTR 132 KW TSI Petrol Engine With Dual-Charging (Compressor Turbocharger)Документ48 страницS0020028320-Nr 83 1 4 LTR 132 KW TSI Petrol Engine With Dual-Charging (Compressor Turbocharger)IongornistuОценок пока нет

- Top Ten Basic Diesel Engine Maintenance SecretsДокумент20 страницTop Ten Basic Diesel Engine Maintenance SecretsdonlynОценок пока нет

- SSP 825803 (Routan Fuel and OBDII Systems) enДокумент70 страницSSP 825803 (Routan Fuel and OBDII Systems) enJoseph MorantОценок пока нет

- Motor Detroit Serie 40eДокумент212 страницMotor Detroit Serie 40eJhoset Apaza Charca100% (1)

- Wankel RCE - Some ReferencesДокумент11 страницWankel RCE - Some ReferencesJgrosayОценок пока нет

- OPEL INSIGNIA 2013 - Powertrain Component ViewsДокумент19 страницOPEL INSIGNIA 2013 - Powertrain Component ViewsGedas GvildysОценок пока нет

- The New Mercedes Benz Four Cylinder Diesel Engine For Passenger CarsДокумент8 страницThe New Mercedes Benz Four Cylinder Diesel Engine For Passenger CarsBobCavОценок пока нет

- Qsx15 BrochureДокумент8 страницQsx15 BrochureferminОценок пока нет

- N00012ED - 3ed - May 2005, EMDECДокумент376 страницN00012ED - 3ed - May 2005, EMDECRafael Dutil LucianaОценок пока нет

- 9800i Spec Sheet PDFДокумент2 страницы9800i Spec Sheet PDFAl FbaОценок пока нет

- SSP 508 The 1.0l 44 55 KW MPI EngineДокумент36 страницSSP 508 The 1.0l 44 55 KW MPI Enginedavorin59Оценок пока нет

- Continuous TrackДокумент13 страницContinuous TrackVeljko100% (1)

- Understanding Model Name of Turbo Garret G Series - WWW - Magyarturbo.huДокумент12 страницUnderstanding Model Name of Turbo Garret G Series - WWW - Magyarturbo.huAnprtmk072Оценок пока нет

- BS IV To BS VI Tata Motors PDFДокумент3 страницыBS IV To BS VI Tata Motors PDFKaranОценок пока нет

- Mazda R26B US - PDF (Recovered)Документ20 страницMazda R26B US - PDF (Recovered)Paul DumitruОценок пока нет

- Exhaust Gas After TreatmentДокумент32 страницыExhaust Gas After TreatmentMajid KhanОценок пока нет

- A V228 StationaryДокумент4 страницыA V228 StationaryMike FinazziОценок пока нет

- Multi AirsystemДокумент13 страницMulti AirsystemSivaji Liar100% (1)

- Electric Variable Valve Timing Actuator (Skyactiv-G 2Документ3 страницыElectric Variable Valve Timing Actuator (Skyactiv-G 2Drew736250% (2)

- Engine Data MiniGuideДокумент28 страницEngine Data MiniGuideMaik AmayaОценок пока нет

- Category MotorsДокумент4 страницыCategory MotorsKevin CondorОценок пока нет

- Megacycle CamДокумент65 страницMegacycle Camcochran04Оценок пока нет

- Toyota Nico PDFДокумент33 страницыToyota Nico PDFDaniel GarciaОценок пока нет

- Haltech f9v5 ManualДокумент99 страницHaltech f9v5 ManualboxyhenricОценок пока нет

- EM2000 Messages 20090211 by Code PDFДокумент169 страницEM2000 Messages 20090211 by Code PDFSudarshan DhumalОценок пока нет

- Cts 11-12 Service Manual CompleteДокумент664 страницыCts 11-12 Service Manual Completemayer57619Оценок пока нет

- Current Ford To International Cross Reference (Complete) As of 12/2006Документ125 страницCurrent Ford To International Cross Reference (Complete) As of 12/2006Waqas RiazОценок пока нет

- Nanni 6.420 TDi Marine Diesel 6cylДокумент16 страницNanni 6.420 TDi Marine Diesel 6cylAlbertoJim90Оценок пока нет

- Maintenance Mstruction: DescriptionДокумент11 страницMaintenance Mstruction: Descriptionamir barekatiОценок пока нет

- 2015 Ford 6.7L Diesel F 250 550 Supplement Version 1 - 60l6d - EN US - 02 - 2014Документ84 страницы2015 Ford 6.7L Diesel F 250 550 Supplement Version 1 - 60l6d - EN US - 02 - 2014Miguel Valdivia QuesadaОценок пока нет

- C V RamanДокумент8 страницC V RamanJayesh KomalwarОценок пока нет

- Differential Pr. Gauges Bellow Type 1Документ2 страницыDifferential Pr. Gauges Bellow Type 1Vara PrasadОценок пока нет

- Code of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Документ11 страницCode of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Sarbendu PaulОценок пока нет

- All Graphs and Charts Available in Show MeДокумент16 страницAll Graphs and Charts Available in Show MeGANGA TAGRAОценок пока нет

- Estimating QuotientsДокумент7 страницEstimating Quotientssheila mae neri100% (1)

- 4$20 Triangles$20 ProofsДокумент23 страницы4$20 Triangles$20 ProofsBaskaran SeetharamanОценок пока нет

- Brazil (1997) The Communicative Value BW PDFДокумент200 страницBrazil (1997) The Communicative Value BW PDFJuan LopezОценок пока нет

- Installation, Operation, and Maintenance ManualДокумент54 страницыInstallation, Operation, and Maintenance ManualIsmael Berlanga ResОценок пока нет

- Mohamad Fakhari Mehrjardi - 1Документ18 страницMohamad Fakhari Mehrjardi - 1Hilmi SanusiОценок пока нет

- 7.GSM ChannelsДокумент24 страницы7.GSM Channelsmanthasaikarthik100% (1)

- Practical - Magnetic - Design (Fill Factor) PDFДокумент20 страницPractical - Magnetic - Design (Fill Factor) PDFAhtasham ChaudhryОценок пока нет

- Phrasal Verbs-Syntactic BehaviorДокумент4 страницыPhrasal Verbs-Syntactic BehaviorAntonija KnezovićОценок пока нет

- Zbrush 4 ShortcutsДокумент3 страницыZbrush 4 ShortcutsJОценок пока нет

- Experimental Techniques For Low Temperature Measurements PDFДокумент2 страницыExperimental Techniques For Low Temperature Measurements PDFVanessaОценок пока нет

- A Report On Traffic Volume StudyДокумент33 страницыA Report On Traffic Volume StudyManoj Durairaj100% (1)

- 2.data Types Ver2Документ56 страниц2.data Types Ver2qwernasdОценок пока нет

- AWK - WikipediaДокумент1 страницаAWK - WikipediachassisdОценок пока нет

- Number Patterns and SequencesДокумент10 страницNumber Patterns and SequencesMohamed Hawash80% (5)

- The Kemetic Tree of LifeДокумент1 страницаThe Kemetic Tree of LifeFlorin CiudinОценок пока нет

- D4304-Syllabus-Neural Networks and Fuzzy SystemsДокумент1 страницаD4304-Syllabus-Neural Networks and Fuzzy Systemsshankar15050% (1)

- ECE ExperimentДокумент13 страницECE Experimentasm98090% (1)

- Physical Quantities and Unit: 9th GradeДокумент28 страницPhysical Quantities and Unit: 9th GradeAlexanderОценок пока нет

- Cable Sizing CalculationДокумент72 страницыCable Sizing CalculationHARI my songs100% (1)

- TR 94 13Документ25 страницTR 94 13Christian Norambuena VallejosОценок пока нет

- IncarnationДокумент3 страницыIncarnationViviana PueblaОценок пока нет

- Full U-Band Rectangular Waveguide-to-Microstrip Transition Using E-Plane ProbeДокумент4 страницыFull U-Band Rectangular Waveguide-to-Microstrip Transition Using E-Plane ProbeSanjib MandalОценок пока нет

- Gauss Method - Nisan 15Документ1 страницаGauss Method - Nisan 15Otis ArmsОценок пока нет

- HydrometerДокумент13 страницHydrometerShubhrajit MaitraОценок пока нет

- Auto-Tune Pid Temperature & Timer General Specifications: N L1 L2 L3Документ4 страницыAuto-Tune Pid Temperature & Timer General Specifications: N L1 L2 L3sharawany 20Оценок пока нет