Академический Документы

Профессиональный Документы

Культура Документы

Lean Cheatsheets

Загружено:

prekajski0 оценок0% нашли этот документ полезным (0 голосов)

71 просмотров4 страницыThis document compares traditional Lean principles with those more suited for high mix, low volume production environments. It notes that in high mix/low volume scenarios, lead time is influenced more by the entire value stream beyond just operations. Takt time and pacemaker concepts are addressed through quoted times and real-time bottleneck management rather than standard times. Continuous improvement focuses more on bottleneck processes and lead times across the full value stream rather than just final goods inventory.

Исходное описание:

lean high mix low volume cheat sheet

Оригинальное название

lean cheatsheets

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document compares traditional Lean principles with those more suited for high mix, low volume production environments. It notes that in high mix/low volume scenarios, lead time is influenced more by the entire value stream beyond just operations. Takt time and pacemaker concepts are addressed through quoted times and real-time bottleneck management rather than standard times. Continuous improvement focuses more on bottleneck processes and lead times across the full value stream rather than just final goods inventory.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

71 просмотров4 страницыLean Cheatsheets

Загружено:

prekajskiThis document compares traditional Lean principles with those more suited for high mix, low volume production environments. It notes that in high mix/low volume scenarios, lead time is influenced more by the entire value stream beyond just operations. Takt time and pacemaker concepts are addressed through quoted times and real-time bottleneck management rather than standard times. Continuous improvement focuses more on bottleneck processes and lead times across the full value stream rather than just final goods inventory.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

Traditional Lean

1.

Customer Value:

Quality known per product or customer

Lead-time standard (problems covered over

with FG, Raw or WIP inventory)

Price economies of scale for both raw materials

& operations to gain price improvements

2. Identify/map the Value Stream:

Management of problem solving (A3, 6sigma, etc.)

TAKT std. for customer of type of product

Value Streams can be fixed long term

Process Mapping less importance (less leadtime & cost in info. flow)

Information flow: standard & repeatable

Lead time: mostly influenced by supply

chain & operations

High Mix Low Volume Lean

1.

Customer Value:

Quality (per part/project spec.)

Lead-time (OTD) entire value stream (Quote,

schedule, purchase, logistics, order fulfill, ship,

install/debug, invoice (cash flow))

Price - maintain & manage against quote

Profit better understood per project & customer

2. Identify/map the Value Stream:

Determine which problems deserve the

effort to root cause problem solve (ABC)

TAKT = planning/managing with quoted time

Value Stream: more flexible as

projects/customers change, only by type of

part/product (i.e. cross training matrix)

Process Mapping: more important to

improve lead-time (OTD) & cost for entire

value stream

Information flow: varies depending on

project type, customer, market

Lead time (value adding): influenced by

workload at every step of information &

material flow (less influence w/ supply chain)

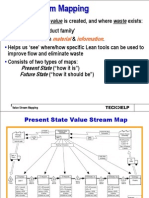

3. Flow how to create flow across all processes: Value

Stream Management

Pacemaker heavier operations focus

(i.e. level every process to takt)

Lead-time (can be overcome with inventory)

SMED

OEE

use to balance each process to Takt

5S

Quality

3. Flow how to create flow: push order in & maint. flow

Bottlenecks:

Flow of information: real time manage

Flow of material: manage in real time (day

by hour, FIFO boards, etc.)

Lead-time competitive advantage

SMED

OEE

focus on bottlenecks, continuously

5S

realign capacity with demand

Quality

4. Pull work towards pull & no need forecast (is only a

solution when can not arrive at 1 piece flow)

Planning plan pacemaker (long CT),

manage inventory (Raw, WIP, FG)

Leveling small batch, JIT

Kanban where you can not reduce changeover, consider Supermarkets for Raw & WIP

4. Pull only a consideration based on ABC (runners,

repeaters, strangers analysis)

Planning launch based on agreed lead-time,

bottlenecks (capacity vs. demand) identified

by day by hour & FIFO boards

Leveling you are already JIT (only applies if

you have runners)

Kanban only applicable if ABC analysis

identifies runners, can use conWIP?, then

apply to raw & WIP (never FG for runners)

5. Perfection kaizen (continuous improvement)

Applies to specific products & standardizing

before next kaizen step

5. Perfection

Applies to general processes

Focus is bottleneck processes

Heavier focus on lead-time (no FG to hide

issues)

Bottlenecks in both flow of information & flow

of material (both have demand vs. capacity

issues)

Lean accounting (Activity Based Costing)

www.LowVolumeLean.com

In High Mix / Low Volume

Lead-time is Dramatically Influenced Outside of Operations

High Mix Low Volume Lean

1.

Customer Value:

Quality (per part/project spec.), might need to

evolve understanding

Lead-time (OTD) entire value stream

(Quote, schedule, purchase, logistics, order

fulfill, ship, install/debug, invoice (cash flow))

Price - maintain & manage against quote,

profit varies more by product & customer,

therefore require a better understanding per

project & customer

Lead-time has less to do with operations

Order

Quot

ation

Technical

Resolution

Order

Raw

Mtl.

Supplier Lean Time

Plan

Order

Fulfill

Pack

Logistic

Invoi

ce

Operations is only a small portion of total lead-time,

Therefore Low Volume Lean specialized

methodologies focus both on the entire value stream

www.LowVolumeLean.com

Takt time & the Pace-maker Principals are addressed

with

Quoted Times & Real-Time Bottleneck management

High Mix Low Volume Lean

2. Identify/map the Value Stream:

Determine which problems deserve the effort

to root cause problem solve (Intuitive, ABC,

etc.)

TAKT = planning/managing with quoted time

Value Stream: more flexible as

projects/customers change, only by type of

part/product (i.e. cross training matrix)

Process Mapping: more important to improve

lead-time (OTD) & cost for entire value stream

Information flow: varies depending on project

type, customer, market

Lead time (value adding): influenced by

workload at every step of information &

material flow (less influence w/ supply chain)

Time Available (per period)

Takt Time = Customer Demand (per period)

Difficult to determine, especially if you

Build to Order

VF-4 Schedule

Use your quoted times (your link to the

customer) & visually monitor planned to

actual time with day by hour

Pacemaker = Traditionally the

process with the longest cycle

time, its typically based on

standard products or product

families.

Instead

Identify and minimize the

impact of the

Bottle-neck in real time

www.LowVolumeLean.com

These are a few simple

examples of how Lean being

applied to

differs from leans traditional

applications to

Scenarios

www.LowVolumeLean.com

Вам также может понравиться

- Production Planning and ControlДокумент12 страницProduction Planning and ControlAbhinit VermaОценок пока нет

- Operational FunctionsДокумент40 страницOperational FunctionsNguyen Anh Thu (FGW HCM)Оценок пока нет

- Slides 7 - Unit 4Документ40 страницSlides 7 - Unit 4Phan Phu Truong (FGW HCM)Оценок пока нет

- Inventory Management Techniques and KPIsДокумент42 страницыInventory Management Techniques and KPIsآية حمديОценок пока нет

- Broad SAP Functionality SAPBIZДокумент17 страницBroad SAP Functionality SAPBIZdan1234786100% (1)

- Operations Management NotesДокумент9 страницOperations Management NotesChen HanyuОценок пока нет

- Logistics OperationsДокумент42 страницыLogistics OperationsFRANCISCO HERNANDEZОценок пока нет

- Lesson 2Документ35 страницLesson 2terry rОценок пока нет

- Value Stream Mapping - Casos PracticosДокумент13 страницValue Stream Mapping - Casos PracticosJOHAN FERNANDO QUIROZ SERNAQUEОценок пока нет

- Sourcing_Process_ManagementДокумент40 страницSourcing_Process_ManagementAbhinandan DoleОценок пока нет

- PPT5 - Topik5 - R0 - Lean Concept and Repetitive ManufacturingДокумент28 страницPPT5 - Topik5 - R0 - Lean Concept and Repetitive ManufacturingmrikyОценок пока нет

- Broad SAP Functionality SAPBIZДокумент17 страницBroad SAP Functionality SAPBIZPrudhvikrishna GurramОценок пока нет

- Components of Logistics, Order Processing, Inventory Planning, Inventory Management Policies, Inventory Management PracticesДокумент27 страницComponents of Logistics, Order Processing, Inventory Planning, Inventory Management Policies, Inventory Management PracticesPremswty Prem100% (1)

- Chapter 4 Scheduling Management NewДокумент64 страницыChapter 4 Scheduling Management NewAzza Rosli100% (1)

- Production PlanДокумент7 страницProduction Plansyed HassanОценок пока нет

- Lecture 4: Overview: Principles For Implementing Lean ManufacturingДокумент20 страницLecture 4: Overview: Principles For Implementing Lean Manufacturingthedjoss2000Оценок пока нет

- OTM Slides1Документ24 страницыOTM Slides1Sushuma NallaОценок пока нет

- Chapter 15 - Material & Capacity Requirements PlanningДокумент23 страницыChapter 15 - Material & Capacity Requirements PlanningAmritaVermaОценок пока нет

- 3.chapter 2 Demand ManagementДокумент23 страницы3.chapter 2 Demand Managementopio jamesОценок пока нет

- 8 PT Guidelines BasicДокумент2 страницы8 PT Guidelines BasicRaul ValdezОценок пока нет

- Materials ManagementДокумент36 страницMaterials ManagementNicole DantesОценок пока нет

- AC2401 BibleДокумент112 страницAC2401 Biblejieyu yangОценок пока нет

- Strategic Lead Time Management and Time-Based CompetitionДокумент20 страницStrategic Lead Time Management and Time-Based CompetitionPradeep ChintadaОценок пока нет

- Operations HandbookДокумент17 страницOperations HandbookVasudev GuduriОценок пока нет

- Chapter3 SupplychaindriversametricsДокумент24 страницыChapter3 SupplychaindriversametricsNoor Harlisa Irdina Mohd HasanОценок пока нет

- Operations Management SchedulingДокумент39 страницOperations Management SchedulingManonmani Mani100% (1)

- Invertory ManagementДокумент29 страницInvertory ManagementVijayakrishnan K. MОценок пока нет

- Module 6 SDMДокумент34 страницыModule 6 SDMdharm287Оценок пока нет

- 4 Slides Value Stream MappingДокумент13 страниц4 Slides Value Stream MappingRanjan Raj Urs100% (2)

- Supply Chain Management Inventory Management: Hendra, S.T., M.T. Dosen Stmik IbbiДокумент11 страницSupply Chain Management Inventory Management: Hendra, S.T., M.T. Dosen Stmik IbbimadarinaaОценок пока нет

- Inventory Management TechniquesДокумент33 страницыInventory Management TechniquesPrince Zia100% (1)

- An Introduction To Lean ManufacturingДокумент45 страницAn Introduction To Lean ManufacturingSid508Оценок пока нет

- Value Stream Mapping & Management - VSMM: Chee HongДокумент9 страницValue Stream Mapping & Management - VSMM: Chee Hongyogesh sharmaОценок пока нет

- Pom 1Документ26 страницPom 1Die8sight SiegeОценок пока нет

- Supply Chain Management: Compiled byДокумент34 страницыSupply Chain Management: Compiled byjorgeОценок пока нет

- Controlling Overview - Understanding Cost Accounting Concepts in SAPДокумент55 страницControlling Overview - Understanding Cost Accounting Concepts in SAPRaj PanigrahiОценок пока нет

- Basic Concepts of OperationsДокумент38 страницBasic Concepts of Operationskarthik rampaОценок пока нет

- Exam CheatsheetДокумент2 страницыExam CheatsheetSandeepОценок пока нет

- Supply Chain in FMCG SectorДокумент12 страницSupply Chain in FMCG SectorGirish BhangaleОценок пока нет

- Process Approach 1Документ4 страницыProcess Approach 1Pristine ChamomileОценок пока нет

- Inventory Management: Optimize Operations with EOQ ModelДокумент59 страницInventory Management: Optimize Operations with EOQ ModelSubhrodeep DasОценок пока нет

- Capacity Planning and ControlДокумент31 страницаCapacity Planning and ControlAdityaОценок пока нет

- Lean Operations and The Toyota Production SystemДокумент31 страницаLean Operations and The Toyota Production SystemRajShekarReddyОценок пока нет

- SCM MBA 4thsemester SOC DAVVДокумент31 страницаSCM MBA 4thsemester SOC DAVVKunal ShirsathОценок пока нет

- MIS - Inventory ControlДокумент79 страницMIS - Inventory ControlVarun MarkandeyaОценок пока нет

- Supply Chain Management: A Presentation by Sourav Kr. VermaДокумент50 страницSupply Chain Management: A Presentation by Sourav Kr. Vermakumarsourav2333Оценок пока нет

- Introduction To Operation Management: Club Kaizen, IIM IndoreДокумент32 страницыIntroduction To Operation Management: Club Kaizen, IIM Indore9755348070Оценок пока нет

- Value Stream Mapping Visualizes Production ProcessДокумент41 страницаValue Stream Mapping Visualizes Production ProcessNOSHEEN MEHFOOZ100% (1)

- Forecasting: Elements of Good ForecastДокумент17 страницForecasting: Elements of Good Forecastshahadat112Оценок пока нет

- Process Selection and Facility LayoutДокумент59 страницProcess Selection and Facility LayoutKhietОценок пока нет

- Value Stream Analysis Kaizen TrainingДокумент38 страницValue Stream Analysis Kaizen TrainingShah ZaibОценок пока нет

- Capacity PlanningДокумент47 страницCapacity Planningcharles makasabiОценок пока нет

- Module 3Документ49 страницModule 3Ananda KrishnanОценок пока нет

- Chapter 5 Aggregate PlanningДокумент40 страницChapter 5 Aggregate PlanningMarvin kakindaОценок пока нет

- Logistics Management: Kurian M J: 08PG0124 Praveen Moses P: 08PG0132 Venu Gopal VДокумент31 страницаLogistics Management: Kurian M J: 08PG0124 Praveen Moses P: 08PG0132 Venu Gopal VVenu Gopal100% (1)

- OP ManagmentДокумент13 страницOP Managmentsebastian. “pollmaster” pОценок пока нет

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowОт EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowРейтинг: 4 из 5 звезд4/5 (1)

- Weller Coping With Lead FreeДокумент32 страницыWeller Coping With Lead FreeprekajskiОценок пока нет

- Minimization of Reworks in The Apparel IndustryДокумент18 страницMinimization of Reworks in The Apparel Industryzoomerfins220% (1)

- Neagoe R29Документ8 страницNeagoe R29prekajskiОценок пока нет

- PokaYoke by GaneshДокумент5 страницPokaYoke by GaneshprekajskiОценок пока нет

- Chapter 1 Lecture NotesДокумент12 страницChapter 1 Lecture NotesRachel FreemanОценок пока нет

- BARMM Inflation Rates Jan 2019 - Jan 2020Документ1 страницаBARMM Inflation Rates Jan 2019 - Jan 2020MTIT-BARMM Bids & Awards CommitteeОценок пока нет

- 10000024113Документ3 123 страницы10000024113Chapter 11 DocketsОценок пока нет

- Specific Factors Model + Standard Trade ModelДокумент14 страницSpecific Factors Model + Standard Trade ModelAbigail VОценок пока нет

- Black Market and The Indian EconomyДокумент6 страницBlack Market and The Indian EconomyMehak LIfez TrailingОценок пока нет

- Major World Cities MapДокумент2 страницыMajor World Cities Mapsachin3030Оценок пока нет

- Financial Analysis of Tata Steel and Jindal Steel and Power Ltd.Документ34 страницыFinancial Analysis of Tata Steel and Jindal Steel and Power Ltd.O.p. SharmaОценок пока нет

- Indian Money Market: Project Report OnДокумент91 страницаIndian Money Market: Project Report OnSachinОценок пока нет

- Karl Marx (1818-1883) : Philosopher, Economist, and SocialistДокумент9 страницKarl Marx (1818-1883) : Philosopher, Economist, and SocialistBurhan HunzaiОценок пока нет

- Kearney, 1986, From The Invisible Hand PDFДокумент32 страницыKearney, 1986, From The Invisible Hand PDFpazeabОценок пока нет

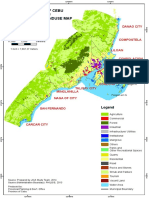

- Cebu Map - Existing Landuse - MetroCebuДокумент1 страницаCebu Map - Existing Landuse - MetroCebuiamfrancoiseОценок пока нет

- Investment Appraisal 1Документ13 страницInvestment Appraisal 1Arslan ArifОценок пока нет

- Introduction of The InsuranceДокумент2 страницыIntroduction of The Insurancepial02020Оценок пока нет

- CHAPTER 16 PartnershipДокумент22 страницыCHAPTER 16 PartnershipbabarОценок пока нет

- GiliДокумент19 страницGiliKartik SharmaОценок пока нет

- Excise DutyДокумент12 страницExcise DutyshreeMaliОценок пока нет

- Nokia Alcatel - Lucent 7210 SAS-MXPДокумент1 страницаNokia Alcatel - Lucent 7210 SAS-MXPComptest Polska Sp z o oОценок пока нет

- Final Report On FertilizerДокумент54 страницыFinal Report On FertilizerShubham Agarwal100% (8)

- Assets and Liabilities DeclarationДокумент2 страницыAssets and Liabilities DeclarationSai Satish Gubbala33% (3)

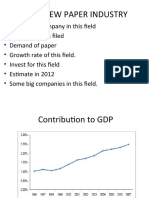

- Overview of Paper IndustryДокумент27 страницOverview of Paper IndustryDương NguyễnОценок пока нет

- Palm oil development trends and indigenous rights in the PhilippinesДокумент31 страницаPalm oil development trends and indigenous rights in the PhilippinesLiyin WongОценок пока нет

- ECG80 Energy Use in The Animal Feed SectorДокумент8 страницECG80 Energy Use in The Animal Feed SectorIppiОценок пока нет

- ACJC GP Paper 2 Prelim 2007Документ10 страницACJC GP Paper 2 Prelim 2007Lee Zi XinОценок пока нет

- Forex WalkthroughДокумент342 страницыForex WalkthroughPhuthuma Beauty SalonОценок пока нет

- OB-23 Ch09-Organization Size, Life Cycle, and DeclineДокумент9 страницOB-23 Ch09-Organization Size, Life Cycle, and DeclineberitahrОценок пока нет

- Intermediaries in LogisticsДокумент29 страницIntermediaries in LogisticsKoushik KoushiОценок пока нет

- Advanced Microeconomic Theory Fall 2021Документ2 страницыAdvanced Microeconomic Theory Fall 2021aОценок пока нет

- LTC Procedural Norms PDFДокумент5 страницLTC Procedural Norms PDFsk_kannan26Оценок пока нет

- ATFX 2023Q2 EN MY AДокумент58 страницATFX 2023Q2 EN MY Anguyen thanhОценок пока нет

- NectarДокумент8 страницNectarSubhav Budhia100% (1)