Академический Документы

Профессиональный Документы

Культура Документы

D. Compounding: o Ec o C S S S Oss e V I C S S S y A e S

Загружено:

Anonymous Bpy4biucdQОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

D. Compounding: o Ec o C S S S Oss e V I C S S S y A e S

Загружено:

Anonymous Bpy4biucdQАвторское право:

Доступные форматы

Polybutadiene and Chloroprene Rubber

51

100. It can be extended with large volumes of black

and oil to obtain economical compounds. Neoprene

WRT is the most crystallization-resistant neoprene.

The T grades are closely related to the W grades

and contain a crosslinked polymer gel fraetion of

polychloroprene to improve behavior. They are

crystal Iization-resisrant

and do require organic

accleration. These types have very low nerve and

shrinkage. TypicaJ grades are TW and TRT.

D. Compounding

Neoprene seldom is chosen over other polymers

(on the basis) of technical factors alone.

Compared to such rubbers as NR and SBR, it is

more expensive per pound. In addition, its density

of 1.23-1.25 is significantly higher than that of

other elastomers, which means higher costs on a

volume basis, Accordingly, if oil resistance is

wanted, a blend of NR and a butadiene

acrylonitrile rubber might be considered. lf high

ozone resistance is wanted, a blend of NR and

EPDM (see Chapter 6, Section JII) would be

appropriate. This works both ways

of course. Addition of BR to neoprene will

improve its flex life; similarly, if EPDM is added,

ozone resistance is bettered, yet the good

processibility of neoprene can be retained. Such

blends are not really homogeneous but helero

geneous. It has been theorized that certain

technical advantages, such as re sistance to

cracking, are achieved because tbe crack

terminates al a polymer phase boundary. There is

evidence that carbon black is not evenly distributed

through a blend but is concentrated more in one of

the polymers, which might explain this

phenomenon.

Neoprene is used frequently in belts, wire and cable,

hose components, and

molded or extruded items. It is used in conveyor

belts when parts transported or ambient conditions

are oily. lts oil resistance is valuable in the tubes

and covers of hoses like gasoline curb pump hose

and oil suction and discharge hose. Service

entrance wire and drop wire require (he

resistance to abras ion and weather that neoprene

provides. Molded pipe gaskets and extruded building

seals are made of neoprene.

Neoprene compounds used in outdoor exposures

are usually black or dark brown, since light-colored

compounds darken in sunlight. On the plus side,

neoprene gives strong, pure gum stock.s with high

tensile strength and adheres well to other material s;

its resistance ro fire can be a unique advantage.

Neoprene vulcanizates commonly meet the

requirements of type BC in ASTM D 2000,

"Standard

Classification System for Rubber

Products in Automotive Applica tions. "

After neoprene has been chosen as the polymer, the

particular type must be

selected. One guideline bere can be the Mooney

viscosity. It is known that the higher (he Mooney

viscosity, the better the acceptance of fillers and

oils, the better the dimensional stability of uncured

shapes, and the higher the tensile strength. Lower

Mooney viscosity means lower mixing

temperature, lower

Copyrighted material

Вам также может понравиться

- Oil-Resistant Rubbers: Machine DesignДокумент5 страницOil-Resistant Rubbers: Machine Designrajeevup2004Оценок пока нет

- A Guide To Grades, Compounding and Processing of Neoprene Rubber (Bament Guide)Документ48 страницA Guide To Grades, Compounding and Processing of Neoprene Rubber (Bament Guide)Neeraj BhallaОценок пока нет

- Acrylonitrile-Butadiene Rubber - NBRДокумент7 страницAcrylonitrile-Butadiene Rubber - NBRRubik Art100% (1)

- DUPONT Neoprene A Guide To GradesДокумент48 страницDUPONT Neoprene A Guide To Gradesfaizal_7138100% (1)

- NeopreneДокумент48 страницNeoprenest_calvoОценок пока нет

- Section6 Material Selection GuideДокумент15 страницSection6 Material Selection GuidenewmanОценок пока нет

- General Rubber Compounds: By: Jim Ward, BRP ManufacturingДокумент4 страницыGeneral Rubber Compounds: By: Jim Ward, BRP Manufacturing최승원Оценок пока нет

- Butyl & Chloroprene 2003Документ16 страницButyl & Chloroprene 2003Suyash TrivediОценок пока нет

- Hydrogenated Nitrile For Oilfield ApplicationsДокумент6 страницHydrogenated Nitrile For Oilfield ApplicationsHuỳnh TGОценок пока нет

- L1-History Types of Rubber and Properties - 38Документ27 страницL1-History Types of Rubber and Properties - 38Resego PhiriОценок пока нет

- A Cry Lo Nit RileДокумент6 страницA Cry Lo Nit RileSilvio CremmОценок пока нет

- J of Applied Polymer Sci - 2023 - Wang - Effects of Polyamide Elastomer On The Morphology Crosslink Density MechanicalДокумент12 страницJ of Applied Polymer Sci - 2023 - Wang - Effects of Polyamide Elastomer On The Morphology Crosslink Density MechanicaljeevaОценок пока нет

- Rubber World HNBR Article - Therban AT PDFДокумент9 страницRubber World HNBR Article - Therban AT PDFAnusha Rajagopalan100% (1)

- Amalrajrb 2 MSC BpsДокумент27 страницAmalrajrb 2 MSC Bpsbehailu amareОценок пока нет

- Material Selection Guide: NBR Nitrile RubberДокумент2 страницыMaterial Selection Guide: NBR Nitrile RubberNAMOGRENA DIAZОценок пока нет

- NLSP I - RubberДокумент27 страницNLSP I - RubberbalachandarОценок пока нет

- DuPont NeopreneДокумент12 страницDuPont NeoprenePrecesijaОценок пока нет

- Valve Material Selection GuideДокумент15 страницValve Material Selection GuideAhmad Fadhil ReviansyahОценок пока нет

- Royal Composites PVT LTD India: WWW - Royalseals.co - inДокумент171 страницаRoyal Composites PVT LTD India: WWW - Royalseals.co - inAalap MankadОценок пока нет

- Product Guide 2012Документ16 страницProduct Guide 2012Daniele BoscoОценок пока нет

- Rubber Type: Teknologi KaretДокумент13 страницRubber Type: Teknologi KaretlarasatiОценок пока нет

- Rubber Compound Preparation For Conveyor BeltДокумент20 страницRubber Compound Preparation For Conveyor BeltNEVIN67% (3)

- Rubber Mining HoseДокумент12 страницRubber Mining HoseStephenОценок пока нет

- Practical Guide To HNBR Chapter 2Документ8 страницPractical Guide To HNBR Chapter 2Azizol WahabОценок пока нет

- Rado - Hydrogenated NBR Elastomer (HNBR), 2021 +Документ4 страницыRado - Hydrogenated NBR Elastomer (HNBR), 2021 +oreamigОценок пока нет

- Santoprene TPV Underhood Factsheet en PDFДокумент2 страницыSantoprene TPV Underhood Factsheet en PDFMarcos Antonio RossiОценок пока нет

- Choosing The Best Hose and Tube For Your Application: Chemical Compatibility GuideДокумент43 страницыChoosing The Best Hose and Tube For Your Application: Chemical Compatibility GuideJuan AcuñaОценок пока нет

- Rubber - Resin Materials - Rubber - Resin Materials - Technologies - NOK CORPORATIONДокумент14 страницRubber - Resin Materials - Rubber - Resin Materials - Technologies - NOK CORPORATIONvamsi patnalaОценок пока нет

- Zeon Productguide 20150717Документ16 страницZeon Productguide 20150717khushboo.mamtani2932Оценок пока нет

- General Properties of Elastomers PDFДокумент10 страницGeneral Properties of Elastomers PDFhadeОценок пока нет

- M Bilal & Afaq Alam Week 1 ReportДокумент8 страницM Bilal & Afaq Alam Week 1 ReportsaudОценок пока нет

- Ther MaxДокумент65 страницTher MaxAmeya SavnalОценок пока нет

- HUBATA Sealings PDFДокумент138 страницHUBATA Sealings PDFMitkoОценок пока нет

- EJMSE - Oil SealДокумент10 страницEJMSE - Oil SealhesОценок пока нет

- 2.synthetic Rubber TRG DR - JACOB K VARKEYДокумент40 страниц2.synthetic Rubber TRG DR - JACOB K VARKEYbodekizОценок пока нет

- Also Could Be Natural Milky White or Honey ColoredДокумент2 страницыAlso Could Be Natural Milky White or Honey Coloredusebio64Оценок пока нет

- Materiale GarnituriДокумент3 страницыMateriale GarnituriFabius PopОценок пока нет

- Nitrile Rubber ApplicationsДокумент2 страницыNitrile Rubber ApplicationsWs LimОценок пока нет

- Nitrile Rubber ApplicationsДокумент6 страницNitrile Rubber ApplicationsFelix CatОценок пока нет

- Fundamentals of Compounding Epdm For Cost - PerformanceДокумент14 страницFundamentals of Compounding Epdm For Cost - PerformanceJicheng PiaoОценок пока нет

- Neoprene TypesДокумент2 страницыNeoprene TypesAnonymous yy8In96j0rОценок пока нет

- Adhesive ChoiceДокумент8 страницAdhesive Choicecsbaweja580% (1)

- Rubber Hose ManufacturingДокумент4 страницыRubber Hose ManufacturingHue Trang Nguyen ThiОценок пока нет

- Introduction To Rubber TechnologyДокумент274 страницыIntroduction To Rubber TechnologyMahbuba ParvinОценок пока нет

- Natural RubberДокумент28 страницNatural RubberHafis PuzhakkalОценок пока нет

- 6.3 PV (-Nitrile Rubber Blends 6.3 Chemistry PVC Resistance Number BeenДокумент4 страницы6.3 PV (-Nitrile Rubber Blends 6.3 Chemistry PVC Resistance Number BeenAmeya SavnalОценок пока нет

- Neoprene Durometer ThicknessДокумент4 страницыNeoprene Durometer ThicknessJizelle JumaquioОценок пока нет

- Elastomers Properties PDFДокумент5 страницElastomers Properties PDFhadeОценок пока нет

- A New Approach With Prepregs For ReinforcingДокумент8 страницA New Approach With Prepregs For ReinforcingRajesh Kumar SОценок пока нет

- Hydrogenated NitrileДокумент2 страницыHydrogenated Nitrileomar shadyОценок пока нет

- LA Cable Materials Applications RelativeCostsДокумент1 страницаLA Cable Materials Applications RelativeCostsAnonymous 12Chu26JlzОценок пока нет

- Material Properties of PEДокумент12 страницMaterial Properties of PEIgnatius SamrajОценок пока нет

- Rubber Linings OverviewДокумент10 страницRubber Linings OverviewhabibОценок пока нет

- Magnetic Flowmeter Material Selection Guide: Technical Data SheetДокумент24 страницыMagnetic Flowmeter Material Selection Guide: Technical Data SheetGILBERTОценок пока нет

- 3.special Purpose Synthetic RubberДокумент31 страница3.special Purpose Synthetic RubberbodekizОценок пока нет

- Essential Rubber Formulary: Formulas for PractitionersОт EverandEssential Rubber Formulary: Formulas for PractitionersРейтинг: 3 из 5 звезд3/5 (1)

- Sampling Procedure For Impact Testing of Structural SteelДокумент4 страницыSampling Procedure For Impact Testing of Structural Steeljoy gultom100% (1)

- Alcohols, Phenols and Ethers - MCQs Test - 3Документ3 страницыAlcohols, Phenols and Ethers - MCQs Test - 3Prasant KumarОценок пока нет

- 9th Chemistry 4 ChapДокумент3 страницы9th Chemistry 4 ChapJaveria ZaidiОценок пока нет

- Separation and Analysis of Binery and Te PDFДокумент35 страницSeparation and Analysis of Binery and Te PDFDiwakar PatelОценок пока нет

- Lanco Antifloat D-14, TDSДокумент2 страницыLanco Antifloat D-14, TDSZein HayekОценок пока нет

- Schematic Diagram of Qualitative Tests For Elements in Organic CompoundsДокумент5 страницSchematic Diagram of Qualitative Tests For Elements in Organic CompoundsChristine DomingoОценок пока нет

- Sabic® PP 575P: PP Homopolymer For Injection MouldingДокумент1 страницаSabic® PP 575P: PP Homopolymer For Injection MouldingPrinchipi YounesОценок пока нет

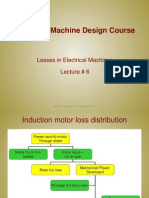

- Lecture6 - Losses in Electric MachinesДокумент24 страницыLecture6 - Losses in Electric Machinesthulasi_krishnaОценок пока нет

- Chemsheets GCSE 1032 More Group 7Документ2 страницыChemsheets GCSE 1032 More Group 7Cheuk Him Ngai0% (1)

- Experiment 8Документ4 страницыExperiment 8api-252952453100% (3)

- Cape Physics 2008 Unit 1Документ10 страницCape Physics 2008 Unit 1kesnaОценок пока нет

- Troubleshooting Precast Cracking in Double Tees - tcm77-1306891 PDFДокумент5 страницTroubleshooting Precast Cracking in Double Tees - tcm77-1306891 PDFsdagnihotriОценок пока нет

- Uhde Dual-Pressure Process For Large-Scale Ammonia Plants: - Saskferco Ammonia-Urea Complex, CanadaДокумент6 страницUhde Dual-Pressure Process For Large-Scale Ammonia Plants: - Saskferco Ammonia-Urea Complex, CanadaMUHAMMAD USMAN0% (1)

- Key Concept Chapter 10 ElectrolysisДокумент20 страницKey Concept Chapter 10 ElectrolysisKim KatОценок пока нет

- Bollard Column Base Plate (Fixed Type)Документ15 страницBollard Column Base Plate (Fixed Type)GANESHОценок пока нет

- Many of The Important Properties of Materials Are Due To The Presence of ImperfectionsДокумент14 страницMany of The Important Properties of Materials Are Due To The Presence of ImperfectionsAbdulrahman AlsubieОценок пока нет

- Comparative Study On Direct Shear Behavior of Manufactured and Recycled Shredded Tyre Steel Fiber Reinforced Self-Consolidating ConcreteДокумент9 страницComparative Study On Direct Shear Behavior of Manufactured and Recycled Shredded Tyre Steel Fiber Reinforced Self-Consolidating ConcreteDiego SukОценок пока нет

- Electrochimica ActaДокумент9 страницElectrochimica ActareiroslesОценок пока нет

- THE IDEAL GAS (Topic6)Документ17 страницTHE IDEAL GAS (Topic6)ch0k3 iiiОценок пока нет

- E985F8E88F069BF1BB6F005056AC67B7Документ1 страницаE985F8E88F069BF1BB6F005056AC67B7Jose ReynosoОценок пока нет

- K10 GRS 2000Документ2 страницыK10 GRS 2000Dilon FernandoОценок пока нет

- BecherДокумент7 страницBechervalholОценок пока нет

- Sop-G3 System IndiaДокумент13 страницSop-G3 System Indiaajayji6565Оценок пока нет

- RC Lecture 11 - ColumnsДокумент19 страницRC Lecture 11 - ColumnsShean Berwin GonzalesОценок пока нет

- Rubio Monocoat Furniture DataДокумент1 страницаRubio Monocoat Furniture DataJosh PiersmaОценок пока нет

- Copper-Brazed Steel Tubing: Standard Specification ForДокумент4 страницыCopper-Brazed Steel Tubing: Standard Specification ForSofiaJabadanEspulgar100% (1)

- IGCSE Prep - 4Документ17 страницIGCSE Prep - 4Yoel Friady HutabaratОценок пока нет

- Economics For Structural Steel Plate GirdersДокумент10 страницEconomics For Structural Steel Plate Girdersthomas kilianОценок пока нет

- Sae J122-2017Документ12 страницSae J122-2017phan hoai nam PhanОценок пока нет

- List of Contractors and Status of Work of Sports Villa 25 To 48A & B Civil Work Plumbing Work Finishing WorkДокумент4 страницыList of Contractors and Status of Work of Sports Villa 25 To 48A & B Civil Work Plumbing Work Finishing WorkManasОценок пока нет