Академический Документы

Профессиональный Документы

Культура Документы

Oily Water Separator Catalogue

Загружено:

Vikk SuriyaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Oily Water Separator Catalogue

Загружено:

Vikk SuriyaАвторское право:

Доступные форматы

NEW

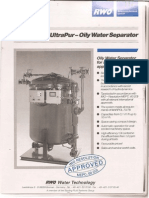

15ppm BILGE SEPARATOR

Conforming to Type Approval Standard MEPC 107(49)

Feature & Specifications

Exclusively for marine use.

Series: USH01

Treatment capability: 0.15 m3h

Exclusive pumpmotor is provided inside, so

the Separator system occupies no space.

The product accredited for type approval by

the Ministry of Land, Infrastructure and

Transport and in accordance with the EC

Marine Equipment Directive.

IMO MEPC.107(49)

Carried on board the ships of 340 G/T or

below.

Taiko Kikai Industries Co.,Ltd, which has already sent out three

series Oily Water Separators to the market, developed USH

series this time as a compilation of its technologies on the

machine, in response to eectuation of the resolution

MEPC.107(49) (applicable to ships for which the keels are laid

down on and after January 2005).

USH series is a state-of-the-art oily water separator with a

coalescer long in service life and high in performance, providing

remarkable capability of treating not only high-specic gravity

high-viscosity oils, but also emulsions containing surface

active agents or suspended solids that have been deemed it

impossible to treat with conventional coalescers.

In addition, USH series is a customer-satisfaction-oriented oily

water separator which has been developed with maintainability

in mind. The users can operate it without feeling any stress on

themselves even during bilge treatment work on a real ship

and become convinced of its prolonged stable performance.

Apart from other USH series (treatment capability: 0.25 to 5

m3h), USH01 has been developed for use on medium- or

small-sized ships. It has high performance for its small size.

In the USH-01 series Oily Water Separator, exclusive pump

motor has been provided inside for the convenience of use.

This allows reasonable use of the Separator in any limited

installation space.

USH-01

15ppm BILGE SEPARATOR

USH-01

Structure & Dimensions

USH-01

305

190

415

Mass at empty120kg

Mass at operation154kg

Power sourceAC100V500VADC24V10A

should be for costom-made

articles of product

CoatingMunsell symbol 7.5BG7/2

163

326

No.

280

230

178

138

CL

230

min.300

Maintenance space

140

The front

370

416

AA Arrowy view

515

Treated water outlet

min.800

Maintenance space

min.800

Disassembly space

175

260

10

14

1

2

12

Waste oil

Outlet

Ball valve

780

590

RC12

11 Return line

20

Oil drain cock

Water test cock

Automatic air

vent valve

Strainer

270Inlet

290Return

Rc12Union

Bilge inlet

163

11 Three-way valve

InstallationPiping Procedures

12 Pump

Siphon breaker

Be sure to exceed a value of

discharge resistance

1/2B

Treated water

discharge line

1

1

1

1

1

1

1

1

1

1

1

STAINLESS STEEL

SUS304

14 Nameplate

Standard Fittings

Water test cock

(Periodically check treated water conditions.)

Hopper

Oil drain cock

(Periodically discharge oil)

1/2B

Three-way valve (handle position)

In horizontal direction during normal

operation or while stopped; in vertical

direction during transfer of highconcentration oil to waste oil tank, or

during pump disassembly.

urce

er so

Pow

1/2B

1/2B

Within 2 to 3 m

Light draft

13 Motor

0.3 m or more

Q'ty

1

BRASS

C3602

BRASS

C3602

STAINLESS STEEL

SUS304

BRONZE

CAC

BRASS

C3602

BRONZE

CAC

BRONZE

CAC

Constant flow

10 valve

50

155

13

135

Pressure gauge

12

70

2

5

Material

MILD STEEL

Body

SS400

Transmitting AL ALLOY CASTING

converter

ADC12

AL ALLOY CASTING

Oil level

ADC12

detector

BRONZE

Solenoid valve CAC

Name

Automatic oil drain device

(solenoid valve, oil level detector,

transmitting converter)

Automatic air vent valve

Test cock

Drain plug

Pressure gauge and cock

Constant flow valve

Exclusive pump (avoid an empty

run), motor and V-pulley, V-belt

Strainer

1/2B

Standard Spare Parts

Sea water

Waste oil tank

Suction strainer

(clean periodically.)

Bilge tank

Automatic oil drain device spare

parts (fuse)

Packing

URLhttp://www.taiko-kk.com

Head Office &

Factory

Tokyo Branch

209-1 Shimotabuse,Tabuse-cho, Kumage-gun, Yamaguchi Pref. 742-1598 Japan

ROTARY

BLOWER

OILY WATER

SEPARATOR

4th floor, Suidobashi MS Building, 3-4-9 Misaki-cho, Chiyoda-ku, Tokyo 101-0061 Japan

TEL81-3-3221-8551 FAX81-3-3221-8555 E-mail: tokyo-br@taiko-kk.com

Osaka Branch

VACUUM

PUMP

TEL81-820-52-3114 FAX81-820-53-1001 E-mail: business@taiko-kk.com

SEWAGE

TREATMENT

DEVICE

SCREW PUMP

8th floor, KC Building, 3-4-7 Kawara-machi, Chuo-ku, Osaka 541-0048 Japan

TEL81-6-6231-6241 FAX81-6-6222-3295 E-mail: osaka-br@taiko-kk.com

GEAR PUMP

CENTRIFUGAL

PUMP

The dimensions and specifications of the products included in this catalogue may be subject to change without notice for purposes of improvement in their performance. 2005/MUTSUMI

Вам также может понравиться

- Handling & Disposal of Bilge Water: Understanding The SystemДокумент18 страницHandling & Disposal of Bilge Water: Understanding The SystemMalkeet Singh Ghotra100% (1)

- The Use of Information and Commmunication Technology in Distance EducationДокумент7 страницThe Use of Information and Commmunication Technology in Distance EducationManas BeckОценок пока нет

- Business Communications Quiz PretestДокумент1 страницаBusiness Communications Quiz Pretestapi-261028040Оценок пока нет

- The Elements of Teaching and LearningДокумент18 страницThe Elements of Teaching and LearningChärlie StäzОценок пока нет

- Bilge Water Management & PollutionДокумент12 страницBilge Water Management & PollutionGeorgios PapakostasОценок пока нет

- 460 Erstl R Egstl R 2015Документ246 страниц460 Erstl R Egstl R 2015Fatahillah Said ArvОценок пока нет

- International Regulations For Preventing Collisions at Sea (COLREGS) PDFДокумент20 страницInternational Regulations For Preventing Collisions at Sea (COLREGS) PDFNairdna P Led OirasorОценок пока нет

- Example of Professional CommunicationДокумент11 страницExample of Professional CommunicationSyafaah JamaludinОценок пока нет

- Bilge Technical Emd00201enДокумент20 страницBilge Technical Emd00201enIsrael SanchezОценок пока нет

- Norwegian Training Center Bilge Water Waste Oil Operation Management PDFДокумент141 страницаNorwegian Training Center Bilge Water Waste Oil Operation Management PDFLuis100% (2)

- A Quick Guide To Key Shipping Regulations - 2017 and OnwardsДокумент1 страницаA Quick Guide To Key Shipping Regulations - 2017 and OnwardsOdumoduChigozieUzomaОценок пока нет

- 01 - COLREG - DO2B-MSNW (2012) Varianta 0 MartorДокумент158 страниц01 - COLREG - DO2B-MSNW (2012) Varianta 0 MartorCiutacu Andrei100% (2)

- COLREGДокумент41 страницаCOLREGselozok1Оценок пока нет

- International Regulations FOR Preventing Collision at SeaДокумент64 страницыInternational Regulations FOR Preventing Collision at SeaSidney Bezerra100% (1)

- Colregs Handout Mars III Ror PC Study SheetДокумент9 страницColregs Handout Mars III Ror PC Study SheetMuhammadHaris100% (1)

- Navigation Exercises For Practice Underway: David BurchДокумент74 страницыNavigation Exercises For Practice Underway: David BurchShoaib hossainОценок пока нет

- Sheets SopepДокумент15 страницSheets Sopepsun qiОценок пока нет

- Curri DevДокумент91 страницаCurri Devchari cruzmanОценок пока нет

- Colregs Q-AДокумент9 страницColregs Q-AMohamed Eassa50% (2)

- Steering Gear SolasДокумент2 страницыSteering Gear SolasJithin Vijayan100% (1)

- Nav RulesДокумент101 страницаNav RulesSidney Bezerra100% (1)

- Vimsas AuditДокумент26 страницVimsas AuditJaspal Singh SahotaОценок пока нет

- Marine Safety Criteria For RepsolДокумент4 страницыMarine Safety Criteria For RepsolnozerbhathenaОценок пока нет

- Marpol Annex 1Документ2 страницыMarpol Annex 1Μανος ΦωτοπουλοςОценок пока нет

- IMO Oil Record BookДокумент12 страницIMO Oil Record BookrmarliansyahОценок пока нет

- Collision Rules (Colregs)Документ33 страницыCollision Rules (Colregs)Mohamed Salah El Din100% (1)

- SOPEP Manual PlanДокумент3 страницыSOPEP Manual Plantumi69Оценок пока нет

- MARPOL Annex V: Regulations For The Prevention of Pollution by Garbage From Ships (New Amendments)Документ4 страницыMARPOL Annex V: Regulations For The Prevention of Pollution by Garbage From Ships (New Amendments)Orlando QuevedoОценок пока нет

- The Ten Commandments of Good CommunicationДокумент57 страницThe Ten Commandments of Good CommunicationbirjaОценок пока нет

- International Transport Workers FederationДокумент18 страницInternational Transport Workers Federationjohndmariner123Оценок пока нет

- Registration of Ships 02.11.2014Документ6 страницRegistration of Ships 02.11.2014johndmariner123Оценок пока нет

- Bunker IngДокумент6 страницBunker IngJackielou LagmanОценок пока нет

- Solas: Maritime LawДокумент26 страницSolas: Maritime Lawmark benson marananОценок пока нет

- Collision Regulation Colregs Bulletin - 12-2013 PDFДокумент2 страницыCollision Regulation Colregs Bulletin - 12-2013 PDFkahl983100% (1)

- Depth Sounder (Echo Sounder)Документ2 страницыDepth Sounder (Echo Sounder)seaОценок пока нет

- TuigДокумент105 страницTuigJay Narayan TiwariОценок пока нет

- IMO Life Saving Appliance Signs 01Документ1 страницаIMO Life Saving Appliance Signs 01parry1701Оценок пока нет

- Personal Safety & Social Responsibility (PSSR) STCW-95Документ2 страницыPersonal Safety & Social Responsibility (PSSR) STCW-95Kunal Nagal100% (1)

- Idintrebare Intrebare Raspuns1 Raspuns2 Raspuns3 Rc1 Rc2 Rc3Документ47 страницIdintrebare Intrebare Raspuns1 Raspuns2 Raspuns3 Rc1 Rc2 Rc3Darius21C100% (1)

- Marpol Annex VДокумент3 страницыMarpol Annex VJulio Chavez DiazОценок пока нет

- Imo ConventionsДокумент85 страницImo ConventionsJose Angel Orozco GarciaОценок пока нет

- Supervision of Crude Oil Washing (COW) OperationsДокумент6 страницSupervision of Crude Oil Washing (COW) Operationstony100% (1)

- Celdas de FlotacionДокумент4 страницыCeldas de FlotacionRodrigo Zura0% (1)

- Cryo Pump PDFДокумент0 страницCryo Pump PDFkanchanabalajiОценок пока нет

- Ficha Doosan Compresoresportatiles XHP1170 en 0Документ4 страницыFicha Doosan Compresoresportatiles XHP1170 en 0death666darkОценок пока нет

- 660III ImprovementsДокумент20 страниц660III Improvementsaugusto100% (1)

- Kaydon KC-30 Turbo-TOC® Turbine Oil Conditioning SystemДокумент2 страницыKaydon KC-30 Turbo-TOC® Turbine Oil Conditioning Systemherysyam1980Оценок пока нет

- Vacuum Pumps WELCH 2522Документ13 страницVacuum Pumps WELCH 2522TedosОценок пока нет

- RWO Folder Oily Water SepДокумент4 страницыRWO Folder Oily Water SepErwin Paulian SihombingОценок пока нет

- Robushi Robox BlowerДокумент2 страницыRobushi Robox Bloweranguyen22153319Оценок пока нет

- Simplex-Turbulo-Systems: TURBULO-MPB Bilge Water SeparatorДокумент4 страницыSimplex-Turbulo-Systems: TURBULO-MPB Bilge Water SeparatorImad Eddine El HadriОценок пока нет

- Am Castrol Hyspin AWH M US Eng Pds 05 07Документ2 страницыAm Castrol Hyspin AWH M US Eng Pds 05 07victorjcrОценок пока нет

- File - 20220609 - 210203 - Ce Handing Over NotesДокумент5 страницFile - 20220609 - 210203 - Ce Handing Over NotesPhuc ChuОценок пока нет

- 3887bhf Ws - BHF Series (b3887bhf)Документ4 страницы3887bhf Ws - BHF Series (b3887bhf)Oscar GonzalesОценок пока нет

- En Daten MS-MFДокумент20 страницEn Daten MS-MFcazan93Оценок пока нет

- Customised Engineered Packages: Reciprocating Air CompressorsДокумент4 страницыCustomised Engineered Packages: Reciprocating Air Compressorsmogwai71Оценок пока нет

- Manual PanasonicДокумент9 страницManual PanasonicWilfredo RiveraОценок пока нет

- KTM Technical Handbook 7.0 Bomba Saturación NikuniДокумент12 страницKTM Technical Handbook 7.0 Bomba Saturación NikuniAnonymous w4ZnisPlazОценок пока нет

- FuelPurifier WestfaliaДокумент193 страницыFuelPurifier WestfaliaHorst100% (2)

- Erc Series BrochureДокумент4 страницыErc Series Brochurelepoulet0% (1)

- Electric Vaporisers For CO: Carbon DioxideДокумент4 страницыElectric Vaporisers For CO: Carbon DioxideVikk SuriyaОценок пока нет

- Replacement To Nathan DV4Документ2 страницыReplacement To Nathan DV4Vikk SuriyaОценок пока нет

- 33 - STR990-1 - Pressure Drop Data YДокумент2 страницы33 - STR990-1 - Pressure Drop Data YblindjaxxОценок пока нет

- Experimental Investigation On Diffusion Bonding of Dissimilar MetalsДокумент8 страницExperimental Investigation On Diffusion Bonding of Dissimilar MetalsVikk SuriyaОценок пока нет

- The Problem: Chakr InnovationДокумент13 страницThe Problem: Chakr InnovationVikk Suriya100% (1)

- Hydrostatic Lubricator For Steam LocomotivesДокумент6 страницHydrostatic Lubricator For Steam LocomotivesVikk SuriyaОценок пока нет

- Pulverized Coal BurnerДокумент8 страницPulverized Coal BurnerVikk SuriyaОценок пока нет

- Sewer Odor Control: Master PlanДокумент168 страницSewer Odor Control: Master PlanVikk SuriyaОценок пока нет

- Jet Blowers and Blast Nozzles: - Ventilating, Exhausting, Purging - Low Vacuum ApplicationsДокумент2 страницыJet Blowers and Blast Nozzles: - Ventilating, Exhausting, Purging - Low Vacuum ApplicationsVikk SuriyaОценок пока нет

- Readiness For ProductionДокумент5 страницReadiness For ProductionVikk SuriyaОценок пока нет

- Mid Term Examination IbsДокумент10 страницMid Term Examination IbsVikk SuriyaОценок пока нет

- Dreadnought Type 2 in 1 Brake EjectorДокумент10 страницDreadnought Type 2 in 1 Brake EjectorVikk SuriyaОценок пока нет

- Vtug-G enДокумент200 страницVtug-G enVikk SuriyaОценок пока нет

- Paint Estimating Calculations PDFДокумент2 страницыPaint Estimating Calculations PDFGaurav Tripathi50% (2)

- Festo Handling ModulesДокумент23 страницыFesto Handling ModulesVikk SuriyaОценок пока нет

- Festo Solenoid ValveДокумент11 страницFesto Solenoid ValveVikk SuriyaОценок пока нет

- Dfpi enДокумент52 страницыDfpi enCarlos VandréОценок пока нет

- Solenoid/pneumatic Valves, ISO 15407-1: Look For The Star!Документ81 страницаSolenoid/pneumatic Valves, ISO 15407-1: Look For The Star!Vikk SuriyaОценок пока нет

- Illuminating Seals, Square Design: Subject To Change - 2018/07Документ3 страницыIlluminating Seals, Square Design: Subject To Change - 2018/07Vikk SuriyaОценок пока нет

- Dfpi enДокумент52 страницыDfpi enCarlos VandréОценок пока нет

- Steam Table For EngineersДокумент103 страницыSteam Table For EngineersVizay KumarОценок пока нет

- Angle Seat Valve Fest Data SheetДокумент41 страницаAngle Seat Valve Fest Data SheetVikk SuriyaОценок пока нет

- Surface Condensers PDFДокумент7 страницSurface Condensers PDFing_julio_siviraОценок пока нет

- Masters Thesis - Jacob MccormickДокумент171 страницаMasters Thesis - Jacob MccormickVikk SuriyaОценок пока нет

- Cooling PDFДокумент8 страницCooling PDFVikk SuriyaОценок пока нет

- Condensor PDFДокумент3 страницыCondensor PDFVikk SuriyaОценок пока нет

- Emergency KitДокумент1 страницаEmergency KitVikk SuriyaОценок пока нет

- Clack Anthracite 2354 LДокумент2 страницыClack Anthracite 2354 LkhristprasatyaОценок пока нет

- Clack Anthracite 2354 LДокумент2 страницыClack Anthracite 2354 LkhristprasatyaОценок пока нет

- LUDWIG - Ethics in The Engineering Profession PDFДокумент11 страницLUDWIG - Ethics in The Engineering Profession PDFmayaОценок пока нет

- Brenya ResumeДокумент4 страницыBrenya ResumechuckjoeОценок пока нет

- Bilgmon488 Instruction ManualДокумент25 страницBilgmon488 Instruction ManualÖzgürMetinОценок пока нет

- Crirical EquipmentДокумент1 страницаCrirical EquipmentАндрей ПримакОценок пока нет

- 02 Process DescriptionДокумент40 страниц02 Process DescriptionAnonymous O0lyGOShYGОценок пока нет

- Refrigerated Vessel Survey Report R1.3 - Part AДокумент9 страницRefrigerated Vessel Survey Report R1.3 - Part AFouad OuazzaniОценок пока нет

- PML 087a - PMS - EngineДокумент70 страницPML 087a - PMS - EngineFidriОценок пока нет

- Ship Piping SystemДокумент19 страницShip Piping SystemAtandho Gama MagwasyarОценок пока нет

- Ek GeneralДокумент24 страницыEk GeneralPRASHANT SAWANTОценок пока нет

- Training Material 126 Company Guidance For Recording Operations in The Oil Record Book PDFДокумент37 страницTraining Material 126 Company Guidance For Recording Operations in The Oil Record Book PDFkurupath100% (1)

- Comm Schedule Updated 4 May 16Документ7 страницComm Schedule Updated 4 May 16PACKIRISAMY CHAKKRAVARTHIОценок пока нет

- Checklist Template ReportДокумент23 страницыChecklist Template ReportrafaelОценок пока нет

- ChiefMate Phase 2 II Question Papers Bank Till Feb19 DG SHIPPING INDIAДокумент189 страницChiefMate Phase 2 II Question Papers Bank Till Feb19 DG SHIPPING INDIAGurjit Singh100% (6)

- Marpol 2007Документ73 страницыMarpol 2007Christian Rodrigo Gonzalez CockbaineОценок пока нет

- Intertanko Dry Dock ChecklistДокумент14 страницIntertanko Dry Dock Checklistsandeepkumar2311Оценок пока нет

- Bilge Water SystemsДокумент5 страницBilge Water SystemshutsonianpОценок пока нет

- Most Frequent PSC Observations in 2019Документ107 страницMost Frequent PSC Observations in 2019Shady Elshazly100% (2)

- List of Important and Not-So-Famous Tanks On A ShipДокумент10 страницList of Important and Not-So-Famous Tanks On A Shipstamatis100% (1)

- 7.15 NYK Engine Cadet Course Handouts (OWS)Документ6 страниц7.15 NYK Engine Cadet Course Handouts (OWS)TowfiqОценок пока нет

- Bunkering: Fuel & Diesel Oil TanksДокумент6 страницBunkering: Fuel & Diesel Oil TanksPanagiotis MouzenidisОценок пока нет

- Manual InstructionsДокумент34 страницыManual InstructionsАндрей100% (4)

- Oily Water Separator CatalogueДокумент2 страницыOily Water Separator CatalogueVikk Suriya100% (1)

- 1583330143phase 2 - MMD Ques Set Till Feb 2020 PDFДокумент211 страниц1583330143phase 2 - MMD Ques Set Till Feb 2020 PDFNelson VargheseОценок пока нет

- Machine AuxiliaryДокумент33 страницыMachine Auxiliarygerson tiendaОценок пока нет

- Maersk Vallvik Machinery Manual Issue 1 April 2011 PDFДокумент288 страницMaersk Vallvik Machinery Manual Issue 1 April 2011 PDFNanu Razvan100% (2)

- OwsДокумент10 страницOwsAnte BudimirОценок пока нет

- Installation Instructions: Oily Water Separator SKIT/S-DEBДокумент28 страницInstallation Instructions: Oily Water Separator SKIT/S-DEBJano GoñiОценок пока нет

- System Structure OWSДокумент10 страницSystem Structure OWSAbiem SebastyanОценок пока нет

- Solas ChaptersДокумент117 страницSolas ChaptersirakliОценок пока нет

- RWO Oily Water Separator PDFДокумент28 страницRWO Oily Water Separator PDFИван БугаенкоОценок пока нет

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionОт EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionРейтинг: 3 из 5 звезд3/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionОт EverandThe Laws of Thermodynamics: A Very Short IntroductionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Waste: One Woman’s Fight Against America’s Dirty SecretОт EverandWaste: One Woman’s Fight Against America’s Dirty SecretРейтинг: 5 из 5 звезд5/5 (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionОт EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisОт EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisРейтинг: 4 из 5 звезд4/5 (2)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseОт EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (51)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОт EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОценок пока нет

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideОт Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideРейтинг: 3.5 из 5 звезд3.5/5 (7)

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyОт EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyРейтинг: 5 из 5 звезд5/5 (1)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsОт EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsОценок пока нет

- Handbook of Mechanical and Materials EngineeringОт EverandHandbook of Mechanical and Materials EngineeringРейтинг: 5 из 5 звезд5/5 (4)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsОт EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsОценок пока нет

- Mechanical Vibrations and Condition MonitoringОт EverandMechanical Vibrations and Condition MonitoringРейтинг: 5 из 5 звезд5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchОт EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchРейтинг: 4 из 5 звезд4/5 (10)

- Geotechnical Engineering Calculations and Rules of ThumbОт EverandGeotechnical Engineering Calculations and Rules of ThumbРейтинг: 4 из 5 звезд4/5 (17)