Академический Документы

Профессиональный Документы

Культура Документы

03-5 QCS 2014

Загружено:

Raja Ahmed HassanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

03-5 QCS 2014

Загружено:

Raja Ahmed HassanАвторское право:

Доступные форматы

QCS 2014

Section 03: Ground Investigation

Part

05: In-Situ Testing, Instrumentation and Monitoring

Page 1

IN-SITU TESTING, INSTRUMENTATION AND MONITORING............................... 2

5.1

5.1.1

5.1.2

GENERAL ............................................................................................................... 2

Scope

2

References

2

5.2

5.2.1

5.2.2

TESTING, INSTRUMENTATION AND MONITORING GENERALLY ...................... 2

Testing

2

Instrumentation and Monitoring

3

5.3

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

TESTS ..................................................................................................................... 3

Tests in accordance with BS 1377 or BS EN 1997

3

Tests in accordance with BS 5930

4

Geophysical Methods of Investigation

4

Special In-Situ Testing

4

Hand Penetrometer and Hand Vane for Shear Strength

5

Self-boring Pressuremeter

5

5.4

5.4.1

5.4.2

5.4.3

INSTRUMENTATION AND MONITORING .............................................................. 6

Groundwater

6

Installation of Standpipes and Piezometers

6

Installation of Gas Monitoring Standpipes

6

at

ar

C

on

st

ru

ct

io

Sp

ec

ifi

ca

tio

ns

20

14

QCS 2014

Section 03: Ground Investigation

Part

05: In-Situ Testing, Instrumentation and Monitoring

Page 2

IN-SITU TESTING, INSTRUMENTATION AND MONITORING

5.1

GENERAL

5.1.1

Scope

Testing of soils in place, and provision of instrumentation and monitoring of groundwater and

subsurface gases.

Related Sections and Parts are as follows:

20

14

This Section

tio

ns

Part 1 ............... General

Part 2 ............... Boreholes

Part 3 ............... Pits and Trenches.

References

The following standards and other documents are referred to in this Part:

ca

5.1.2

ec

ifi

ASTM D 420 ...............Site Characterization for Engineering, Design, and Construction

Purposes

ASTM D 2488 .............Description and Identification of Soils (Visual-Manual Procedure)

Sp

BS 1377......................Methods of tests for soils for civil engineering purposes

BS 5930......................Code of practice for site investigations

BS 7022......................Geophysical logging of boreholes for hydrogeological purposes

ct

io

BS EN 1997................Ground Investigation and testing

on

st

ru

The Geological Society Engineering Group Working Party Report on Engineering

Geophysics, Quarterly Journal of Engineering Geology, 21, pp. 207-271, 1988.

Clarke B.G. and Smith A., A model specification for radial displacement measuring

pressuremeters, Ground Engineering, Volume 25, No. 2, March, 1992.

TESTING, INSTRUMENTATION AND MONITORING GENERALLY

ar

C

5.2

Testing

The following information shall be submitted for each test record to be included in the daily

report, preliminary log and factual report:

at

5.2.1

(a)

Date of test.

(b)

Project name, exploratory hole number and location.

(c)

Depth and location of test or depths covered by test.

(d)

Information on water levels in exploratory hole during testing.

(e)

Original ground level at test site.

(f)

Soil type and description as identified from the sample.

All results shall be reported in SI units.

QCS 2014

Section 03: Ground Investigation

Part

05: In-Situ Testing, Instrumentation and Monitoring

Page 3

Where load, displacement or other measuring equipment is used which necessitates regular

calibration, then this shall be carried out in accordance with the relevant standard (the

preferred method) or the manufacturer's instructions, by a calibration service approved by the

Central Materials Laboratory. Evidence of calibrations and copies of calibration charts shall

be supplied to the Engineer prior to commencing work and when otherwise requested.

5.2.2

Instrumentation and Monitoring

The top of each standpipe, gas monitoring standpipe and piezometer tube shall be protected

by a cover. The type of protective cover shall be approved by the Engineer.

When instructed by the Engineer, the Contractor shall install a protective fence around the

top of a standpipe or piezometer. The fence shall be constructed of corrosion treated angle

iron, galvanised wire, and corrosion resistant wire mesh fencing suitable for use in the

climate of Qatar or a fence as a agreed upon with the Engineer.

Daily readings of depths to water in groundwater monitoring standpipes and piezometers

shall be made by the Contractor, with an instrument approved by the Engineer.

Where the presence of gas is suspected or when directed by the Engineer, gas

measurements, using an approved in-situ meter, shall be made by the Contractor during

construction of exploratory holes and in gas monitoring standpipes. The depth to water and

barometric pressure shall be measured immediately after each gas measurement.

Unless otherwise designated, piezometers, and standpipes protection shall not be removed

from the site.

Other instrumentation and monitoring shall be carried out as designated.

5.3

TESTS

5.3.1

Tests in accordance with BS 1377 or BS EN 1997

The following in-situ tests shall be carried out and reported in accordance with BS 1377 or

BS EN 1997:

at

Q

ct

on

st

ru

in-situ density by

ar

C

(a)

io

Sp

ec

ifi

ca

tio

ns

20

14

(i)

Small pouring cylinder method.

(ii)

Large pouring cylinder method.

(iii)

Water replacement method.

(iv)

Core cutter method.

(v)

Nuclear method.

(b)

Static cone penetration test (CPT), capacity to suit scheduled depths unless otherwise

designated

(c)

Dynamic probing (DPH or DPSH).

(d)

Standard penetration test (SPT).

(e)

Plate loading test.

(f)

Shallow pad maintained load test.

QCS 2014

Section 03: Ground Investigation

Part

05: In-Situ Testing, Instrumentation and Monitoring

California bearing ratio (CBR).

(h)

Vane shear strength.

(i)

Apparent resistivity of soil.

(j)

Redox potential.

(k)

Pressurementer or Self-boring Pressuremeter (PMT)

(l)

Pocket Penetrometer.

14

(g)

Page 4

Tests in accordance with BS 5930

The following in-situ tests shall be carried out where applicable and reported in accordance

with BS 5930:

20

5.3.2

ns

Constant head permeability test.

Variable head permeability test.

Packer permeability test.

tio

(a)

(b)

(c)

Geophysical Methods of Investigation

Geophysical testing shall be carried out as designated. The Contractor shall submit to the

Engineer a full description of equipment and procedure for each geophysical method

required.

The equipment and procedure, and information to be submitted for the following geophysical

methods of investigation, shall be as described in BS 5930, BS 7022 and the Geological

Society Engineering Group Working Party Report on Engineering Geophysics:

Sp

ec

ifi

ca

5.3.3

io

electrical resistivity method

(b)

seismic refraction and reflection method

(d)

magnetic method

gravity method

electromagnetic method

at

ar

C

(e)

on

st

ru

(c)

ct

(a)

(i)

Ground conductivity.

(ii)

Transient electromagnetic.

(iii)

Ground probing radar (optional).

(f)

Borehole geophysical logging.

(g)

Cross-hole seismic method.

(h)

Multi Channel Analysis of Surface Waves (MASW)

(i)

Refraction Microtremor (ReMi)

5.3.4

Special In-Situ Testing

Special in-situ testing shall be carried out as designated.

The Contractor shall allow for the excavation of boreholes, trenches or trial pits necessary for

the execution of inspection tests.

QCS 2014

Section 03: Ground Investigation

Part

05: In-Situ Testing, Instrumentation and Monitoring

Page 5

Inspection tests shall be decided as directed by the Engineer. These tests shall include but

not limited to those in Table 3.2.

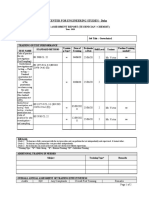

Table 3.2: Quality Assurance Tests for Completed Work

In-situ CBR

Field density

Plate load Test

Layer Thickness

Field density

DCP Test

Layer Thickness

SPT

DCP Test

Pressure meter

20

Deep Fill

(boreholes)

tio

ns

Shallow Fill

(trench or test pit)

14

Recommended Test per Layer

ca

Large Scale Loading

Hand Penetrometer and Hand Vane for Shear Strength

Hand penetrometer and hand vane tests shall be carried out where required to give a

preliminary estimate of undrained shear strength of the soil tested.

Hand (or pocket) penetrometer equipment shall be of an approved proprietary make with

2

stainless steel tip of end area 31 mm with an engraved penetration line 6 mm from the tip.

Sp

ec

ifi

5.3.5

on

st

ru

ct

io

The scale shall be suitably graduated. The procedure for the test shall be in accordance with

the manufacturer's instructions. Both unconfined compressive strength and estimated shear

strength shall be reported for the soil tested.

3

Hand vane equipment shall be of an approved proprietary make with stainless steel vanes

having a length of 19 mm or 33 mm and a length-to-diameter ratio of 2:1. The scale shall be

suitably graduated. The procedure for test shall be in accordance with BS 5930 and the

manufacturer's instructions. Peak shear strength and residual shear strength shall be

The reported shear strengths for the hand penetrometer and handvane shall be the average

of 3 tests in close proximity. Tests giving inconsistent results shall be reported and

comments on the relevance of the tests noted.

at

ar

C

recorded.

Self-boring Pressuremeter

The equipment shall be of the Cambridge type (soft ground) self-boring pressuremeter (SBP)

unless otherwise designated. The instruments, calibration, operator, installation, testing

procedure, on-site data processing and analysis, information to be submitted, report data

processing and analysis and information to be submitted in the report shall be as described

by Clarke and Smith (1992) and as designated..

5.3.6

QCS 2014

Section 03: Ground Investigation

Part

05: In-Situ Testing, Instrumentation and Monitoring

Page 6

5.4

INSTRUMENTATION AND MONITORING

5.4.1

Groundwater

When groundwater is encountered in exploratory holes, the depth from ground level of the

point of entry shall be recorded together with depth of any casing. Exploratory hole

operations shall be stopped and the depth from ground level to water level recorded with an

approved instrument at 5 minutes intervals for a period of 20 minutes. If at the end of the

ns

20

14

period of 20 minutes the water level is still rising, this shall be recorded together with the

depth to water below ground level, unless otherwise instructed by the Engineer, and the

exploratory hole shall then be continued. If casing is used and this forms a seal against the

entry of groundwater, the Contractor shall record the depth of casing at which no further entry

or only insignificant infiltration of water occurred.

Water levels shall be recorded as required by the Contract and at the beginning and end of

each shift. On each occasion when groundwater levels are recorded, the depth of the

exploratory hole, the depth of any casing and the time shall also be recorded.

Where artesian conditions are encountered, the Contractor shall immediately inform the

Engineer and agree a method for dealing with the conditions.

5.4.2

Installation of Standpipes and Piezometers

Standpipes for monitoring groundwater levels and changes in groundwater levels shall be

installed in exploratory holes, as instructed by the Engineer. They shall be to the designated

form and detail, and appropriate dimensions and depths shall be recorded at the time of

installation.

Standpipe piezometers for monitoring groundwater levels in exploratory holes shall be

installed as instructed by the Engineer. They shall be to the designated form and detail, and

appropriate dimensions. The installation details of the standpipe piezometers shall be

recorded.

The Contractor shall install piezometers of the hydraulic, electrical or pneumatic type

described in BS 5930 or as designated by the Engineer.

ar

C

on

st

ru

ct

io

Sp

ec

ifi

ca

tio

Installation of Gas Monitoring Standpipes

Standpipes for monitoring gas concentration in exploratory holes shall be installed as

instructed by the Engineer. Warning signs or other safety measures required by the Civil

Defence Department of the Government shall be complied with. Standpipes shall be of the

designated form and detail. All dimensions and depths shall he recorded at the time of

installation.

at

5.4.3

END OF PART

Вам также может понравиться

- 06-4 QCS 2014Документ57 страниц06-4 QCS 2014Raja Ahmed Hassan79% (14)

- Dimensional Control ProcedureДокумент12 страницDimensional Control ProcedureBethel NdifonОценок пока нет

- 05-10 QCS 2014Документ12 страниц05-10 QCS 2014Raja Ahmed HassanОценок пока нет

- 05-5 QCS 2014Документ31 страница05-5 QCS 2014Raja Ahmed Hassan100% (11)

- Guidance On The Design and Installation of Groundwater Monitoring PointsДокумент99 страницGuidance On The Design and Installation of Groundwater Monitoring PointsAnonymous G6ceYCzwt100% (1)

- New Irish Geo TechДокумент61 страницаNew Irish Geo TechgabemzamanОценок пока нет

- 06-2 QCS 2014Документ25 страниц06-2 QCS 2014Raja Ahmed Hassan100% (6)

- Soil Investigation ReportДокумент58 страницSoil Investigation Reportc.m.jibeesh100% (1)

- Engineering ProceduresДокумент23 страницыEngineering ProceduresadammzjinОценок пока нет

- Test Method For Earthwork Compaction Control by Nuclear GaugeДокумент29 страницTest Method For Earthwork Compaction Control by Nuclear GaugeLennieCartujanoLuceñoОценок пока нет

- 2 - Site InvestigationДокумент63 страницы2 - Site InvestigationTamunosaki AwolayeoforiОценок пока нет

- Well Testing MethodologyДокумент10 страницWell Testing Methodologyمعين عزامОценок пока нет

- Pipeline Design For On Bottom Stability in River BedДокумент15 страницPipeline Design For On Bottom Stability in River Bedoperating pandaОценок пока нет

- 02-15 QCS 2014Документ17 страниц02-15 QCS 2014Raja Ahmed HassanОценок пока нет

- Acceptance CriteriaДокумент11 страницAcceptance Criteriarajali798890% (10)

- Geotechnical Engineering Calculations and Rules of ThumbОт EverandGeotechnical Engineering Calculations and Rules of ThumbРейтинг: 4 из 5 звезд4/5 (17)

- 05-13 QCS 2014Документ15 страниц05-13 QCS 2014Raja Ahmed Hassan33% (3)

- Ultrasonic Testing of Austenitic and Austenitic Ferritic Stainless Steel ForgingsДокумент17 страницUltrasonic Testing of Austenitic and Austenitic Ferritic Stainless Steel ForgingsAlvice Max100% (1)

- Method Statement For Ug Piping 6423dp420!00!00200 00 - Rev03Документ20 страницMethod Statement For Ug Piping 6423dp420!00!00200 00 - Rev03mister pogi100% (2)

- QCS-2010 Section 19 Part 6 Commissioning of SystemsДокумент6 страницQCS-2010 Section 19 Part 6 Commissioning of Systemsbryanpastor106Оценок пока нет

- 05-15 QCS 2014Документ14 страниц05-15 QCS 2014Raja Ahmed Hassan100% (2)

- Technical Specifications For Soil InvestigationДокумент23 страницыTechnical Specifications For Soil InvestigationPonnada MarkandeyarajuОценок пока нет

- UTДокумент28 страницUTMohdHuzairiRusli100% (1)

- TR 26 2010 (ICS 93.020) - Technical Reference For Deep ExcavationДокумент31 страницаTR 26 2010 (ICS 93.020) - Technical Reference For Deep Excavationshish0iitrОценок пока нет

- Saep 1146Документ8 страницSaep 1146Ronanki RaviОценок пока нет

- Sensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesОт EverandSensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesОценок пока нет

- Ansaldo NDT Specifications 22GRKW v1 0Документ117 страницAnsaldo NDT Specifications 22GRKW v1 0pvssrh9929Оценок пока нет

- Land Rig Condition Survey Scope of WorkДокумент23 страницыLand Rig Condition Survey Scope of WorkAboozar FathinejadОценок пока нет

- 04-1 QCS 2014Документ7 страниц04-1 QCS 2014Raja Ahmed Hassan100% (1)

- 06-1 QCS 2014Документ10 страниц06-1 QCS 2014Raja Ahmed HassanОценок пока нет

- 05-14 QCS 2014Документ7 страниц05-14 QCS 2014Raja Ahmed HassanОценок пока нет

- 06-8 QCS 2014Документ7 страниц06-8 QCS 2014Raja Ahmed HassanОценок пока нет

- Section 10 Piling WorksДокумент31 страницаSection 10 Piling WorksKS LeeОценок пока нет

- Cone Penetration Testing: Methods and InterpretationОт EverandCone Penetration Testing: Methods and InterpretationРейтинг: 5 из 5 звезд5/5 (3)

- Bay.t-510 Close Prac Exam #3Документ22 страницыBay.t-510 Close Prac Exam #3Karim Mamdouh50% (2)

- Example-Site Investigation Factual ReportДокумент200 страницExample-Site Investigation Factual Reportপ্রিয়দীপ প্রিয়মОценок пока нет

- 06-6 QCS 2014Документ30 страниц06-6 QCS 2014Raja Ahmed HassanОценок пока нет

- Contract Agreement For Hammer Nasa ConstДокумент17 страницContract Agreement For Hammer Nasa ConstAcroll_pjОценок пока нет

- ICE UK Specification For Ground Investigation - IntroДокумент13 страницICE UK Specification For Ground Investigation - IntroWhiskoОценок пока нет

- 05-1 QCS 2014Документ10 страниц05-1 QCS 2014Raja Ahmed HassanОценок пока нет

- Final Report IDP 3 Geotechnical Department - Group 3Документ49 страницFinal Report IDP 3 Geotechnical Department - Group 3Mija Ismail100% (2)

- Env 1997-3-2000Документ151 страницаEnv 1997-3-2000Zanfir StefanОценок пока нет

- 03-1 QCS 2014Документ10 страниц03-1 QCS 2014Raja Ahmed HassanОценок пока нет

- Industrial Piping and Equipment Estimating ManualОт EverandIndustrial Piping and Equipment Estimating ManualРейтинг: 5 из 5 звезд5/5 (7)

- API 570 - Mockup CB - Paper 2Документ16 страницAPI 570 - Mockup CB - Paper 2Shanawas Abdul Razak100% (1)

- Above Ground Storage Tank Inspection GuidelinesДокумент7 страницAbove Ground Storage Tank Inspection GuidelinesTina Miller100% (1)

- Procedure For Fabrication and Erection of HP Piping Extract From Tata Cons - LTDДокумент12 страницProcedure For Fabrication and Erection of HP Piping Extract From Tata Cons - LTDSushanta NaikОценок пока нет

- Robe Draft Geotechnical Report - by ZablonДокумент33 страницыRobe Draft Geotechnical Report - by ZablonASAMNEW GULILATОценок пока нет

- S TR CIVIL OHL (Rev.0 2018) 1648785693296Документ33 страницыS TR CIVIL OHL (Rev.0 2018) 1648785693296Vimala PonnusamyОценок пока нет

- IACS - REC - 20 NDT of Ship Hull Steel StructuresДокумент11 страницIACS - REC - 20 NDT of Ship Hull Steel Structuresalinor_tnОценок пока нет

- 05-19 QCS 2014Документ8 страниц05-19 QCS 2014Raja Ahmed HassanОценок пока нет

- TWI-UT-Forgings Procedure For Level 3Документ9 страницTWI-UT-Forgings Procedure For Level 3willypumphandle_5309100% (1)

- Earthworks SpecificationsДокумент37 страницEarthworks SpecificationsconcretemadОценок пока нет

- APPENDIX IV Geotechnical Factual ReportДокумент69 страницAPPENDIX IV Geotechnical Factual ReportlidongmeiОценок пока нет

- 06-3 QCS 2014Документ13 страниц06-3 QCS 2014Raja Ahmed Hassan100% (1)

- Qcs 2010 Part 10 Pipeline Cleaning and Inspection SurveyДокумент18 страницQcs 2010 Part 10 Pipeline Cleaning and Inspection SurveyRotsapNayrbОценок пока нет

- Geotechnical Investigation: Method StatementДокумент6 страницGeotechnical Investigation: Method StatementRajesh SinghОценок пока нет

- Ultrasonic TestДокумент11 страницUltrasonic TestHarry DobleОценок пока нет

- Hydrotest Prosedure - All ProjectДокумент7 страницHydrotest Prosedure - All ProjectRony Sevenfold SweetChild OfMine'Rezpec100% (1)

- UT Procedure PDFДокумент23 страницыUT Procedure PDFcentaury2013Оценок пока нет

- API 570 Exam ClosedДокумент12 страницAPI 570 Exam ClosedMisbah ur Rehman100% (1)

- Ultrasonic Testing of Ferritic or Martensitic Steel ForgingsДокумент17 страницUltrasonic Testing of Ferritic or Martensitic Steel ForgingsrkkumarcpriОценок пока нет

- 05-17 QCS 2014Документ8 страниц05-17 QCS 2014Raja Ahmed Hassan100% (2)

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingОт EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghОценок пока нет

- Ultrasonic Testing of Steel ForgingsДокумент17 страницUltrasonic Testing of Steel ForgingsKevin ThomassinОценок пока нет

- Cone Penetrometer Components: 7.3.2 Test MethodsДокумент8 страницCone Penetrometer Components: 7.3.2 Test MethodsJihad HamdounОценок пока нет

- BTC003-B020-CM-PRO-00003-C01 CMS For Survey of Temp facilities-PSG1Документ42 страницыBTC003-B020-CM-PRO-00003-C01 CMS For Survey of Temp facilities-PSG1Levan JaparidzeОценок пока нет

- Annex UU PDFДокумент7 страницAnnex UU PDFAnonymous B7pghhОценок пока нет

- Api 510 Close Book - 4Документ20 страницApi 510 Close Book - 4tayyabОценок пока нет

- BS 5996 UT and Specifying Qualitty Gradw For SteelДокумент10 страницBS 5996 UT and Specifying Qualitty Gradw For Steelyasser awadallhОценок пока нет

- Well Testing Procedure ExampleДокумент15 страницWell Testing Procedure ExampleMohamed MamdouhОценок пока нет

- Foundation Consultants LTD.: M/S Kakoli Dying and Printing Works Ltd. Report OnДокумент53 страницыFoundation Consultants LTD.: M/S Kakoli Dying and Printing Works Ltd. Report Onপ্রিয়দীপ প্রিয়মОценок пока нет

- Approval Project Manager: Ministry of Electricity (Moe) Republic of IraqДокумент6 страницApproval Project Manager: Ministry of Electricity (Moe) Republic of IraqAlinaIordacheОценок пока нет

- Hydrostatic Testing Specification for PipelinesДокумент12 страницHydrostatic Testing Specification for PipelinesMoaatazz NouisriОценок пока нет

- NDE FORGED COMPONENTSДокумент5 страницNDE FORGED COMPONENTSveeramalaiОценок пока нет

- Specifications For CrossingsДокумент58 страницSpecifications For Crossingsapi-3698996100% (1)

- Collapse Tests of Pipe Casing and Tubing: February 2000Документ10 страницCollapse Tests of Pipe Casing and Tubing: February 2000Ankit LonareОценок пока нет

- 1.method of Statement For Subsoil Investigation WorksДокумент14 страниц1.method of Statement For Subsoil Investigation WorksMonirul Islam BadalОценок пока нет

- Fragmento 2 Api 650 - 2020Документ6 страницFragmento 2 Api 650 - 2020PEPITO GRILLO2Оценок пока нет

- 06-1 Road Works General QCS 2014Документ6 страниц06-1 Road Works General QCS 2014VJ Qatar75% (4)

- 05-8 QCS 2014Документ16 страниц05-8 QCS 2014Raja Ahmed HassanОценок пока нет

- 05-18 QCS 2014Документ5 страниц05-18 QCS 2014Raja Ahmed HassanОценок пока нет

- 05-16 QCS 2014Документ10 страниц05-16 QCS 2014Raja Ahmed HassanОценок пока нет

- 05-3 QCS 2014Документ5 страниц05-3 QCS 2014Raja Ahmed HassanОценок пока нет

- 05-11 QCS 2014Документ8 страниц05-11 QCS 2014Raja Ahmed HassanОценок пока нет

- 05-6 QCS 2014Документ15 страниц05-6 QCS 2014Raja Ahmed HassanОценок пока нет

- 05-12 QCS 2014Документ11 страниц05-12 QCS 2014Raja Ahmed HassanОценок пока нет

- 05-9 QCS 2014Документ6 страниц05-9 QCS 2014Raja Ahmed HassanОценок пока нет

- 05-7 QCS 2014Документ8 страниц05-7 QCS 2014Raja Ahmed HassanОценок пока нет

- 05-4 QCS 2014Документ5 страниц05-4 QCS 2014Raja Ahmed HassanОценок пока нет

- 04-2 QCS 2014Документ5 страниц04-2 QCS 2014Raja Ahmed HassanОценок пока нет

- 04-4 QCS 2014Документ13 страниц04-4 QCS 2014Raja Ahmed HassanОценок пока нет

- D Lab 006 AДокумент13 страницD Lab 006 AAyman EshraОценок пока нет

- SR1912264 - Soft PDFДокумент63 страницыSR1912264 - Soft PDFAburvarajОценок пока нет

- QP002-F001 Training Assessment ReportДокумент2 страницыQP002-F001 Training Assessment Reporthghghg3Оценок пока нет

- hd2208 PDFДокумент41 страницаhd2208 PDFjn115Оценок пока нет

- Adv Geotech Forensic Eng CompileWebДокумент277 страницAdv Geotech Forensic Eng CompileWebfarahazuraОценок пока нет

- List of Soil, Concrete, Aggregate and Cement Testing ServicesДокумент28 страницList of Soil, Concrete, Aggregate and Cement Testing ServicesAnonymous G6ceYCzwtОценок пока нет

- HD 2594Документ20 страницHD 2594Emilio EmiОценок пока нет

- TGN41Документ51 страницаTGN41Sittinan BenОценок пока нет

- 14.01 - General Design - Structures in Areas of Mining Subsidence - BD-10-97Документ31 страница14.01 - General Design - Structures in Areas of Mining Subsidence - BD-10-97Oscar MendozaОценок пока нет

- Design of Piles in London Clay Revised GuideДокумент16 страницDesign of Piles in London Clay Revised GuideLaurentiu TarbucОценок пока нет

- 03-3 Pits and TrenchesДокумент5 страниц03-3 Pits and TrenchesAbderrahmaneTemhachetОценок пока нет

- Borelog Report 1 PDFДокумент251 страницаBorelog Report 1 PDFNorhafizah Khairol AnuarОценок пока нет

- Martin Hencher, 1986Документ11 страницMartin Hencher, 1986Anonymous EYiyk7luОценок пока нет

- 255-2901 - Civil Pcakage of Vivo Energy Tanzania Depot - R0Документ216 страниц255-2901 - Civil Pcakage of Vivo Energy Tanzania Depot - R0Bruno Richard PhocusОценок пока нет