Академический Документы

Профессиональный Документы

Культура Документы

Grundfosliterature 5564673

Загружено:

warmaster81Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Grundfosliterature 5564673

Загружено:

warmaster81Авторское право:

Доступные форматы

grundfos communication interfaces

CIU 251 Communication interface for

Dedicated Controls and for sewage AUTOADAPT

for remote automation, control and monitoring

The CIU 251 is a standard interface module for remote wireless data transmission via a GSM/GPRS network and can be

used as follows:

As an SMS interface it enables users to control and monitor Grundfos AutoAdapt pumps and the Grundfos Dedicated

Controls sewage controller from a mobile phone. It is possible to get a message whenever a warning or an alarm occurs,

to request the status or to do simple control like START, STOP and adjusting of setpoint.

The GSM/GPRS module can work as a SCADA Interface enabling a SCADA system or another PLC controller to establish

a remote connection either via GSM Call-up using the Modbus RTU protocol or via a GPRS connection using the Modbus

TCP protocol with the system.

Extensive amounts of data points are available from the system, when connected via the CIU 251. The interface offers

uncomplicated wireless data transmission and remote control of pumping stations and commercial buildings.

The interface module can be installed as a wall-mounted unit and is equipped with a 24-240 VAC/ VDC power supply.

To connect a Dedicated Controls to a CIU251 a CIM 050 GENIbus interface is required.

Build-in I/O module for handling of extra analog and

digital input and output signals. These can be configured and accessed via SMS or via GSM/GPRS using the

Modbus protocol.

Advantages at a glance

> Modular design

> Wireless remote control and monitoring

> Incoming/outgoing pit interlock function

> Status request and control via SMS

> GSM call-up and call-back

> GPRS connection with call-back option

> Built-in battery backup possible

> External GSM antenna option

> Analog and digital inputs and outputs

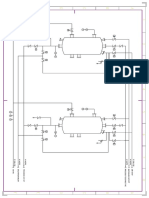

IO BOARD

NO

C

NC

IO BOARD

1

2

3

AI1

AI2

4

5

IO BOARD

1

2

3

4

5

DI1

DI2

Using CIU 251 with Dedicated Controls and for sewage AUTOADAPT

Protocol

Recommended cable type

Maximum cable length

GENIbus

Screened, double twisted-pair

1200 m/4000 ft

GSM/GPRS communication

Protocol

SMS

GSM call up (Modbus RTU)

GPRS (Modbus TCP)

GSM antenna

Available as an option

Battery

Included with CIU 251

SIM card

To be supplied by user/

installer

SMS features:

Read product status

Read network status

Get messages

Control

Configuration

E.g. pressure, power, temperature

etc. (depends on product type)

Request active alarms/warnings

Request I/O signal status

E.g. signal level, battery status,

GSM/GPRS status and data statistics.

Alarm/ warning event messages

Heart beat messages

Pit interlocking

Reset alarms

SMS access control via PIN code

Configuration of SMS functions

Configuration of GSM options

Configuration of GPRS connection

I/O board:

2 configurable inputs (digital or

analog 0/4-20mA, 0-10V)

1 Relay output (230V, 2 A)

1 Analog signal output (0-10V)

1 Temperature input (Pt100/

Pt1000 , 2-wire)

2 digital inputs

CIU 251 GSM/ GPRS

1

available for today, yesterday and totally

Pit Control

Reset alarm

Interlock pit

Custom relay control (On/Off/Pulse)

Pump Control

Pumps On/Off/Auto

Pump down

Configuration

Set pit and pumps control levels

Pit status

Pit operation mode

Active alarms/warnings

Pit mode (single/multi)

Status/function of float switches

Presence of sensors

Real time clock (read and set)

Pit control source (Manual/Auto)

Pit and pumps control levels

Water level

Water level max

In/out flow

Power/Energy consumption

Specific energy

Volume

Overflow volume/time/counter

Operation time

Operation time for simultaneous pumps

Mixer average starts per hours

3 x user defined sensor inputs

Float switches

Digital inputs

8 x I/O logic outputs

1

1

Pump status

Presence of pump

Pump enabled/disabled

Running/Stopped

Active alarms/warnings

Auxiliary equipment status

Control source

Operation time

Starts counter (total/average)

Latest continuous operation time

Max continuous operation time

Time to service

Flow (actual/latest)

Current (actual/latest)

Voltage/frequency

Current asymmetry

Power/Power factor /Energy consumption

Motor temperature

Insulation

Water in oil

1

1

1

1

Special

Hour log (latest 72h of main pit/pump values)

Event log (50 latest alarms/warnings w. time stamp)

User defined data log (40000 registers)

*) Available for today, yesterday and totally

For information related to Modbus TCP, PROFINET or GRM please

contact Grundfos

1): To connect a CIU 251 and sewage AUTOadapt pumps you need

additional a CIU 902 and a CIM 050. Than wire it by GENIbus cable to

the CIU 251.

Grundfos Holding A/S

Poul Due Jensens Vej 7

DK-8850 Bjerringbro

Tel: +45 87 50 14 00

www.grundfos.com

98616736 / 0514 / 10869-D&I

GENIbus communication

Data points

1)

24-240 VAC/VDC, 10% / + 15%

0 - 60 Hz

Max. 11 W

IEC: 0.2 - 4 mm2, UL: 24-12 AWG

IP 54, according to IEC 60529

6 x M16 4 10

20 C to +45 C (4 F to +113 F)

20 C to +60 C (4 F to +140 F)

182 x 108 x 82

Sewage

AUTOADAPT

Supply voltage

Frequency

Power consumption

Cable size

Enclosure class

Cable entry

Operation temperatures

Storage temperatures

Dimensions (H/W/D)

mm

Dedicated

Controls

General data

Вам также может понравиться

- VLT AutomationDrive FC 300 90-0 KW - Design Guide - MG34S202 25Документ1 страницаVLT AutomationDrive FC 300 90-0 KW - Design Guide - MG34S202 25warmaster81Оценок пока нет

- Ramna ZemjaДокумент2 страницыRamna Zemjawarmaster81Оценок пока нет

- Room Thermostats: Basic DocumentationДокумент38 страницRoom Thermostats: Basic Documentationwarmaster81Оценок пока нет

- KNX System: ManualДокумент48 страницKNX System: Manualwarmaster81Оценок пока нет

- Nozasti Osiguraci GGДокумент6 страницNozasti Osiguraci GGwarmaster81Оценок пока нет

- Grundfosliterature 1531Документ18 страницGrundfosliterature 1531warmaster81Оценок пока нет

- HSC01 SM10 MEC07 00002: Duty SpecificationДокумент5 страницHSC01 SM10 MEC07 00002: Duty Specificationwarmaster81Оценок пока нет

- Ednopolna Shema 09-06-2017 Layout1Документ1 страницаEdnopolna Shema 09-06-2017 Layout1warmaster81Оценок пока нет

- Filter A4 H PDFДокумент1 страницаFilter A4 H PDFwarmaster81Оценок пока нет

- HSC01 SM10 Mta01 00001 Ou100017929 R1Документ1 страницаHSC01 SM10 Mta01 00001 Ou100017929 R1warmaster81Оценок пока нет

- Cake Slice Box Base TemplateДокумент1 страницаCake Slice Box Base Templatewarmaster81Оценок пока нет

- First Number Protection Against Solid Objects Second Number Protection Against Liquids Ik Code Protection Against Mechanical ImpactsДокумент2 страницыFirst Number Protection Against Solid Objects Second Number Protection Against Liquids Ik Code Protection Against Mechanical Impactswarmaster81Оценок пока нет

- Ednopolna Shema 12-09-2016 Layout1Документ1 страницаEdnopolna Shema 12-09-2016 Layout1warmaster81Оценок пока нет

- HSC01 SM10 MEC07 00002: Duty SpecificationДокумент5 страницHSC01 SM10 MEC07 00002: Duty Specificationwarmaster81Оценок пока нет

- Atv61 Programming Manual en 1760649 08 PDFДокумент265 страницAtv61 Programming Manual en 1760649 08 PDFConrado AlvarezОценок пока нет

- Grundfosliterature 3367013 PDFДокумент1 страницаGrundfosliterature 3367013 PDFwarmaster81Оценок пока нет

- TNN Layout1Документ1 страницаTNN Layout1warmaster81Оценок пока нет

- Filter A4 HДокумент1 страницаFilter A4 Hwarmaster81Оценок пока нет

- Crtez Filter A4 HДокумент1 страницаCrtez Filter A4 Hwarmaster81Оценок пока нет

- GrundfosliteratureДокумент86 страницGrundfosliteraturewarmaster81Оценок пока нет

- IK Impact Test Schedule: Table 1: Relation Between IK Code and Impact EnergyДокумент1 страницаIK Impact Test Schedule: Table 1: Relation Between IK Code and Impact Energywarmaster81Оценок пока нет

- Guide To Low Voltage Circuit Breaker Standards - 2015Документ36 страницGuide To Low Voltage Circuit Breaker Standards - 2015k1gabitzu9789100% (2)

- C120N Circuit Breakers (Curves B, C, D)Документ4 страницыC120N Circuit Breakers (Curves B, C, D)warmaster81Оценок пока нет

- Controlling and Monitoring Directly From A Cell Phone: CCM 164 Examples of UseДокумент1 страницаControlling and Monitoring Directly From A Cell Phone: CCM 164 Examples of Usewarmaster81Оценок пока нет

- 451 59a PDFДокумент44 страницы451 59a PDFwarmaster81Оценок пока нет

- Prisma G: Low Voltage CatalogueДокумент200 страницPrisma G: Low Voltage Cataloguewarmaster81Оценок пока нет

- Product Data Sheet: Thermal Overload Relay For Motor - Tesys Lr9 - 132... 220 A - Class 10Документ2 страницыProduct Data Sheet: Thermal Overload Relay For Motor - Tesys Lr9 - 132... 220 A - Class 10warmaster81Оценок пока нет

- Grundfosliterature 5768738Документ36 страницGrundfosliterature 5768738warmaster81Оценок пока нет

- Abb PLC Phtc02u en WebДокумент181 страницаAbb PLC Phtc02u en Webwarmaster81Оценок пока нет

- EX215028 Busbar CatalogueДокумент164 страницыEX215028 Busbar Cataloguewarmaster81Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Gate Question (Limit) PDFДокумент4 страницыGate Question (Limit) PDFArpit Patel75% (4)

- Rigstoreef Impact or Enhancement On Marine Biodiversity 2157 7625 1000187Документ9 страницRigstoreef Impact or Enhancement On Marine Biodiversity 2157 7625 1000187tavis80Оценок пока нет

- Director Product Development Engineering in Detroit MI Resume Brian ThompsonДокумент2 страницыDirector Product Development Engineering in Detroit MI Resume Brian ThompsonBrianThompson2Оценок пока нет

- Yoga Nidra - Text PDFДокумент265 страницYoga Nidra - Text PDFVinod Kumar100% (1)

- Upper Int U2 OnlineReviewsAndRecommendations PDFДокумент2 страницыUpper Int U2 OnlineReviewsAndRecommendations PDFZsuzsa StefánОценок пока нет

- ExtPascal Advanced Configuration Complete Eng v4Документ31 страницаExtPascal Advanced Configuration Complete Eng v4jofreezeОценок пока нет

- Exalted 2e Sheet2 Mortal v0.1Документ2 страницыExalted 2e Sheet2 Mortal v0.1Lenice EscadaОценок пока нет

- ESL BOOKS - IELTS Academic Writing Task 1 Vocabulary by ESL Fluency - PreviewДокумент7 страницESL BOOKS - IELTS Academic Writing Task 1 Vocabulary by ESL Fluency - Previewanirudh modhalavalasaОценок пока нет

- NoteДокумент4 страницыNoteMost WonОценок пока нет

- Testing: Instructor: Iqra JavedДокумент32 страницыTesting: Instructor: Iqra Javedzagi techОценок пока нет

- T3904-390-02 SG-Ins Exc EN PDFДокумент89 страницT3904-390-02 SG-Ins Exc EN PDFBrunoPanutoОценок пока нет

- The FlirterДокумент2 страницыThe Flirterdddbbb7Оценок пока нет

- Finding The Right Place On The Map: Central and Eastern European Media Change in A Global PerspectiveДокумент306 страницFinding The Right Place On The Map: Central and Eastern European Media Change in A Global PerspectiveIntellect BooksОценок пока нет

- Promise To Keep by Mario BencastroДокумент146 страницPromise To Keep by Mario BencastroArte Público PressОценок пока нет

- Exalted Signs Sun in AriesДокумент6 страницExalted Signs Sun in AriesGaurang PandyaОценок пока нет

- Abstract On Budgetary ControlДокумент22 страницыAbstract On Budgetary ControlIhab Hosny AhmedОценок пока нет

- CP100 Module 2 - Getting Started With Google Cloud PlatformДокумент33 страницыCP100 Module 2 - Getting Started With Google Cloud PlatformManjunath BheemappaОценок пока нет

- Construction Manual California PDFДокумент956 страницConstruction Manual California PDFAlexander Ponce VelardeОценок пока нет

- BS 8901 SEG Press ReleaseДокумент3 страницыBS 8901 SEG Press Releasetjsunder449Оценок пока нет

- SAHCorporateBrochure WEBДокумент72 страницыSAHCorporateBrochure WEBKrsna SinghОценок пока нет

- English 4 Realistic FictionДокумент5 страницEnglish 4 Realistic FictionRose Marie RebutaОценок пока нет

- Project Demo On Pet Shop: Group Members: Muhammad Talha Malik Shamook Saad Muhammad HamzaДокумент10 страницProject Demo On Pet Shop: Group Members: Muhammad Talha Malik Shamook Saad Muhammad HamzaRaja Saad0% (1)

- TGC 121 505558shubham AggarwalДокумент4 страницыTGC 121 505558shubham Aggarwalshubham.aggarwalОценок пока нет

- How To Use SQL Servers Extended Events and Notifications White Paper 24902Документ20 страницHow To Use SQL Servers Extended Events and Notifications White Paper 24902Santosh KadamОценок пока нет

- Critical Incident Stress DebriefingДокумент20 страницCritical Incident Stress DebriefingatenampОценок пока нет

- Journal of Teacher Education-2008-Osguthorpe-288-99 PDFДокумент13 страницJournal of Teacher Education-2008-Osguthorpe-288-99 PDFFauzan WildanОценок пока нет

- Project Execution PlanДокумент69 страницProject Execution PlanGraco Calle100% (6)

- Belarc Advisory I7g8Документ5 страницBelarc Advisory I7g8Roberto AlladoОценок пока нет

- Mission Statement Generator WorksheetДокумент9 страницMission Statement Generator WorksheetMohamed SururrОценок пока нет

- Leadership and FollowershipДокумент43 страницыLeadership and FollowershipNishant AgarwalОценок пока нет