Академический Документы

Профессиональный Документы

Культура Документы

Value Stream Mapping

Загружено:

esatjournalsАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Value Stream Mapping

Загружено:

esatjournalsАвторское право:

Доступные форматы

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

VALUE STREAM MAPPING: A CASE STUDY OF AUTOMOTIVE

INDUSTRY

Palak P. Sheth1, Vivek A. Deshpande2, Hiren R. Kardani3

1

PG student, 2Associate Professor, Department of Mechanical Engineering, G.H.Patel College of Engineering &

Technology, Gujarat, India

3

Engineer, Lear Corporation, Gujarat, India

Abstract

Nowadays in a competitive market, companies require small lead times, low costs and high customer service levels. As such,

companies pay more effort to reduce lead time. Value Stream Mapping (VSM) techniques are used in some big companies like Toyota.

Value Stream Mapping (VSM) is the one of the lean manufacturing tool. This paper addresses the implementation of value stream

mapping in automotive industry. Value Stream mapping aim is identified waste in terms of non-value added activities. Current State

Map is prepared to give details about the existing position and identify various problem areas. Future State Map is made to show the

implementation action plan. A case study carried out in Lear Corporation Halol.

Keywords: Value Stream Mapping, Lead time, Lean manufacturing tool

--------------------------------------------------------------------***---------------------------------------------------------------------1. INTRODUCTION

2. LITERATURE REVIEW

Companies are continually striving to increase productivity

and output of their operations. [1] Lean has been originally

created and defined as the process of eliminating waste Toyota

along with the support a system to reduce or eliminate waste

and non-value added activities from the various processes. [3]

Value Stream is all the steps, both value added and non value

added required taking a product or service from raw material

to the customer.[2] Some examples of value added and non

value added activities are listed below: Value Added

activities-molding, welding etc. Non-value added activities walking, waiting, inspecting, reworking etc.

R. M. Belokar, Sandeep Singh Kharb, Vikas (2012) Kumar

drawn current state map for automobile industry. The tunnel

floor is taken for the case study. The cycle time of the welding

process is more than the takt time. By changing the layout and

improve the process capability of welding process.

Value Stream Mapping is visualization and streamlines work

processes using the tools and techniques of Lean

Manufacturing.VSM help to identify, demonstrate and

decrease waste in the processes. Waste being any activity that

does not add value to the final product.VSM can serve as a

blue print for Lean Manufacturing.

VSM has three types

1. Process level VSM In process VSM, material and

information flow with in a particular cell or production line.

2. Factory level or door-to-door VSM In factory level VSM,

material and information flow within a four walls of a factory

3. Extended level VSM Focusing material and information

flow of several companies

From this case study we are focusing on factory level or doorto-door VSM

Value Stream Mapping is used to identify the current process

of small scale industry. The current state map is used to

identify the wastes and non-value added activities in the

production process. A future state mp is created with the waste

activities eliminated and improve process cycle time and

reduce work in process inventory. (Rahul R Joshi, G.R.Naik

(2012)).Dinesh and A.Prabhukarthi (2013) explain value

stream mapping in pump manufacturing industry. They draw

current and future state map were developed with the objective

if improving productivity according to customer

requirements.Florin Buruiana and A.M.Goncalves Coelho

have created current state map in shaft manufacturing

industry. Draw and analyze the current state map found that

the large inventory between two processes, and big difference

between total lead times and value added time. Then draw a

future state map with providing a supermarket pull system and

one work cell and reduced a lead time.

3. VSM METHODOLOGY

VSM has four major steps as given by Rother and Shook. [8]

1. Select a product family

2. Draw Current state map

3. Draw future state map

4. Develop work plan for implementation future state.

__________________________________________________________________________________________

Volume: 03 Issue: 01 | Jan-2014, Available @ http://www.ijret.org

310

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

4. CASE STUDY

Step-3 Map the process flow

A case study conducted at automotive industry and some of

the observations may be useful to engineers in implementing

VSM in small, medium and large industries.

This step involves various processes to complete the product.

In addition, measure relevant data to put in a value stream

mapping box. Moreover, see the WIP between two processes.

4.1 Selection of Product Family

Step-4 Map the material flow

The first step is selection of critical part family. After study of

all part families, one part family was selected over all the

product families. The frame is main assemblies in a car seat.

The flow of material from raw material to finished goods is

given by supplier to customer.

Step-5 Map the information flow

4.2 Current State Map

Before draw a current state map collect a require data to draw

current state map.

The information flow provided demand information.

Information are given by electronic or manually.

Step-6 Draw the Time line

Data collecting method: Method that will be used in collecting

data needed is observation to the activities that performed in

the shop floor. Data is collected by using a stopwatch.

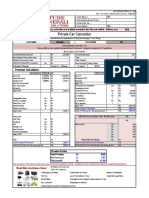

Table 1: Time matrix for each process

Process Name

Operator

Cushion Assembly

Cycle Time

(Value Added)

416

Marriage Assembly

265

Final Inspection

FG stock

5190

Calculate production lead times for inventory triangles by

dividing quantity of inventory by the customer daily

requirement. [8]

Current State Map shown in Fig 1.

4.3 Future State Map

Analyzing the current state map, the lead time and amount of

inventory are more between processes. Supermarket is used

between two processes to reduce inventory wastage during

process and convert the process from build to stock (push) to

make to order (pull). Future State Map shown in Fig 2.

5. SOFTWARE USED TO DRAW VSM

Mapping the value stream always start with the customer

demand. To create a current state map following steps are

followed.

E-Draw Max, Version 7 was used to draw all the maps. EDraw Max is vector-based diagramming software with rich

examples. E-Draw Max software is easy to create flow charts,

network-diagrams, chart and graphics, value stream mapping,

SWOT diagram etc. E-Draw Max includes all the libraries and

examples of E-draw product line.

Step-1 Calculate Takt Time

Takt time is defined as net available time divided by customer

demand.

The net available time is the total operation time during a

specific period, meaning the total amount of time, which adds

value on value stream. Customer Demand can be determined

on customer forecast or based on the currently customer order.

[9]

Step-2 Understand customer demand

Customer demand based on monthly or weekly. Customer

demand is 1778 sets/month.

__________________________________________________________________________________________

Volume: 03 Issue: 01 | Jan-2014, Available @ http://www.ijret.org

311

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

Fig 1:- Current State Map

__________________________________________________________________________________________

Volume: 03 Issue: 01 | Jan-2014, Available @ http://www.ijret.org

312

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

Fig 2:- Future State Map

__________________________________________________________________________________________

Volume: 03 Issue: 01 | Jan-2014, Available @ http://www.ijret.org

313

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

6. COMPARISON OF CURRENT STATE MAP

AND FUTURE STATE MAP

Variable

Lead Time

C/T NVA(sec)

Distance(m)

Before

0.3

802

145

After

0.1

597

68

Improvement

66.7%

25.6%

53.1%

CONCLUSIONS

By using value stream mapping we observed that non-value

added time is reduce by 25.6%.Also,the WIP is reduced and

thereby lead time is reduced by 66.7%.This proves the utility

of value stream mapping technique..

REFERENCES

[1]. Juan C Tinoco [2004] Implementation of Lean

Manufacturing

[2]. R.M.Belokar, Vikas Kumar, Sandeep Singh Kharb, An

application of value stream mapping in automotive industry,

IJITEE, July-2012, pp 152-157

[3]. G.Saranya, Mr.S.B.Nithyananth, Improvement of

crankshaft assembly supply chain using lean techniques,

IJMER, Apr-2012, pp-403-406

[4]. Rahul R Joshi, Prof G.R.Naik, Process improvement by

using value stream mapping, IJERT, July-2012

[5]. J.Dinesh, A.Prabhukarthi, Reduction of lead time using

value stream mapping in pump manufacturing industry,

MISSA, April-2013.

[6]. Soniya Parihar, Sanjay Jain, Lokesh Bajpai, value stream

mapping: Case study of assembly process, IJERT, Oct-2012.

[7]. Anderes Nielsen, Getting started with value stream

mapping, 2008.

[8]. Rother M., J.Shook, Learning to see, Lean Enterprise

Institute, 1999

[9]. Emil suciu, Mihal, Arvinte value stream mapping-A lean

production methodology, 2011

__________________________________________________________________________________________

Volume: 03 Issue: 01 | Jan-2014, Available @ http://www.ijret.org

314

Вам также может понравиться

- Value Stream Mapping A Case Study of AutomotiveДокумент5 страницValue Stream Mapping A Case Study of AutomotiveInternational Journal of Research in Engineering and TechnologyОценок пока нет

- The Journey to Excellence: Successfully Applying Lean Thinking in Your BusinessОт EverandThe Journey to Excellence: Successfully Applying Lean Thinking in Your BusinessОценок пока нет

- Simulation-based Lean Six-Sigma and Design for Six-SigmaОт EverandSimulation-based Lean Six-Sigma and Design for Six-SigmaРейтинг: 3 из 5 звезд3/5 (2)

- Applying Value Stream Mapping in Hospital Outpatient Department (MedicineДокумент42 страницыApplying Value Stream Mapping in Hospital Outpatient Department (MedicineAl-MuktadirОценок пока нет

- Develop a Transformation Roadmap A Clear and Concise ReferenceОт EverandDevelop a Transformation Roadmap A Clear and Concise ReferenceОценок пока нет

- Mapping The Current State Value StreamДокумент12 страницMapping The Current State Value StreamKhodayar SadeghiОценок пока нет

- An Evolutionary Model of Continuous Improvement Behaviour: John Bessant, Sarah Caffyn, Maeve GallagherДокумент11 страницAn Evolutionary Model of Continuous Improvement Behaviour: John Bessant, Sarah Caffyn, Maeve GallagherNathalia Cáceres100% (1)

- Business Process Optimization A Complete Guide - 2021 EditionОт EverandBusiness Process Optimization A Complete Guide - 2021 EditionОценок пока нет

- Talent Management Strategies A Complete Guide - 2020 EditionОт EverandTalent Management Strategies A Complete Guide - 2020 EditionОценок пока нет

- LEAN STRATEGY: Why people in great companies cannot wait for MondaysОт EverandLEAN STRATEGY: Why people in great companies cannot wait for MondaysОценок пока нет

- Leading with Lean: An Experience-Based Guide to Leading a Lean TransformationОт EverandLeading with Lean: An Experience-Based Guide to Leading a Lean TransformationОценок пока нет

- Essay On Value Stream MappingДокумент3 страницыEssay On Value Stream MappingAanchal ChawlaОценок пока нет

- Value Stream Mapping Software A Complete Guide - 2020 EditionОт EverandValue Stream Mapping Software A Complete Guide - 2020 EditionОценок пока нет

- Continuous Process Improvement A Complete Guide - 2020 EditionОт EverandContinuous Process Improvement A Complete Guide - 2020 EditionОценок пока нет

- Lean OfficeДокумент21 страницаLean OfficebradleyjtennantОценок пока нет

- Project Stakeholder Engagement A Complete Guide - 2019 EditionОт EverandProject Stakeholder Engagement A Complete Guide - 2019 EditionОценок пока нет

- Best Practices in Lean Six Sigma Process Improvement: A Deeper LookОт EverandBest Practices in Lean Six Sigma Process Improvement: A Deeper LookОценок пока нет

- Cohort Analysis A Complete Guide - 2020 EditionОт EverandCohort Analysis A Complete Guide - 2020 EditionРейтинг: 1 из 5 звезд1/5 (1)

- The Ultimate Guide to Successful Lean Transformation: Top Reasons Why Companies Fail to Achieve and Sustain Excellence through Lean ImprovementОт EverandThe Ultimate Guide to Successful Lean Transformation: Top Reasons Why Companies Fail to Achieve and Sustain Excellence through Lean ImprovementРейтинг: 4.5 из 5 звезд4.5/5 (3)

- SMED single minute exchange of die A Complete Guide - 2019 EditionОт EverandSMED single minute exchange of die A Complete Guide - 2019 EditionОценок пока нет

- A Project ON Lean Manufacturing Prepared BY Kunal Bansal Ty-D ROLL NO: 3204Документ10 страницA Project ON Lean Manufacturing Prepared BY Kunal Bansal Ty-D ROLL NO: 3204Kunal BansalОценок пока нет

- Business Process Re Engineering A Complete Guide - 2020 EditionОт EverandBusiness Process Re Engineering A Complete Guide - 2020 EditionОценок пока нет

- Are You Ready To Change The World? Thoughts On Technology Leadership For The FutureОт EverandAre You Ready To Change The World? Thoughts On Technology Leadership For The FutureОценок пока нет

- The Going Lean Fieldbook: A Practical Guide to Lean Transformation and Sustainable SuccessОт EverandThe Going Lean Fieldbook: A Practical Guide to Lean Transformation and Sustainable SuccessОценок пока нет

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsОт EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Design for Six SIGMA Complete Self-Assessment GuideОт EverandDesign for Six SIGMA Complete Self-Assessment GuideРейтинг: 1 из 5 звезд1/5 (1)

- The Medicine of Lean Six Sigma: And the 5 Side Effects to AvoidОт EverandThe Medicine of Lean Six Sigma: And the 5 Side Effects to AvoidОценок пока нет

- Value Stream MappingДокумент56 страницValue Stream Mappinggodle7535Оценок пока нет

- PTE 3 Week Study ScheduleДокумент3 страницыPTE 3 Week Study ScheduleesatjournalsОценок пока нет

- Analysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFДокумент4 страницыAnalysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFesatjournalsОценок пока нет

- An Improved Geo-Encryption Algorithm in Location Based Services PDFДокумент4 страницыAn Improved Geo-Encryption Algorithm in Location Based Services PDFesatjournalsОценок пока нет

- An Efficient Information Retrieval Ontology System Based Indexing For Context PDFДокумент7 страницAn Efficient Information Retrieval Ontology System Based Indexing For Context PDFesatjournalsОценок пока нет

- Analysis and Characterization of Dendrite Structures From Microstructure Images of Material PDFДокумент5 страницAnalysis and Characterization of Dendrite Structures From Microstructure Images of Material PDFesatjournalsОценок пока нет

- An Octa-Core Processor With Shared Memory and Message-Passing PDFДокумент10 страницAn Octa-Core Processor With Shared Memory and Message-Passing PDFesatjournalsОценок пока нет

- Analytical Assessment On Progressive Collapse Potential of New Reinforced Concrete Framed Structure PDFДокумент5 страницAnalytical Assessment On Progressive Collapse Potential of New Reinforced Concrete Framed Structure PDFesatjournalsОценок пока нет

- Analysis of Outrigger System For Tall Vertical Irregularites Structures Subjected To Lateral Loads PDFДокумент5 страницAnalysis of Outrigger System For Tall Vertical Irregularites Structures Subjected To Lateral Loads PDFesatjournalsОценок пока нет

- A Review Paper On Smart Health Care System Using Internet of ThingsДокумент5 страницA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsОценок пока нет

- Analysis of Cylindrical Shell Structure With Varying Parameters PDFДокумент6 страницAnalysis of Cylindrical Shell Structure With Varying Parameters PDFesatjournalsОценок пока нет

- Analysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFДокумент6 страницAnalysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFesatjournalsОценок пока нет

- Analysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFДокумент7 страницAnalysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFesatjournalsОценок пока нет

- A New Type of Single-Mode Lma Photonic Crystal Fiber Based On Index-Matching Coupling PDFДокумент8 страницA New Type of Single-Mode Lma Photonic Crystal Fiber Based On Index-Matching Coupling PDFesatjournalsОценок пока нет

- A Study and Survey On Various Progressive Duplicate Detection MechanismsДокумент3 страницыA Study and Survey On Various Progressive Duplicate Detection MechanismsesatjournalsОценок пока нет

- A Comparative Investigation On Physical and Mechanical Properties of MMC Reinforced With Waste Materials PDFДокумент7 страницA Comparative Investigation On Physical and Mechanical Properties of MMC Reinforced With Waste Materials PDFesatjournalsОценок пока нет

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsДокумент6 страницA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsОценок пока нет

- A Servey On Wireless Mesh Networking ModuleДокумент5 страницA Servey On Wireless Mesh Networking ModuleesatjournalsОценок пока нет

- A Review On Fake Biometric Detection System For Various ApplicationsДокумент4 страницыA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsОценок пока нет

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemДокумент8 страницA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsОценок пока нет

- I JR Et 20160503007dfceДокумент5 страницI JR Et 20160503007dfcegtarun22guptaОценок пока нет

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemДокумент8 страницA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsОценок пока нет

- A Critical Review On Experimental Studies of Strength and Durability Properties of Fibre Reinforced Concrete Composite PDFДокумент7 страницA Critical Review On Experimental Studies of Strength and Durability Properties of Fibre Reinforced Concrete Composite PDFesatjournalsОценок пока нет

- I JR Et 20160503007dfceДокумент5 страницI JR Et 20160503007dfcegtarun22guptaОценок пока нет

- A Review On Fake Biometric Detection System For Various ApplicationsДокумент4 страницыA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsОценок пока нет

- Ad Hoc Based Vehcular Networking and ComputationДокумент3 страницыAd Hoc Based Vehcular Networking and ComputationesatjournalsОценок пока нет

- A Review Paper On Smart Health Care System Using Internet of ThingsДокумент5 страницA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsОценок пока нет

- A Women Secure Mobile App For Emergency Usage (Go Safe App)Документ3 страницыA Women Secure Mobile App For Emergency Usage (Go Safe App)esatjournalsОценок пока нет

- A Servey On Wireless Mesh Networking ModuleДокумент5 страницA Servey On Wireless Mesh Networking ModuleesatjournalsОценок пока нет

- A Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesДокумент9 страницA Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesesatjournalsОценок пока нет

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsДокумент6 страницA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsОценок пока нет

- American Car - November 2014 UKДокумент116 страницAmerican Car - November 2014 UKenricoio100% (2)

- Ford Focus Mk2 ManualДокумент224 страницыFord Focus Mk2 ManualIosif Babias50% (2)

- Woco Flyer enДокумент3 страницыWoco Flyer enRazvanPopОценок пока нет

- Volvo Op Manual VNL & VNM 2001Документ353 страницыVolvo Op Manual VNL & VNM 2001Thomas S Fulford IIIОценок пока нет

- Traffic VolumeДокумент11 страницTraffic VolumeLai YenОценок пока нет

- WardsAutoOutlook Global Forecast Haig StoddardДокумент24 страницыWardsAutoOutlook Global Forecast Haig StoddardDudala VenkateshОценок пока нет

- Workshop Manual Range Rover Sport 2005-2013 Sec.1 GeneralДокумент611 страницWorkshop Manual Range Rover Sport 2005-2013 Sec.1 GeneralJorge Felipe Sepúlveda HaugenОценок пока нет

- Front Hub and Stub Axle PDFДокумент48 страницFront Hub and Stub Axle PDFvaleriyОценок пока нет

- Caryaire Equipments India Pvt. LTD.: Nimbuscooling@yahoo - Co.inДокумент1 страницаCaryaire Equipments India Pvt. LTD.: Nimbuscooling@yahoo - Co.inBhuvan BajajОценок пока нет

- Future Quote For Hyundai I20 Normal - Niren PatelДокумент1 страницаFuture Quote For Hyundai I20 Normal - Niren Patelniren4u1567Оценок пока нет

- Briggs and Stratton Model 9000, Model 10000, Part GuideДокумент64 страницыBriggs and Stratton Model 9000, Model 10000, Part Guidegaryg11100% (1)

- PF-200B Eff. SN 20013-01Документ162 страницыPF-200B Eff. SN 20013-01Jose Eduardo Casanueva OchoaОценок пока нет

- Tartanilla Towards A Touristic FutureДокумент10 страницTartanilla Towards A Touristic FutureRomeo Jumao-as Toring Jr.Оценок пока нет

- Idaho Wrecker Sales 2014 CatalogДокумент49 страницIdaho Wrecker Sales 2014 CatalogFred DanОценок пока нет

- CQI-15 Welding System AssessmentДокумент34 страницыCQI-15 Welding System AssessmentRamziAhmed60% (5)

- Purchasing An Automobile Gerilynn12Документ5 страницPurchasing An Automobile Gerilynn12api-293949691Оценок пока нет

- Audi A4 TSBДокумент4 страницыAudi A4 TSBkoltonv8929Оценок пока нет

- Who Are We?: Corporate Mission StatementДокумент4 страницыWho Are We?: Corporate Mission StatementRanjith SОценок пока нет

- Manac Project Tata Nano: Target CostingДокумент39 страницManac Project Tata Nano: Target CostingAladinОценок пока нет

- Manual Frenos CorollaДокумент47 страницManual Frenos CorollaSantos Junnior Hipolito SandovalОценок пока нет

- CFRP in CarsДокумент12 страницCFRP in CarsAnalfabetas Vacas Pitas Do Ask e afinsОценок пока нет

- MFS 40 - 50Документ85 страницMFS 40 - 50Gabriel PetersonОценок пока нет

- LT5012 PCB BroInside Final PDFДокумент39 страницLT5012 PCB BroInside Final PDFDavid LopezОценок пока нет

- IMP Workshop ManualДокумент336 страницIMP Workshop Manualsyllavethyjim67% (3)

- Denso PDFДокумент12 страницDenso PDFbruttus139Оценок пока нет

- Job AdvertisementsДокумент4 страницыJob AdvertisementsFederico Nicolas AnticoОценок пока нет

- Tata Nano Supply Chain ImportanceДокумент25 страницTata Nano Supply Chain ImportanceSathisha He H EОценок пока нет

- PI60447e - TITAN ATF 3292 - 04Документ3 страницыPI60447e - TITAN ATF 3292 - 04mike2581Оценок пока нет

- Replacement - RadiatorДокумент4 страницыReplacement - RadiatorErwin David Garcia WefferОценок пока нет

- AutoLine Industries Ltd.Документ26 страницAutoLine Industries Ltd.pgundecha100% (1)