Академический Документы

Профессиональный Документы

Культура Документы

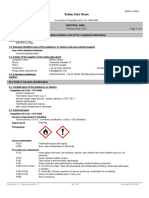

Knauf Insulation GMBH Material Safety Data Sheet: Section I - Chemical Product and Company Identification

Загружено:

Avicena AlbiruniОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Knauf Insulation GMBH Material Safety Data Sheet: Section I - Chemical Product and Company Identification

Загружено:

Avicena AlbiruniАвторское право:

Доступные форматы

Knauf Insulation GmbH

Health Hazard

Fire Hazard

Physical Hazard

Personal Protection

MATERIAL SAFETY DATA SHEET

NFPA RATING

HMIS RATING

SECTION I - CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

Product: Fiber Glass Insulation - ECOSE Technology

MSDS Number:

1014

(Rev. 5)

Trade Designations: EcoBatt (Unfaced and Faced) Building Insulation, EcoBatt QuietTherm (Unfaced and

Faced) Building Insulation, Acoustical/IB Board, Acoustical Board Smooth, Air Duct Board (Eclipse, Type M),

KB Blanket, Black Acoustical Board, Black Diffuser Board, Condensation Control Blanket, Duct Wrap (Faced and

Unfaced), Earthwool 1000 Pipe Insulation*, ET Batt*, ET Blanket*, ET Board*, ET Panel*, Equipment Liner M,

Fabrication Board*, Flexible Duct Material, Hullboard*, Insulation Board (Faced and Unfaced)*, KFR/ET Range

Insulation*, KN Series, KwikFlex*, Manufactured Housing Duct Board, Manufactured Housing Insulation, Metal

Building Insulation, Metal Building Filler Insulation, Pipe & Tank Insulation*, Earthwool Redi-Klad 1000 Pipe

Insulation*, Rigid Plenum Liner, Sill Sealer, Sonic XP Duct Liner, Wall & Ceiling Liner M (* See Section

VIII).

Manufacturer: Knauf Insulation GmbH

Date Issued:

Address: One Knauf Drive

Shelbyville, IN 46176-1496

January 23, 2013

Product Stewardship Support Line:

317-398-4434, x8212

24 hr Emergency (Chemtrec) Phone:

800-424-9300

SECTION II - COMPOSITION/INFORMATION ON INGREDIENTS

Chemical Name

CAS Number

Fibrous Glass

65997-17-3

Proprietary Binder

N/A

Key:

%

83-99

TLV

PEL

1 fiber/cc

1 fiber /cc

None

None

1-17

TLV = ACGIH, 8 hr. time weighted average (TWA); PEL = OSHA permissible exposure limit.

TLV and PEL limits are for respirable fibers length <5um, diameter >3um, aspect ratio <5:1.

SECTION III - HAZARDS IDENTIFICATION

Emergency Overview:

OSHA regulations do not require respiratory protection as long as the exposure to fiber glass wool does not exceed 1

fiber/cubic centimeter (f/cc) TWA (8 hour time weighted average). Fiber Glass wool exposure in the home,

commercial buildings, and manufacturing facilities are generally found to be less than 1 f/cc. Installers and

fabricators should be aware of their exposure levels and take appropriate actions if needed per recommended work

practices. Guidance on typical fiber exposures for various applications can be obtained from the North American

Insulation Manufacturers Association, www.NAIMA.org. Knauf STRONGLY recommends following all safe work

practices while working with and/or installing fiber glass wool products.

Issued: January 23, 2013

Page 1 of 4

Trade Name: Fiber Glass Insulation - ECOSE Technology

MSDS Number: 1014

SECTION III - HAZARDS IDENTIFICATION

HMIS Rating:

Health: 1

Fire: 0

Physical Hazard: 0

Protection: B

Primary Routes of Entry: Via respirable fibers to the lungs and respiratory system and airborne fibers to the skin

and eyes.

Primary Target Organs: Lungs, respiratory system, skin and eyes.

Potential Health Effects:

Acute: Mechanical irritation of the skin, eyes and upper respiratory system. Fiber glass wool is classified as a

nuisance dust by OSHA.

Chronic: Results from the most recent cohort and nested case-control epidemiological studies of U.S. workers

exposed to glass wool have not provided evidence of an association between exposure to fibers and risk for

respiratory cancer or mesothelioma.

Skin Contact: There are confirmed reports of contact dermatitis.

Eye Contact: A mechanical irritant which can cause moderate to severe eye irritation.

Ingestion: Non-hazardous when ingested. Potentially a mild irritant to the GI tract if excessive quantity is

ingested.

Medical Conditions Aggravated by Exposure: Pre-existing chronic upper respiratory and lung diseases such as,

but not limited to, bronchitis, emphysema and asthma. Skin disease such as dermatitis.

Biosolubility: All Knauf Insulation products covered by this MSDS are independently certified by EUCEB to be

manufactured using biosoluble glass formulations and thus exempt from labeling under NTP or California Prop 65

requirements.

SECTION IV - FIRST AID MEASURES

Inhalation: Remove to fresh air. Drink water to clear throat and blow nose to evacuate dust. If coughing and

irritation develop, call a physician.

Eye Contact: Flush with large amounts of water until irritation subsides, as least 15 minutes. See a physician if

irritation persists.

Skin Contact: Normal good personal hygiene practices. Wash with mild soap and warm water after each exposure.

Ingestion: Emergency procedures not normally required. May be a temporary irritant to the GI system.

SECTION V - FIREFIGHTING MEASURES

NFPA Rating:

Health: 1

Fire: 0

Reactivity: 0

Other: 0

Extinguishing Method: Use water, foam, dry chemical or carbon dioxide.

Special Firefighting Procedures: Wear self contained breathing apparatus and protective clothing. Dense smoke

may limit visibility in enclosed areas.

Fire or explosion Hazards: Resin, paper or plastic facings will burn causing dense acrid smoke.

Issued: January 23, 2013

Page 2 of 4

Trade Name: Fiber Glass Insulation - ECOSE Technology

MSDS Number: 1014

SECTION VI - ACCIDENTAL RELEASE MEASURES

Clean-up Procedures: Pick up or shovel material into waste container taking care to minimize dust and fiber

generation. Vacuum clean-up is preferred. If sweeping is required use a dust suppressant.

Personal Precautions: If dusty conditions exist, wear a face mask approved for use with dusts such as 3M 8210,

N95 or equivalent.

Environmental Precautions: This product is not regulated under RCRA Hazardous Waste Regulations. May be

disposed in landfill. Comply with federal, state and local regulations.

SECTION VII - HANDLING AND STORAGE

Storage Requirements: Store in dry area. Keep area clean. Vacuum clean dust. Use a dust suppressant if

sweeping is necessary.

Special Sensitivity or Incompatibility: Hydrofluoric acid will react with and dissolve glass.

Handling Precautions: Assure proper respiratory protection if dust potential exceeds PEL/TLV.

SECTION VIII - EXPOSURE CONTROLS/PERSONAL PROTECTION

* Heat-Up Precautions: During initial heat-up of high temperature insulation products to temperatures above

350F, an odor and smoke may be given off. Adequate ventilation should be provided to protect against fumes. In

confined spaces, occupants should wear self-contained breathing apparatus during this period.

Engineering Controls: Maintain sufficient mechanical or natural ventilation to assure fiber concentrations remain

below PEL/TLV. Use local exhaust if necessary. Power equipment should be equipped with properly designed dust

collection devices.

Respiratory Protection: When over PEL/TLV wear an approved respirator such as 3M 8210, N95 or equivalent, to

protect against respirable glass wool fibers. Concentrations of fibers that exceed the recommendations of the mask

manufacturer will need a higher level of respiratory protection, such as a half mask respirator with appropriate dust

filters.

Eye Protection: Wear safety glasses with side shields, goggles or face shield when handing, installing or fabricating

to protect eyes against dust and fibers.

Skin Protection (clothing): Long-sleeved, loose fitting clothes and head covering are recommended. Wash work

clothes separately from other clothing, towels and linens to prevent fiber migration. Rinse washer thoroughly.

SECTION IX - PHYSICAL AND CHEMICAL PROPERTIES

Physical Form: Brown or tan fibrous product.

Melting Point: >1300F

Specific Gravity: Variable

Solubility in Water: Insoluble

Pure/Mixture: Mixture

SECTION X - REACTIVITY

Stability: This is a stable, non-reactive product.

Hazardous Decomposition Products: Thermal decomposition of the resin may include carbon dioxide, carbon

monoxide, carbon particulate and traces of other decomposition products.

Issued: January 23, 2013

Page 3 of 4

Trade Name: Fiber Glass Insulation - ECOSE Technology

MSDS Number: 1014

SECTION XI - TOXICOLOGICAL/ECOLOGICAL INFORMATION

LD50: N/Av

LC50: N/Av

Toxicological Hazards: See the Emergency overview on page 1, Section II.

Ecological Hazards: No data exists for this product.

Teratogenicity, Mutagenicity, other Reproductive Effects: None known

SECTION XII - DISPOSAL CONSIDERATIONS

Waste Disposal Method This product is not regulated under RCRA Hazardous Waste Regulations. May be

disposed in landfill. If unsure, contact the local office of the USEPA, your local public health department or the

local landfill regulators.

SECTION XIII - TRANSPORTATION INFORMATION

US DOT Shipping Name: Not regulated

DOT Label: None

UN/NA Number: None

SECTION XIV - REGULATORY INFORMATION

OSHA Status: This product is regulated as a nuisance dust under OSHA criteria.

TSCA/CEPA Status: All components of this product are included in the TSCA and CEPA Chemical Inventories.

CERCLA Reportable Quantity: N/Ap

SARA Title III:

Section 302 Extremely Hazardous: This product contains no extremely hazardous substances as defined and

listed in section #302.

Section 311/312 Hazard Categories: Reportable as a hazardous substance. Check with your Local

Emergency Planning Committee for reportable quantities.

Section 313 Toxic Chemicals: This product does not contain substances which are reportable under Section

313.

California Safe Drinking Water and Toxic Enforcement Act (Prop. 65) This product is exempt from labeling

requirements under this Act.

Canada (WHMIS): This product is a class D2A controlled product under Canadian WHMIS regulations.

SECTION XV - APPROVALS

Reason for Issue: Update Sections III & XIV

Rev:

Prepared by: Knauf Insulation

Approval Date:

1/23/13

Supersedes Date: 07/12/12

SECTION XVI - DISCLAIMER

As of the date of this document, the foregoing information is believed to be accurate and is provided in good faith to

comply with applicable federal and state laws. However, no warranty or representation of law or fact, with respect to

such information, is intended or given.

Issued: January 23, 2013

Page 4 of 4

Вам также может понравиться

- Knauf Duct Liner Cured Product MSDS SheetДокумент4 страницыKnauf Duct Liner Cured Product MSDS SheetductworkОценок пока нет

- CertainTeed Fiberglass Insulation MSDSДокумент10 страницCertainTeed Fiberglass Insulation MSDSbsiofncОценок пока нет

- MSDS SolarguardДокумент5 страницMSDS SolarguardKeyleen LinaresОценок пока нет

- Rockwool Pipe MSDSДокумент5 страницRockwool Pipe MSDSJullius CarballoОценок пока нет

- Flat MSDS PDFДокумент3 страницыFlat MSDS PDFroviijo0% (1)

- Cellular GlassДокумент7 страницCellular GlassSergio PereiraОценок пока нет

- Used Oil MsdsДокумент7 страницUsed Oil Msdspequenita34Оценок пока нет

- 3M Material Safety Data Sheet Cc-4 and Cc-55 (Cable Cleaner - Bulk Liquid)Документ7 страниц3M Material Safety Data Sheet Cc-4 and Cc-55 (Cable Cleaner - Bulk Liquid)ramlijavierОценок пока нет

- Genflex Roofing Systems, LLC Material Safety Data SheetДокумент4 страницыGenflex Roofing Systems, LLC Material Safety Data SheetgjroddyОценок пока нет

- Msds Sigma Ecofleet 530 (Ecol Ha)Документ8 страницMsds Sigma Ecofleet 530 (Ecol Ha)kumarОценок пока нет

- MSDS - 200000000474 - REG - NA - EN - John Mansville Series 800 Insulation MSDS No-1077Документ7 страницMSDS - 200000000474 - REG - NA - EN - John Mansville Series 800 Insulation MSDS No-1077Carlos ChisanОценок пока нет

- Safety Data SheetДокумент7 страницSafety Data SheetEliya Maya SistaОценок пока нет

- F84C-5 - Sat - MSDSДокумент4 страницыF84C-5 - Sat - MSDSDenise Koh Chin HuiОценок пока нет

- Safety Data Sheet Abs Sheet: Section 1: IdentificationДокумент5 страницSafety Data Sheet Abs Sheet: Section 1: IdentificationSabhaya ChiragОценок пока нет

- S25754 PDFДокумент7 страницS25754 PDFCharls DeimoyОценок пока нет

- Fiberglass MSDS by Owens Corning (TM)Документ11 страницFiberglass MSDS by Owens Corning (TM)EG Giwangkara SОценок пока нет

- IKOpro Quick Dry Bitumen Primer MSDSДокумент5 страницIKOpro Quick Dry Bitumen Primer MSDSAnonymous y1pIqcОценок пока нет

- 3M 1099 MSDSДокумент8 страниц3M 1099 MSDSRavi Shankar M GОценок пока нет

- 3M (TM) Vetbond Tissue Adhesive / LIQUID BANDAID MSDSДокумент7 страниц3M (TM) Vetbond Tissue Adhesive / LIQUID BANDAID MSDSRick OshayОценок пока нет

- Tyrin 200Документ10 страницTyrin 200Nicol AlejandraОценок пока нет

- VYDYNE® Nylon 6,6-6Документ6 страницVYDYNE® Nylon 6,6-6ccocos7182Оценок пока нет

- Diaper Dilemma Prelab AnswersДокумент7 страницDiaper Dilemma Prelab Answers217854Оценок пока нет

- Material Safety Data Sheet: 1. Product and Company IdentificationДокумент9 страницMaterial Safety Data Sheet: 1. Product and Company IdentificationMokshaОценок пока нет

- Dimethylformamide - Nugentec Ghs MsdsДокумент8 страницDimethylformamide - Nugentec Ghs MsdsstabinmathewОценок пока нет

- Material Safety Data Sheet Furan Resin Section I - Product & Company IdentificationДокумент4 страницыMaterial Safety Data Sheet Furan Resin Section I - Product & Company IdentificationSHAIK ASIMUDDINОценок пока нет

- CEFOR 1050P Polyethylene Resin English SDS For Saudi Arabia 18oct2015-1Документ9 страницCEFOR 1050P Polyethylene Resin English SDS For Saudi Arabia 18oct2015-1Lukasz ZdunekОценок пока нет

- EverGreen MSDS 05.12Документ5 страницEverGreen MSDS 05.12AuburnMfgОценок пока нет

- Nepheline Syenite - Various Grades (A200-A270)Документ5 страницNepheline Syenite - Various Grades (A200-A270)Lynne MarrОценок пока нет

- Polyken 2019 PrimerДокумент5 страницPolyken 2019 Primernrd9771Оценок пока нет

- Safety Data Sheet: Section 1 - Product and Company IdentificationДокумент8 страницSafety Data Sheet: Section 1 - Product and Company IdentificationAnas AbdollahОценок пока нет

- SDS CN en PDFДокумент8 страницSDS CN en PDFKhanh Ly Nguyen ThiОценок пока нет

- Material Safety Data Sheet: 1. Product and Company IdentificationДокумент7 страницMaterial Safety Data Sheet: 1. Product and Company Identificationoverlord5555Оценок пока нет

- Penetrox HT x-1552 A (GHS)Документ10 страницPenetrox HT x-1552 A (GHS)yesrtyОценок пока нет

- CatalaseДокумент6 страницCatalaseSОценок пока нет

- Thermal Ceramics Superwool Coshh SheetДокумент6 страницThermal Ceramics Superwool Coshh Sheetstuart3962Оценок пока нет

- Nalco Tri Act 1820Документ13 страницNalco Tri Act 1820anon_336536469Оценок пока нет

- SDS - DOWSIL™ 813FR Fire Retardant Silicone-MinДокумент14 страницSDS - DOWSIL™ 813FR Fire Retardant Silicone-MinRajneesh SainiОценок пока нет

- Avonite Surfaces Foundations-C8201CДокумент9 страницAvonite Surfaces Foundations-C8201CaggibudimanОценок пока нет

- Safety Data Sheet: 1. Product and Company IdentificationДокумент9 страницSafety Data Sheet: 1. Product and Company IdentificationMRWHUОценок пока нет

- Safety Data SheetДокумент8 страницSafety Data SheetCorry ApriliaОценок пока нет

- Sulph Acid (MSDS) PDFДокумент4 страницыSulph Acid (MSDS) PDFKhursheed AhmadОценок пока нет

- Whittemore Company Material Safety Data SheetДокумент4 страницыWhittemore Company Material Safety Data SheetPao BarillasОценок пока нет

- DMDS MSDSДокумент11 страницDMDS MSDSamirhosseine00Оценок пока нет

- Nytro Orion I Safety Data SheetДокумент8 страницNytro Orion I Safety Data SheetwilmanzitoОценок пока нет

- Safety Data Sheet: 1. Product and Company IdentificationДокумент8 страницSafety Data Sheet: 1. Product and Company IdentificationSrinivasan KОценок пока нет

- Tandex 245Документ10 страницTandex 245Harnani NanikОценок пока нет

- DMDS Data SheetДокумент7 страницDMDS Data Sheetfarooq798100% (1)

- 209 Flexo Wash SDSДокумент8 страниц209 Flexo Wash SDSNabil NnОценок пока нет

- EB Solvent - MsdsДокумент11 страницEB Solvent - MsdsNisma NilamsariОценок пока нет

- Carbon-Off! (Aerosol) : Material Safety Data SheetДокумент1 страницаCarbon-Off! (Aerosol) : Material Safety Data SheetdimasfebriantoОценок пока нет

- R-A 1Документ3 страницыR-A 1api-242806172Оценок пока нет

- 492 MSDSДокумент5 страниц492 MSDSsrinivignaОценок пока нет

- MSDS CuCO3Документ7 страницMSDS CuCO3Mas BagusОценок пока нет

- Syltherm 800 Silicone Heat Transfer Fluid MSDSДокумент8 страницSyltherm 800 Silicone Heat Transfer Fluid MSDSNasser AlshalwyОценок пока нет

- Calsium CarbidДокумент7 страницCalsium CarbidOsman OmerОценок пока нет

- Msds Sigma Phenguard 930-935-940 (Sigma Phenguard) HardenerДокумент8 страницMsds Sigma Phenguard 930-935-940 (Sigma Phenguard) HardenerkumarОценок пока нет

- MSDS PAROIL S - GB - enДокумент7 страницMSDS PAROIL S - GB - enTeguh SОценок пока нет

- 00.SDS Xiameter Afe1520-EnДокумент11 страниц00.SDS Xiameter Afe1520-EnrolandoОценок пока нет

- Safety Data Sheet: According To EC Directive 91/155/EECДокумент6 страницSafety Data Sheet: According To EC Directive 91/155/EECSiti HannaОценок пока нет

- The Health & Safety Guide for Film, TV & Theater, Second EditionОт EverandThe Health & Safety Guide for Film, TV & Theater, Second EditionРейтинг: 4 из 5 звезд4/5 (1)

- Understanding Computing From The QuranДокумент8 страницUnderstanding Computing From The QuranZaid Ghazzawi100% (1)

- ABRSM Singing SyllabusДокумент78 страницABRSM Singing Syllabusjj1jj2jj3jj4100% (2)

- Form VisaДокумент1 страницаForm VisaAvicena AlbiruniОценок пока нет

- Plato DialoguesДокумент300 страницPlato Dialoguesjohanna_341529511100% (1)

- 19 TsurumiДокумент11 страниц19 TsurumiAvicena AlbiruniОценок пока нет

- Muslim Heritage in Religionswissenschaft: A Preliminary Study On The Purposiveness & The Non-Purposiveness of Muslim ScholarshipДокумент18 страницMuslim Heritage in Religionswissenschaft: A Preliminary Study On The Purposiveness & The Non-Purposiveness of Muslim ScholarshipAvicena AlbiruniОценок пока нет

- Understanding The Hadith PDFДокумент230 страницUnderstanding The Hadith PDFAvicena AlbiruniОценок пока нет

- RepublicДокумент20 страницRepublicAvicena AlbiruniОценок пока нет

- What Is StandingДокумент1 страницаWhat Is StandingAvicena AlbiruniОценок пока нет

- BabylonДокумент22 страницыBabylonFaridRameliОценок пока нет

- The Other Islam Stephen S PDFДокумент5 страницThe Other Islam Stephen S PDFAvicena AlbiruniОценок пока нет

- CEДокумент4 страницыCEAvicena AlbiruniОценок пока нет

- Adgeo 14 3 2008Документ9 страницAdgeo 14 3 2008Avicena AlbiruniОценок пока нет

- Solar System Beyond PlanetsДокумент27 страницSolar System Beyond PlanetsParag MahajaniОценок пока нет

- Social Rule System TheoryДокумент11 страницSocial Rule System TheoryAvicena AlbiruniОценок пока нет

- Systems Science CATEGORYДокумент2 страницыSystems Science CATEGORYAvicena AlbiruniОценок пока нет

- The Science of ValueДокумент4 страницыThe Science of ValueAvicena AlbiruniОценок пока нет

- Theories of Political Behavio1Документ3 страницыTheories of Political Behavio1Avicena AlbiruniОценок пока нет

- RepublicДокумент20 страницRepublicAvicena AlbiruniОценок пока нет

- The History of Political ThoughtДокумент6 страницThe History of Political ThoughtAvicena AlbiruniОценок пока нет

- Theories of Political Behavio1Документ3 страницыTheories of Political Behavio1Avicena AlbiruniОценок пока нет

- Rigour or Rigor (See: o o o o oДокумент6 страницRigour or Rigor (See: o o o o oAvicena AlbiruniОценок пока нет

- Collective BehaviorДокумент6 страницCollective BehaviorAvicena AlbiruniОценок пока нет

- Aleph NumbersДокумент4 страницыAleph NumbersAvicena AlbiruniОценок пока нет

- Political CultureДокумент7 страницPolitical CultureAvicena Albiruni100% (1)

- Political PhilosophyДокумент24 страницыPolitical PhilosophyAvicena AlbiruniОценок пока нет

- Plutocracy Is Rule by The: Modern PoliticsДокумент3 страницыPlutocracy Is Rule by The: Modern PoliticsAvicena AlbiruniОценок пока нет

- Outline PoliticsДокумент8 страницOutline PoliticsAvicena AlbiruniОценок пока нет

- Chomsky Linguistic BrainДокумент16 страницChomsky Linguistic BrainrzbcОценок пока нет

- L579 PDFДокумент32 страницыL579 PDFDeny AlfonsoОценок пока нет

- Risk Assessment - Plumbing Pump SetДокумент8 страницRisk Assessment - Plumbing Pump SetJhOichriz Reginaldo Cuevas100% (1)

- Safety Audit NДокумент24 страницыSafety Audit NAbdulSamad100% (1)

- En 13015-2001 - A1-2008 PDFДокумент26 страницEn 13015-2001 - A1-2008 PDFMayada M. SalmanОценок пока нет

- C5G Tech Specs enДокумент65 страницC5G Tech Specs enСања БанковићОценок пока нет

- 043 Inspection and Assessment of The Structural Integrity and Safety of All Poles and Towers Bearing Power Lines and Telecommunication CablesДокумент1 страница043 Inspection and Assessment of The Structural Integrity and Safety of All Poles and Towers Bearing Power Lines and Telecommunication Cablesma. ramelle anna peraltaОценок пока нет

- SMCДокумент32 страницыSMCEduardo HuaytaОценок пока нет

- Agri Fos 400 MSDSДокумент3 страницыAgri Fos 400 MSDSDaniela VargasОценок пока нет

- Expert Guide To: Unsafe Act and Unsafe Conditions With ExamplesДокумент21 страницаExpert Guide To: Unsafe Act and Unsafe Conditions With ExamplesAjay RajeevОценок пока нет

- WAH & Confined Space Rescue Plan Formats 1Документ2 страницыWAH & Confined Space Rescue Plan Formats 1soumyajeet NayakОценок пока нет

- Installation, Operation, and Maintenance Manual: Fire Pump Drive Engine CFP11E SeriesДокумент155 страницInstallation, Operation, and Maintenance Manual: Fire Pump Drive Engine CFP11E SeriesDhiyo MulyadiОценок пока нет

- Interior Communications Electrician, Volume 1Документ1 412 страницInterior Communications Electrician, Volume 1nicholas lee100% (1)

- Pfeiffer P3 MSDSДокумент7 страницPfeiffer P3 MSDSPin SantosОценок пока нет

- Permit To Work Guidance Note PDFДокумент7 страницPermit To Work Guidance Note PDFFOZCANОценок пока нет

- Drilling Operations Manual Combined - V5Feb2015' PDFДокумент498 страницDrilling Operations Manual Combined - V5Feb2015' PDFBadinescu Sergiu-Cristian100% (3)

- On & Offsite Emergency Plans of FactoriesДокумент19 страницOn & Offsite Emergency Plans of FactoriesTruth Seeker100% (1)

- 339 Epoxy Primer Base-SDS - NZДокумент9 страниц339 Epoxy Primer Base-SDS - NZjoshОценок пока нет

- Aerospace Medical ProgramДокумент59 страницAerospace Medical ProgramPunyashlok BiswalОценок пока нет

- Syllabus Risk ManagementДокумент10 страницSyllabus Risk ManagementMyyMyy JerezОценок пока нет

- Risk AssessmentДокумент3 страницыRisk Assessmentss04946197Оценок пока нет

- R.A. 10601 Afmech LawДокумент11 страницR.A. 10601 Afmech LawChristan John AbrenicaОценок пока нет

- Management of Food Inspection in TanzaniaДокумент104 страницыManagement of Food Inspection in TanzaniaMichael MalabejaОценок пока нет

- Training Programme CatalogueДокумент39 страницTraining Programme CatalogueSatyabrat Gaan100% (1)

- SSD Boiler Operator Body of Knowledge Rev 8Документ10 страницSSD Boiler Operator Body of Knowledge Rev 8Tin Aung KyiОценок пока нет

- Bryston P120-M30 ServiceДокумент149 страницBryston P120-M30 ServiceRamon JohnsonОценок пока нет

- MSDS Dinitrol 4942 Feb 20Документ9 страницMSDS Dinitrol 4942 Feb 20Silva GoncaloОценок пока нет

- Shell Omala 100Документ7 страницShell Omala 100PN RaoОценок пока нет

- Fire Tech - Ind. Safety MGMT - CTS 2.0 - NSQF-3Документ41 страницаFire Tech - Ind. Safety MGMT - CTS 2.0 - NSQF-3suryanarayanpanda79Оценок пока нет