Академический Документы

Профессиональный Документы

Культура Документы

Us20140196515 PDF

Загружено:

nangkarak8201Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Us20140196515 PDF

Загружено:

nangkarak8201Авторское право:

Доступные форматы

US 20140196515A1

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2014/0196515 A1

Bloxham

(43) Pub. Date:

(54) APPARATUS AND METHOD FOR FORMING

(30)

J 11]. 17, 2014

Foreign Application Priority Data

A SCREW FLIGHT

Jul. 5,2011

(75) Inventor:

Gregory John Bloxham, Beecroft (AU)

(AU) .............................. .. 2011902667

Publication Classi?cation

(51)

(73) Assignee: ADVANCED SPIRAL

TECHNOLOGY PTY LIMITED,

Int. Cl.

BZID 11/14

(52) us CL

Castle Hill, New South Wales (AU)

CPC .................................... .. 3210 11/14 (2013.01)

USPC

72/67

14/130 837

(22)

PCT Filed.

JUL 5, 2012

This invention relates to an apparatus for forming a helical

screW ?ight from a ?ight blank. The apparatus includes a base

(86)

PCT NO"

PCT/AU2012/000803

mounted to the base and is con?gured to formineg engage the

Mar. 27, 2014

blank corresponding to a predetermined pitch of the ?ight.

............................................................ ..

1.N .:

21

(2006.01)

pp

ABSTRACT

and an engaging means. The engaging means is movably

371 (c)(1),

(2), (4) Date:

(57)

blank so as to form a tWist in at least a portion of the ?ight

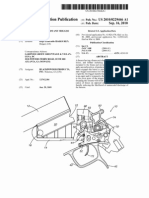

Patent Application Publication

Jul. 17, 2014 Sheet 1 0f 17

US 2014/0196515 A1

Patent Application Publication

Jul. 17, 2014 Sheet 2 0f 17

US 2014/0196515 A1

OFILTLER

l

4

///

"4

H.

O

/K\|

r

LU

5m,

E

(D

g.

'>

o.

2.

/

\

MR

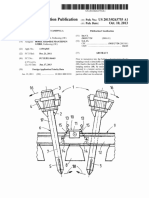

Patent Application Publication

HIDRA

_ u

LI

Jul. 17, 2014 Sheet 3 0f 17

con. FILTER \

.

.

US 2014/0196515 A1

/|SOLATION SWITCH

EMERGENCY SWITCH

LINEAR GUIDE

, \

>

29

\5

I,

/'LINEAR GUIDE

30

4'

L.H. SIDE VIEW

FIGURE 3

HYDRAULIC

1 __

ELECTRICAL

TOUCH

ggalTEOL

-

PLATE

, (15)

_

'

I:

28

I Q

4/

ll

\ J

12

s

l '

\

(15)

INTERFACE

PLATE

FRONT ELEVATION

HGURE4

SIGHT GUAGE

SCREEN

SIDE DIE '

SIDE DIE,

'

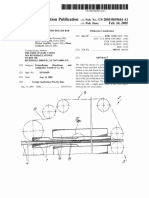

Patent Application Publication

GUIDE 1295

Jul. 17, 2014 Sheet 4 0f 17

I:5

US 2014/0196515 A1

GUIDE my

i

Patent Application Publication

Jul. 17, 2014 Sheet 5 0f 17

Inner Diameter "ID"

"Outer Diameter "OD"

FIGUREG

US 2014/0196515 A1

Patent Application Publication

Jul. 17, 2014 Sheet 6 0f 17

_ Flight Pitch "PT"

HGURE7

Flight Thickness "TH"

FIGUREB

US 2014/0196515 A1

Patent Application Publication

' BENDTINUTKREI'NCSEURTE

Jul. 17, 2014 Sheet 7 0f 17

US 2014/0196515 A1

Patent Application Publication

Jul. 17, 2014 Sheet 8 0f 17

US 2014/0196515 A1

3. MOVE THE RULE TO LINE-UP THE SCRIBE AND CENTRE

LINES THEN LOCK IN PLACE BY TIGHTENING BOLTS

4. LOOSEN BOLTS

08 CL

_2_0

09 09 0v

os

llllllllllllll'I?llInwllllllll

30

H Ilmmll'llullll

so so

70 so

29.

l 1. CHECK THAT SCRIBE LINE /

'7

5 >

IS LINED UP WITH DIE MID

PLATE CENTRE Ll E! IF'YES

THEN ROCEED TO NEXT PAGE

2. LOOSEN BOLTS

IF NO THEN FOLLOW POINTS 2 AND 3

HGURE10

Patent Application Publication

Jul. 17, 2014 Sheet 9 0f 17

FIGURE 11

US 2014/0196515 A1

Patent Application Publication

Jul. 17, 2014 Sheet 10 0f 17

US 2014/0196515 A1

1. RULE GUIDE MUST BE FREE,

TO MOVE WITH IN CHANNEL

A

511 100110 120130 140150160

7018 190 00 2J0 22012

3. SLIDE THE RULE ASSEMBLY UP

-

OR DOWN UNTIL BASE OFFSET

2' bb'fFHURPU'EELT'igUE'TDEBiggE

MEASUREMENT IS ACHIEVED

OFFSET) MEASUREMENT

FIGURE 12

Patent Application Publication

Jul. 17, 2014 Sheet 11 0f 17

US 2014/0196515 A1

1. LOCK RULE.

ASSEMBLY

O

22

20

AV

>

'

v 01

'

/

2. REMOVE RULE GUIDE

HGURE13

20

Patent Application Publication

, ~

Jul. 17, 2014 Sheet 12 0f 17

4'

SELECT AND INSERT APPROPRIATEV

(DIE SIDE PLATE) AS PER (FLIGHT

DIE CONFIGURATION PROGRAM)

INTO BACK PLATE CHANNELS

HGURE14

US 2014/0196515 A1

Patent Application Publication

Jul. 17, 2014 Sheet 13 0f 17

3. LOCK (DIE SIDE PLATE) INTO POSITION

1. SLIDE

SDIE SIDE

PLATE TOWARDS RULE /

2. UNTIL CONTACT BETWEEN DIE

SIDE PLATE) AND RULE ED E

19"}

20

24

FIGURE .15

US 2014/0196515 A1

Patent Application Publication

Jul. 17, 2014 Sheet 14 0f 17

US 2014/0196515 A1

I. ADJUST THE DISTANCE BETWEEN SUPPORT BRACKET)

AND RULE EDGE ALONG (DIE SIDE LATE) TOP EDGE

TO MATCH THE (SUPPORT OFFSET) MEASUREMENT

\ 2. LOCK (SUPPORT BRACKET)

FIGURE 16

Patent Application Publication

Jul. 17, 2014 Sheet 15 0f 17

US 2014/0196515 A1

1. ADJUST THE DISTANCE BETWEEN SUPPORT BRACKET)

AND RULE EDGE ALONG (DIE SIDE LATE) TOP EDGE

TO MATCH THE (SUPPORT OFFSET) MEASUREMENT

.21 6 /7 5\ v7\\/7

\

mmmlmmm

all):

WIMIOQIWIO'IUEIUZIDHMI MOI

llllllllllll lllllomulllllllllllllllllll

@y

N2. LOCK (SUPPORT BRACKET)

FIGURE 17

Patent Application Publication

Jul. 17, 2014 Sheet 16 0f 17

US 2014/0196515 A1

2.

|

>

17

<

15

FormGa 5 .

0;

21'

o oE

12

HGURE18

2

6

5

HollGap

Aif1521

o

12 28

Extract Gap

HGUREZO

Patent Application Publication

Jul. 17, 2014 Sheet 17 0f 17

US 2014/0196515 A1

\a\

SIDE PLATE ANGLE

LLSIDE PLATE LENGTH+_>

FIGURE 21

Jul. 17, 2014

US 2014/0196515 A1

APPARATUS AND METHOD FOR FORMING

A SCREW FLIGHT

FIELD OF THE INVENTION

[0001]

This invention relates generally to the ?eld of mate

rials handling equipment. More particularly, the present

invention relates to screw or auger ?ights (particularly sec

annular) wherein the annulus shapedblank has an inner diam

eter and an outer diameter. The engaging means is preferably

adapted to twist the portion of the annulus about a mean

radius line of the annulus. It will be appreciated by those

skilled in the art that, by twisting the blank about its mean

radius line, undesirable rounding or rolling across the cross

section of the blank is substantially avoided.

tional ?ights) and to an apparatus and method of forming such

[0014]

?ights.

sides of the blank such that forming movement of the engag

ing means forms a twist in at least a portion of the ?ight blank.

[0015] In some embodiments, the engaging means includes

primary engaging means for engaging the blank at at least two

BACKGROUND OF THE INVENTION

[0002] Any discussion of the prior art throughout the speci

?cation should in no way be considered as an admission that

such prior art is widely known or forms part of common

general knowledge in the ?eld.

[0003]

Screw or auger ?ights are typically used in bulk

handling industries for e?iciently moving ?uid, granular or

semi-solid material. Rotation of the ?ight causes the material

to be conveyed along the surface of a spiralled coil section.

[0004] The means and method of manufacturing conven

tional sectional screw ?ights involves pressing each section of

?ight between a set of appropriately shaped dies. Each section

of ?ight is then typically welded to a shaft in sequence to form

The engaging means preferably engages opposed

spaced apart positions, whereby the primary engaging means

is con?gured to cause relative movement between the at least

two engaged positions so as to form the twist in the blank.

[0016] In certain preferred embodiments, the primary

engaging means includes two pairs of (primary) side plates.

Each side plate is preferably a die formed plate having an

engaging portion such as, for example, an engaging edge or

surface for engaging the blank. Each side plate is preferably.

arranged so as to extend in a direction which is substantially

normal to the mean radius line of the blank.

a complete conveyor screw.

[0017] Preferably, each pair of side plates has a ?rst ?xed

plate and a second movable plate, the second plate being

[0005]

movable relative to the ?xed plate.

The conventional die pressing method has a number

of inherent disadvantages. These disadvantages include that,

[0018]

depending on the thickness of the blank material used, is it

often necessary to repeat the die pressing operation several

times in order to conform the shape of the annulus to the shape

of the dies between which the blank is pressed. The require

ment to repeat the pressing cycle necessarily adds to the costs

of production of screw ?ights produced via this method.

means includes secondary engaging means for engaging the

blank at at least one position in between the primary engaging

means. The secondary engaging means preferably engages

In some preferred embodiments, the engaging

the blank at a central or mid-point between the primary

engaging means. Preferably, the secondary engaging means

includes a pair of mid-plates. The mid-plates preferably

[0006] Furthermore, the blank typically undergoes plastic

include a ?xed mid-plate and a movable mid-plate, the mov

deformation during the pressing process which can lead to

inaccuracy in ?ight pro?les outside of desired manufacturing

able mid-plate being movable relative to the ?xed mid-plate.

[0019] The ?xed plates of both the primary and secondary

tolerances. Such variations away froth desired manufacturing

tolerances necessarily lead to inferior products and a resulting

engaging means are preferably mounted to a mounting means

such as a mounting frame connected to the base. Preferably,

reduction in product performance and lifespan.

the mounting means includes a receiving formation for

[0007]

receiving each ?xed plate. The receiving formation prefer

ably includes a pair of spaced apart channels, grooves, slots,

In addition, for each particular size and pitch for a

?ight, two sets of dies are needed if both left and right hand

?ights are to be produced, further adding to the costs of using

dies to form screw ?ights.

[0008] It is also di?icult to produce accurate dies which will

ridges, or other suitable formation for receiving the ?xed side

plates, and a central receiving formation (e.g. channel) for

receiving the ?xed mid-plate.

produce a ?ight of a particular size and pitch. Accordingly, it

[0020]

is typically necessary to use an iterative process of trial and

error whereby several sets of dies are produced, tested and

tion for mounting the plate in or on or otherwise to the receiv

modi?ed until the desired properties of a ?ight can be

achieved from the die set.

[0009] It is an object of the present invention to overcome

or ameliorate one or more of the disadvantages of the prior art,

or at least to provide a useful alternative.

SUMMARY OF THE INVENTION

[0010] According to a ?rst aspect of the invention, there is

provided an apparatus for forming a helical screw ?ight from

Preferably, each ?xed plate has a mounting forma

ing formation. The mounting formation of each plate is pref

erably complementary in shape to that of the receiving

formation. For example, the mounting formation and the

receiving formation may be con?gured as a tongue-and

groove type arrangement.

[0021] In certain embodiments, securing means is provided

for securing each ?xed side plate in position, relative to the

mounting means. The securing means preferably includes

one or more locking screws for holding the mounting forma

a ?ight blank, the apparatus including:

tion (e. g. tongue) in the associated channel. Preferably, each

receiving formation is con?gured to enable the associated

[0011]

[0012]

mined position along the length of the receiving formation.

a base; and

engaging means movably mounted to the base, the

engaging means being con?gured to formingly engage the

blank so as to form a twist in at least a portion of the ?ight

blank corresponding to a predetermined pitch of the ?ight.

[0013] Preferably, the ?ight blank is in the form of an

annulus, more preferably, an open ended annulus (e.g. a pen

?xed plate to be selectively mounted at a desired or predeter

For example, the ?xed plates can be slid along the associated

channel and then locked in the desired position.

[0022] Preferably, a locking means such as, for example, a

lock-bolt is provided for locking the ?xed mid-plate in posi

tion, relative to the mounting means.

Jul. 17, 2014

US 2014/0196515 A1

[0023]

The movable plates of the primary engaging means

and the secondary engaging means are preferably mounted to

a movable frame, the frame being movably mounted to the

base to enable relative movement between the ?xed plates and

the movable plates.

[0024] The movable frame preferably has a mounting for

mation for mounting the movable plates. Preferably, the

mounting formation of the movable frame corresponds to

(e. g. mirrors) the mounting formation of the ?xed mounting

frame such that the engaging portion of each pair of ?xed and

movable plates is substantially aligned. That is, the pairs of

side plates and the pair of mid-plates are preferably in engag

plates and the mid-plate in a counter-clockwise direction, or

vice versa. Again, it will be appreciated that side plates can be

mounted to achieve the desired direction of rotation for pro

ducing either a right-hand or left-hand twist in the blank.

[0030] Each side plate (?xed and movable) is generally

trapezoidal in shape, wherein its engaging edge is tapered

relative to its mounting formation. To achieve the desired

rotation of the blank at the point held between the side plates,

the ?rst pair of side plates are arranged such that the tapered

edges of the ?xed and movable plates in the ?rst pair are

ing alignment.

substantially parallel and extend at a negative angle (or posi

tive angle for opposite hand formation). Similarly, the second

pair of side plates are arranged such that the tapered edges of

[0025]

the ?xed and movable plates in the second pair are substan

The receiving formations are preferably arranged

such that the pairs of side plates are angled relative to one

another. Preferably, the side plates are con?gured such that

the relative angle therebetween is less than 180 degrees. In

certain preferred embodiments, the side plates are arranged to

have an angle of approximately 60 degrees therebetween. It

will be appreciated that the primary engaging members are

not limited to being angled at 60 degrees, but could, in other

embodiments, be angled at any suitable angle less than 180

degrees. For example, the side plates can be angled at

approximately 30, 45, 65, 75, 90, 105, 120, 135 or 145

degrees relative to each other.

[0026]

Preferably, a support means is associated with the

side plates for supporting the ?ight blank, in use. The support

means is preferably con?gured to support the outer diameter

of the blank. Preferably, the support means includes a ?rst

support bracket mountable to a ?xed side plate of a ?rst pair

tially parallel and extend at a positive angle (or negative angle

for opposite hand formation).

[0031]

It will therefore be appreciated that, due to the

tapered engaging edges of the side plates, the relative linear

movement between the ?xed and movable side plates results

in a rotation of the part of the blank between the plates about

the mean radius line to produce the desired twist in the blank.

[0032] In at least one preferred embodiment, the actuating

means is con?gured such that the apparatus operates with a

forming force in the range of 0 to 60 tonne at 200 bar (2,900

psi), and the forming speed is within the range of 0 to 80

mm/ s. Embodiments operating within these parameters can

be suitable for forming a helical screw from a blank having a

thickness in the range of 1 mm to 300 mm.

[0033]

According to a second aspect of the invention, there

is provided a method of forming a helical screw ?ight, the

of primary engaging side plates and a second support bracket

method including:

mountable to a movable side plate of a second pair of primary

[0034]

providing a ?ight blank of a predetermined size; and

engaging side plates. Each support bracket is preferably

selectively adjustably positionable relative to the associated

[0035]

formingly engaging the blank so as to form a twist in

side plate and secured thereto by a suitable locking means

such as one or more locking elements (e.g. screws). It will be

appreciated that the support brackets can be selectively

mounted to the desired side plates, depending on whether a

right-hand or left-hand helical screw ?ight is to be formed by

at least a portion of the ?ight blank, the twist substantially

corresponding to a predetermined pitch of the ?ight.

[0036] Preferably, the method includes twisting at least a

portion of the blank generally about a mean radius line of the

blank.

[0037]

Preferably, the method includes engaging the blank

the apparatus.

[0027] The moveable frame is preferably moved by an

with primary engaging means at at least two spaced apart

actuating means. The actuating means preferably includes a

to cause relative movement between the at least two engaged

positions so as to form the twist in the blank.

hydraulically driven cylinder, the hydraulic cylinder being

positions, whereby the primary engaging means is con?gured

selectively movable between an extended position and a

[0038]

retracted position for moving the movable frame and thus the

engaging means for engaging the blank at at least one position

movable plates of the primary and secondary engaging

in between the primary engaging means, whereby the

means. Preferably, the hydraulic cylinder has a cylinder rod

engaged portion of the blank on one side of the secondary

engaging means is twisted in a ?rst direction and the engaged

portion of the blank on the other side of the secondary engag

ing means is twisted in a second opposed direction.

which is con?gured to cause linear movement of the movable

frame when the cylinder rod extends or retracts.

[0028] To facilitate the forward and backwards linear

movement of the movable frame, the movable frame and base

[0039]

The method preferably includes using a secondary

Preferably, the method includes determining the

are preferably ?tted with guide means. Preferably, the guide

size of the blank from at least one of a desired pitch, outer

means includes at least one front guide bar and at least one

diameter, inner diameter, and thickness of the formed helical

rear guide bar extending from the movable frame. The at least

one front guide bar is arranged to pass through an aperture in

a front guide plate and the at least one rear guide bar is

arranged to pass through an aperture in a rear guide plate. In

screw ?ight.

one particularly preferred embodiment, there is provided two

front guide bars and two rear guide bars.

[0029] Preferably, a ?rst pair of side plates is con?gured to

rotate the portion of the blank between that pair of side plate

and the mid-plate (i.e. secondary engaging means) in a clock

wise direction, and a second pair of side plates is con?gured

to rotate the portion of the blank between that pair of side

[0040] According to a third aspect of the invention, there is

provided a screw (or auger) ?ight which has been manufac

tured in accordance with the method of the second aspect of

the invention.

[0041] According to a fourth aspect of the invention, there

is provided a method of setting up an apparatus for forming a

helical screw ?ight from a ?ight blank, the method including:

[0042] securing a central engaging means to the apparatus;

[0043] aligning a set up device with the central engaging

means;

Вам также может понравиться

- Us20030075626 PDFДокумент28 страницUs20030075626 PDFprouserdesigner77Оценок пока нет

- TEPZZ - 4 885B - T: European Patent SpecificationДокумент10 страницTEPZZ - 4 885B - T: European Patent SpecificationshamsОценок пока нет

- TEPZZ 5649 8B - T: European Patent SpecificationДокумент13 страницTEPZZ 5649 8B - T: European Patent SpecificationneusonОценок пока нет

- Ep 19175792 Nwa 1Документ16 страницEp 19175792 Nwa 1John Paul EspanoОценок пока нет

- Us2996100 PDFДокумент8 страницUs2996100 PDFerzrzretgertfertgeОценок пока нет

- United States Patent: Kronseder (45) Date of Patent: Oct. 4, 2005Документ14 страницUnited States Patent: Kronseder (45) Date of Patent: Oct. 4, 2005DANESIОценок пока нет

- Tube Saport PDFДокумент4 страницыTube Saport PDFjr110livecomОценок пока нет

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Документ13 страниц(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuОценок пока нет

- TEPZZ 5 Z 55B - T: European Patent SpecificationДокумент38 страницTEPZZ 5 Z 55B - T: European Patent SpecificationzhenyupanОценок пока нет

- United States Patent: (12) (10) Patent N0.: US 7,377,754 B2Документ23 страницыUnited States Patent: (12) (10) Patent N0.: US 7,377,754 B2Selvaraji MuthuОценок пока нет

- Inventii ConstructiiДокумент21 страницаInventii ConstructiiAdriana Daniela SanduОценок пока нет

- Us 7638082Документ10 страницUs 7638082Fa BelОценок пока нет

- 915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWДокумент15 страниц915 9000 990 112 /// 325 Aaa 3002 295 022 225 464 710 965 150 DWWMetin MehelОценок пока нет

- United States Patent (10) Patent No.: US 8,251,371 B2Документ4 страницыUnited States Patent (10) Patent No.: US 8,251,371 B2shamsОценок пока нет

- United States Patent (19) : Park Et Al. (11) Patent NumberДокумент10 страницUnited States Patent (19) : Park Et Al. (11) Patent NumberCarlos ArenasОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Документ15 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Jin Song100% (1)

- Pipe Sealing PATENTДокумент23 страницыPipe Sealing PATENTDaniel InemughaОценок пока нет

- ReadingДокумент6 страницReadingTrinh Quang ThanhОценок пока нет

- Patente Americana - Us 8615970Документ22 страницыPatente Americana - Us 8615970Maurício OliveiraОценок пока нет

- Us 5271461Документ18 страницUs 5271461ask101Оценок пока нет

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Документ7 страницSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaОценок пока нет

- United States Patent (19) (11) Patent Number: 4,727,781: Yuehui Et Al. (45) Date of Patent: Mar. 1, 1988Документ31 страницаUnited States Patent (19) (11) Patent Number: 4,727,781: Yuehui Et Al. (45) Date of Patent: Mar. 1, 1988Siul OtreborОценок пока нет

- Composite Bridge Plug System (US Patent 6796376)Документ16 страницComposite Bridge Plug System (US Patent 6796376)PriorSmartОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1Документ14 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1zbhdzpОценок пока нет

- Bell NippleДокумент12 страницBell NippleiswantmachooОценок пока нет

- Us4540334 PDFДокумент9 страницUs4540334 PDFJigar SutharОценок пока нет

- United States Patent (19) : B JornstadДокумент4 страницыUnited States Patent (19) : B JornstadlfilippiniОценок пока нет

- European Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorДокумент16 страницEuropean Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorSelvaraji MuthuОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0170973 A1Документ9 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0170973 A1almedinОценок пока нет

- United States Patent: (12) (10) Patent N0.: US 7,377,719 B1Документ10 страницUnited States Patent: (12) (10) Patent N0.: US 7,377,719 B1Ye PhoneОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Документ14 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Kalai SelvanОценок пока нет

- Patent Application Publication (10) Pub. No.: US 2002/0153034 A1Документ25 страницPatent Application Publication (10) Pub. No.: US 2002/0153034 A1Paballo MontleОценок пока нет

- EP1321438B1Документ10 страницEP1321438B1Alessandro PatanèОценок пока нет

- Us 20090020472Документ12 страницUs 20090020472ankitsarvaiyaОценок пока нет

- United States Patent (19) (11) 4,298,078Документ9 страницUnited States Patent (19) (11) 4,298,078lfilippiniОценок пока нет

- Us 5546957Документ7 страницUs 5546957SurgaveryОценок пока нет

- Patent Application Publication (10) Pub. No.: US 2007/0023474 A1Документ11 страницPatent Application Publication (10) Pub. No.: US 2007/0023474 A1chicken curryОценок пока нет

- Form Fill Seal MachineДокумент19 страницForm Fill Seal MachineFrank GengОценок пока нет

- US4893426Документ7 страницUS4893426Jean DelaronciereОценок пока нет

- United States Patent (191: SheppardДокумент7 страницUnited States Patent (191: SheppardandreОценок пока нет

- EP2369289A1Документ10 страницEP2369289A1awe234100% (1)

- EP000003126210B1 ROAD WHEEL HutchineДокумент25 страницEP000003126210B1 ROAD WHEEL Hutchine임학진Оценок пока нет

- Tamping Method With 4 Hand TamperДокумент3 страницыTamping Method With 4 Hand TamperjasonОценок пока нет

- US5303813Документ7 страницUS5303813AdailsonОценок пока нет

- Us 20140311650Документ8 страницUs 20140311650rashom0099088Оценок пока нет

- Compressed Air MotorДокумент10 страницCompressed Air Motorjahson362Оценок пока нет

- 偏心枪支噪音抑制器和组装方法定位装置 PDFДокумент6 страниц偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongОценок пока нет

- TEPZZ 89 8 - B - T: European Patent SpecificationДокумент31 страницаTEPZZ 89 8 - B - T: European Patent SpecificationAna LisaОценок пока нет

- TEPZZ - 6 48B - T: European Patent SpecificationДокумент13 страницTEPZZ - 6 48B - T: European Patent SpecificationshamsОценок пока нет

- United States Patent: (10) Patent N0.: (45) Date of PatentДокумент8 страницUnited States Patent: (10) Patent N0.: (45) Date of PatentwererОценок пока нет

- Patent Application Publication (10) Pub. No.: US 2005/0039616 A1Документ13 страницPatent Application Publication (10) Pub. No.: US 2005/0039616 A1Erin GokОценок пока нет

- X III 110111113////////////////////////////11ml: (12) Ulllted States Patent (10) Patent N0.: US 8,453,633 B2Документ9 страницX III 110111113////////////////////////////11ml: (12) Ulllted States Patent (10) Patent N0.: US 8,453,633 B2djsfОценок пока нет

- 块化插入触发器的方法和装置5 PDFДокумент23 страницы块化插入触发器的方法和装置5 PDFJin SongОценок пока нет

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoДокумент7 страницUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinОценок пока нет

- Us 6131519Документ4 страницыUs 6131519dgfhjsdg hfsdhyjОценок пока нет

- 322 (W422i / /41i3/3i 4) (1 Im: (19) United StatesДокумент9 страниц322 (W422i / /41i3/3i 4) (1 Im: (19) United StatesdjsfОценок пока нет

- United States Patent: Blahnik (45) Date of Patent: Jun. 13, 2006Документ16 страницUnited States Patent: Blahnik (45) Date of Patent: Jun. 13, 2006Ipolos KawnОценок пока нет

- Connecting Rod CrackerДокумент12 страницConnecting Rod CrackerOkta Pariantoro Budi SetiawanОценок пока нет

- Mr. Toh Heng Guan - ASEAN Secretariat - Readiness of MRA On Automotive ProductsДокумент18 страницMr. Toh Heng Guan - ASEAN Secretariat - Readiness of MRA On Automotive Productsnangkarak8201Оценок пока нет

- Locomotives - Is LNG The Next Generation - Railway AgeДокумент4 страницыLocomotives - Is LNG The Next Generation - Railway Agenangkarak8201Оценок пока нет

- Data Book BaliДокумент427 страницData Book Balinangkarak8201Оценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2008/0307789 A1Документ9 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2008/0307789 A1nangkarak8201Оценок пока нет

- Form-Und Lagetoleranzen e PDFДокумент1 страницаForm-Und Lagetoleranzen e PDFnangkarak8201Оценок пока нет

- Us8316665 PDFДокумент9 страницUs8316665 PDFnangkarak8201Оценок пока нет

- Indonesia Historical TimelineДокумент2 страницыIndonesia Historical Timelinenangkarak8201Оценок пока нет

- Ge 7s04 PDFДокумент24 страницыGe 7s04 PDFnangkarak8201100% (1)

- Ge 7s11Документ29 страницGe 7s11nangkarak8201Оценок пока нет

- LNG VaporizerДокумент4 страницыLNG Vaporizernangkarak8201Оценок пока нет

- Ge 7s12 PDFДокумент25 страницGe 7s12 PDFnangkarak8201100% (2)

- LNG 4 - Operational Integrity 7-3-09-Aacomments-Aug09Документ8 страницLNG 4 - Operational Integrity 7-3-09-Aacomments-Aug09nangkarak8201Оценок пока нет

- Ge 7s09aДокумент28 страницGe 7s09anangkarak8201100% (1)

- LNG 3 - LNG Ships 7.3.09-Aacomments-Aug09Документ7 страницLNG 3 - LNG Ships 7.3.09-Aacomments-Aug09nangkarak8201Оценок пока нет

- Ge 7s04Документ24 страницыGe 7s04nangkarak8201Оценок пока нет

- Ge 7s04Документ24 страницыGe 7s04nangkarak8201Оценок пока нет

- Ge 7ltfДокумент20 страницGe 7ltfnangkarak8201Оценок пока нет

- Technical Bulletin: Curve Fit Equations For Ferrite MaterialsДокумент6 страницTechnical Bulletin: Curve Fit Equations For Ferrite Materialsnangkarak8201Оценок пока нет

- Design A New System Tasksheet Designnewsystem 2010Документ2 страницыDesign A New System Tasksheet Designnewsystem 2010nangkarak8201Оценок пока нет

- Ma6452 Notes 1 PDFДокумент238 страницMa6452 Notes 1 PDFJohn Eric BernardОценок пока нет

- Assignment 2 AST-451 PDFДокумент8 страницAssignment 2 AST-451 PDFPriya SinghОценок пока нет

- Algebra Set - 4Документ2 страницыAlgebra Set - 4Harsh singhalОценок пока нет

- Excel DataДокумент50 страницExcel DataninthsevenОценок пока нет

- EM11Документ17 страницEM11Jerry LedesmaОценок пока нет

- Operational Objectives DefinitionДокумент1 страницаOperational Objectives DefinitionZven BlackОценок пока нет

- KrolresumeДокумент3 страницыKrolresumeapi-282046209Оценок пока нет

- Math - Final Time LessonДокумент12 страницMath - Final Time Lessonapi-272910790Оценок пока нет

- DIFTДокумент3 страницыDIFTUnknown LiteОценок пока нет

- Syllabus For AutoCAD-3D Modeling.Документ3 страницыSyllabus For AutoCAD-3D Modeling.yesuppu56Оценок пока нет

- Unit 4 Groundwater FlowДокумент36 страницUnit 4 Groundwater FlowdaanaahishmaelsОценок пока нет

- Saphelp Utilities472 en 81 A0023b288dd720e10000000a114084 FramesetДокумент97 страницSaphelp Utilities472 en 81 A0023b288dd720e10000000a114084 FramesetAshish AgarwalОценок пока нет

- 5135 Rover Ruckus Engineering NotebookДокумент164 страницы5135 Rover Ruckus Engineering Notebookapi-502004424Оценок пока нет

- Marine Engineering Mtech AssignmentДокумент3 страницыMarine Engineering Mtech AssignmentDaniel Inemugha100% (1)

- Rubik Cubes Formulas1Документ5 страницRubik Cubes Formulas1kiran reddy malladiОценок пока нет

- MCA III Complied 23.06.16Документ243 страницыMCA III Complied 23.06.16Shahriar AhmedОценок пока нет

- Unit 4 - CEPDEДокумент71 страницаUnit 4 - CEPDEsrinu02062Оценок пока нет

- Animal Classification Using Facial Images With Score-Level FusionДокумент7 страницAnimal Classification Using Facial Images With Score-Level FusionSanketh ReddyОценок пока нет

- MTAP Math ChallengeДокумент5 страницMTAP Math ChallengeHaron Abedin100% (1)

- Uco Bank Form Iepf 1Документ437 страницUco Bank Form Iepf 1sandip_exlОценок пока нет

- Unit III Real Valued FunctionДокумент6 страницUnit III Real Valued FunctionMasuma KhanОценок пока нет

- Math - Module 1Документ7 страницMath - Module 1Carlos PadillaОценок пока нет

- Leary 2001 Introduction To Behavioral Research Methods Capitol 9Документ25 страницLeary 2001 Introduction To Behavioral Research Methods Capitol 9Diana AndriescuОценок пока нет

- Instructions For ParLeSДокумент13 страницInstructions For ParLeSRyshardson GeovaneОценок пока нет

- HTML Symbols PDFДокумент3 страницыHTML Symbols PDFSaisri KОценок пока нет

- Sample PDF of STD 11th Precise Physics Notes Book Science Maharashtra Board PDFДокумент34 страницыSample PDF of STD 11th Precise Physics Notes Book Science Maharashtra Board PDFNihaal SinghОценок пока нет

- Chapter 3 Linear EquationsДокумент10 страницChapter 3 Linear Equationsabhalimy2001934Оценок пока нет

- 7th Lecture (Introduction To Probability)Документ17 страниц7th Lecture (Introduction To Probability)amaar siyalОценок пока нет

- StressДокумент14 страницStressFrank PingolОценок пока нет

- Anaerobic RespirationДокумент3 страницыAnaerobic RespirationccwairОценок пока нет