Академический Документы

Профессиональный Документы

Культура Документы

Optimal Kinematic

Загружено:

mibarjan0 оценок0% нашли этот документ полезным (0 голосов)

62 просмотров6 страницOPTIMAL KINEMATIC DESIGN OF A

WINDSHIELD WIPER MECHANISM

Оригинальное название

OPTIMAL KINEMATIC

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документOPTIMAL KINEMATIC DESIGN OF A

WINDSHIELD WIPER MECHANISM

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

62 просмотров6 страницOptimal Kinematic

Загружено:

mibarjanOPTIMAL KINEMATIC DESIGN OF A

WINDSHIELD WIPER MECHANISM

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

Bulletin of the Transilvania University of Braov Vol. 8 (57) No.

1 - 2015

Series I: Engineering Sciences

OPTIMAL KINEMATIC DESIGN OF A

WINDSHIELD WIPER MECHANISM

Adrian C-tin BUTA1

Abstract: In this paper we attempt to carry out the kinematic analysis and

optimization of the windshield wiper mechanisms using the MBS (Multi-Body

Systems) environment ADAMS of MSC Software. The kinematic model of the

wiper mechanism contains the bodies, connected by geometric constraints

(joints), and the kinematic restriction (motion driver) that control the angular

position of the motor crank. The application is performed by considering a

tandem pattern double-lever (with two blades) windshield wiper mechanism.

Key words: kinematics, multi-body system, optimization, wiper mechanism.

1. Introduction

The increasingly growing demand for

more comfortable vehicles imposes a new

way for kinematic and dynamic analysis of

the different subsystems, including the

windshield wiper mechanism, by taking

into consideration virtual models that are

closer to the physical models on the

vehicle. In this way, the complexity of the

theoretical model is increasing, and for this

reason such models cannot be analyzed

with classical methods and programs.

In these terms, the usage of mechanical

systems

analysis

and

simulation

environments

is

necessary.

These

programs automatically formulate and

solve the kinematic and dynamic equations

taking into consideration the geometric elastic model of the system, and they

allows important advantages: reduces time

and cost, reduces the product cycles,

reduces the number of expansive physical

prototypes,

allows

making

virtual

measurements in any point and area of the

system and for any parameter [1], [3-5].

1

Schaeffler Romania.

In this paper, we attempt to analyze and

optimize the kinematic model of the

windshield wiper mechanisms using the

multi-body systems (MBS) environment

ADAMS of MSC Software. The modelling

of the wiper mechanism as multi-body

system is made in the following steps [2],

[6]: modeling bodies and restrictions,

establishing the coordinate systems

attached to bodies, defining the part's

geometry in the local coordinate frames,

defining the orientation of the bodies and

determining the transformation matrix

from the local frame to the global

reference frame, defining the geometric

and kinematical constraint equations.

Parameterizing the virtual model, defining

the design variables, defining the objective

function for optimization and performing

design study makes the kinematic

optimization of the wiper mechanisms.

2. Kinematic Model of the Wiper System

The windshield wiper mechanisms are

vehicle-specific systems in which the

Bulletin of the Transilvania University of Braov Series I Vol. 8 (57) No. 1 - 2015

wiping motion is transferred from the

wiper motor to the pivot-shaft assemblies

via linkages. A compact wiper system

consists of the following components:

wiper motor with thermo-switch, wiper

gearing, motor crank, steel base-plate,

crank linkage, pivot-shaft assembly with

oscillating crank, and second pivot-shaft

assembly with plate (for parallel wipe

pattern), respectively. The linkage forces

are supported by the sheet metal of the car

body.

For the present-day vehicles, the

following wiper systems are frequently

used [10]: single-lever systems with

parallel wipe patterns, single-lever systems

with sector wipe patterns, opposed-pattern

double-lever systems with parallel wipe

patterns, opposed-pattern double-lever

systems with overlapping sector wipe

patterns, tandem-pattern double-lever

systems with overlapping sector wipe

patterns, and tandem-pattern three-lever

systems with extra-wide overlapping sector

wipe patterns, respectively.

The kinematic model of the windshield

wiper system contains the rigid parts

(bodies) from the wiper mechanism,

connected through geometric constraints

(standard joints), and the geometric

parameters that define the mechanism (the

locations of the joints); the input is made

using a kinematic restriction (motion

generator - driver), applied in the joint

between the motor crank and the bodys

base-plate (rigidly connected to ground),

which controls the angular position or

velocity of the motor crank.

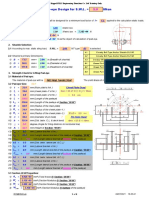

For this paper, a tandem pattern double

lever wiper system was considered (Figure

1). The wiper mechanism contains two

spatial four-bar linkages: ABCD - to

command the left wiper arm/blade, and

DC1EF - to command the right wiper

arm/blade.

The motor crank (1) and the left / right

wiper arms (3, 5) are connected to the

grounded part (i.e. the car body) using

revolute joints (A, D, and F). The crank

linkages (2, 4) are connected to the motor

crank, respectively to the wiper arms,

using spherical (B, E) and cylindrical

joints (C, C1).

Fig. 1. The tandem pattern double lever

wiper mechanism

The geometric model of the windshield

wiper mechanism was made using CAD

software (CATIA), and then the geometry

was transferred to ADAMS using the

STEP (Standard for the Exchange of

Product Model Data) file format.

3. Kinematic Analysis in MBS

Environment

In a multi-body systems environment,

such as ADAMS, the steps to create a

virtual (software) model mirror the same

steps to build a physical (hardware) model,

as follows: build - create parts, constrain

the parts (using geometric and kinematic

restrictions), and test - measure

characteristics,

perform

simulations,

review animations, review numeric results

as plots.

The degree of mobility (DOM) of the

wiper mechanism is given by the Grubler

count, DOM = 6n rg = 30 29 = 1,

where: n - the number of mobile bodies,

and rg - the total number of geometric

constraints (rg = 5 - revolute joint, rg = 4 cylindrical joint, rg = 3 - spherical joint). In

the kinematic model, this degree of

mobility is controlled by a motion

Buta, A.C-tin: Optimal Kinematic Design of a Windshield Wiper Mechanism

generator of type 1(t). Considering the

input speed of the motor crank n1 = 65

[rot/min], we obtain: 1 = n1 / 30 = 6.803,

so that 1 = 1t = 6.803 t [rad/sec].

The kinematic analysis of the windshield

wiper mechanism is made having in view to

determine the specific parameters that

define the behaviour of the system [7-9]:

parking position (the wiper arms rest

position on the windshield), wiping angle,

and wipe-pattern size. The input data for

analysis consist from the windshield

dimension (size), the installation point for

drive unit, and the clamping length

(maximum thickness of the sheet steel to

which the pivot-shaft assembly is fastened).

Analyzing the kinematic model of the

above-described wiper mechanism, a lot of

results were obtained. For example, in

Figure 2 the wiping angles and the angular

velocities for the left and right wiper arms

are shown. At the same time, Figure 3

shows several graphical simulation frames,

which were obtained by using the

ADAMS/Animation module.

4. Optimal Kinematic Design

The kinematic optimization of the

windshield wiper mechanism is made with

the following steps: parameterizing the

model, defining the design variables,

defining the design objective for

optimization, performing design study, and

optimizing the model on the basis of the

main design variables.

The parameterization of the wiper

mechanism is made by the points that

define the structural model, in fact the

locations of the geometric constraints joints (see Figure 1). The parameterization

simplifies changes to model because it

helps to automatically resize, relocate and

orient parts. In this way, relationships into

the model are created, so that when a point

is changed, any other objects (bodies,

joints) that depend on it will be updated.

Fig. 2. Results of the kinematic analysis

Bulletin of the Transilvania University of Braov Series I Vol. 8 (57) No. 1 - 2015

locations of the joints were attached to the

design points. In these conditions, when a

coordinate of a point will be modified, the

objects that depend on it (bodies, joints)

will be accordingly changed.

Fig. 3. Graphical simulation frames

Design variables represent elements in

model that allow creating independent

parameters and tie modeling objects to

them. In our case, the design variables

represent the locations for the design

points. Design variable allows running

automated simulations that vary the values

of the variable over specified ranges to

understand the sensitivity to the variable or

to find the optimum values.

In addition, using design variables,

design studies can be performed. Design

study represents a set of simulations that

help to adjust a parameter to measure its

effect on the performance of the wiper

system model. Design study describes the

ability to select a design variable, sweep

the variable through a range of values and

then simulate the motion behaviour of the

various designs in order to understand the

sensitivity of the overall system to these

design variations. As result, design study

allows to identify the main design

variables, with great influence on the

kinematic behaviour of the wiper system.

Therefore, for beginning, the points that

define the structural model of the

windshield wiper system, shown in the

table editor from Figure 4, were modeled

in the global coordinate frame, which is an

inertial frame attached to car body (the

points A0, D0, and F0 were used to define

the axis of the revolute joints). Afterwards,

the geometry of the bodies and the

Fig. 4. Table editor for design points

In the next step, the global coordinates of

the points were transformed in design

variables, having in view to control the

virtual model in the optimization process.

Each coordinate is a design variable,

therefore for the above-described spatial

windshield wiper mechanism, 30 design

variables will result, as follows: DV_1

XA, DV_2 YA, DV_3 ZA, DV_4

XA0, DV_5 YA0, DV_6 ZA0, and so

on.

In this way, ADAMS creates a variable

with the initial value, and modifies the

point to use the design variable as the

coordinate value. The initial value and the

variation field (range) for each design

variable can be established in order to keep

the wiper system in rational constructive

limits.

The design objectives are represented by

the parameters that describe the kinematic

behavior of the system (see section 3). In

this paper, the wiping angles were

considered as goal for optimization. For

beginning, measures that define the left

and right wiping angles were modeled

using the orientation by Euler angles, and

Buta, A.C-tin: Optimal Kinematic Design of a Windshield Wiper Mechanism

then the design objectives were attached to

these measures. In order to increase the

wiping angles, the maximum absolute

values during simulation were taken into

consideration.

a)

b)

Having in view to identify the influence

of the design variables on the design

objectives,

design

studies

were

successively performed for each design

variable, in their variation fields (ranges).

In this way, two types of design variables

are obtained: main variables, which have

great influence on the design objectives,

and secondary variables (their influence

can be neglected).

As example, the influence of the

coordinates of the point B on the right

wiping angle is shown in Figure 5,

considering the following variation fields:

a) XB ={105, 110, 115}, b) YB = {420,

425, 430}, c) ZB = {665, 670, 675}.

According to these diagrams, YB and XB

are main design variables, while ZB is a

secondary variable.

Analyzing such comparative results, all

the main design variables can be identified.

These

variables

are

taken

into

consideration

for

the

kinematic

optimization of the windshield wiper

mechanism.

Afterwards, the inverse dynamic model,

which includes the forces that act in the

wiper system, can be used to determine the

turning moment applied to the motor crank

in order to generates the kinematic

behavior. Finally, the dynamic model is

used to evaluate the real behavior of the

wiper mechanism. These aspects will be

approached in a future work (paper).

5. Final Remarks

c)

Fig. 5. Results of the design studies for the

right wiping angle

The study presented in this paper

demonstrates the capabilities of the

modelling & simulation in virtual

environment in the design process of the

windshield wiper mechanisms. Simulationbased design practices allow to more

quickly assessing form, fit, and function of

the wiper systems.

In this way, there is created the frame to

optimize the kinematic & dynamic

Bulletin of the Transilvania University of Braov Series I Vol. 8 (57) No. 1 - 2015

behaviour of the windshield wiper

mechanisms in a fraction of the cost of

traditional hardware prototype processes.

References

1. Alexandru, C.: Kinematic and

Dynamic Analysis of the Windshield

Wiper Mechanisms Used for Motor

Vehicles. In: Bulletin of the

Transilvania University of Braov

(2004) Vol. 11 (46), Series A, p. 7-12.

2. Alexandru, C.: Design Algorithm of

the Windshield Wiper Mechanisms

of the Passenger Vehicles. In:

Proceedings of the 10 th International

Research Expert Conference Trends

in the Development of Machinery

and Associated Technology - TMT,

Barcelona-Lloret de Mar, 2006, p.

757-760.

3. Alexandru, C.: Software Platform

for Analyzing and Optimizing the

Mechanical

Systems.

In:

Proceedings of the 10 th IFToMM

International Symposium on Science

of Mechanisms and Machines SYROM, Braov, 2009, p. 665-677.

4. Alexandru, C.: A Mechatronic

Approach of the Windshield Wiper

Mechanisms. In: Annals of the

Oradea University, Fascicle of

Management and Technological

Engineering (2012) Vol. XI, No. 1,

p. 3.1-3.6.

5. Alexandru, C., Barbu, I.: Functional

Design of the Windshield Wiper

6.

7.

8.

9.

10.

Mechanisms Using Virtual Models.

In: Proceedings of the IX IFToMM

International Conference on the

Theory

of

Machines

and

Mechanisms, Liberec, 2004 p. 2328.

Alexandru, C., Barbu, I.: Modeling

of

the

Windshield

Wiper

Mechanisms as Multibody Systems.

In: Proceedings of the IX IFToMM

International Conference on the

Theory

of

Machines

and

Mechanisms, Liberec, 2004, p. 2934.

Buta, A.C.: Study on the Friction

between the Wiper Blade and the

Windshield.

Bulletin

of

the

Transilvania University of Braov

(2014) Vol. 7 (56), No. 1, Series I,

p. 1-6.

Buta, A.C.: The Conceptual Design

of a Windshield Wiper Mechanism.

In: Annals of the Oradea University,

Fascicle of Management and

Technological Engineering (2007)

Vol. VI, p. 120.

Buta, A.C.: The Conception of a

New

Action

System

of

the

Windshield Wipers Mechanisms and

the Reciprocal Validations of the

Physical and the Virtual Results. In:

Annals of the Oradea University,

Fascicle of Management and

Technological Engineering (2007)

Vol. VI, p. 121.

*** Wiper Systems for Commercial

Vehicles. Bosch GmbH, 1997.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- ENGINEER'S Report For Generator Set of LaundryДокумент3 страницыENGINEER'S Report For Generator Set of LaundryNathan Esteban79% (14)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- BS en 755-7 PDFДокумент6 страницBS en 755-7 PDFRok HermanОценок пока нет

- LF Student Workbook 05.5Документ42 страницыLF Student Workbook 05.5indikumaОценок пока нет

- Designing A Keyphasor TriggerДокумент8 страницDesigning A Keyphasor TriggerMahesh JadhavОценок пока нет

- L-1 Butterfly Valve InstallДокумент9 страницL-1 Butterfly Valve InstallgerardtrОценок пока нет

- 2019 G 2.0 MPI NU Schematic Diagrams Brake System Anti-Lock Brake System (ABS) Schematic DiagramsДокумент1 страница2019 G 2.0 MPI NU Schematic Diagrams Brake System Anti-Lock Brake System (ABS) Schematic DiagramsbeongoОценок пока нет

- Outdoor UnitsДокумент47 страницOutdoor UnitsSayeed AnwarОценок пока нет

- Bom - UPLДокумент20 страницBom - UPLalokbdasОценок пока нет

- Bernoulli's Principle and Application: Ang SovannДокумент45 страницBernoulli's Principle and Application: Ang SovannKantilal MalwaniaОценок пока нет

- 160 Kva MangrolДокумент6 страниц160 Kva MangrolrajendranrajendranОценок пока нет

- NLM - 1Документ5 страницNLM - 1Ramesh BadamОценок пока нет

- NR 310102 Structural Analysis 1Документ8 страницNR 310102 Structural Analysis 1Srinivasa Rao G100% (1)

- Service Manual MIL-9000 and MIL-12000: Electric WinchesДокумент29 страницService Manual MIL-9000 and MIL-12000: Electric WinchesGlen C. ChadwickОценок пока нет

- Colder Catalog 27-30 PMC ConnectorsДокумент4 страницыColder Catalog 27-30 PMC ConnectorsDENNIZОценок пока нет

- Texturing Methods PDFДокумент4 страницыTexturing Methods PDFAnoop KizhakathОценок пока нет

- NGL PumpsДокумент4 страницыNGL Pumpsamol patkiОценок пока нет

- A Review of Flow and Heat TransferДокумент28 страницA Review of Flow and Heat TransferOssama Bohamd100% (1)

- Compression Test MachineДокумент3 страницыCompression Test Machineahana expotech lab abeerОценок пока нет

- WCTE 2018 Conference Paper Stoner FinalVerДокумент7 страницWCTE 2018 Conference Paper Stoner FinalVerMichael StonerОценок пока нет

- SWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Документ2 страницыSWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Paulo MoreiraОценок пока нет

- RC Mini ProjekДокумент11 страницRC Mini ProjekMohd HisbullahОценок пока нет

- Mechanical Properties of Stainless SteelДокумент8 страницMechanical Properties of Stainless SteelFahrul Nur ArifinОценок пока нет

- IMI CCI Product DRAG-Control-Valves AW LRESДокумент4 страницыIMI CCI Product DRAG-Control-Valves AW LRESOscarGomezMecanicoОценок пока нет

- DistillationTheory 1Документ21 страницаDistillationTheory 1Prashant KumarОценок пока нет

- Eview Nnovations May 2022 Ce Board Exam RENDON 6 (Hydraulics)Документ3 страницыEview Nnovations May 2022 Ce Board Exam RENDON 6 (Hydraulics)Kian InductivoОценок пока нет

- Session 2Документ74 страницыSession 2Syed Shahzad AliОценок пока нет

- Distillation Column Tray Selection & Sizing - 1 - Separation TechnologiesДокумент30 страницDistillation Column Tray Selection & Sizing - 1 - Separation TechnologiesHuzefa Calcuttawala0% (1)

- 500MWДокумент18 страниц500MWAlok Ranjan TripathiОценок пока нет

- Catalog Doovac MVO ManualДокумент27 страницCatalog Doovac MVO ManualRock MarkОценок пока нет

- PLB-0384-DAT-4830-ME-0005: ABB India LTDДокумент3 страницыPLB-0384-DAT-4830-ME-0005: ABB India LTDAlex Labraña RojoОценок пока нет