Академический Документы

Профессиональный Документы

Культура Документы

Saddle Road Transportation Analysis 1

Загружено:

vpjagannaathАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Saddle Road Transportation Analysis 1

Загружено:

vpjagannaathАвторское право:

Доступные форматы

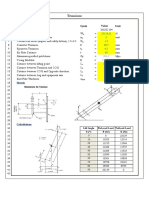

ROAD TRANSPORTATION ANALYSIS

Saddle & Shipping Data:

Ws= Shipping weight + 1.5 impact factor

A= Saddle Length

B= Saddle Height from vessel Center

b= Saddle Width

Saddle include angel

COG= Left Tan line to COG distance

L1= Saddle sepration, Saddle CL to CL

D1= Distance from left saddle to left tan line

D2= Distance from right saddle to right tan line

L2= COG to left saddle

L3= COG to right saddle

Vessel Data:

I.D Inside diameter of the vessel

ts = thickness of shell

r = Inside radius of the vessel

R = Outer radius of the vessel

L = Vessel T/L to T/L distance

A' = Left saddle to Left T/L

A'' = Right saddle to Right T/L

Stress Values: Shipping/Transportation, assued the vessel is cold and not pressurized.

FY = Yield stress of saddle

Sa = Allowable stress of saddle (0.9 * FY)

Sb = Bending stress of saddle (2/3 * Sa)

Transportation Force Coefficients, (for road transportation):

Kx = Transverse load coefficients,

Ky = Vertical load coefficients

Kz = Longitudinal load coefficients,

Unit

68689.5 Kg

4199 mm

2650 mm

475 mm

132

673614 N

2126 mm

4000 mm

1100 mm

600 mm

1026 mm

2974 mm

4500 mm

25 mm

2250 mm

2275 mm

5700 mm

1100 mm

600 mm

248.2 N/mm2

223.38 N/mm2

148.92 N/mm2

0.5

1.5

1.0

Load per saddle due to transport forces:

Fx= Trasverse loading due to shipping forces (Kx*Ws)

Fy= Vertical loading due to shipping forces (Ky*Ws)

Fz= Longitudinal loading due to shipping forces (Kz*Ws)

336806.94 N

1010420.83 N

673613.89 N

Due to FX

Q1 = Load on left saddle, [W SL2/L1]+[FXB/2A]

Q2 = Load on right saddle, [WSL3/L1]+[FXB/2A]

279061.84 N

607111.80 N

Due to FY

Q1 = Load on left saddle,[(WS+FY)L2]/L1

Q2 = Load on right saddle,[(W S+FY)L3]/L1

431954.91 N

1252079.81 N

Due to FZ

Q1 = Load on left saddle, [W SL2/L1]+[FZB/L1]

Q2 = Load on right saddle, [WSL3/L1]+[FZB/L1]

Max, Q1 =

Max, Q2 =

619051.16 N

947101.13 N

619051.16 N

1252079.81 N

Q = Saddle is designed for the Max Load

1252079.81 N

1 / 2

Load Diagrams for Moments and Forces:

L1 = Saddle sepration, Saddle CL to CL

L2 = Vessel skirt/leg base to left saddle

L3 = vessel right saddle to top head

OAL = L1+ L2 + L3

4000 mm

2000 mm

2282 mm

8282 mm

673614 N

81.3347 N/mm

313062 N

360552 N

W = weight of vessel plus any impact factors

w = W / OAL

Q1 = Load on left saddle, w[(L1 +L2)2 - L23] / 2L1

Q2 = Load on right saddle, [W-Q 1]

M1 = Moment at left saddle, wL22 / 2

162669376.27 N-mm

M2 = Moment at mid span, Q1(Q1/2w - L2)

1117745778.54 N-mm

M3 = Moment at right saddle, wL / 2

2

3

1

2

3

4

5

6

211776170.25 N-mm

Longitudinal bending at left saddle without stiffeners,

S1 = (+) M1/(K1r2ts)

3.23 N/mm2

S2 = (-) M1/(K7r2ts)

-1.27 N/mm2

Longitudinal bending at mid span without stiffeners,

S1 = (+) M2/(K1r2ts)

22.19 N/mm2

S2 = (-) M2/(K7r2ts)

-8.72 N/mm2

Longitudinal bending at right saddle without stiffeners,

S1 = (+) M3/(K1r2ts)

4.20 N/mm2

S2 = (-) M3/(K7r2ts)

-1.65 N/mm2

Tangential Shear at left saddle - shell not stiffened A' < 0.5R

S7 = K3Q1/(rts)

Tangential Shear at right saddle - shell not stiffened A'' < 0.5R

S7 = K3Q2/(rts)

8

Since, L=

9

10

5700

Circumferential bending at horn of left saddle, shell not stiffened [L < 8R]

S10 = (-)(Q1/(4ts(b+1.56(rts)-12K6Q1R/(Lt2s)

Circumferential bending at horn of right saddle, shell not stiffened [L < 8R]

S10 = (-)(Q2/(4ts(b+1.56(rts)-12K6Q2R/(Lt2s)

Circumferential Tension/Compression at left saddle[A' < 0.5R]

S12 = (-) K5Q1/ts(b+1.56(rts)

11

Circumferential Tension/Compression at right saddle[A'' < 0.5R]

S12 = (-) K5Q2/ts(b+1.56(rts)

12

1100 < 1137.5 mm

7.64 N/mm2

600 < 1137.5

15.45 N/mm2

A/R= 0.4835164835

5700 < 18200 mm

40.11 N/mm2

5700 < 18200 mm

61.37 N/mm2

1100 < 1137.5 mm

-21.2751872905 N/mm2

600 < 1137.5 mm

-32.5494160288 N/mm2

K1 = 0.398

K7 = 1.013

K1 = 0.398

K7 = 1.013

K1 = 0.398

K7 = 1.013

K3 = 0.694

K3 = 0.694

K6 = 0.01

K6 = 0.01

K5 = 0.726

K5 = 0.726

Stress result for transportation saddle:

Type of Stress

1 Longitudinal bending @ left Saddle,

2 Longitudinal bending @ left Saddle,

3 Longitudinal bending @ midspan,

4 Longitudinal bending @ midspan,

5 Longitudinal bending @ right Saddle,

6 Longitudinal bending @ right Saddle,

7 Tangential Shear @ left saddle,

8 Tangential Shear @ right saddle,

9 Circumferential Stress @ horn of left saddle,

10 Circumferential Stress @ horn of right saddle,

11 Circumferential Compression @ left saddle,

12 Circumferential Compression @ left saddle,

S1 =

S2 =

S1 =

S2 =

S1 =

S2 =

S7 =

S7 =

S10=

S10=

S12=

S12=

Allowable

223.38

223.38

223.38

223.38

223.38

223.38

99.28

99.28

186.15

186.15

186.15

186.15

Actual

Unit

3.23 N/mm2

-1.27 N/mm2

22.19 N/mm2

-8.72 N/mm2

4.20 N/mm2

-1.65 N/mm2

7.64 N/mm2

15.45 N/mm2

40.11 N/mm2

61.37 N/mm2

-21.28 N/mm2

-32.55 N/mm2

Since all the above resultant stress are within the allowable stress, Hence saddle provided for transportation is adequate.

2 / 2

Вам также может понравиться

- Saddle Stresses On Shell During Transportation: Equipment NoДокумент5 страницSaddle Stresses On Shell During Transportation: Equipment NoshazanОценок пока нет

- Column Skirt Support Design CalculationДокумент5 страницColumn Skirt Support Design CalculationRitesh VishambhariОценок пока нет

- Pressure Vessel Lifting Lug CalculationДокумент2 страницыPressure Vessel Lifting Lug Calculationtekstep767% (3)

- Davit Design Calculation: L 1 D V H V H V DДокумент2 страницыDavit Design Calculation: L 1 D V H V H V DSiva baalanОценок пока нет

- Tailing LugДокумент3 страницыTailing LugSajad AbdulОценок пока нет

- Jn1399 - 71t Lifting LugДокумент5 страницJn1399 - 71t Lifting LugRiyan EsapermanaОценок пока нет

- Lug SupportДокумент2 страницыLug SupportSachin5586Оценок пока нет

- Base Ring Fillet Size CalculationДокумент4 страницыBase Ring Fillet Size Calculationmiteshpatel191Оценок пока нет

- Lifting Lug Design CalculationsДокумент17 страницLifting Lug Design CalculationsSiva baalan100% (1)

- Sample Design Calculation - Vessel Supported On LugsДокумент4 страницыSample Design Calculation - Vessel Supported On LugsAbhay Upadhyay0% (1)

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFДокумент4 страницыBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiОценок пока нет

- LIFTING LUG AND LIFTING COVER DESIGN REFERENCEДокумент4 страницыLIFTING LUG AND LIFTING COVER DESIGN REFERENCERohith V VОценок пока нет

- Flange Pad CalcsДокумент4 страницыFlange Pad CalcstomОценок пока нет

- Davit Cal 2251B Davit Arm CalculationДокумент4 страницыDavit Cal 2251B Davit Arm Calculationnitin400Оценок пока нет

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionДокумент3 страницы"Lifting - Lug" - Lifting Lug Analysis: Program Descriptionnamasral100% (3)

- Crossover Area Calc For Floating HeadДокумент2 страницыCrossover Area Calc For Floating HeadRitesh VishambhariОценок пока нет

- Anchor Bolt Chairs - CalculationДокумент8 страницAnchor Bolt Chairs - Calculationchicaiza123Оценок пока нет

- Tailing Lug - 173004-05Документ1 страницаTailing Lug - 173004-05shazan100% (1)

- Horizontal Vessel Stress AnalysisДокумент12 страницHorizontal Vessel Stress AnalysissridharОценок пока нет

- Support RingДокумент13 страницSupport RingvamsiОценок пока нет

- Lifting Lug CalculationsДокумент1 страницаLifting Lug CalculationsshazanОценок пока нет

- Report Rectangular Tank - REV 0 - 28.11.12Документ26 страницReport Rectangular Tank - REV 0 - 28.11.12JijinJohn100% (1)

- ANCHOR BOLT DESIGN - Gulf Publishing - Pressure Vessel Design Manual 3rd Edition 195Документ1 страницаANCHOR BOLT DESIGN - Gulf Publishing - Pressure Vessel Design Manual 3rd Edition 195Alessio BarboneОценок пока нет

- Platform Cleat CalculationДокумент1 страницаPlatform Cleat Calculationmiteshpatel191Оценок пока нет

- Anchor Bolt CalculationДокумент2 страницыAnchor Bolt CalculationNaresh KumarОценок пока нет

- Davit Arm CalculationДокумент4 страницыDavit Arm Calculationjoeriji0% (1)

- Calculation of left and right saddle supports for offshore tankerДокумент12 страницCalculation of left and right saddle supports for offshore tankerrustamriyadiОценок пока нет

- Trunnion AnalysisДокумент45 страницTrunnion AnalysisChiragJansariОценок пока нет

- Lecture 11 - MDPE - Design of Support - Leg & Skirt SupportДокумент47 страницLecture 11 - MDPE - Design of Support - Leg & Skirt SupportPatel DhruvilОценок пока нет

- Lifting Lug Calculation For Small Horizontal VesselДокумент2 страницыLifting Lug Calculation For Small Horizontal VesselshaishavОценок пока нет

- Curb AngleДокумент1 страницаCurb Angle940623015859Оценок пока нет

- Support Leg DesignДокумент4 страницыSupport Leg DesignDeepika0% (2)

- Saddle Design at Operating ConditionДокумент17 страницSaddle Design at Operating ConditionGanesh Bhardwaj100% (2)

- Analysis of a rectangular pressure vesselДокумент7 страницAnalysis of a rectangular pressure vesselPressure VesselОценок пока нет

- Saddle CalcДокумент26 страницSaddle CalcVamsi S100% (2)

- Cdo CalcДокумент3 страницыCdo CalcJeric FarinОценок пока нет

- WRC 297Документ9 страницWRC 297akisdassas100% (1)

- Flat Plate - Roark & YoungДокумент15 страницFlat Plate - Roark & YoungPrasad Pingle0% (1)

- E.4 Leg Support CalculationДокумент2 страницыE.4 Leg Support Calculationnaim100% (1)

- 28 Roark Flat PlatesДокумент14 страниц28 Roark Flat Platesgutmont0% (1)

- Cone Weight CalculationДокумент10 страницCone Weight CalculationRajesh OwaiyarОценок пока нет

- Rectangular Tanks:: Rectangle Tank DesignДокумент23 страницыRectangular Tanks:: Rectangle Tank Designshna jabarОценок пока нет

- Saddle Calc PD5500Документ4 страницыSaddle Calc PD5500rsubramaniОценок пока нет

- PFS FWKO Tank EvaluationДокумент12 страницPFS FWKO Tank EvaluationkoyahassanОценок пока нет

- 150 VV 1010 Davit CalculationДокумент3 страницы150 VV 1010 Davit Calculationdraj1875977Оценок пока нет

- Lifting and Tailing StackДокумент42 страницыLifting and Tailing StackSudar MyshaОценок пока нет

- Calculation of Trunnions Rev3Документ3 страницыCalculation of Trunnions Rev3Bilel MahjoubОценок пока нет

- C.G. CalculationДокумент7 страницC.G. CalculationraveemakwanaОценок пока нет

- Tank DesignДокумент89 страницTank DesignDietrich von BismarckОценок пока нет

- Equipment Anchorage To Wood Roof Based On NDS 05 / IBC 09 / CBC 10 Input Data & Design SummaryДокумент1 страницаEquipment Anchorage To Wood Roof Based On NDS 05 / IBC 09 / CBC 10 Input Data & Design SummaryMarianne Aravilla Dela CruzОценок пока нет

- Saddle - Analysis by PV-EliteДокумент17 страницSaddle - Analysis by PV-EliteSunilОценок пока нет

- ASME Vessel AnalysisДокумент17 страницASME Vessel AnalysiscutefrenzyОценок пока нет

- Saddle AnalysisДокумент17 страницSaddle AnalysisvishalsatheОценок пока нет

- ASME Horizontal Vessel AnalysisДокумент10 страницASME Horizontal Vessel AnalysisSyedZainAliОценок пока нет

- Combined footing design 1000 knДокумент480 страницCombined footing design 1000 knAnonymous HJ7hmihhОценок пока нет

- Lifting Forces CalculationsДокумент9 страницLifting Forces CalculationsDhiren4742100% (2)

- Resistance by Holtrop and MennonДокумент2 страницыResistance by Holtrop and MennonBharath Kumar VasamsettyОценок пока нет

- SaddlesДокумент14 страницSaddlescoldness_13Оценок пока нет

- Comp 2Документ9 страницComp 2YYo YudiОценок пока нет

- Plate StandДокумент6 страницPlate Standmoseslugtu6324Оценок пока нет

- BEAMANAL - Single & Continuous Beam AnalysisДокумент6 страницBEAMANAL - Single & Continuous Beam AnalysistambokОценок пока нет

- Penetration ReinforcementДокумент1 страницаPenetration ReinforcementvpjagannaathОценок пока нет

- Stiff NerДокумент6 страницStiff NerNiraj ShindeОценок пока нет

- BEAMCOL13.xlsДокумент9 страницBEAMCOL13.xlsNEOОценок пока нет

- Diaphragm Moment Plate Connection DesignДокумент51 страницаDiaphragm Moment Plate Connection DesignMichenerparkОценок пока нет

- Beam Allowable End Reaction and End Moment AnalysisДокумент3 страницыBeam Allowable End Reaction and End Moment AnalysisEFECANОценок пока нет

- Beam Allowable End Reaction and End Moment AnalysisДокумент3 страницыBeam Allowable End Reaction and End Moment AnalysisEFECANОценок пока нет

- BEAMANAL - Single & Continuous Beam AnalysisДокумент6 страницBEAMANAL - Single & Continuous Beam AnalysistambokОценок пока нет

- SteelSpan MADДокумент7 страницSteelSpan MADvpjagannaathОценок пока нет

- Vpci - 309 / Vpci - 309 SF: Corrosion Inhibiting Vpci Powder For Ferrous MetalsДокумент2 страницыVpci - 309 / Vpci - 309 SF: Corrosion Inhibiting Vpci Powder For Ferrous MetalsvpjagannaathОценок пока нет

- Diaphragm Moment Plate Connection DesignДокумент51 страницаDiaphragm Moment Plate Connection DesignMichenerparkОценок пока нет

- HMPP Hempaline Bro - WEBДокумент6 страницHMPP Hempaline Bro - WEBvpjagannaathОценок пока нет

- Protective Coating Systems Guide: InfrastructureДокумент11 страницProtective Coating Systems Guide: InfrastructurevpjagannaathОценок пока нет

- Steel Manbasket DesignДокумент9 страницSteel Manbasket DesignvpjagannaathОценок пока нет

- Project TrackerДокумент2 страницыProject Trackerbawen hsОценок пока нет

- ASME B16.9 Lateral Tee DimensionsДокумент1 страницаASME B16.9 Lateral Tee DimensionsvpjagannaathОценок пока нет

- Standards Update Notice (Sun) ISSUED: July 8, 2020: Standard InformationДокумент3 страницыStandards Update Notice (Sun) ISSUED: July 8, 2020: Standard InformationvpjagannaathОценок пока нет

- Filtration and Separation in RefineriesДокумент30 страницFiltration and Separation in RefineriesvpjagannaathОценок пока нет

- Concatenate Numerical Values: Value 1 Value 2Документ18 страницConcatenate Numerical Values: Value 1 Value 2vpjagannaathОценок пока нет

- Api 650 Tank Design: One Foot MethodДокумент4 страницыApi 650 Tank Design: One Foot MethodRafaelxxxОценок пока нет

- Static Equipment in Oil and Gas - BaherДокумент95 страницStatic Equipment in Oil and Gas - BaherBaher Elsheikh100% (9)

- Aisc Shapes Database v15.0Документ14 страницAisc Shapes Database v15.0ErickSimonОценок пока нет

- Pipe component dimensions and specifications chartДокумент17 страницPipe component dimensions and specifications chartangeljosОценок пока нет

- Pipe component dimensions and specifications chartДокумент17 страницPipe component dimensions and specifications chartangeljosОценок пока нет

- Quick Worst Case Flange Extension ChartДокумент2 страницыQuick Worst Case Flange Extension ChartMartin FindlayОценок пока нет

- Pipe component dimensions and specifications chartДокумент17 страницPipe component dimensions and specifications chartangeljosОценок пока нет

- 16 - Blending and AgitationДокумент20 страниц16 - Blending and AgitationRafael ReyesОценок пока нет

- 16 - Blending and AgitationДокумент20 страниц16 - Blending and AgitationRafael ReyesОценок пока нет

- HSFG Part I Bolt & NutДокумент1 страницаHSFG Part I Bolt & NutvpjagannaathОценок пока нет

- Electrode CalculatorДокумент2 страницыElectrode CalculatorvpjagannaathОценок пока нет

- Elastic-Plastic Load Carrying Capacity of Steel MembersДокумент3 страницыElastic-Plastic Load Carrying Capacity of Steel MembersArupananda PrustyОценок пока нет

- Codal Provision For BeamДокумент2 страницыCodal Provision For BeamNoor Mohd100% (1)

- SSC-JE Mechanical Obj. Paper 9789389269475Документ23 страницыSSC-JE Mechanical Obj. Paper 9789389269475Shivam AgrawalОценок пока нет

- Beam and CorbelДокумент14 страницBeam and CorbelAkshay DuggalОценок пока нет

- L&T Construction Heavy Civil Infrastructure - Edrc: Chennai Metro Rail Corporation Limited Embye ConsortiumДокумент115 страницL&T Construction Heavy Civil Infrastructure - Edrc: Chennai Metro Rail Corporation Limited Embye ConsortiumGladson JsОценок пока нет

- Skid Lifitng Lug CalculationsДокумент5 страницSkid Lifitng Lug CalculationsinnovativekarthiОценок пока нет

- Timber and Steel Design IntroductionДокумент40 страницTimber and Steel Design IntroductionCloe Dianne SillaОценок пока нет

- Designing Silo Walls For Flow Patterns : Aci Structural Journal Technical PaperДокумент10 страницDesigning Silo Walls For Flow Patterns : Aci Structural Journal Technical PaperJuan Cruz CoronelОценок пока нет

- Lab Report 1 - Two and Three Hinged ArchesДокумент19 страницLab Report 1 - Two and Three Hinged ArchesNurshahadah Shahrunnizam100% (3)

- Cee-3313: Reinforced Concrete Design and Project-I 2014/2015 Y3-CE/UR/CSTДокумент18 страницCee-3313: Reinforced Concrete Design and Project-I 2014/2015 Y3-CE/UR/CSTShoturuОценок пока нет

- Springs: Dr. Ashish Deshmukh, Associate Professor, Svkms Nmims Mpstme, MumbaiДокумент43 страницыSprings: Dr. Ashish Deshmukh, Associate Professor, Svkms Nmims Mpstme, MumbaiVanessa SmithОценок пока нет

- (SILVA) Response of Standard Caltrans Pile-To-pile Cap Connections Under Simulated Seismic LoadsДокумент375 страниц(SILVA) Response of Standard Caltrans Pile-To-pile Cap Connections Under Simulated Seismic Loadshal9000_mark1Оценок пока нет

- NASA Stress Intensity Factors Equations TM-85793Документ40 страницNASA Stress Intensity Factors Equations TM-85793scuneo100% (1)

- Lateral-Torsional Buckling of Beams and The Southwell PlotДокумент15 страницLateral-Torsional Buckling of Beams and The Southwell PlotPablo Augusto Krahl0% (1)

- Factory: A ON Structural Analysis and Design ofДокумент19 страницFactory: A ON Structural Analysis and Design ofRoshan KejariwalОценок пока нет

- MODULAR QUIZ - 59 - Reinforced Concrete DesignДокумент8 страницMODULAR QUIZ - 59 - Reinforced Concrete DesignCornelio J. FernandezОценок пока нет

- Equivalent Uniform Live Loads Under Transit Vehicles For Floor Slab of Long Span Urban Transportation Hubs PDFДокумент14 страницEquivalent Uniform Live Loads Under Transit Vehicles For Floor Slab of Long Span Urban Transportation Hubs PDF4ranjitОценок пока нет

- Design and Development of Overhead Monor PDFДокумент5 страницDesign and Development of Overhead Monor PDFFiroz PawaskarОценок пока нет

- Base PlateДокумент10 страницBase PlateMd MohsinОценок пока нет

- Shaft Design: Design Against Static LoadingДокумент6 страницShaft Design: Design Against Static Loadingakshat singhОценок пока нет

- Nzee Storage TanksДокумент13 страницNzee Storage Tanksvttrlc100% (1)

- Report Composite AnkurДокумент19 страницReport Composite AnkurAnkur DubeyОценок пока нет

- HALFEN Bolts: The Advantages at A GlanceДокумент6 страницHALFEN Bolts: The Advantages at A Glancerevmen.2Оценок пока нет

- PCs Corbel EN-4-2009 1228 0Документ32 страницыPCs Corbel EN-4-2009 1228 0zeme6Оценок пока нет

- Daram Khola Surge ShaftДокумент21 страницаDaram Khola Surge ShaftSaugat ThapaОценок пока нет

- Bridge Bearing Main - 2 Design Calculation (R-0)Документ27 страницBridge Bearing Main - 2 Design Calculation (R-0)mohan1441Оценок пока нет

- Unit 14 Structural Mechanics in Construction and Civil EngineeringДокумент14 страницUnit 14 Structural Mechanics in Construction and Civil EngineeringmikeОценок пока нет

- EIL Civil Enginnering Question With AnswersДокумент19 страницEIL Civil Enginnering Question With AnswersYogendra PatilОценок пока нет

- Ce6402 Sve QBДокумент215 страницCe6402 Sve QBilayarsiОценок пока нет

- Behavior and Design of Buried Concrete PipesДокумент50 страницBehavior and Design of Buried Concrete PipesAdam FredrikssonОценок пока нет